Sourcing PCB components refers to the acquisition of the different parts needed for assembling a printed circuit board (PCB). This process is fundamental to keeping your project on track from beginning to end.

So, Ready to get started? Don’t hesitate to reach out for assistance with your PCB sourcing needs! We’re here to help you navigate the component landscape and set your projects up for success.

This guide aims to break down the complexities of component sourcing, providing insight into strategies, best practices, and emerging industry trends. Our goal is to ensure your projects not only meet standards but also exceed expectations.

Understanding Components Sourcing in PCB Manufacturing and Assembly

Overview of Components Sourcing for Electronics Manufacturing

Components sourcing isn’t just a box-checking exercise; it’s about establishing a solid foundation for your entire production process. Whether you’re on the hunt for resistors, capacitors, or intricate integrated circuits, the decisions made during sourcing can dramatically impact both the quality of your products and your overall production costs.

Think of it this way: your circuit board’s performance hinges on the components you choose. You wouldn’t whip up a feast without sourcing the freshest ingredients, would you? It’s the same principle for your PCBs—quality components equal quality output.

Let’s break it down. Components sourcing involves evaluating suppliers, understanding pricing structures, and navigating lead times to ensure that every piece fits perfectly into your assembly puzzle. To give you a clearer picture, here’s a simple table that highlights the core components you might need:

| Component Type | Common Uses | Typical Sourcing Sources |

| Resistors | Current limiting, voltage division | Distributors, online marketplaces |

| Capacitors | Energy storage, filtering | Electronic component suppliers |

| Integrated Circuits | Data processing, amplification | OEMs, specialized distributors |

| Connectors | Electrical interconnection | Specialized suppliers |

| PCB Fabrication Materials | Substrate, layers, finish | Raw material suppliers |

Why Components Sourcing Matters in PCB Production?

Choosing the right components can save you from a mountain of stress later on. Ensuring that the parts you’re using are dependable and of high quality lays the groundwork for smooth assembly processes. Imagine being in the middle of production and facing delays because a supplier drops the ball—it’s like waiting for your favorite pizza on game night, and when it finally arrives, it’s cold! Nobody wants to deal with that kind of hassle.

Here’s where it pays off to have a reliable sourcing strategy. A few tips to get you on the right track:

●Know Your Suppliers: Building a rapport with suppliers can lead to better service and priority during peak times.

●Quality Over Price: Sometimes the cheapest option can cost you more in the long run. Don’t skimp on quality.

Key Challenges in Components Sourcing and How to Overcome Them

1.Supply Chain Disruptions: The electronics supply chain can often resemble a rollercoaster ride—full of unexpected twists and turns. From natural disasters to political unrest, there are numerous factors that can disrupt your supply. The best defense? Establish relationships with multiple suppliers and keep a buffer stock of crucial components. Think of this as your safety net—one that keeps your operations steady when the unexpected hits.

2.Counterfeit Components: The threat of counterfeit parts looms large in the electronics industry. It’s imperative to engage with reputable suppliers and implement strict quality checks. Thoroughly vet your suppliers—this due diligence can prevent you from making costly blunders that could derail your projects. A good practice is to require certifications from your suppliers to ensure authenticity.

3.Rapid Technological Changes: With technology advancing at breakneck speed, staying updated on the latest components can feel like chasing shadows. Regularly immerse yourself in industry news, attend trade shows, and actively seek out emerging technologies that can enhance your product offerings. Connecting with other industry professionals can also provide insights into where the market is heading.

4.Global Market Fluctuations: The global marketplace can shift overnight due to economic factors, tariffs, or other unforeseen circumstances. Diversifying your sourcing locations can provide some protection against these fluctuations. If one region faces challenges, you have options elsewhere.

5.Inventory Management: Balancing inventory levels can be tricky—too much stock ties up cash, while too little can halt production. Consider implementing just-in-time (JIT) inventory systems to streamline your processes. This approach can minimize waste and maximize efficiency, allowing you to respond quickly to market demands.

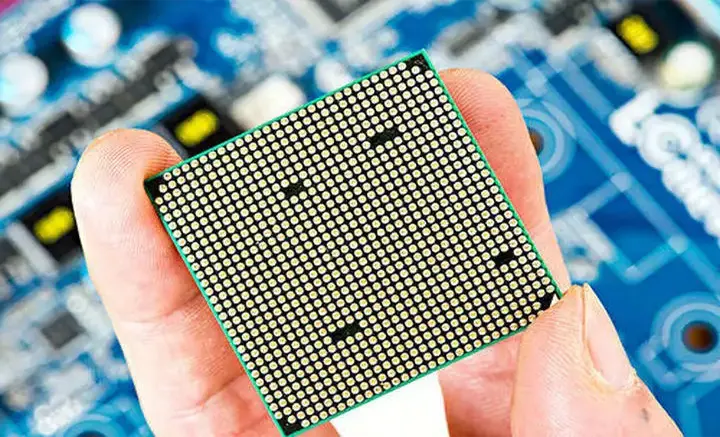

Types of PCB Components

Exploring the landscape of Printed Circuit Boards means getting acquainted with the various components that make them tick. The type and design of these components depend on the specific needs of their assembly process. Here’s a look at some of the most commonly used PCB components, along with insights into what they do and where they fit in.

Commonly Used PCB Components

| Component | Description | Applications |

| Resistors | Limit electric current flow; available in fixed, variable, and specialized types. | Current control, voltage division |

| Capacitors | Store and release electrical energy; types include ceramic, electrolytic, and tantalum. | Power smoothing, filtering, timing |

| LEDs | Light Emitting Diodes used for indicators and displays; available in various colors and sizes. | Visual indicators, displays |

| Power Inverters | Convert DC to AC power; essential for renewable energy applications. | Solar applications, backup power |

| Power Regulators | Maintain steady output voltage; includes linear and switching types. | Power supply stability |

| Batteries | Provide portable power; options include lithium-ion and nickel-metal hydride. | Mobile devices, backup power |

| Transistors | Act as switches or amplifiers; types include BJTs and FETs. | Signal processing, switching |

| Inductors | Store energy in a magnetic field; used for current smoothing. | Power supplies, filters |

| Diodes | Allow current to flow in one direction; includes Zener and Schottky types. | Protection circuits, voltage regulation |

| Connectors | Facilitate connections between PCB components; includes USB, backplane, etc. | Component interfacing |

| Sensors | Detect environmental changes; types include temperature and motion sensors. | Automation, user interaction |

| Integrated Circuits (ICs) | Compact assemblies of multiple electronic components; types include microcontrollers and signal processors. | Data processing, control functions |

| Modules for Energy Harvesting | Capture ambient energy for powering devices. | Remote sensors, IoT applications |

| Switches | Control current flow; can be simple push buttons or complex rotary switches. | User control, device operation |

| Transformers | Change voltage levels in AC circuits; vital for power supply applications. | Voltage regulation, isolation |

Understanding the variety of components available for PCBs is fundamental in designing efficient and effective electronic devices. From resistors to connectors, each component has its unique function and contributes to the overall performance of your project.

Need help with your PCB manufacturing and assembly? Reach out to us! We’re here to help you navigate the components maze and make your project a success!

Building a Reliable Components Sourcing Strategy

Defining Requirements for Effective Components Sourcing

Before diving into the sourcing game, take a moment to define exactly what you need. Crafting a detailed list of specifications for each component is like having a solid recipe before whipping up a meal—without it, you might end up with a dish that misses the mark. Here are some aspects to keep in mind:

●Tolerance Levels: Specify the acceptable range of values for each component. For instance, if you’re sourcing resistors, outline whether you need ±5% or ±1% tolerance. This ensures the components will function as intended in your circuit.

●Size Specifications: Be explicit about dimensions. Knowing the exact footprint of components will help avoid compatibility issues with your PCB layout.

●Compatibility: Ensure that the components you’re sourcing are compatible with your existing PCB design. Double-checking pin configurations and electrical characteristics can save you from headaches later on.

Having clear requirements doesn’t just help streamline your sourcing process; it also acts as a safeguard against mismatched parts that could derail your project. To give you a clearer picture, here’s a simple table showcasing the critical specifications for common components:

| Component Type | Specification | Example Requirements |

| Resistors | Tolerance levels | ±1%, Size 0805 |

| Capacitors | Voltage rating, capacitance | 16V, 10μF, Size 0603 |

| Integrated Circuits | Pin count, package type | 28-pin DIP, 8mm x 8mm |

| Connectors | Pin spacing, type | 2.54mm spacing, male header |

Assessing Component Quality and Compatibility for PCBs

Quality assurance should be at the forefront of your sourcing strategy. Implementing rigorous testing protocols for incoming components ensures that only the best make it into your production line. After all, you wouldn’t construct a house with subpar materials, so why compromise on your PCBs?

Here’s how to elevate your quality assessment:

●Incoming Inspection: Develop a checklist for inspecting components upon arrival. This can include visual inspections for any physical damage, checking labels for authenticity, and verifying component specifications against your predefined requirements.

●Testing Procedures: Adopt standardized testing procedures for critical components. For instance, you might want to conduct functional tests on integrated circuits to ensure they operate within the specified parameters.

●Supplier Audits: Regularly assess your suppliers’ processes and facilities. This will help you gauge their commitment to quality and may uncover any areas that require improvement.

By focusing on quality, you can reduce the risk of defects that could result in costly rework or product failures.

Identifying Critical Sourcing Points for PCB Assembly Efficiency

Charting out your assembly process and pinpointing the moments where sourcing components can boost efficiency is a smart move. Understanding where potential bottlenecks may arise allows you to make informed decisions that enhance your overall production flow.

●Component Availability: Keep an eye on lead times for critical components. Having a clear understanding of supplier delivery schedules can help you avoid production delays. Creating a visual timeline can help your team stay on track.

●Delivery Speed: Evaluate the speed of delivery from your suppliers. If a supplier consistently misses deadlines, it might be time to consider alternatives. Quick turnaround times can mean the difference between launching a product on schedule or falling behind.

●Inventory Management: Striking the right balance between excess inventory and shortages is a tightrope walk. Consider employing just-in-time (JIT) practices to minimize waste while ensuring you have enough stock on hand to meet production demands.

Here’s a quick reference table to identify sourcing points:

| Touchpoint | Impact | Action |

| Component Availability | Affects assembly schedules | Track lead times and reorder points |

| Delivery Speed | Influences production timelines | Assess supplier performance regularly |

| Inventory Levels | Impacts cash flow | Implement JIT or similar systems |

It’s high time to get your component sourcing strategy squared away! Lay out what you need, keep quality front and center, and sketch out your assembly process. A well-thought-out sourcing game plan not only cuts down on headaches but also paves the way for an easy assembly process. So roll up your sleeves and jump into your sourcing strategy—your PCBs are worth it!

Selecting the Right Components Sourcing Partners

Evaluating Components Suppliers for PCB Manufacturing

Choosing the right suppliers can feel a lot like dating—you want to find someone reliable who shares your values and understands your needs. The last thing you want is to get involved with a supplier that leaves you hanging when you need them the most. Here’s how to make sure you pick a winner:

1.Track Record and Certifications: Look for suppliers with a solid reputation in the industry. Do your homework—check their certifications such as ISO or IPC. These standards show they adhere to high-quality practices. Customer reviews can give you insights into their reliability and service quality. Don’t be shy—ask for references and testimonials!

2.Delivery Performance History: Timeliness plays a huge role in sourcing components. If a supplier frequently delivers late, that should raise a red flag. Be sure to ask for performance metrics, like their on-time delivery rates. A supplier who reliably meets deadlines can help keep your production schedule on point. Don’t settle for anything less—making informed choices now will pay off down the road!

3.Engagement and Responsiveness: The best suppliers are those who communicate well. Look for partners who respond promptly to inquiries and are proactive about keeping you updated on order statuses. This level of engagement can ease your mind and allow you to focus on what you do best.

Here’s a handy table to summarize key evaluation points:

| Evaluation Criteria | What to Look For | Red Flags |

| Track Record | Certifications, years in business | Lack of credentials or poor reviews |

| Delivery Performance | On-time delivery statistics | Frequent delays |

| Engagement | Responsiveness to communication | Slow replies or unavailability |

| Customer Support | Availability of support teams | Poor customer service |

Key Criteria for Choosing PCB Components Sourcing Vendors

When it comes to selecting PCB components sourcing vendors, you need to look beyond just pricing. Here are some key criteria to consider:

●Quality Control Processes: Investigate how your potential vendors ensure the quality of their components. Do they conduct incoming inspections? Are they transparent about their testing procedures? Vendors with robust quality control measures help minimize the risk of defects in your final products.

●Communication Style: A smooth partnership is built on effective communication. Evaluate whether the supplier is easy to reach and if they provide clear information. Misunderstandings can lead to costly mistakes, so it’s best to work with someone who keeps the lines open.

●Competitive Pricing: While you want the best bang for your buck, never sacrifice quality for a lower price. Request quotes from multiple vendors to compare pricing structures, but make sure you’re also factoring in the quality of components offered. It’s all about finding that sweet spot.

●Flexibility: Can your potential vendor accommodate your specific needs? Whether you need custom parts or have fluctuating order volumes, flexibility in your supplier can greatly enhance your sourcing strategy. A good supplier will be willing to adapt to your requirements.

Here’s a quick comparison chart for these criteria:

| Criteria | Description | Questions to Ask |

| Quality Control | Measures for ensuring component quality | What testing do you conduct? |

| Communication | Clarity and responsiveness | How quickly do you respond to inquiries? |

| Pricing | Competitiveness without compromising quality | Can you provide a breakdown of costs? |

| Flexibility | Ability to adapt to customer needs | How do you handle custom requests? |

Long-term Partnering Strategies for Sustainable Components Sourcing

Once you’ve secured dependable suppliers, it’s crucial not to take them for granted. Cultivating these partnerships is key for long-term success in sourcing. Here are some tips to build and maintain strong relationships:

●Regular Communication: Keep the dialogue flowing. Schedule regular check-ins to discuss performance, address any concerns, and share updates about your production needs. This ongoing communication helps to build trust and ensures everyone is on the same page.

●Feedback Mechanism: Be open to giving and receiving feedback. If a supplier excels in certain areas, let them know! Conversely, if there are issues, provide constructive feedback. This fosters an environment where both parties feel comfortable discussing improvements.

●Collaborative Opportunities: Explore opportunities for joint ventures, such as product development initiatives or shared inventory management. Working together on projects can enhance your relationship and may lead to innovative solutions that benefit both parties.

●Celebrate Successes: Don’t forget to celebrate milestones together! Whether it’s a successful delivery or a completed project, acknowledging achievements can strengthen your partnership.

Here’s a quick overview of strategies for sustainable partnerships:

| Strategy | Description | Benefits |

| Regular Communication | Ongoing dialogue about performance and needs | Builds trust and transparency |

| Feedback Mechanism | Constructive feedback exchange | Promotes continuous improvement |

| Collaborative Opportunities | Joint projects or initiatives | Innovative solutions and cost savings |

| Celebrate Successes | Acknowledge achievements together | Strengthens relationships |

Components Sourcing Options: Domestic vs. International Suppliers

Pros and Cons of Local Components Sourcing for PCB Needs

When it comes to sourcing components domestically, there are distinct advantages that can make this option appealing:

1.Quicker Delivery Times: Local suppliers often provide faster shipping options, which can be a lifesaver when you’re on a tight schedule. Imagine needing a batch of resistors urgently and knowing that they’ll arrive the next day—talk about a stress reliever!

2.Easier Communication: Time zone differences and language barriers can complicate international dealings. With local suppliers, you’re likely to find smoother communication, making it easier to resolve issues on the fly. You can hop on a call or meet face-to-face, which can foster a better working relationship.

3.Supporting Local Economies: Sourcing domestically means you’re investing in your community. This not only helps local businesses thrive but can also improve your company’s reputation by showcasing your commitment to supporting the economy.

However, there are some drawbacks to consider:

●Higher Costs: One of the biggest trade-offs of sourcing locally is the potential for increased prices. Local components often come with a higher price tag compared to their international counterparts. It’s like paying a premium for artisanal bread versus picking up a loaf from the grocery store. You’ve got to weigh the benefits against the costs.

●Limited Availability: Sometimes, local suppliers might not have the specific components you need. It’s crucial to assess whether they can meet your diverse requirements. If your project calls for specialized parts, you might find yourself at a dead end.

Here’s a comparison chart to highlight the pros and cons:

| Pros of Local Sourcing | Cons of Local Sourcing |

| Faster delivery times | Higher costs |

| Easier communication | Limited availability |

| Supports local economies | Potential lack of variety |

Understanding International Components Sourcing for Cost Efficiency

On the flip side, sourcing components from international suppliers can open the door to a broader selection and often more competitive pricing. Here’s what to consider:

1.Wider Range of Components: International suppliers may have access to parts that are hard to find locally. Whether you’re looking for specialized ICs or the latest capacitors, the global market can offer an extensive variety.

2.Cost Savings: Often, you’ll find that international components come at a lower price, which can significantly impact your overall project budget. For companies operating at scale, these savings can add up quickly. Think of it as finding a killer sale on electronics—you snag the same quality for less!

However, there are challenges that come with this approach:

●Longer Lead Times: While you might score great prices, expect to wait longer for your components to arrive. This can delay your production schedule, so plan ahead. It’s like waiting for that online order—you know it’s going to take some time, so you prepare accordingly.

●Language Barriers and Time Zone Differences: Communication can get tricky when dealing with suppliers from different parts of the world. Make sure you have a solid plan in place to manage these aspects, as misunderstandings can lead to costly errors.

Here’s a breakdown to help you weigh the options:

| Pros of International Sourcing | Cons of International Sourcing |

| Access to a wider range of components | Longer lead times |

| Lower costs | Potential language barriers |

| Competitive pricing | Challenges in supply chain logistics |

Balancing Quality, Cost, and Logistics in Global Sourcing

When you’re sourcing components globally, it’s essential to think beyond just the price tag. Consider the total cost of ownership (TCO), which includes:

●Shipping Costs: Don’t forget to factor in shipping fees. Sometimes, those savings can evaporate when you add in freight charges.

●Tariffs and Taxes: International purchases can come with unexpected tariffs that can inflate your costs. Stay updated on trade regulations to avoid surprises.

●Risk of Delays: Global sourcing can sometimes lead to delays due to customs or other logistical hiccups. If your PCB assembly depends on timely component delivery, weigh the benefits against potential risks.

This handy table summarizes the key factors for consideration:

| Factor | Considerations |

| Shipping Costs | Include in your overall budget |

| Tariffs and Taxes | Research applicable tariffs for your components |

| Risk of Delays | Build buffer time into your project timelines |

Optimizing Components Sourcing for Cost and Quality

Cost-Effective Strategies in Components Sourcing for PCBs

When it comes to sourcing components for your PCBs, being savvy can save you some serious cash. Here are some strategies to help you maximize your budget while still getting quality parts:

1.Bulk Purchasing Discounts: Don’t shy away from buying in bulk. Many suppliers offer discounts when you place larger orders. If you foresee a steady need for certain components, stock up! Think of it as a grocery store sale—buying more now can lead to substantial savings later.

2.Vendor Promotions: Keep your eyes peeled for seasonal promotions or clearance sales from suppliers. Signing up for newsletters or following suppliers on social media can keep you in the loop on these deals. You might just snag a sweet discount when you least expect it!

3.Negotiation: Never underestimate the power of negotiation. Just like haggling at a flea market, many suppliers are open to discussing terms that benefit both parties. If you’re a repeat customer or placing a large order, leverage that relationship to negotiate better pricing or payment terms.

Here’s a quick table summarizing these cost-effective strategies:

| Strategy | Description |

| Bulk Purchasing Discounts | Order larger quantities to secure lower prices |

| Vendor Promotions | Stay updated on sales and special offers |

| Negotiation | Discuss terms that work for both you and the vendor |

Balancing Quality Control with Budget Constraints in Sourcing

Finding the right balance between cost and quality is no small feat—it can feel like a careful balancing act. To keep your expenses in check without compromising on performance, here’s a solid approach:

1.Tiered Sourcing Strategy: Implement a tiered sourcing approach, where you prioritize high-quality components for critical parts of your PCB. For non-essential elements, consider cost-effective alternatives. For instance, while you might splurge on a high-performance microcontroller, it’s perfectly fine to opt for a budget capacitor for less crucial areas.

2.Regular Quality Checks: No matter how great the deal looks, always perform quality checks on incoming components. Consider setting up a standardized testing process to ensure that every part meets your specifications before it makes its way into production. This proactive measure helps you avoid potential issues down the line.

3.Documentation and Tracking: Maintain detailed records of your sourcing decisions, including costs and quality assessments. This practice not only keeps you organized but also allows you to analyze your choices over time, helping you make better decisions in future projects.

Sourcing High-Quality PCB Components without Breaking the Bank

Utilizing technology can make a world of difference in your sourcing efforts. Here are a few strategies to help you track prices and quality effectively:

1.Price Tracking Tools: Take advantage of technology to monitor component prices across various suppliers. Using price tracking software or platforms can give you insights into trends and help you identify the best times to buy. For example, if you see a particular resistor trending down in price, it might be a good time to stock up.

2.BOM Management Software: Implement Bill of Materials (BOM) management software to streamline your sourcing process. These tools can help you keep track of component specifications, prices, and supplier details all in one place. It’s like having a personal assistant dedicated to your sourcing needs!

3.Supplier Comparison: Create a comparison table for different suppliers, highlighting pricing, lead times, and quality ratings. This visual representation makes it easy to assess your options and choose the best supplier for your specific requirements.

Here’s a sample comparison table for clarity:

| Supplier | Price | Lead Time | Quality Rating |

| Supplier A | $0.10 | 3 days | 4.5/5 |

| Supplier B | $0.08 | 5 days | 4.2/5 |

| Supplier C | $0.12 | 2 days | 4.8/5 |

Mitigating Risks in PCB Components Sourcing

Navigating Supply Chain Disruptions in Components Sourcing

Supply chain disruptions can feel like a punch in the gut, but with the right approach, you can soften the blow. Here are steps to create a robust risk management plan that keeps your components sourcing on track:

1.Identify Alternative Suppliers: Don’t put all your eggs in one basket. Make a list of reliable backup suppliers for each critical component. This way, if your primary source hits a snag, you’ll have options at the ready. A diverse supplier base not only mitigates risks but can also lead to better pricing and service as you leverage competition.

2.Develop Backup Sourcing Strategies: Sometimes, it pays to think outside the box. Consider alternate sourcing strategies, such as local suppliers or less conventional markets. For instance, if you typically source components from Asia, don’t overlook European or domestic manufacturers. This diversification can help you sidestep potential disruptions.

3.Regularly Review and Update Your Plan: The world of components sourcing is constantly changing. Schedule periodic reviews of your risk management plan to adapt to new trends and challenges in the market. Staying ahead of potential issues can be the difference between keeping production on track or facing delays.

Here’s a quick table outlining steps to manage supply chain risks:

| Strategy | Description |

| Identify Alternative Suppliers | Compile a list of backup suppliers for each part |

| Develop Backup Sourcing Strategies | Explore local and unconventional sourcing options |

| Regularly Review Your Plan | Update your risk management strategy periodically |

Counterfeit Detection in Components Sourcing for PCB Manufacturing

Counterfeit components can throw a wrench in your operations, but there are proactive measures you can take to combat this issue:

1.Stringent Verification Processes: Establish rigorous protocols for verifying the authenticity of incoming components. This could include checks for proper documentation, inspections for physical attributes, and cross-referencing with manufacturer specifications. Always trust but verify!

2.Utilizing Technology: Implement technologies like RFID tagging and blockchain to track the authenticity of your parts. These technologies help create a secure record of each component’s journey from manufacturer to your facility. While it may seem like an upfront investment, it pays off in the long run by protecting your PCB quality and reputation.

3.Training and Awareness: Keep your team informed about the risks associated with counterfeit components. Conduct training sessions that focus on recognizing signs of counterfeit parts and proper verification techniques. Knowledge is power, and a well-informed team can help safeguard your sourcing practices.

Here’s a quick checklist for counterfeit detection:

| Verification Method | Description |

| Documentation Checks | Review certificates and proof of authenticity |

| Physical Inspections | Examine components for unusual features or flaws |

| RFID and Blockchain Tracking | Use technology for secure tracking of components |

Developing Contingency Plans in Components Procurement

Having a Plan B is like having a safety net—you’ll feel a lot more secure knowing it’s there. Here are ways to develop effective contingency plans:

1.Identify Secondary Suppliers: As part of your risk management strategy, research and establish relationships with secondary suppliers. This could mean identifying alternative vendors that offer similar components or manufacturers that can meet your needs on short notice.

2.Maintain a Safety Stock: Consider keeping a safety stock of critical components that are prone to shortages or long lead times. This buffer can help you navigate unexpected disruptions without halting production. Just make sure to monitor inventory levels regularly to avoid excess.

3.Develop Clear Protocols: Outline specific actions to take when disruptions occur, including how to engage secondary suppliers and how to manage your safety stock. Having clear, documented procedures ensures that your team can act swiftly when issues arise.

Here’s a table summarizing key elements of a contingency plan:

| Element | Description |

| Identify Secondary Suppliers | Research and build relationships with backup vendors |

| Maintain a Safety Stock | Keep critical components on hand to avoid downtime |

| Develop Clear Protocols | Document actions to take in case of disruptions |

Integrating Components Sourcing into PCB Manufacturing Workflow

Steps for Streamlining Components Sourcing and Inventory Management

In the PCB manufacturing process, having your components sourcing streamlined is like having a well-oiled machine—smooth and efficient. Here’s how to make it happen:

1.Utilize Inventory Management Software: Leverage advanced inventory management tools that offer real-time visibility into stock levels, lead times, and reorder points. This tech not only saves you from running out of components but also keeps your cash flow in check. For instance, tools like NetSuite or Fishbowl can automatically notify you when stock hits a predetermined level, allowing you to place orders right when you need them.

2.Implement Just-in-Time (JIT) Inventory: JIT is like being on a diet—you only keep what you need and avoid unnecessary bulk. This strategy minimizes excess inventory and reduces storage costs. Work closely with suppliers to ensure they can deliver components right when you need them, allowing you to cut costs while keeping operations lean.

3.Regular Inventory Audits: Schedule consistent audits to ensure your inventory records align with actual stock. This helps catch discrepancies that could lead to production delays. Create a checklist to streamline the audit process, making it as smooth as butter!

Here’s a quick table highlighting effective strategies for inventory management:

| Strategy | Description |

| Real-Time Inventory Tracking | Use software for immediate insights on stock levels |

| Just-in-Time (JIT) Inventory | Order components only when needed to minimize costs |

| Regular Audits | Conduct frequent checks to align records with stock |

Coordinating Sourcing with PCB Assembly for Efficiency

When it comes to syncing up sourcing with assembly, clear communication makes the whole process smooth as butter. Here’s how to get your teams moving in sync:

1.Establish Clear Communication Channels: Set up direct lines of communication between your sourcing and assembly teams. Tools like Slack or Microsoft Teams can facilitate instant messaging and file sharing, ensuring everyone stays in the loop.

2.Hold Regular Meetings: Schedule weekly check-ins to discuss priorities and address any hiccups in the process. These meetings can be as simple as a 15-minute huddle to align goals and expectations. It’s all about keeping the conversation flowing!

3.Create a Shared Calendar: Utilize a shared calendar for both teams to track production schedules, delivery timelines, and any upcoming sourcing needs. This visual tool can help everyone see the bigger picture and anticipate challenges before they become headaches.

Here’s a table summarizing best practices for team coordination:

| Practice | Description |

| Communication Tools | Use platforms like Slack for instant updates |

| Weekly Check-Ins | Hold brief meetings to align priorities |

| Shared Calendar | Track schedules and deadlines visually |

Monitoring Sourcing Process to Prevent Production Delays

Keeping tabs on your sourcing is like making sure your vehicle’s engine is primed—it keeps everything humming along just right. Here’s how to stay on top of your sourcing process:

1.Set Up Performance Metrics: Define key performance indicators (KPIs) that gauge sourcing efficiency. Track metrics like lead times, delivery performance, and supplier reliability. Tools like Tableau can help visualize this data, making it easier to spot trends and issues.

2.Identify Bottlenecks: Regularly review your sourcing metrics to pinpoint any slowdowns in your supply chain. If you notice a supplier consistently delivering late, it may be time to have a chat or consider alternatives.

3.Proactive Issue Resolution: Address potential problems before they escalate. If lead times start creeping up, communicate with suppliers immediately to understand the cause and explore solutions together.

Here’s a quick overview of effective monitoring strategies:

| Monitoring Strategy | Description |

| Key Performance Indicators (KPIs) | Track metrics to assess sourcing efficiency |

| Bottleneck Identification | Regularly review performance to spot slowdowns |

| Proactive Communication | Reach out to suppliers to resolve issues promptly |

Don’t let inefficiencies slow you down! Start integrating these strategies into your components sourcing process today. By utilizing inventory management tools, fostering communication between teams, and closely monitoring performance, you can elevate your PCB manufacturing workflow to new heights. Let’s keep things running like a dream—your production depends on it!

Trends in Components Sourcing for PCB Industry

Sustainable Components Sourcing Practices in PCB Manufacturing

The shift to sustainable practices isn’t just a passing fad—it’s setting the pace for long-term success. Here’s how to bring a greener approach into your sourcing strategies:

1.Sourcing Eco-Friendly Components: More businesses are moving toward sustainable practices by choosing environmentally-friendly materials for their products. Seek out suppliers who offer eco-friendly options, such as components crafted from recyclable materials or manufactured using renewable energy sources. Partnering with these suppliers not only strengthens your brand’s commitment to the environment but also appeals to a rapidly growing base of eco-aware consumers looking for products that align with their values.

2.Certifications Matter: When seeking sustainable components, check for certifications like RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals). These certifications can serve as badges of honor, signaling to customers that you’re committed to sustainability.

3.Collaboration for Sustainability: Partnering with suppliers who share your sustainability vision can amplify your efforts. Joint initiatives for reducing waste or optimizing logistics can enhance your environmental impact. Consider forming a task force with suppliers to brainstorm and implement green practices.

Here’s a quick look at sustainable practices:

| Sustainable Practice | Description |

| Eco-Friendly Materials | Source components made from recyclable or renewable materials |

| Certification Checks | Ensure suppliers meet sustainability standards |

| Collaborative Initiatives | Work with suppliers on joint sustainability projects |

Impact of AI and Automation on Components Sourcing

Artificial Intelligence (AI) and automation are revolutionizing the sourcing game in ways that can give you a competitive edge:

1.Predictive Analytics: AI tools can analyze historical data to forecast inventory needs. This enables you to stock up on components that are likely to be in demand, helping you dodge potential shortages and keeping production on track.

2.Supplier Performance Monitoring: Automation can help you keep tabs on your suppliers’ performance. Set up systems that automatically track delivery times and quality metrics, allowing you to make data-driven decisions about which suppliers to stick with. This data can be presented in user-friendly dashboards for quick insights.

3.Efficiency Boosts: Implementing AI-driven tools can streamline your sourcing process by automating routine tasks, such as order placements and inventory updates. This frees up your team to focus on strategic initiatives rather than getting bogged down in administrative duties.

Here’s a table showcasing AI benefits:

| AI Application | Description |

| Predictive Analytics | Forecast inventory needs to prevent shortages |

| Supplier Monitoring | Track supplier performance with automated metrics |

| Task Automation | Reduce manual tasks to improve efficiency |

Emerging Technologies in PCB Components Procurement

Staying current with the latest tech is how you keep your sourcing process sharp and efficient. With each new advancement, from materials to sourcing software, you gain the chance to refine your approach, reduce costs, and ensure high-quality outcomes for your assembly line. Today’s suppliers who embrace emerging tech, whether through AI-driven inventory tracking or innovative components, can help you stay on the cutting edge.

1.Blockchain for Transparency: Blockchain technology offers a secure and transparent way to track the journey of components from suppliers to manufacturers. By implementing this tech, you can ensure authenticity and enhance trust within your supply chain. Consider using platforms like IBM Food Trust, which has proven successful in other industries.

2.IoT Solutions for Real-Time Tracking: Internet of Things (IoT) devices can provide real-time data on component shipments. This allows you to monitor conditions during transit and make quick adjustments if issues arise, like temperature fluctuations for sensitive components.

3.Automation Tools: Explore new procurement automation tools that integrate with your existing systems. These can streamline processes from sourcing to invoicing, providing a seamless experience that reduces the chance for human error.

Here’s a glimpse of emerging technologies:

| Technology | Application |

| Blockchain | Secure and transparent tracking of components |

| IoT Solutions | Real-time monitoring of shipment conditions |

| Procurement Automation Tools | Streamline sourcing and invoicing processes |

Why Choose JarnisTech for Your Electronic Components Sourcing?

Ready to need us to quote for your PCB components? To get your Bill of Materials (BOM) cost sorted, please send your BOM list to [email protected]. We’ll have a quote winging its way to you in no time.

1.Your Go-To Hybrid Distributor in Shenzhen

JarnisTech stands out as a leading hybrid distributor of electronic parts right in the heart of Shenzhen. We’ve got a diverse lineup of both active and passive components, including integrated circuits (ICs), memory chips, diodes, transistors, and much more. If you’re on the hunt for electromechanical components like connectors and switches or those hard-to-find electronic parts, you’re in the right spot.

2.Authorized Partnerships and Expanding Offerings

We proudly serve as an authorized agent for select brands and partner with various authorized distributors to broaden our offerings. Our commitment to expanding our inventory ensures that you have access to a vast range of electronic components. We cater to Original Equipment Manufacturers (OEMs), Electronic Contract Manufacturers (ECMs), and Electronics Manufacturing Services (EMS) providers, as well as design houses, delivering a complete supply chain solution for all your electronic component needs.

3.Broad Industry Coverage

Our expertise spans several industries, including industrial control systems, military applications, LED lighting, medical devices, automotive electronics, consumer gadgets, optoelectronic communications, power management networks, and beyond. Whether you need to purchase on the spot, match your BOM, find cost-effective solutions, or place small-batch orders, we’ve got you covered.

4.Distribution You Can Count On

With years of experience under our belt, JarnisTech has forged strong collaborations with numerous well-known manufacturers and their agents. We also distribute famous brands in the U.S. and beyond, ensuring you get what you need without breaking the bank.

5.Authentic Components at Competitive Prices

From trusted brand manufacturers to direct suppliers, you can bet your components are the real deal. We offer competitive pricing on all our products, so you know you’re getting bang for your buck.

6.Top-Notch Product Range

We maintain deep ties with major players in the industry, giving us access to an extensive array of products. Whether you’re looking for integrated circuits, MOSFETs, diodes, voltage regulators, or various types of capacitors, resistors, and connectors, we’ve got it all under one roof.

Product Categories Overview

| Category | Examples | Applications |

| Integrated Circuits (ICs) | Microcontrollers, Op-Amps | Consumer Electronics, Industrial Control |

| Discrete Components | Diodes, Transistors | Power Management, Signal Processing |

| Electromechanical Parts | Connectors, Relays | Automation, Telecommunications |

| Passive Components | Resistors, Capacitors | Circuit Stabilization, Filtering |

| Specialty Components | MOSFETs, Voltage Regulators | Automotive, Medical Devices |

7.Speedy Shipping for Your Convenience

Thanks to our established channels and extensive inventory, we can deliver your components fast. We make sure to keep a robust stock of conventional items, so your orders won’t face delays. Our professionals conduct thorough inspections on all components to guarantee authenticity and quality.

8.Quality Service That Speaks Volumes

With a mix of excellent products and a wealth of expertise in market trends, we offer you cost-effective solutions and the fastest inventory procurement in the business.

9.Full Traceability for Peace of Mind

Our operations include complete supply chain management, sourcing only from franchised distributors or directly from manufacturers. This practice ensures you receive the highest quality products at the most competitive unit costs. Every supplier we work with is reliable, and our entire procurement process is traceable.

Get Your BOM Quotes Today!

With years of experience in inspection and distribution, we’re here to provide you with the most trustworthy products and solutions. Send us your product information or BOM, and we’ll deliver a price estimate along with your expected delivery date.

BOM Request Process-

| Step | Action | Details |

| Step 1 | Prepare BOM List | Include all necessary component details |

| Step 2 | Send to Sales | Email to [email protected] |

| Step 3 | Receive Quote | Expect a prompt response with pricing |

As a PCB manufacturing and Assembly producer, we understand the ins and outs of electronic components, ensuring you get the best in every purchase.

FAQs on Components Sourcing for PCB Manufacturing

What Are the Essential Components Needed in PCB Manufacturing?

Every PCB will have its unique requirements, but commonly used components include capacitors, resistors, diodes, and integrated circuits. The exact components will depend on your specific application.

How Can I Ensure Reliable Components Sourcing for My PCB Assembly?

Build strong relationships with reputable suppliers, implement stringent quality checks, and maintain a diverse sourcing strategy. A proactive approach will help you avoid many common pitfalls.

What Strategies Are Recommended for Reducing Sourcing Costs?

Consider bulk purchasing, negotiating with suppliers, and keeping an eye on alternative sourcing options. Implementing a robust inventory management system can also help minimize costs associated with excess stock.

Advanced PCB Assembly

PCBs We Can Assemble

- Min size: PCB whose width/length is less than 30mm should be panelized.

- Max size: single board 500mm*400mm | panel board 310mm*410mm.

- Layer Count: 1-60 layers (1-20 layers for mass production).

- Copper Thickness: 1/2oz – 17oz.

- PCB Types: Rigid PCBs, Flex PCBs, Rigid Flex PCBs, Rogers PCBs, Ceramic PCBs, etc.

- Surface Finishes: Lead/Lead-free HASL, ENIG, ImSilver, OSP, Gold plated, Immersion Gold, etc.

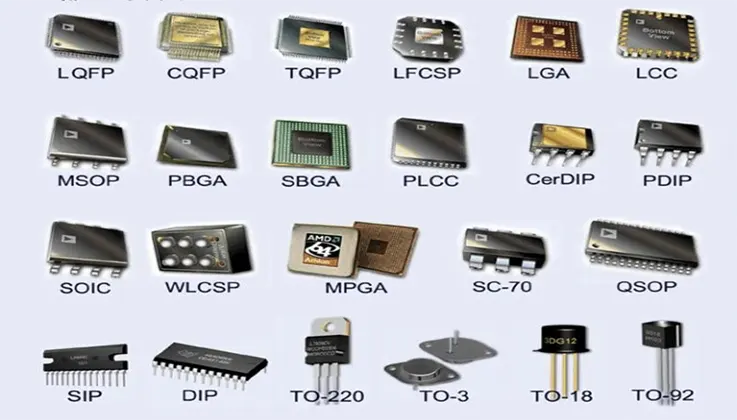

Components We Can Assemble

- SMT sizes: 01005, 0201 or larger.

- BGA pitch: 0.35mm or greater.

- BGA Ball count: 2 – 50.

- Fine pitch: 0.4mm or greater.

- WLCSP pitch: 0.35mm or greater.

- Components Height: 0.1mm – 12mm.

- BGA, micro-BGA, POP, CSP, LGA package, Flip chip, Hard metric connectors, Cable & wire, etc.

- Min. Components Spacing: 0.20mm for SMT parts, no specific demand for Thru-hole parts.

Custom PCB Assembly Capabilities

- Quick Turn.

- IPC III standard compliant.

- Prototype Quantities to Production Quantities.

- Single PCB Assembly and PCB Panel Assembly.

- Single and Double-sided PCB Assembly.

- Leaded Assembly, Lead-free or RoHS Compliant Assembly and No-clean Process Assembly.

- SMT Assembly, Thru-hole (DIP) Assembly, and Combo of SMT and Thru-hole Assembly.

- Consigned PCB Assembly, Partial consigned PCB Assembly and Full turnkey PCB Assembly.