Finding the right partner for your PCB needs can sometimes feel like searching for a needle in a haystack. Fortunately, JarnisTech stands out as a premier one-stop manufacturer and supplier. Renowned for its top-notch services and expertise, JarnisTech is well-equipped to meet the demands of various industries. Whether you’re involved in electronics manufacturing, are an OEM, a PCB buyer, or just diving into the circuit board market, understanding the advantages of teaming up with a Shengyi PCB manufacturer can genuinely elevate your project outcomes. Don’t hesitate—let’s get started on your journey to success!

Why Should You Choose Shengyi PCB Laminates?

When it comes to crafting high-quality printed circuit boards (PCBs), the choice of laminates can make all the difference. At JarnisTech, we proudly offer Shengyi laminates that deliver reliability and performance. Let’s take a closer look at why opting for these laminates from a trusted supplier is a smart move.

1. Superior Quality and Performance

Shengyi laminates are recognized for their superior quality. Designed to deliver excellent electrical insulation, they ensure your circuits function seamlessly. This reliability proves invaluable in high-frequency applications, where subpar material can jeopardize signal integrity. With Shengyi, you’re not just getting materials; you’re investing in consistent performance that keeps your projects on track. Let’s elevate your designs with materials that truly make a difference!

Here’s a quick comparison of the performance characteristics of Shengyi laminates versus generic options:

| Characteristic | Shengyi Laminates | Generic Laminates |

| Dielectric Strength | 20 kV/mm | 15 kV/mm |

| Thermal Stability | Up to 180°C | Up to 130°C |

| Moisture Absorption | < 0.1% | > 0.3% |

The numbers don’t lie—when you go with Shengyi, you’re setting yourself up for success.

2. Enhanced Reliability

Using high-quality Shengyi laminates means fewer failures down the line. These materials undergo rigorous testing and comply with international standards, so you can rest easy knowing your PCB will stand the test of time.

For instance, in a recent project involving medical devices, we selected Shengyi laminates to ensure durability and performance. The result? A 30% decrease in warranty claims due to material failures!

3. Versatility Across Applications

Shengyi laminates are like a Swiss Army knife—suitable for a variety of applications. Whether you’re working on consumer electronics, automotive components, or industrial machinery, these laminates offer the flexibility you need.

Here’s a look at some applications where Shengyi laminates shine:

| Application | Benefits of Shengyi Laminates |

| Consumer Electronics | Lightweight and cost-effective |

| Automotive | High thermal resistance and durability |

| Industrial Machinery | Excellent chemical resistance and stability |

With such versatility, you can tackle diverse projects without worrying about material constraints.

4. Competitive Pricing

While quality is key, cost matters too. Partnering with a reputable supplier like JarnisTech gives you access to competitive pricing on Shengyi laminates. This means you can get the best of both worlds: premium materials at a price that won’t break the bank.

5. Support and Expertise

When you choose Shengyi laminates through JarnisTech, you’re not just buying a product; you’re gaining a partner. Our team of experts is ready to assist you with any questions, ensuring you select the right laminate for your specific needs. We’re here to help you hit the ground running.

Are you ready to enhance your PCB designs? Don’t compromise on quality when it comes to your laminates. Connect with JarnisTech today, and let us help you select the ideal Shengyi laminates for your projects. Your circuits board project deserve the best—let’s make it happen together!

Shengyi PCB Laminates Types

When diving into the world of Shengyi PCBs, the choice of laminate material can truly make a difference in performance and reliability. Let’s break down the key types of laminates we offer, highlighting their unique benefits and applications. You’ll see why picking the right material is like finding the perfect tool for the job—everything just clicks!

1. FR-4 Laminates

FR-4 is the gold standard in PCB materials. It’s a glass-reinforced epoxy laminate known for its balance of durability and electrical insulation. FR-4 is like the Swiss Army knife of laminates; it fits a wide range of applications—from consumer electronics to automotive components.

This laminate can handle various environmental conditions and is compatible with multiple surface finishes. Plus, it’s cost-effective, making it a go-to for budget-conscious projects.

2. High-Frequency Laminates

For projects that need to keep signals clear and crisp, Shengyi’s high-frequency laminates are where it’s at. Designed for RF and microwave applications, these laminates minimize signal loss and ensure that your communications gear performs at its best.

Applications:

●Telecommunications

●Wireless devices

●Radar systems

Using these laminates means you won’t have to worry about losing your signal in the noise!

3. Metal Core PCBs (MCPCB)

When thermal management is a must, metal core PCBs come to the rescue. These laminates are specifically designed for high-power applications like LED lighting and power electronics. They effectively dissipate heat, keeping your components cool and operational.

Table 2: MCPCB Features

| Feature | Description |

| Heat Dissipation | Excellent |

| Weight | Heavier than FR-4 |

| Application | LEDs, power supplies |

This laminate ensures that performance is never compromised, allowing you to push the boundaries of what’s possible.

4. Polyimide Laminates

If flexibility is your goal, polyimide laminates are the way to go. Renowned for their exceptional thermal and chemical resistance, these laminates excel in flexible circuits, especially in challenging environments. Whether you’re pushing the limits of design or tackling unique applications, polyimide laminates provide the reliability you need.

Applications:

●Aerospace

●Medical devices

●Consumer electronics

Polyimide is your best bet for applications that require bending without breaking the bank—or the circuit!

5. Specialty Laminates

JarnisTech doesn’t stop at the basics; we offer specialty laminates tailored to specific needs. These materials can be customized for high-temperature applications or unique mechanical properties. If your project calls for something special, we’ve got you covered!

Choosing the right laminate isn’t just about materials; it’s about making informed decisions that drive success in your projects. With Shengyi’s diverse range of laminates, you can be confident that your designs will stand out for all the right reasons. Ready to get started? Let’s connect and turn your ideas into reality!

Shengyi PCB Liminates Material Product List

Shengyi S1000h PCB Circuit Board

Shengyi S1000h PCB Circuit Board

| Product Name | Product Description | Tg | Td | CTE |

| S1150GH | High Performance, Mid-Tg Halogen-free Material | 160 | 400 | 2.3% |

| S1000 | Low CTE, Mid-Tg laminate | 155 | 335 | 3.40% |

| S1600 | CTI600 | 135 | 310 | 4.50% |

| Q160 | Thermal conductive FR-4.0 | 130 | 310 | 2.80% |

| S1000H

| Low CTE, Mid-Tg Material | 155 | 348 | 2.80% |

| S1000-2 | Low CTE, high thermal resistance, high Tg laminate | 180 | 345 | 2.80% |

| S1000-2M | Low CTE, High Thermal Resistance, High Tg Material | 180 | 355 | 2.40% |

| S1190 | High Tg, High reliability, high thermal resistance base material for high-layer count PCB | 200 | 350 | 2.3% |

| Q260 | Thermal conductive CEM-3 | 122 | / | 3.5% |

| ST210G | Thermal conductive CEM-3,high CTI | 122 | 360 | 3.5% |

| S1150G | Halogen free, mid-Tg material | 155 | 355 | 2.8% |

| S1170G | Halogen free, high Tg,FR-15.1 | 180 (DMA) | 390 | 2.3% |

| SML02G | Halogen free, high Tg,FR-15.1 | 195 | 420 | 2.3% |

| SDI03K | Low Dk, halogen free, high Tg,FR-4.1 | 200 | 390 | 2.3% |

| S1141 150 | UV blocking, mid-Tg | 150 | 310 | 4.20% |

| S1600L | CTI600 | 150 | 355 | 3.20% |

| S1130 | Natural color | 135 | 310 | 4.50% |

| S1141 | UV blocking | 140 | 310 | 4.50% |

| S3110 | Normal type CEM-1 | / | / | 6.2% |

| S3116 | High thermal resistance, High CTI | / | / | 6.5% |

| Q360G | High CTI Halogen Free CEM-1 | / | / | / |

| S2130/S2130JB | Normal type CEM-3 | 130 | / | 5.2% |

| S2131/S2131JB | UV Blocking, Normal type CEM-3 | 130 | / | 5.2% |

| S2126 | High CTI CEM-3 | 130 | / | 5.2% |

| S2600F | High thermal resistance, High CTI, Anti-CAF | 125 | 332 | 4.8% |

| S2155G | Halogen Free | 130 | 335 | 4.8% |

If you are unable to locate the substrate number you are looking for from the list above. Please send a message to [email protected]. We’ll be happy to get your details and contact you shortly.

Properties of Shengyi PCB

When it comes to choosing materials for PCBs, it’s all about understanding the properties that make them stand out. At JarnisTech, we focus on delivering top-notch materials that ensure reliability and performance across various applications. Let’s dive into the key characteristics and advantages that set our PCBs apart from the pack!

Thermal Stability

One of the standout features of Shengyi PCBs is their impressive thermal stability. Our materials can handle temperature fluctuations without compromising integrity. This is particularly beneficial for high-power applications where heat management is a concern.

Table 1: Thermal Properties of Shengyi PCBs

| Property | Value |

| Glass Transition Temperature | 130°C – 180°C |

| Thermal Conductivity | Up to 1.0 W/mK |

This ability to withstand varying temperatures keeps your devices functioning optimally, whether in consumer electronics or industrial machinery.

Electrical Insulation

Shengyi PCBs are designed with superior electrical insulation properties. This characteristic minimizes signal loss and prevents short circuits, ensuring reliable performance in both high-frequency and low-frequency applications.

Applications:

●RF and microwave devices

●Telecommunications equipment

When your project demands precision, our insulation properties deliver just that!

Mechanical Strength

The mechanical strength of our PCBs is another area where we excel. With robust materials that resist warping and bending, Shengyi PCBs provide the durability needed for tough environments.

Table 2: Mechanical Properties

| Property | Value |

| Flexural Strength | 200 MPa |

| Peel Strength | 2.5 N/mm |

This strength ensures that your circuits can handle real-world challenges without breaking a sweat.

Chemical Resistance

In industries like medical and aerospace, exposure to harsh chemicals is a reality. Shengyi PCBs boast excellent chemical resistance, allowing them to thrive in environments where other materials might falter.

Examples:

●Medical devices in sterilization processes

●Aerospace components exposed to fuel and oils

●This resilience ensures longevity and reliability in critical applications.

Customization Options

Every project has unique needs, and that’s where our customization options come into play. At JarnisTech, we offer tailored solutions that allow you to select materials based on specific electrical, thermal, and mechanical properties. This flexibility ensures that you get exactly what you need, no compromises!

Why Choose a One-stop Shengyi PCB Supplier?

Choosing a one-stop Shengyi PCB supplier can significantly impact your PCB manufacturing experience. This approach brings all your PCB needs together under one roof, simplifying your workflow and enhancing collaboration. By selecting a comprehensive partner, you’re not just finding a manufacturer; you’re gaining a dedicated ally who understands your unique challenges and goals.

Benefits of Working with a One-stop Shengyi PCB Supplier

So why exactly does a one-stop Shengyi PCB supplier make life easier? It all boils down to convenience, quality, and speed. Let’s break it down:

Seamless Integration Across All Processes: Imagine trying to juggle multiple suppliers for different parts of your PCB process—one for materials, one for design, another for assembly. Sounds like a logistical nightmare, right? With a one-stop Shengyi PCB supplier- JarnisTech, all these processes are streamlined under one roof. This integration eliminates unnecessary back-and-forth communication, reduces errors, and speeds up delivery times.

Cost Efficiency: By consolidating your needs with one supplier, you’re cutting out the middleman, reducing extra costs. Whether it’s materials, fabrication, or assembly, a one-stop supplier like JarnisTech offers a more economical solution, especially when you’re working with tight budgets or large-scale orders.

Tailored Solutions: Every project has its quirks, and a one-stop Shengyi PCB supplier(JarnisTech) is equipped to handle the customization required to meet specific design needs. From choosing the right base materials like FR4, polyimide, or copper-clad laminates, to implementing the necessary electrical configurations, Shengyi offers personalized solutions that fit your unique requirements.

Flexibility for Every Project Type

JarnisTech doesn’t just handle the simple stuff. We specialize in everything from complex multilayer boards to high-temperature-resistant polyimide PCBs. Need something with high-frequency characteristics for your telecommunications project? JarnisTech’s got you covered. Working on a tight schedule for a prototype? Our one-stop solution is your fast track to success.

Supplier-to-Customer Synergy: A Partnership That Works

When you work with a comprehensive supplier like JarnisTech, you’re not left in the dark. Clear communication and collaboration are baked into the process. That means fewer delays, fewer miscommunications, and more time focusing on what matters—developing the next big thing in electronics. In a sense, JarnisTech becomes part of your team, helping you solve problems before they even happen.

| Advantages of One-stop Shengyi Supplier | Description |

| Consolidation of Processes | From design to production, everything is managed in-house. |

| Cost Savings | Eliminate intermediary costs with direct manufacturing. |

| Custom Solutions | Materials and design options tailored to your project needs. |

| Streamlined Communication | Reduced delays and miscommunications through integrated processes. |

Ready to make your PCB design process more efficient? Partnering with JarnisTech as your one-stop supplier isn’t just about making your life easier—it’s about boosting your business potential. Don’t waste time coordinating with multiple vendors; let JarnisTech handle it all so you can focus on innovation. Contact us today, and let’s get your project moving!

Introduction to One-stop Shengyi PCB Manufacturing

Choosing a one-stop Shengyi PCB manufacturer can significantly impact your operations in the electronics sector. This approach consolidates your PCB needs under one roof, simplifying your workflow and enhancing collaboration. When you opt for a one-stop solution, you’re not just looking for a supplier; you’re seeking a partner who understands your unique challenges and objectives.

Streamlined Processes for Efficiency

Imagine the time saved when all your PCB requirements, from design to production, are handled by a single manufacturer. This eliminates the headaches that come with managing multiple vendors, allowing for smoother communication and faster turnaround times. Think of it like having a reliable pit crew in a race—you’re focused on the finish line, and they take care of all the details.

Tailored Solutions to Fit Your Needs

With JarnisTech, customization is at your fingertips. Whether you’re diving into complex high-frequency applications or exploring flexible PCBs, JarnisTech offers an array of materials and designs tailored to meet specific industry demands.

Here’s a quick look at some of the materials available:

| Material Type | Best Used For |

| FR4 | Standard applications, cost-effective solutions |

| Polyimide | High-temperature environments, aerospace applications |

| Copper Clad Laminates | High conductivity needs, specialized electronic designs |

Let’s talk turkey—real results matter. A notable case involved a leading electronics manufacturer that partnered with JarnisTech. By leveraging the one-stop capabilities, we reduced production time by 25%. This jump in efficiency not only improved their output but also had a positive impact on their overall revenue. That’s what we call a win-win situation!

Cost-effectiveness in Fabrication One-stop Shengyi PCB Boards

When it comes to PCB manufacturing, cost-effectiveness isn’t just about getting the lowest price. It’s about finding that sweet spot where quality, efficiency, and price converge. Working with a one-stop Shengyi PCB supplier-JarnisTech offers distinct advantages that can help businesses save time and money without cutting corners. Let’s dive into the factors that make one-stop PCB manufacturing a cost-effective choice and why partnering with a reputable Shengyi PCB supplier delivers true value.

Breaking Down the Cost Factors

When analyzing the cost of PCB manufacturing, several key elements come into play:

Material Selection: The choice of base materials, such as Shengyi’s laminates, FR4, or polyimide, plays a significant role in determining overall costs. High-quality materials ensure durability and reliability, which reduces the need for costly rework or product recalls. By sourcing premium materials directly from Shengyi, manufacturers can get competitive pricing without sacrificing performance.

Manufacturing Processes: Advanced manufacturing techniques like laser drilling, automated optical inspection (AOI), and surface mount technology (SMT) increase efficiency and reduce waste. This means fewer defective boards and faster production times, which translate into cost savings. Shengyi’s streamlined processes are designed to maximize output while minimizing overhead.

Design Optimization: Partnering with a one-stop supplier allows for collaboration during the design phase. With JarnisTech’s engineers involved from the start, our engineers can recommend design tweaks that reduce complexity and material usage, all while maintaining functionality. For example, minimizing unnecessary layers in a multilayer PCB can lower material and production costs.

Volume Discounts: When you stick with one supplier for both prototyping and large-scale production, you benefit from volume discounts. JarnisTech offers competitive pricing tiers based on order size, making it easier to manage costs as your project scales.

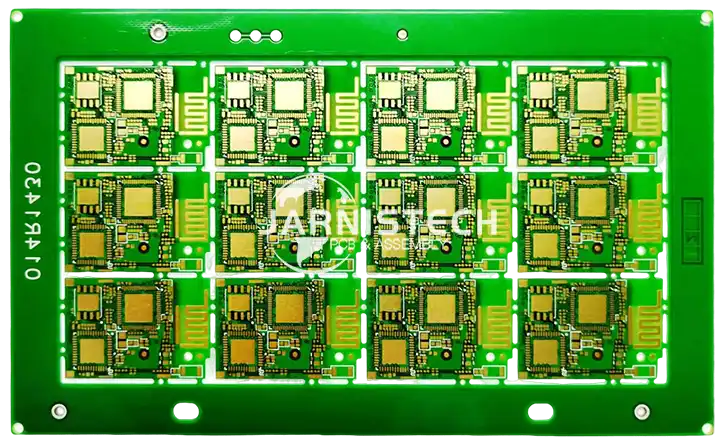

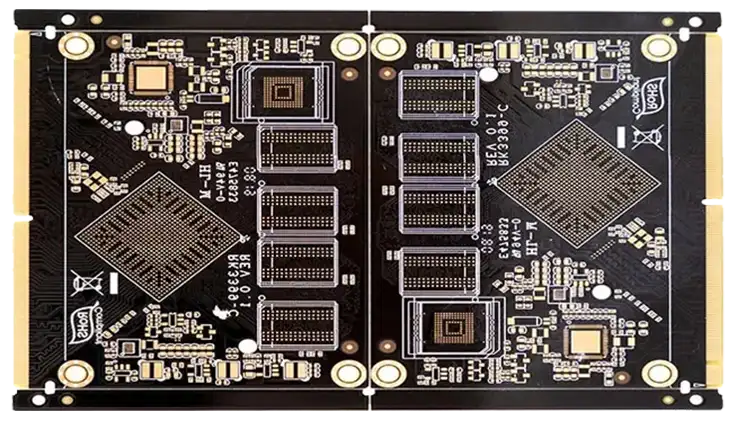

One-stop Shengyi PCB

One-stop Shengyi PCB

Technical Expertise in One-stop Shengyi PCB Design and Production

At JarnisTech, we don’t just create PCBs—we craft solutions. Our engineering team’s expertise in Shengyi PCB design and production is built on years of hands-on experience and cutting-edge knowledge. Here’s a look at what makes us stand out as a leading Shengyi PCB supplier.

PCB Design Mastery

Our engineers are equipped with deep knowledge of advanced design tools, such as CAD (Computer-Aided Design) software. CAD tools allow for precision in laying out circuits, ensuring every trace, pad, and via is perfectly positioned for optimal performance. Using tools like Altium Designer, we streamline the creation of complex multilayer PCBs with pinpoint accuracy.

| Tool | Function |

| Altium Designer | Schematic capture, PCB layout |

| AutoCAD | Mechanical design and modeling |

| CAM350 | PCB manufacturing data prep |

This approach ensures that our designs are not just functional but optimized for both manufacturing and performance, making your devices work smarter and faster.

Materials Expertise

When using Shengyi laminates in PCB manufacturing process, it’s not just about selecting a material—it’s about understanding its strengths and limitations. Our engineers specialize in selecting materials with the right electrical, thermal, and mechanical properties to suit specific projects. Whether it’s high-frequency signal transmission or maintaining dimensional stability, we know exactly which Shengyi material fits the bill.

For instance:

●Shengyi S1000-2 is a go-to for applications requiring high Tg (glass transition temperature), ensuring stability in high-heat environments.

●Shengyi S1141 offers excellent electrical performance for high-speed applications, giving you the signal integrity you need.

Layered PCB Manufacturing Techniques

Creating multilayer PCBs is an art, and our engineering team has perfected it. From selecting appropriate pre-preg materials to ensuring accurate registration between layers, every step is carefully planned. By leveraging automated inspection systems, we maintain tight tolerances and perfect alignment across up to 20 layers or more.

This layering process is critical for:

●Reducing board size in compact electronic devices.

●Enhancing signal integrity through efficient grounding techniques.

| Multilayer PCBs | Typical Use Case |

| 4-layer PCBs | Consumer electronics |

| 8-layer PCBs | Telecommunications devices |

| 16-layer PCBs | Aerospace & defense systems |

Precision in Assembly

We’re also skilled at putting together the puzzle pieces of PCB assembly. Our engineers are pros in Surface Mount Technology (SMT) and Through-Hole Technology (THT). SMT allows for densely packed components, giving us the ability to miniaturize designs without sacrificing performance. Meanwhile, THT provides the durability needed in high-stress applications like automotive and aerospace.

Here’s how we make the magic happen:

●SMT: Our assembly lines are equipped with high-speed pick-and-place machines that position thousands of components with pinpoint precision, minimizing errors and maximizing output.

●THT: Our automated insertion systems ensure that components like transformers and connectors are securely fastened for rugged applications.

Real-World Problem Solving

There’s a difference between book knowledge and what works in the real world. Our engineering team has faced every challenge in the book, from handling tight thermal constraints in high-power applications to optimizing signal routing for high-speed designs. We solve problems, plain and simple—no matter how complex.

Example Case Study: One of our clients needed a 12-layer PCB for a high-frequency communications device. The challenge was minimizing signal loss while fitting everything into a compact form factor. By selecting Shengyi’s high-performance material S7130, and tweaking the stack-up configuration, we achieved the required signal integrity while staying within the client’s size constraints. Problem solved!

Commitment to Innovation

At JarnisTech, we’re always pushing the envelope. Our engineers are constantly researching the latest advancements in PCB design and manufacturing, ensuring we stay ahead of the curve. Whether it’s incorporating new materials or implementing AI-driven inspection systems, innovation is part of our DNA.

The Production Process of Shengyi PCBs

The production of Shengyi PCBs is a meticulous journey that transforms raw materials into high-performance circuit boards. Each step is carefully crafted to ensure that the final product meets stringent industry standards and customer expectations. Let’s dive into the detailed steps involved in manufacturing Shengyi PCBs.

Steps in the Production Process

1.Design and Prototyping: The journey begins with the design phase, where engineers collaborate with clients to create tailored PCB layouts. This includes selecting materials, defining layer counts, and establishing electrical specifications. Prototyping allows for testing design concepts before full-scale production.

2.Material Selection: High-quality materials are fundamental for producing top-notch PCBs. Shengyi carefully selects premium laminates, copper foil, and other essential components that align with diverse performance standards. Think of this selection process as curating the finest ingredients for a gourmet dish—only the best will suffice! By investing in superior materials, you ensure your projects are built to last and perform at their best.

3.Manufacturing: The manufacturing phase includes etching the circuit patterns onto the copper layers, drilling holes for vias, and applying solder masks. Advanced equipment ensures precision at every turn, from laser drilling to photolithography.

4.Assembly: In this step, components are soldered onto the PCB using techniques like Surface Mount Technology (SMT) or through-hole technology. This is where the magic happens, turning a bare board into a fully functional circuit.

5.Testing and Quality Control: Each PCB undergoes rigorous testing to ensure functionality and reliability. Automated testing systems and visual inspections guarantee that every unit meets quality standards before it ships out.

Quality Control in Manufacturing Shengyi PCB

When it comes to PCB manufacturing, quality control isn’t just a step in the process—it’s the backbone of reliability. In a world where precision and reliability are everything, JarnisTech’s commitment to quality assurance ensures that every board leaving our facility is built to meet the highest standards.

The Precision Behind the Process

JarnisTech’s quality control starts at the material selection stage and extends through every phase of production. Every laminate, copper layer, and solder mask is tested rigorously to ensure that it meets the specified criteria. It’s kind of like baking a cake—if you start with bad ingredients or skip any steps, the result just won’t measure up. That’s why us emphasizes stringent testing and inspection procedures at each checkpoint.

To keep everything on track, we use a mix of automated and manual inspection methods, ensuring no stone is left unturned. This includes advanced X-ray systems, flying probe testers, and visual inspections by skilled technicians who know exactly what to look for. The result? PCBs that not only perform well in the lab but also in real-world applications.

Quality Control Measures in Action

For example, in high-frequency PCB designs used in the telecommunications industry, even the slightest defect can cause significant issues. JarnisTech’s testing protocols ensure that signal integrity remains intact, even in the most demanding environments. Whether it’s ensuring copper thickness consistency or maintaining dielectric strength, our attention to detail means your final product will be rock solid.

| Quality Control Stage | Description |

| Material Inspection | Verification of raw materials like laminates, copper, and solder masks. |

| Electrical Testing | Includes flying probe and in-circuit testing to ensure full functionality. |

| Visual and Automated Inspection | Checks for visible defects and internal inconsistencies using X-ray and automated optical systems. |

Quality Standards for Shengyi PCBs

We follows stringent industry standards, ensuring our PCBs meet and often exceed expectations. Adherence to these standards provides customers with peace of mind, knowing that our boards are built with precision and care.

●Certifications that Matter

Jarnistech’s PCBs comply with some of the most respected international certifications in the industry. For starters, our facility holds ISO 9001 certification, which guarantees that every step of the process is documented, audited, and optimized. Additionally, Shengyi complies with IPC standards, which govern everything from design specifications to material quality.

For example, IPC-A-600 sets the bar for PCB acceptability standards, ensuring each board is free from visible and latent defects. Another key certification is RoHS compliance, which guarantees the use of environmentally friendly, lead-free materials. With such rigorous checks in place, our customers know they’re getting boards that meet global standards for safety and performance.

So why settle for anything less? By choosing JarnisTech, you’re not just getting a supplier; you’re getting a partner that stands behind its quality from start to finish. Contact us today and let us show you why their dedication to quality control makes all the difference. Don’t let subpar quality hold your projects back—partner with Jarnistech for the precision and reliability your business deserves!

Advanced Testing Capabilities About Shengyi PCBs Circuit Board

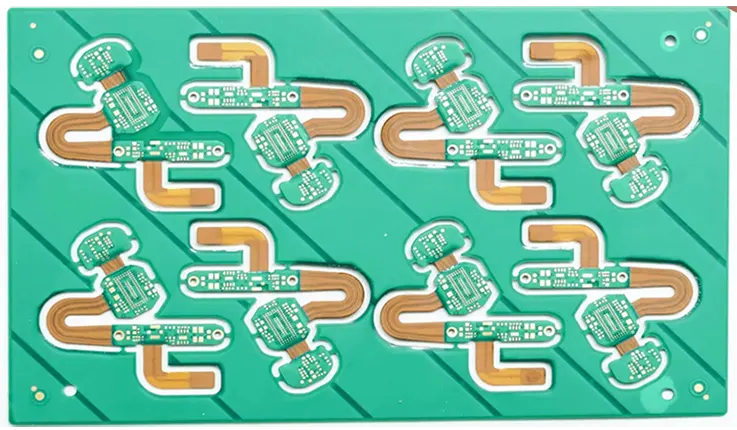

Polyimide Shengyi Flexible PCB

Polyimide Shengyi Flexible PCB

When it comes to manufacturing reliable PCBs with Shengyi materials, testing isn’t just a step—it’s a commitment. At JarnisTech, we don’t just slap together circuits and hope they work. We put each board through the wringer, using a wide array of testing methods to catch even the tiniest flaws before your product hits the market. Let’s break down how we keep your projects running strong by utilizing some of the most advanced testing capabilities in the industry.

1. Flying Probe Testing

Ever wondered how we test electrical functionality without a full production run? That’s where flying probe testing (FPT) comes into play. This non-contact testing method is perfect for prototypes or low-volume orders. Instead of building a custom fixture, FPT uses multiple probes to “fly” over the board, testing each net for opens, shorts, and component orientation.

| Feature | Benefit |

| No fixture needed | Ideal for small batches |

| High accuracy | Pinpoint defects fast |

| Versatile | Handles both rigid and flex PCBs |

Think of it as the early warning system for your PCBs—catching issues long before they become major headaches. It’s like taking your car for a test drive before you hit the highway.

2. Automated Optical Inspection (AOI)

If there’s one thing we trust in PCB testing, it’s our eagle-eyed machines. Automated Optical Inspection (AOI) gives us the ability to inspect boards down to the microscopic level. Using high-resolution cameras, we compare each board against the digital design, looking for missing components, soldering defects, and improper alignments.

With Shengyi materials being top-tier, precision is non-negotiable. AOI ensures that every trace, pad, and component is where it should be. It’s like having a high-tech bouncer at the door, kicking out any defects before they get into the party.

Fun fact: AOI is so sharp, it can detect defects as small as 0.1mm!

3. In-Circuit Testing (ICT)

For mass production orders, we go big with in-circuit testing (ICT). This method involves creating a custom test fixture that connects directly to specific test points on the PCB. ICT is designed to validate that all components are functioning properly, with real-time analysis of voltages, currents, and signals. Essentially, we’re checking every component like it’s a part of a symphony—each one has to hit the right note.

| Testing Method | Best Used For |

| Flying Probe Testing | Prototypes, low-volume orders |

| In-Circuit Testing | High-volume production |

| AOI | Comprehensive visual inspection |

By combining ICT with Shengyi’s high-performance materials, we can make sure your boards perform not only in our lab but out in the real world where it matters. It’s like setting up your PCBs for a flawless performance, no matter the environment.

4. Burn-In Testing

When reliability is non-negotiable, burn-in testing is our go-to. Here, we push your PCB to its limits by running it under stress—higher than normal voltage and temperatures. This method simulates harsh operating conditions and helps weed out any weak components that could fail early in the field. Think of it as a stress test for your board, ensuring that it’ll stand up to anything you throw at it.

Shengyi PCBs, known for their thermal stability, thrive in this environment, making them perfect for high-reliability applications like aerospace, automotive, and medical devices.

| Test Parameter | Typical Condition |

| Temperature | Up to 150°C |

| Duration | 24 to 72 hours |

| Voltage Stress | 10-20% above normal rating |

5. Functional Testing

Now, we get down to business with functional testing. It’s the final checkpoint where we test the board under real-world conditions, making sure it performs exactly as intended. This process involves loading the board with its actual firmware and making sure it interacts with other components seamlessly. If we’re building a communication board, for instance, we test its ability to transmit and receive data as expected.

You wouldn’t take a car off the lot without driving it first, right? Functional testing ensures your PCB can take the heat—literally and figuratively—before it ships out the door.

Ready for the Real World? We’ve Got Your Back!

When you work with JarnisTech, you’re not just getting a Shengyi PCB—you’re getting peace of mind. Every board goes through a battery of tests designed to catch potential issues before they become costly mistakes. Ready to stop worrying about the reliability of your PCBs? Let’s make it happen together.

Custom Solutions and Capabilities in JarnisTech PCB Manufacturing

When it comes to PCB manufacturing, one size definitely doesn’t fit all. At JarnisTech, we pride ourselves on offering tailored solutions that cater specifically to your unique needs. Our Shengyi PCBs are crafted through a blend of advanced technology and skilled craftsmanship, ensuring that we can meet a wide range of specifications without compromising quality. Let’s dive into the custom manufacturing processes we provide.

1. Tailored Design Services

Every project starts with a solid design, and that’s where our team excels. We offer custom design services that let you collaborate with our engineers from the get-go. Whether you need a compact design for IoT devices or a multi-layer board for complex applications, we have the expertise to bring your vision to life. Our design phase includes:

| Design Service | Key Feature |

| Custom Layouts | Adapted to specific dimensions |

| Material Selection | Choose from a range of Shengyi laminates |

| Simulation Testing | Verify performance before production |

2. Flexible Production Options

At JarnisTech, flexibility is our middle name. Whether you’re looking for small batch runs or large-scale production, we’ve got you covered. Our manufacturing processes can adapt to different volume requirements without sacrificing quality. Here’s how we manage it:

●Small Batch Production: Ideal for startups and prototyping, allowing you to test the waters without diving in headfirst.

●High-Volume Manufacturing: Perfect for established companies needing mass production at lightning speed.

Our production line is set up to pivot quickly, ensuring you get what you need, when you need it. No more waiting around—let’s get your product to market!

3. Advanced Material Options

Selecting the right materials is a key factor in your PCB’s success. We provide a diverse range of Shengyi materials tailored to various performance needs, from thermal stability to dielectric properties. Think of it as choosing the perfect ingredients for a recipe—each one contributes to a top-notch final product. Let us help you find what fits your project best!

Here’s a snapshot of our options:

| Material Type | Application |

| FR-4 | General-purpose applications |

| High-Frequency Laminates | Ideal for RF and microwave circuits |

| Flexible Materials | Perfect for wearable tech |

4. Custom Testing Protocols

Quality control doesn’t stop at manufacturing; it extends into custom testing protocols designed around your specifications. Our testing capabilities include:

●Environmental Testing: Assess how your PCB holds up in extreme temperatures and humidity.

●Electrical Testing: Ensure every component works as intended before it’s delivered.

This tailored approach means you can be confident your PCBs will perform in real-world conditions. We want you to hit the ground running, not facing a hiccup when it matters most.

5. Quick Turnaround Times

In today’s competitive market, speed is everything. We understand that delays can hit your bottom line, so we’ve fine-tuned our manufacturing processes to ensure rapid turnaround times while maintaining top-notch quality. Whether you need prototypes quickly or efficient production runs, we’re here to support your needs.

Wrapping Up

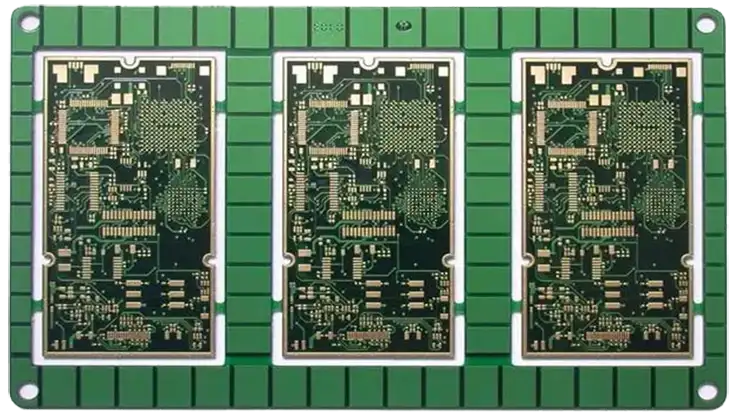

Shengyi Rigid-Flex PCB

Shengyi Rigid-Flex PCB

JarnisTech: The best one-stop Shengyi PCB manufacturer and supplier.

Choosing the right partner for your PCB needs is no small feat, and when it comes to navigating the complexities of circuit board manufacturing, a one-stop Shengyi PCB manufacturer like JarnisTech stands out as an exceptional choice. Let’s wrap up the benefits that make us your go-to supplier.

●Comprehensive Solutions Under One Roof

●Expertise That Counts

●Flexibility That Adapts to You

●Quality You Can Trust

●Rapid Turnaround Times

●Personalized Customer Support

When you choose JarnisTech as your one-stop Shengyi PCB manufacturer, you’re not just selecting a supplier—you’re partnering with a team dedicated to your success. Ready to take the next step? Let’s connect and turn your ideas into reality! With our comprehensive services and unwavering support, you’ll be equipped to tackle any challenge that comes.

Frequently Asked Questions About Shengyi PCB

Why should I choose a one-stop Shengyi PCB supplier like JarnisTech?

Choosing a one-stop supplier simplifies the manufacturing process, ensures consistent quality, and can lead to cost savings by consolidating services under one roof.

What types of PCBs does Shengyi manufacture?

Shengyi manufactures a wide range of PCBs, including standard FR4 boards, high-frequency boards, flexible circuits, and custom solutions tailored to specific needs.

What materials are used in Shengyi PCBs?

Shengyi offers various base materials, including FR4, polyimide, and copper-clad laminates, each selected based on the specific requirements of the application.

What testing methods does Shengyi use?

Shengyi utilizes multiple testing methods, including electrical, thermal, and mechanical testing, to ensure the reliability and performance of its PCBs.

How can I get a quote for a PCB project?

To obtain a quote, you can contact jarnistech’s customer service team through our website or by phone, providing details about your project specifications.