When it comes to Printed Circuit Boards (PCBs), the choice of materials isn’t just about making a product that works; it’s about crafting a solution that performs at top-notch levels under the specific demands of the project. Whether you’re working on next-gen telecommunications equipment, aerospace applications, or advanced automotive electronics, the materials you choose can make a difference in your board’s performance and durability. Among these materials, Isola PCB laminates have earned a name for quality and consistency, allowing engineers to push the envelope in terms of speed, temperature resistance, and signal integrity.

Isola’s materials, including popular options like FR408HR, 370HR, and P95/P25, have shown their capability in high-frequency applications, as well as in high-density interconnect (HDI) designs. By understanding the unique attributes and advantages of Isola laminates, you can make informed decisions that fit your technical requirements and meet the expectations of today’s electronic manufacturing standards

Key Technical Attributes and Performance Benefits of Isola PCB Materials

When selecting materials for printed circuit boards, understanding the technical attributes of those materials can significantly influence performance. Isola PCB materials are known for their exceptional properties that enhance functionality in various applications. Let’s dive deeper into these attributes, highlighting their benefits while keeping it engaging and easy to digest.

1.High-Tg and Heat Resistance in Extreme Environments for Isola PCB Applications

Thermal performance is a significant concern for engineers designing PCBs that operate in demanding environments. High glass transition temperature (Tg) materials, like Isola’s FR408HR and 370HR, are specifically engineered to withstand extreme thermal conditions without degrading.

What is Tg-

Tg refers to the temperature at which a material transitions from a hard and relatively brittle state into a more flexible or rubber-like state. For instance, a Tg above 170°C allows Isola materials to maintain structural integrity even when subjected to prolonged exposure to high temperatures.

Real-World Applications-

Consider the automotive sector, where PCBs are often exposed to extreme conditions, such as under-hood temperatures. Using Isola’s high-Tg laminates ensures that these PCBs do not warp or lose their electrical properties, leading to enhanced reliability and safety.

| Material | Tg (°C) | Typical Applications |

| FR408HR | 180 | Automotive, Aerospace |

| 370HR | 170 | Industrial Controls |

This table illustrates how different Isola materials are optimized for specific environments, making them a go-to choice for engineers aiming to ensure longevity and performance.

2.Dielectric Stability for Signal Integrity in High-Frequency Isola PCBs

In high-frequency applications, ensuring signal integrity is a top priority. Isola materials are crafted to effectively reduce signal loss, which helps maintain reliable communication across various electronic systems.

Why Dielectric Stability Matters-

A stable dielectric constant allows for consistent signal propagation, minimizing distortion and degradation over distance. Isola materials, such as P95, exhibit low loss factors, which means they can handle high-speed data transfer with ease.

Example in Telecommunications-

In telecommunications infrastructure, where data integrity is non-negotiable, Isola materials support the design of antennas and transmission lines that deliver clear, uninterrupted signals. This quality stands out particularly in applications like 5G technology, which demands exceptional performance at high frequencies.

| Material | Dissipation Factor | Frequency Range (GHz) |

| P95 | 0.002 | 1 – 20 |

| P25 | 0.003 | 1 – 18 |

This data underscores how Isola materials maintain performance across various frequency ranges, making them indispensable for modern communication systems.

3.Environmental and Mechanical Robustness of Isola PCB Laminates

Durability in diverse conditions is a hallmark of Isola PCB materials. Their robust design ensures that they can withstand mechanical stress, moisture, and chemical exposure, making them suitable for a wide range of applications.

Mechanical Strength-

Isola laminates possess high tensile strength, enabling them to endure the rigors of production and operational stress. This resilience is particularly useful in applications where vibration or shock is prevalent, such as in automotive and aerospace industries.

Chemical Resistance-

The ability of Isola materials to resist various chemicals enhances their applicability in industrial settings. For example, PCBs used in manufacturing environments where exposure to solvents is common benefit from this property, preventing material degradation and ensuring longevity.

| Material | Moisture Absorption (%) | Chemical Resistance |

| FR408HR | 0.1 | Solvent-resistant |

| 370HR | 0.05 | High chemical resistance |

Industry-Leading Isola PCB Materials and Their Specialized Applications

When it comes to choosing the right PCB material, Isola stands tall with an impressive lineup. Each material is designed with specific applications in mind, ensuring that they perform like a champ in their respective fields. Let’s dive into some of the heavy hitters in Isola’s arsenal and see how they’re making waves in various industries.

1. Isola FR408HR for High-Speed Digital Applications

If speed is your top priority, Isola FR408HR is your go-to material. Specifically designed for high-speed digital applications, it ensures that every nanosecond is maximized.

Speed Meets Stability-

FR408HR features a high glass transition temperature (Tg) of 180°C, making it an outstanding choice for applications that operate under elevated temperatures. With its low dielectric loss properties, this material ensures that signals remain sharp and distinct.

Perfect Fit for Data Centers-

Imagine a data center where timing is everything . In such an environment, FR408HR stands out, allowing server farms to manage hefty data loads with ease. Its dependable performance minimizes disruptions, which is a major advantage for IT teams focused on maintaining seamless operations.

Performance Metrics-

| Parameter | Value |

| Tg | 180°C |

| Dielectric Constant | 3.5 |

| Loss Factor | 0.015 |

This table sums up why FR408HR is the go-to choice for engineers aiming to push the limits of high-speed digital technology.

2. Isola 370HR for High-Reliability and High-Temperature Requirements

Next up is Isola 370HR, which is engineered for high-reliability applications in harsh environments. If you’re in industries where failure isn’t an option, this is your material.

Built Tough for Tough Tasks-

The 370HR is designed to withstand extreme temperatures without flinching, making it ideal for military and aerospace applications where conditions can be downright brutal. Its robustness ensures that systems remain operational even under pressure.

Applications Across the Board-

Think military drones or aerospace equipment—this material ensures that PCBs can handle the heat (literally) without any drama. Engineers trust 370HR to deliver reliable performance in the field, where every component counts.

Performance Metrics-

| Parameter | Value |

| Tg | 170°C |

| Thermal Conductivity | 0.5 W/mK |

| Moisture Absorption | 0.05% |

With these specifications, the 370HR stands out as a reliable choice for those looking to avoid any nasty surprises in high-stakes situations.

3. Isola P95/P25 in RF and Microwave PCB Applications

Finally, we have the exceptional Isola P95 and P25, specifically engineered for RF and microwave applications. These materials are designed to ensure that signal integrity is maintained, even at the highest frequencies.

Antenna Performance Like No Other-

When working with radio frequencies, keeping signal quality top-notch is essential. The P95 and P25 materials are designed with low dielectric losses, which enable clear transmission and reception of signals. This feature makes them a preferred choice among RF engineers.

Great Fit for 5G and Beyond-

As the world moves toward faster communication technologies, these materials are stepping up to the plate. They’re particularly well-suited for 5G applications, ensuring that the next generation of wireless communication is fast and reliable.

Performance Metrics-

| Material | Dissipation Factor | Frequency Range (GHz) |

| P95 | 0.002 | 1 – 20 |

| P25 | 0.003 | 1 – 18 |

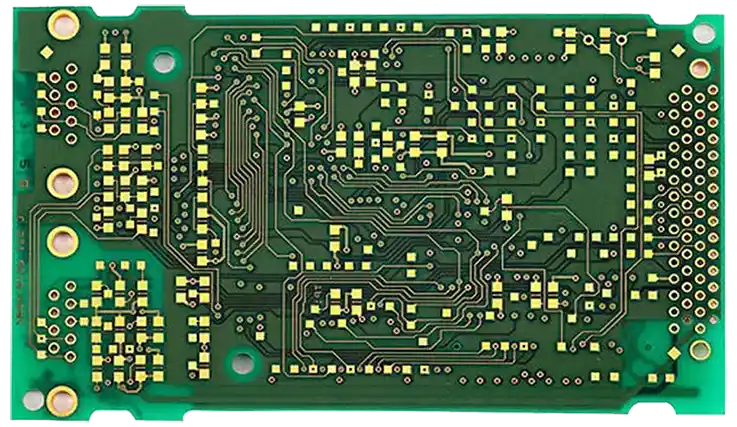

Advanced Multi-layer and HDI Fabrication Techniques Using Isola PCB Materials

In the world of printed circuit boards, mastering the art of multi-layer and HDI (High-Density Interconnect) fabrication can make all the difference. With Isola PCB materials, engineers and designers can push the envelope in creating complex, high-performance boards that meet today’s demanding standards. Let’s break down some advanced techniques in this space.

1. Layer Stacking and Registration Techniques for Multi-layer Isola PCBs

Layer stacking is a fundamental aspect of multi-layer PCB design, allowing multiple circuits to be integrated into a single compact board.

Precision Layer Registration-

Getting the layers to line up just right is no walk in the park. Using advanced registration techniques, designers ensure that each layer aligns perfectly. This precision is key to preserving signal integrity throughout the system, particularly when dealing with high-frequency signals. It’s all about getting the details spot on to keep everything functioning smoothly!

Example of Layer Stacking-

Consider a typical 6-layer PCB used in a telecommunications device. By strategically stacking layers for power, ground, and signal routing, designers can create a balanced structure that minimizes crosstalk and maximizes performance. Here’s a simple layout:

| Layer Number | Layer Type | Function |

| 1 | Signal | High-speed signal routing |

| 2 | Ground | Ground plane for noise reduction |

| 3 | Power | Power distribution |

| 4 | Signal | Additional signal routing |

| 5 | Ground | Secondary ground plane |

| 6 | Signal | High-speed signal routing |

This kind of thoughtful stacking can lead to improved overall performance.

2. Impedance Control with Isola PCB Materials in High-Speed HDI Designs

When working with HDI PCBs, impedance control is a must. Engineers need to maintain the desired impedance to ensure signal integrity, especially in high-speed applications.

Understanding Impedance-

Impedance mismatches can cause reflections that disrupt signal transmission. By utilizing Isola materials, which offer consistent dielectric properties, designers can achieve precise impedance control throughout the design. This consistency makes it easier to design traces that maintain the required impedance values.

Application-

For example, an HDI PCB designed for a 5G mobile device. By carefully calculating trace widths and spacing, engineers can use Isola’s materials to achieve controlled impedance values of 50 ohms or 75 ohms, which are typical for RF applications. This attention to detail keeps signals clear and reduces loss, ensuring the device performs like a champ.

| Trace Width (mm) | Dielectric Thickness (mm) | Impedance (Ohms) |

| 0.3 | 0.2 | 50 |

| 0.5 | 0.3 | 75 |

3. Thermal Management Solutions for High-Power HDI Isola PCBs

As devices ramp up in power, effectively managing heat becomes a major focus. High-power applications can produce a lot of heat, so proper thermal management is key to preventing performance drops. Keeping temperatures in check ensures devices operate at their best and helps extend their lifespan.

Thermal Management Strategies-

Isola materials are engineered to handle heat, allowing for better thermal dissipation. Designers can incorporate thermal vias, copper planes, and heatsinks to ensure that heat is efficiently managed across the PCB.

Case Study: High-Power Applications-

Let’s say you’re designing a power amplifier PCB. The use of Isola materials allows you to implement a robust thermal management system that keeps temperatures in check. For instance, by utilizing thicker copper layers in critical areas, the board can effectively dissipate heat without compromising performance.

| Design Feature | Description | Benefits |

| Thermal Vias | Vias filled with thermal conductive material | Improve heat transfer to other layers |

| Copper Planes | Large copper areas for heat dissipation | Reduce hot spots on the PCB |

| Heatsinks | Additional components for cooling | Further enhance thermal management |

PCB Design Best Practices for Optimizing Isola PCB Material Performance

Creating high-performance printed circuit boards with Isola materials requires thoughtful design strategies. By adhering to best practices, engineers can significantly enhance the performance and reliability of their boards. Here, we’ll explore layout strategies, advanced configurations, and material selection to ensure top-notch performance.

1. Layout Strategies for Signal Integrity in High-Frequency Isola PCB Circuits

When creating PCBs for high-frequency applications, maintaining signal integrity takes center stage. Every little detail in the layout can make a difference in keeping those signals sharp and clean. It’s all about precision—getting it right means ensuring reliable communication in the fast-paced world of electronics. Attention to these elements helps keep everything on point, allowing devices to perform at their best without any hiccups.

Minimizing Loop Areas-

Keeping loop areas small helps reduce electromagnetic interference (EMI) and crosstalk. Aim to route your return paths closely to the signal traces. This technique not only enhances signal quality but also reduces the risk of unexpected voltage spikes.

Controlled Impedance Traces-

To maintain signal integrity, you need to calculate and control the impedance of traces. This involves considering trace width, spacing, and the dielectric constant of the Isola material used. Tools like impedance calculators can be a lifesaver here.

Example of Effective Layout-

Let’s look at a high-frequency design for a Wi-Fi module. By implementing tightly coupled microstrip designs with controlled impedance, engineers ensured that the signals remained stable across varying frequencies.

| Design Element | Best Practice | Benefit |

| Trace Width | Keep within design guidelines for impedance | Enhances signal clarity |

| Layer Stack-Up | Utilize ground planes and power planes | Minimizes noise and enhances reliability |

| Return Path Routing | Route closely to signal traces | Reduces EMI and improves integrity |

2. Advanced Layer Configurations for High-Frequency Isola PCB Designs

Advanced layer configurations are essential when dealing with complex circuits. These configurations can dictate how signals traverse the board and interact with each other.

Utilizing Differential Pairs-

For high-speed signals, differential pairs are a go-to solution. By routing pairs of traces that carry opposite signals, engineers can minimize noise and enhance signal integrity. The tight coupling between the pairs aids in maintaining a balanced signal, even over longer distances.

Multi-layer Strategies-

For a 10-layer PCB in a 4G base station, thoughtful layer placement is the name of the game for keeping noise in check while boosting performance. By organizing layers for signals, power, and ground, designers can maximize power delivery and manage interference from various components. This layer stacking approach means the board can handle higher frequencies smoothly, allowing signals to travel cleanly. A setup like this ensures efficient power flow and maintains the clarity needed for reliable operation in demanding wireless networks.

Example Configuration-

Here’s a simplified view of a 10-layer configuration:

| Layer Number | Layer Type | Purpose |

| 1 | Signal | High-speed signal routing |

| 2 | Ground | Reference plane |

| 3 | Power | Distribution |

| 4 | Signal | Differential pair |

| 5 | Ground | Secondary reference |

| 6 | Signal | Additional high-speed signals |

| 7 | Power | Redundant distribution |

| 8 | Signal | High-frequency signals |

| 9 | Ground | EMI shielding |

| 10 | Signal | Final high-speed outputs |

3. Selecting Complementary Materials for Impedance Matching with Isola PCBs

Selecting the right materials is a big part of hitting peak performance. By combining Isola substrates with other compatible materials, engineers can fine-tune impedance matching and maximize the circuit’s response. This pairing ensures that signals move through the system with minimal disruption, optimizing efficiency and reducing losses in high-frequency setups.

Understanding Material Properties-

It’s essential to consider the dielectric constant and loss tangent of the materials in use. For instance, when designing a PCB that needs to interface with RF components, pairing Isola materials with low-loss dielectrics can yield better impedance control.

Practical Material Selection-

If you’re working on a radar system, combining Isola materials with ceramic substrates can help achieve the desired performance. This approach allows for improved thermal management and reduced signal loss, leading to more reliable operation.

| Material | Dielectric Constant | Application |

| Isola FR408HR | 3.8 | High-speed digital |

| Isola 370HR | 3.4 | High-reliability applications |

| Ceramic Substrates | 6.0 | RF and microwave applications |

Optimizing PCB designs with Isola materials isn’t just about the specs; it’s about thinking ahead. Take these best practices to heart, and your boards will not only perform but will set you apart in a competitive market. So, don’t wait—dive into your next project with confidence, armed with the knowledge to make it a standout success!

Manufacturing Processes Tailored for Isola PCB Materials

In today’s rapidly advancing electronics sector, the methods used in fabricating Isola’s PCB materials ensure that each finished board is robust, dependable, and well-suited for high-performance tasks. From controlled lamination to precise etching, each step is meticulously designed to maintain the product’s integrity and meet exacting standards. Let’s break down some core techniques that make these materials the go-to choice for demanding applications.

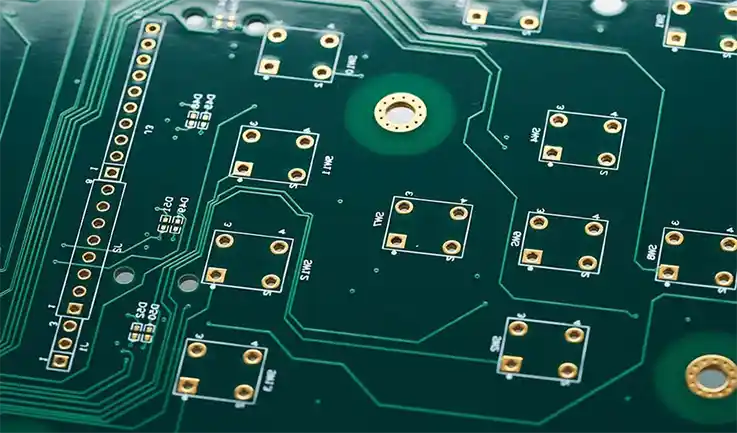

1. Laser Drilling and Microvia Techniques for Precision in Isola PCB Fabrication

Laser drilling has become a go-to method in the PCB manufacturing process, particularly for creating microvias in Isola materials. This technique enables precision drilling, which is essential in modern, compact PCB designs.

Precision and Speed-

Laser drilling allows for creating microvias that are smaller than traditional drilling methods can achieve. This high-precision process ensures that the vias can accommodate the high-density interconnects found in today’s devices. The ability to drill without mechanical stress on the material means there’s less risk of damaging the laminate.

Case Study: Microvia Applications-

Consider a smartphone PCB where space is at a premium. By employing laser drilling, manufacturers can create microvias that facilitate connections between layers while maintaining the integrity of the Isola material. This results in a thinner design without sacrificing performance.

Advantages of Laser Drilling-

The advantages are clear:

●Reduced thermal stress on materials, leading to fewer defects.

●Increased flexibility in design, allowing for more intricate layouts.

●Lower costs associated with waste and rework.

| Aspect | Traditional Drilling | Laser Drilling |

| Hole Size | Limited to larger diameters | Capable of sub-100 micron holes |

| Speed | Slower | Fast, efficient process |

| Material Stress | Higher risk of damage | Minimal impact |

2. Lamination and Curing Techniques to Maximize Durability of Isola PCBs

The lamination and curing processes are crucial in determining the durability and performance of Isola PCBs. These techniques ensure that layers are bonded effectively, creating a strong, reliable circuit board.

Lamination Process-

In this phase, layers of Isola materials are stacked and subjected to heat and pressure. This process enhances adhesion and improves the overall mechanical strength of the PCB. By utilizing advanced equipment and materials, manufacturers can achieve uniform thickness and density across layers.

Curing Techniques-

After lamination, the PCB moves to a curing stage that strengthens the resin and firmly bonds the layers. This process often uses specialized methods like thermal or UV curing to give the board the resilience it needs to handle demanding, high-heat environments. By solidifying the material properties, these curing techniques help the PCB maintain structural integrity and perform reliably over time, especially in applications where heat resistance can’t be compromised.

Illustrative Example-

Take for instance the production of PCBs for automotive applications. These boards must withstand extreme conditions, including temperature fluctuations and mechanical stress. Utilizing advanced lamination and curing techniques ensures that the boards remain reliable, even under demanding circumstances.

| Technique | Description | Benefit |

| Thermal Lamination | Uses heat and pressure to bond layers | Ensures strong adhesion |

| UV Curing | Cures resin using ultraviolet light | Reduces curing time, enhances properties |

3. Quality Assurance and Testing for High-Reliability Isola PCB Materials

Ensuring the quality and reliability of Isola PCBs is non-negotiable. Manufacturers implement rigorous testing protocols throughout the production process.

Testing Techniques-

Various methods are used to evaluate the performance and durability of PCBs. From automated optical inspection (AOI) to electrical testing, each step helps catch defects early in the manufacturing process.

Real-world Application-

In aerospace, where endurance and precision are non-negotiable, each PCB goes through rigorous testing to meet demanding standards. These tests include thermal cycling to evaluate the board’s ability to handle extreme temperature changes and vibration tests that simulate intense launch conditions. These procedures help confirm that each board can handle the punishing conditions of space travel, maintaining its integrity and performance under pressure.

Continuous Improvement-

Quality assurance doesn’t stop at testing. Manufacturers are continually refining their processes based on test results, leading to improved manufacturing techniques and better overall product performance.

| Testing Method | Purpose | Outcome |

| Automated Optical Inspection | Detects surface defects and misalignments | Early identification of issues |

| Electrical Testing | Verifies electrical connections and functionality | Ensures reliability in operation |

Assembly Techniques for Ensuring Longevity and Performance in Isola PCBs

When it comes to assembling Isola PCBs, the techniques employed can significantly impact the longevity and overall performance of the final product. Ensuring that these boards are assembled with precision and care can save time, reduce costs, and enhance reliability. Let’s break down some of the best practices in this area.

1. SMT Assembly Best Practices for Stability in Isola PCB Materials

Surface Mount Technology (SMT) is the go-to assembly method for modern PCBs, including those made from Isola materials. Mastering SMT can greatly enhance the stability and performance of your boards.

Proper Pad Design-

One of the key factors in SMT assembly is the design of the pads on the PCB. Ensuring the pads are correctly sized and spaced can help improve solder joint integrity. A well-designed pad layout minimizes the risk of solder bridging, which can lead to short circuits.

Solder Paste Application-

Applying the right amount of solder paste is another crucial step. Too much paste can cause solder to overflow, while too little can lead to weak joints. Utilizing automated stencil printing can help achieve consistent results across all boards.

Example of SMT Success-

Consider a manufacturer that implemented an advanced stencil printing process for their Isola PCBs. By optimizing the solder paste application, they reported a 30% reduction in defects and significantly improved assembly reliability. This is a prime example of how attention to detail pays off.

| Best Practice | Impact |

| Proper Pad Design | Enhances solder joint integrity |

| Consistent Solder Paste Application | Reduces defects and enhances reliability |

| Automated Inspection | Catches issues before they escalate |

2. Compatibility of Wave and Selective Soldering with Isola PCB Materials

For soldering Isola PCB materials, both wave and selective soldering are viable options, each with its own distinct techniques to bring out the best in these materials. Wave soldering provides broad coverage that’s great for components mounted on one side, while selective soldering is the go-to for precision work on complex, multilayer boards. Knowing the specifics of each method helps to bring out optimal performance, especially when considering thermal impact and component density.

Wave Soldering Technique-

This method involves passing a PCB over a wave of molten solder. While effective for bulk soldering, it may not be suitable for all Isola PCBs, particularly those with sensitive components. The high temperatures and molten solder can potentially damage delicate parts.

Selective Soldering Advantages-

Selective soldering offers pinpoint precision, making it ideal for dense assemblies where component spacing is tight. This technique applies solder exactly where it’s needed, preserving delicate parts while securing solid connections across high-density PCBs. It’s a choice that meets the demands of complex layouts without putting sensitive components in harm’s way.

Case Study: Balancing Techniques-

A company faced challenges with their assembly line due to mixed components on their Isola PCBs. By analyzing their soldering approach and switching to selective soldering for sensitive areas, they improved yield rates by 25%. This highlights the importance of choosing the right method for specific applications.

| Soldering Method | Pros | Cons |

| Wave Soldering | Fast and efficient for through-hole components | Potential damage to sensitive parts |

| Selective Soldering | Targeted application preserves component integrity | Slower than wave soldering |

3. Post-Assembly Thermal Management in High-Performance Isola PCBs

Once assembly wraps up, keeping thermal conditions under control is a must to ensure Isola PCBs perform over the long haul. Effective heat management locks in stable performance, warding off issues that could arise from overheating and helping the board stand up to challenging environments.

Understanding Thermal Dynamics-

High-performance PCBs often generate significant heat during operation. Implementing proper thermal management strategies can help dissipate heat and prevent damage. This includes the use of thermal vias, heat sinks, and even embedded cooling solutions.

Real-Life Application: Automotive Electronics-

Take automotive electronics as an example. These devices operate under varying conditions, often leading to thermal challenges. By incorporating thermal management strategies early in the design and assembly process, manufacturers can ensure that the PCBs maintain their functionality and reliability over time.

Implementing Effective Solutions-

Effective thermal management strategies may include:

●Thermal vias: Enhancing heat dissipation by providing pathways for heat to escape from critical components.

●Heat sinks: Attaching heat sinks to high-heat-generating components can significantly lower temperatures.

●Active cooling: In extreme cases, using fans or other cooling solutions can be beneficial.

| Thermal Management Strategy | Benefit |

| Thermal Vias | Enhances heat dissipation |

| Heat Sinks | Reduces localized heating |

| Active Cooling | Suitable for high-temperature applications |

Key Procurement Strategies for Sourcing High-Quality Isola PCB Materials

Securing top-notch materials forms the backbone of effective PCB manufacturing. For Isola PCB materials, savvy sourcing methods can make a real difference in product performance and reliability. Let’s dive into a few smart approaches to ensure these materials tick all the right boxes for quality and cost-effectiveness.

1. Supplier Evaluation and Material Specifications for Isola PCBs

Finding the right supplier goes beyond just price shopping. It’s about forging partnerships that ensure quality and reliability. Here’s how to evaluate suppliers effectively:

Understanding Material Specifications-

Every Isola material comes with its own set of specifications that dictate its performance. Familiarizing yourself with these specifications helps ensure that the materials meet your project requirements. This includes understanding dielectric properties, thermal performance, and chemical resistance.

Supplier Reputation-

When evaluating suppliers, look for those with a solid reputation in the industry. Reading reviews and case studies can provide insight into their reliability. Consider asking potential suppliers for references from previous clients to gauge their performance and quality control measures.

On-Site Audits-

Nothing beats a hands-on approach. Conducting on-site audits can help you get a feel for the supplier’s processes and capabilities. You’ll want to check their manufacturing capabilities, quality control processes, and how they handle potential issues.

Example of Supplier Evaluation-

A company looking to source Isola FR408HR for high-speed digital applications conducted a thorough evaluation of several suppliers. They found that one supplier not only offered competitive pricing but also had a robust quality assurance process. This led to a successful partnership and higher overall product reliability.

| Evaluation Criteria | Importance |

| Material Specifications | Ensures alignment with project needs |

| Supplier Reputation | Reduces risk and enhances reliability |

| On-Site Audits | Provides insight into supplier capabilities |

2. Cost Management in Procuring Advanced Isola PCB Materials

Managing costs effectively can make a huge difference in your bottom line. Here are some strategies to keep in mind:

Bulk Purchasing-

Buying in bulk can often lead to significant discounts. If your production needs allow it, consider negotiating bulk purchase agreements with your suppliers. This not only reduces costs but also helps secure a consistent supply of materials.

Total Cost of Ownership (TCO)-

Instead of narrowing in on the upfront cost, think big-picture by weighing the total cost of ownership. This approach considers not only the price tag on materials but also factors like shipping, handling, and any added expenses from delays or quality issues that might come up. Adopting this broader perspective makes for better decision-making and, ultimately, more cost-effective sourcing.

Long-Term Contracts-

Establishing long-term contracts with suppliers can stabilize costs and ensure material availability. This approach also allows for more effective budgeting and forecasting.

Case Study: Cost Management Success-

One PCB manufacturer implemented a TCO analysis when sourcing Isola materials. They discovered that a slightly more expensive supplier had fewer defects and lower returns, ultimately saving them money in the long run. By looking at the big picture, they made a better decision for their business.

| Cost Management Strategy | Benefit |

| Bulk Purchasing | Reduces per-unit costs |

| TCO Analysis | Helps identify long-term savings |

| Long-Term Contracts | Stabilizes costs and secures supply |

3. Custom Ordering for Specific Isola PCB Material Needs

Every project has its own set of requirements, and customizing orders can provide the tailored solutions necessary for success.

Understanding Customization Options-

Isola offers a range of materials that can be tailored to meet specific performance characteristics. Engaging with your supplier about customization options ensures that you get the exact specifications you need.

Collaborative Development-

Work closely with suppliers to develop materials that suit your unique needs. This could include altering the thickness of a laminate or adjusting thermal properties. Establishing a collaborative relationship can yield innovative solutions tailored to your applications.

Flexibility and Responsiveness-

In today’s rapid market environment, the capacity to adjust swiftly is important. Suppliers that implement flexible ordering methods can effectively handle fluctuations in demand or changes in project requirements, which helps you stay nimble.

Success Story: Custom Solutions-

A company developing a new medical device required specific thermal properties in their PCB materials. By collaborating with their supplier on custom orders, they were able to create a product that met their exact specifications. This not only improved performance but also enhanced patient safety.

| Custom Ordering Benefit | Description |

| Tailored Material Properties | Meets specific project requirements |

| Collaborative Development | Fosters innovation and adaptability |

| Flexibility | Enhances responsiveness to market changes |

Which Is Superior Between Isola and Nelco PCB material?

When it comes to comparing Isola and Nelco PCB materials, both have a strong reputation in the industry, and the choice between them often hinges on specific application requirements, performance characteristics, and material properties. Let’s break down the comparison in a comprehensive manner.

1. Performance Overview

Thermal and Mechanical Properties-

Both Isola and Nelco materials are engineered for high performance, providing excellent mechanical strength and thermal stability. Here are some key points to consider:

●Isola PCB Materials

Isola laminates, such as the 370HR, IS415, IS680, and FR408, are known for their high thermal reliability. Many of these materials meet RoHS standards, making them suitable for lead-free applications. Their high glass transition temperature (Tg) makes them ideal for applications requiring stability under extreme heat conditions.

●Nelco PCB Materials

Similarly, Nelco offers a range of high-performance materials designed to withstand harsh environments. Their products also exhibit strong thermal and mechanical properties, making them suitable for various applications, including telecommunications and military devices. The N7000 series, for instance, is recognized for its superior heat resistance and dielectric properties.

2. Material Variety and Applications

Both manufacturers provide a broad selection of materials tailored to different needs. Here’s a deeper look:

●Isola’s Product Range

Isola’s lineup includes multiple high-Tg laminates like FR406N, 185HR, and the innovative G200. Each laminate is crafted for specific performance criteria, addressing various applications in the electronics field. For instance, the FR408 is frequently used in high-frequency applications due to its excellent dielectric properties.

●Nelco’s Product Range

Nelco also boasts a diverse portfolio with specialized products. Their N4000-13 series, for example, is designed for high-speed digital applications, offering low loss and superior signal integrity. Nelco’s materials are often favored in sectors where high reliability and performance are non-negotiable, such as aerospace and automotive.

3. Environmental Compliance and Sustainability

Both Isola and Nelco prioritize environmental compliance, but their approaches may vary:

●Isola’s Environmental Commitment

Isola materials meet RoHS standards, guaranteeing they are free from harmful substances. This dedication supports manufacturers looking to adopt environmentally friendly practices. By ensuring compliance, companies can confidently pursue sustainable solutions that align with modern eco-conscious demands.

●Nelco’s Sustainability Efforts

Nelco also adheres to strict environmental regulations, offering materials that support sustainable manufacturing practices. Their efforts in reducing waste during production and developing recyclable materials resonate well with the industry’s shift towards greener solutions.

4. Comparative Table of Isola and Nelco PCB Materials

| Attribute | Isola PCB Materials | Nelco PCB Materials |

| Thermal Properties | High Tg (up to 185°C), excellent heat resistance | Excellent heat resistance across various series |

| Mechanical Strength | Superior mechanical stability, less prone to warping | High mechanical strength, ideal for demanding applications |

| Environmental Compliance | RoHS compliant, lead-free options available | Strict adherence to environmental regulations |

| Application Suitability | High-speed digital, RF, and microwave circuits | Telecommunications, aerospace, automotive |

| Popular Models | 370HR, IS415, IS680, FR408 | N4000-13, N7000 series |

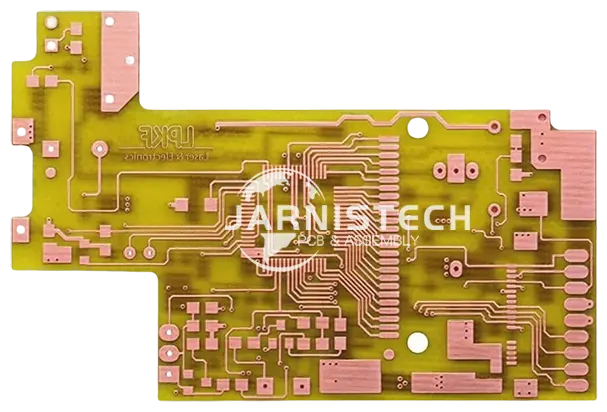

Why Choose JarnisTech?

Your Premier Isola PCB Supplier in China

When it comes to top-notch Isola PCBs, JarnisTech stands out as a leader in production and distribution across the globe. With over 20 years of experience under our belts, we’ve honed our expertise in crafting high-quality Isola PCBs that you can rely on. Our commitment to excellence positions us as a trusted manufacturer, dedicated to delivering only the best in high-performance PCB solutions.

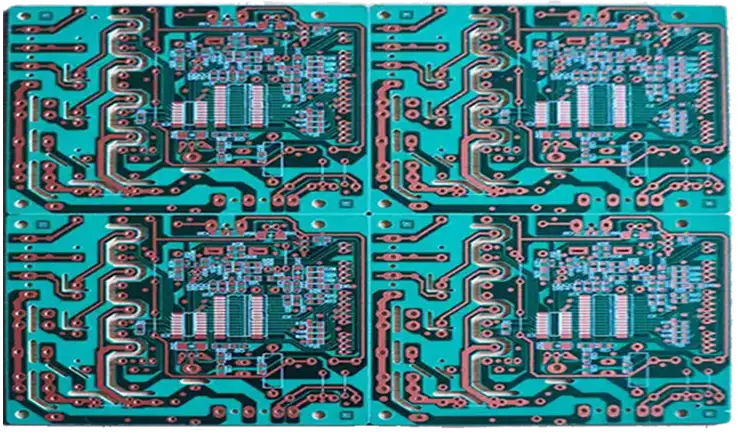

1. Comprehensive Inventory of High-Frequency PCB Materials

If you’re in search of high-frequency PCB materials, you’ve landed in the right spot. Our inventory includes not only Isola materials but also Dupont, Arlon, Rogers, and Teflon PCBs. We strive to keep a variety of materials in stock, ensuring you have quick access to what you need. For any specific part numbers that aren’t currently available, we’re more than happy to place a special order to fulfill your requirements.

| Materials Isola Products | ||

| 370HR | IS620i | I-Speed |

| FR406 | IS415 | I-TERA MT40 |

| FR408 | IS410 | I-TERA MT40 (RF/MW) |

| FR408HR | Green Speed | Terra Green |

| P95/P25 | GETEK | Terra Green (RF/MW) |

| P96/P26 | 185HR | Tachyon 100G |

| G200 | 370HR | Astra MT77 |

| IS680-300 | IS550 New Product Q2 2019 | |

| 370HR | FR408HR | |

2. High-Performance Isola PCBs for Diverse Applications

We manufacturing Isola PCBs boards for top-notch performance, benefiting from the high-quality materials used in their production. These boards cater to a diverse range of electronic markets, including networking and communications, computing devices, and various high-end consumer electronics. Whether utilized in data centers or advanced gadgets, our PCBs are crafted to fulfill the demanding requirements of contemporary technology.

3. Tailored Solutions for Advanced Industries

At JarnisTech, we don’t just stop at general applications. We specialize in producing Isola PCBs for some of the most advanced sectors, including:

●Automotive: Supporting cutting-edge automotive technology, our PCBs are designed to withstand the harshest conditions.

●Military: We adhere to stringent military specifications to ensure reliability and performance in critical applications.

●Medical: Our Isola PCBs comply with healthcare standards, making them suitable for life-saving medical devices.

●Aerospace: Meeting aerospace regulations, our boards are built for durability and precision in demanding environments.

4. Compliance with Industry Standards

JarnisTech is proud to offer Isola PCBs that meet a host of industry standards, including:

●IPC 6012 CLASS 3/3A

●AS9100D

●ISO 9001

●MIL-PRF-31032

●MIL-PRF-5110

This level of certification ensures that our products not only meet but exceed industry expectations, giving you peace of mind in your selection of materials.

5. Customer-Centric Approach

Your satisfaction is our top priority! We are here to support your projects from the ground up. If you need assistance or have specific inquiries about our Isola PCBs, don’t hesitate to reach out to us. Let us know how we can help you, and together, we can find the perfect PCB solutions tailored to your needs.

6. Easy Ordering and Customer Support

Your convenience is our priority! Simply reach out to us at [email protected] with your inquiries or special requests. Our dedicated team is ready to assist you in navigating your options and securing the right materials for your projects. With our reliable service and support, you can count on JarnisTech as your trusted one stop PCB manufacturing and supplier.

Join the JarnisTech Family

Discover why so many industry professionals choose JarnisTech as their trusted partner in PCB manufacturing. Let’s work together to bring your projects to life with our exceptional Isola PCBs. Don’t miss out on the chance to elevate your products—contact us today and see what we can do for you!

FAQ

What makes Isola PCB materials suitable for high-frequency applications?

Isola materials have low loss characteristics and stable dielectric properties, making them ideal for maintaining signal integrity at high frequencies.

Are Isola PCB materials environmentally friendly?

Many Isola laminates meet industry standards for environmental safety, including RoHS compliance, making them suitable for eco-conscious manufacturing.

How do Isola materials handle thermal management in high-power circuits?

Isola laminates exhibit excellent thermal conductivity and high Tg, which allows them to effectively dissipate heat in high-power applications.

What are the main advantages of using Isola laminates in HDI PCBs?

Isola laminates offer precise impedance control, enhanced thermal management, and mechanical robustness, making them ideal for complex HDI designs.

What factors should I consider when sourcing Isola PCB materials?

Key factors include supplier certification, material availability, lead times, and pricing. It’s essential to choose reputable suppliers to ensure quality.