When it comes to top-tier PCB solutions, Nanya PCB is a trusted choice for those familiar with the industry. Here at JarnisTech, we’re all about making things straightforward. With premium materials, sharp engineering, and cutting-edge production processes, we offer a complete set of solutions designed to make your job easier, whether you’re a manufacturer, designer, or part of a procurement team. Our lineup covers all bases, ready to meet the needs of OEMs and PCB designers alike. Reach out and let’s make your next project a breeze.

Types of Nanya PCB Laminates Materials

We offer a wide selection of Nanya laminates, designed to meet the diverse needs of your projects. Our expertise in manufacturing high-quality PCBs using Nanya laminates makes us a reliable partner for businesses looking to develop efficient, durable, and high-performance PCBs.

We can provide in the following Nanya laminate materials:

●CEM-3-98

●CEM-3-09HT

●NPGN-170R

●NPGN-150

●FR-4-86

Each material is designed for specific applications, offering unique properties that ensure your PCB’s performance under varying conditions.

CEM-3-98: Versatile and Cost-Effective

If you’re looking for a cost-efficient solution for standard electronics applications, CEM-3-98 is the way to go. It’s an ideal laminate material for projects where performance needs to balance with cost, and it works wonders for consumer electronics and automotive industries.

Example: We used CEM-3-98 in a recent project for a consumer electronics company, ensuring a lightweight and affordable PCB without compromising the reliability of the board.

| Material | Main Use | Benefit |

| CEM-3-98 | Consumer electronics | Cost-effective, reliable |

CEM-3-09HT: High-Temperature Performance

When things heat up, CEM-3-09HT steps in. This laminate material is perfect for high-temperature environments. It’s especially useful in industries like automotive or industrial equipment, where high temperatures could be a concern.

Example: We provided CEM-3-09HT for an automotive supplier who needed a reliable PCB that could handle high-heat conditions without compromising functionality.

| Material | Main Use | Benefit |

| CEM-3-09HT | Automotive, industrial | Withstands high temperatures |

NPGN-170R: Excellent Mechanical Properties

For those needing superior mechanical strength, NPGN-170R is the laminate of choice. This material excels in applications that require high durability and resistance to stress. It’s perfect for medical devices or military-grade applications where mechanical strength is crucial.

Example: In a project with a medical device manufacturer, we used NPGN-170R to ensure the PCB could handle the rigorous mechanical demands of a portable diagnostic device.

| Material | Main Use | Benefit |

| NPGN-170R | Medical, military | Superior mechanical strength |

NPGN-150: Flexible and Reliable

If you need flexibility without sacrificing performance, NPGN-150 is your go-to laminate. This material supports flexible PCB designs, offering durability for applications in wearable tech or consumer electronics.

Example: We helped a wearable tech company create flexible PCBs using NPGN-150, ensuring that the product could be lightweight, flexible, and highly reliable.

| Material | Main Use | Benefit |

| NPGN-150 | Wearable tech, consumer | Flexible and reliable |

FR-4-86: The Standard for High-Performance PCBs

For general-purpose PCBs, FR-4-86 is a staple. Known for its high electrical insulation properties and strength, it’s used in a wide variety of sectors, from telecommunications to home appliances.

Example: An OEM client needed an FR-4-86 laminate to create a reliable and high-performance PCB for their smart home devices. The result? A high-quality, durable PCB that exceeded performance expectations.

| Material | Main Use | Benefit |

| FR-4-86 | Telecommunications | High-performance, reliable |

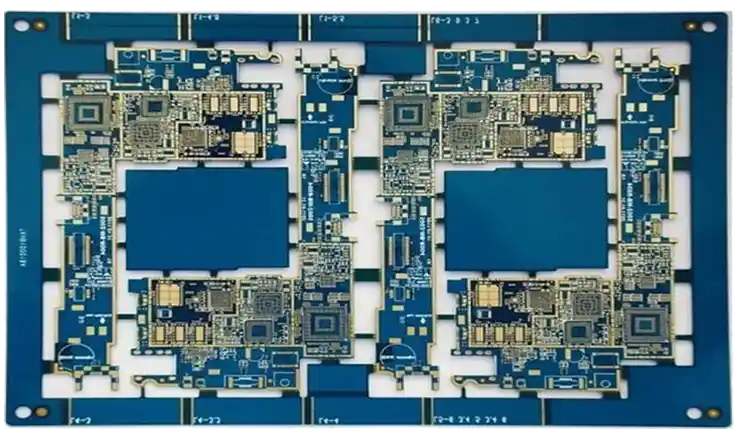

Cutting-Edge Technology, Precision Engineering

At JarnisTech, our manufacturing process utilizes the latest equipment and technology to craft PCBs with the highest precision. We work with a team of expert engineers and production professionals to ensure that each PCB we create meets your exact specifications.

Ready to take your PCB project to the next level? Get in touch today, and let’s talk about how our Nanya laminates can make a difference for you!

The Importance of NanYa Laminates in Nanya PCB Production

As we know that the right materials make all the difference, and that’s why we rely on Nan Ya laminates to bring out the best in our PCBs. These laminates add that extra edge of durability and efficiency our customers count on, especially in challenging fields like automotive electronics, telecom, and consumer tech. With Nan Ya’s materials, we’re able to create robust multilayer and HDI designs that handle high-frequency applications and meet strict performance standards—all built to stand the test of time.

How Nan Ya Laminates Enhance Nanya PCB Performance?

When it comes to performance, Nanya PCB goes all in with Nan Ya Laminates, as these materials are engineered to provide superior thermal stability and electrical properties. In simpler terms, Nan Ya Laminates help Nanya PCB stay ahead of the curve, offering enhanced signal integrity and improved power handling capabilities—no matter how high the demand gets. These materials make sure that signal transmission is smooth and consistent, reducing the chances of any signal degradation.

This makes Nanya PCB products the go-to choice for industries that rely on consistent, high-speed performance. For example, 5G network equipment demands extremely low signal loss over long distances, and Nan Ya Laminates help meet this need by maintaining signal quality even under the toughest conditions.

Example:

Take smart cars for instance. Nanya PCB, equipped with Nan Ya Laminates, ensures in-vehicle communications stay crisp and clear, without any interference. Whether it’s safety systems or autonomous driving tech, the Nan Ya Laminates provide the backbone for strong electrical integrity in these next-gen vehicles.

| Property | NanYa Laminates | Standard Laminates |

| Thermal Stability | High | Moderate |

| Signal Integrity | Excellent | Good |

| High-Frequency Handling | Outstanding | Average |

| Durability | Superior | Standard |

Nanya PCB’s Use of Advanced Nan Ya Laminates for High-Performance Solutions

Nanya PCB integrates advanced Nan Ya Laminates into its PCB production process to deliver boards that excel in high-frequency and high-temperature environments. These laminates are specially designed to support high-performance applications such as RF, 5G, and IoT devices. With Nan Ya Laminates in their production toolkit, Nanya PCB ensures that every board has the endurance and electrical precision required for next-gen electronic devices.

The application of these advanced materials allows Nanya PCB to produce designs that boast exceptional durability and can endure thermal cycling, which is necessary for components that go through rapid temperature changes during daily operations.

Let’s talk about 5G base stations—they need PCBs that can handle high-frequency data loads without skipping a beat. By using Nan Ya laminates, our boards are built to keep signals flowing steadily and maintain stable temperatures, even under demanding 5G conditions. This approach ensures reliable connectivity and peak performance, helping 5G networks operate smoothly and efficiently.

The Role of NanYa Laminates in Strengthening Nanya PCB Designs

We’re all about maximizing the strength and longevity of our PCB designs, and NanYa laminates are a big part of that approach. These materials not only support performance under challenging conditions but also help extend the lifespan of each board. By integrating Nan Ya laminates, we’re able to produce PCBs that stay tough over time, cutting down on wear and boosting reliability. For our clients, this means dependable, long-term solutions that keep their projects moving forward without a hitch.

Moreover, Nan Ya Laminates significantly improve flexibility in design while ensuring high-density interconnections (HDI). The strength and reliability they offer make them an ideal choice for complex and multilayer PCBs.

Example: Take wearable electronics—they often face constant movement, environmental exposure, and pressure. Nanya PCB, using Nan Ya Laminates, produces flexible PCBs that hold up well over time, offering longevity and ensuring that devices stay functional without the need for frequent replacements.

Types of PCB Offered by Nanya PCB

Nanya PCB offers an extensive selection of PCBs that meet the exact demands of today’s tech-driven industries. Whether you need multilayer boards for advanced electronics or high-density interconnect (HDI) boards for next-gen devices, Nanya PCB’s variety of solutions covers all bases. Our boards are designed to cater to specific industry requirements and push the envelope in both functionality and reliability.

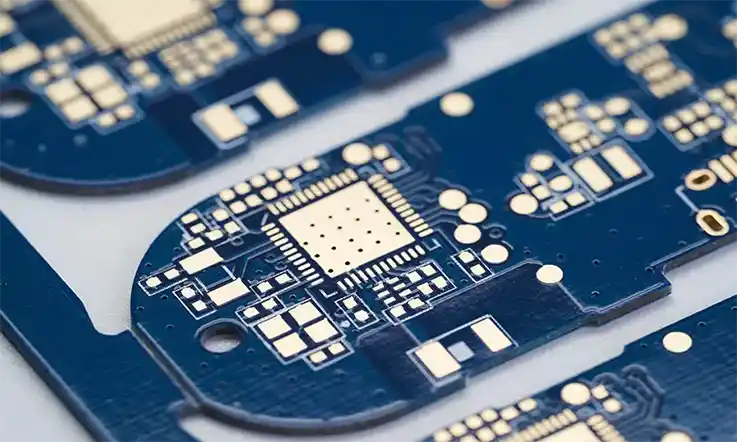

Multilayer PCBs for Enhanced Functionality

When it comes to multilayer PCBs, Nanya PCB laminates materials that are a perfect match for high-density needs, where every bit of space counts. These layered boards give you the best of both worlds—compact size and serious power—making them ideal for devices like smartphones, laptops, and industrial machinery. With each layer adding capability without extra bulk, our multilayer PCBs are designed to support complex technology in a streamlined form, ready to handle demanding applications with both efficiency and durability.

We use precision manufacturing to stack layers like nobody’s business—up to 12 layers or more—ensuring that your designs are as efficient and reliable as they come. For consumer electronics, automotive tech, and even medical devices, Nanya multilayer PCBs provide a robust foundation for all your complex systems.

Example: Think of your smartphone—it’s slim, sleek, and packs an immense amount of power into a small package. That’s made possible with multilayer PCB technology from Nanya PCB. More layers = more functionality without any added bulk. With our cutting-edge manufacturing technology, you get more features and durability in less space—a setup that’s hard to beat.

| Application | Multilayer PCB | Standard PCB |

| Signal Integrity | High | Moderate |

| Compact Design | Superior | Average |

| Durability | Built-in | Limited |

| Power Handling | Excellent | Standard |

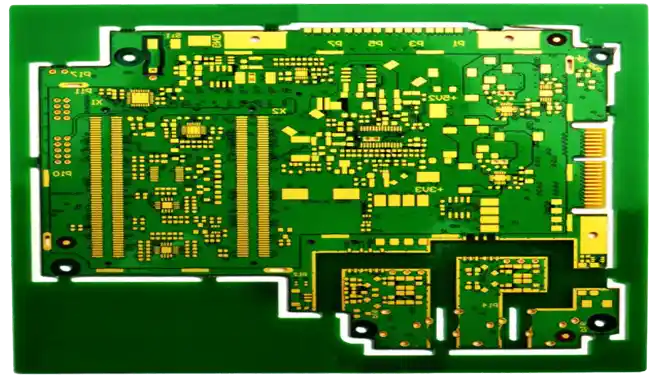

HDI PCBs for Cutting-Edge Technology

When you’re designing next-gen electronics, you need HDI PCBs that can keep up with the demand for high-speed data and precision manufacturing. Use Nanya PCB laminates produces HDI boards that are not just advanced—they’re built for the future. Whether it’s for 5G devices, telecommunication, or medical systems, these boards support high-frequency signals while still fitting into the tight spaces required by modern electronics.

At JarnisTech, we’re all about staying ahead of the curve. Our HDI PCBs offer fine-pitch technology, enabling dense interconnections that reduce the footprint while boosting performance.

Example: Consider a 5G communication device. The signal has to travel at lightning speed without any interruptions. Without HDI PCB technology, you’d run into signal loss and data bottlenecks.

| Property | HDI PCBs | Traditional PCBs |

| Data Transmission Speed | Fast | Slower |

| Space Efficiency | Superior | Less Efficient |

| Signal Integrity | Excellent | Moderate |

| Manufacturing Complexity | High | Low |

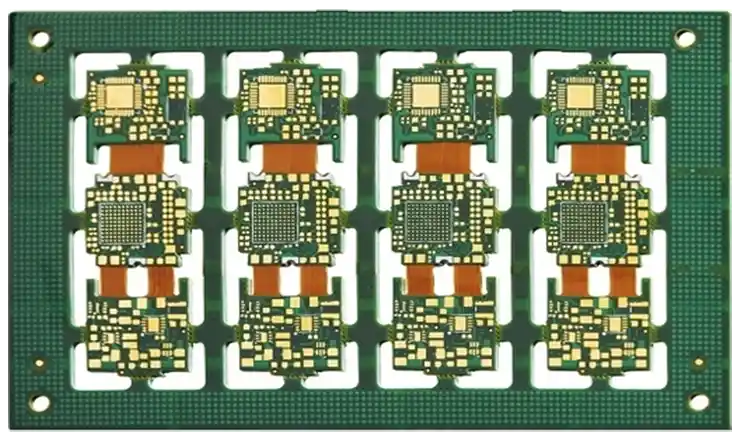

Rigid-Flex PCBs: The Perfect Blend of Durability and Flexibility

For applications that require both strength and flexibility, Nancy PCB offers rigid-flex PCBs. These boards are perfect for industries like automotive, aerospace, and wearables, where they need to endure movement while maintaining performance. The combination of rigidity and flexibility allows these designs to fit into dynamic environments, offering durability without compromising on function. Whether for wearables or automotive technology, Nanya rigid-flex PCBs provide a versatile solution that meets the toughest demands.

Nanya rigid-flex PCBs are made using top-tier materials that hold up under stress—whether it’s the constant bending of a wearable device or the rigorous demands of a high-tech automotive system.

Let’s talk about wearable technology. These devices need to fit snugly around the wrist, bend during use, and still perform flawlessly. A rigid-flex PCB is the secret sauce that allows these gadgets to stay lightweight and durable.

| Feature | Rigid-Flex PCB | Traditional PCB |

| Flexibility | High | None |

| Durability | Strong | Low |

| Space Efficiency | Excellent | Average |

| Application | Wearables, Automotive, Aerospace | Consumer Electronics |

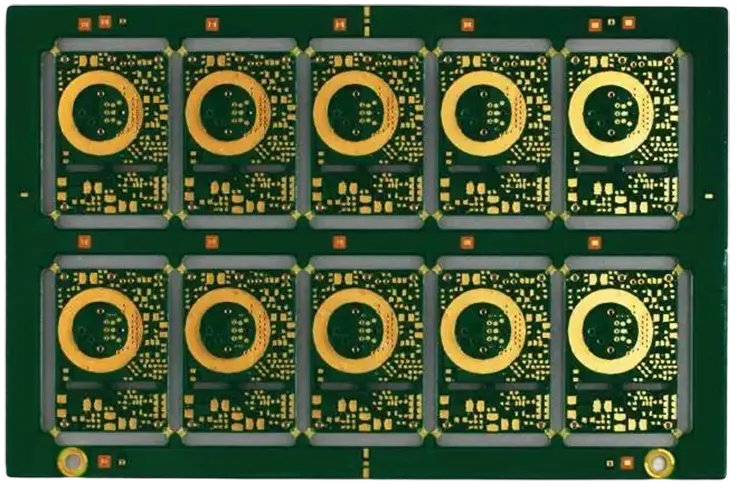

Nanya PCB: Advanced Manufacturing Techniques and Quality Control

At Jarnistech, we don’t just manufacture PCBs—we perfect them. Our goal is simple: deliver top-tier products that meet the highest standards of quality, performance, and reliability. We pride ourselves on using cutting-edge fabrication technologies and rigorous testing processes to make sure that each PCB we produce stands up to the toughest demands. Precision, quality, and efficiency are the backbone of everything we do.

Precision Engineering for Complex Designs

When you work with us, you can expect nothing less than flawless engineering. Our focus on precision engineering means that every PCB, whether it’s an HDI board, multilayer board, or any other specialized design, is built to perfection. From the first concept to the finished product, we ensure that every board is manufactured with meticulous attention to detail, ensuring the highest level of accuracy. No compromises—just the exact design specifications you need, every time.

Example:

Let’s take a look at HDI PCBs for high-frequency devices. These boards require superfine traces and tight tolerances. With our state-of-the-art engineering and manufacturing, we ensure that each connection and signal path is perfect. You won’t find a better-built PCB out there—trust us on that.

| Board Type | Precision Requirement | Manufacturing Technology Used |

| HDI PCB | Ultra-fine pitch | Laser Drilling, Fine-line Printing |

| Multilayer PCB | High layer count | Automated Layer Registration |

| Rigid-flex PCB | Flexible and rigid combo | Flexible Substrate Engineering |

Rigorous Testing and Quality Assurance

We know you can’t afford to gamble when it comes to PCB reliability. That’s why we leave nothing to chance. Each PCB that leaves our facility undergoes rigorous testing to ensure it’s in peak condition. From thermal cycling to electrical conductivity and visual inspection, we put our boards through the wringer to guarantee that they can handle the toughest environments—whether it’s automotive, medical, or consumer electronics. No cutting corners here; just solid, proven quality.

Example:

Take the example of a medical device PCB. This board needs to withstand extreme temperatures, thermal stress, and high-frequency signals. We simulate these conditions in our testing labs, making sure your device’s circuit board is up to the task. If it passes our tests, it’s good to go. If not, we tweak, refine, and test again.

| Test Type | Purpose | Industry Application |

| Thermal Cycling | Test temperature tolerance | Automotive, Industrial |

| Electrical Conductivity | Verify signal transmission | Medical, Telecommunication |

| Visual Inspection | Detect defects | Consumer Electronics, Wearables |

Automation in Manufacturing for Efficiency

We don’t just want to make high-quality PCBs; we want to make them efficiently and cost-effectively. That’s why we’ve integrated automation into our manufacturing processes. Automated systems help streamline production, reduce human error, and speed up turnaround times without sacrificing quality. The result? Faster delivery, lower costs, and the same top-notch PCBs that you expect from us.

By automating many of our processes, we not only boost efficiency but also ensure consistency and precision in every PCB we produce. From automated drilling to laser cutting and screen printing, we use advanced automation technologies that keep everything running like clockwork.

Example: Think about the difference between hand-soldering and automated soldering. While hand-soldering can be time-consuming and prone to mistakes, our automated systems ensure that every joint is soldered precisely, ensuring uniformity across thousands of boards.

| Automation Feature | Impact on Production | Benefit |

| Automated Drilling | Faster production cycles | Reduced lead time, enhanced precision |

| Laser Cutting | Precise component shaping | Minimizes material waste |

| Automated Soldering | Consistent solder joints | Higher quality, fewer defects |

Ready to take your PCB production to the next level? Don’t settle for less—get in touch with JarnisTech today, and let’s make your next project a success. With our precision engineering, thorough testing, and cutting-edge automation, we’ll get you the PCBs you need without the headache. Contact us now to start working on your next project!

Meeting the Demands of OEMs and Manufacturers with Nanya PCB

When it comes to OEMs (Original Equipment Manufacturers), there’s no room for error. Manufacturers demand top-notch PCBs that can stand the test of time, deliver performance, and keep costs under control. That’s where we come in. At Jarnistech, we’ve made a name for ourselves by providing precise, reliable, and cost-effective solutions that meet the needs of both large and small manufacturers alike.

Tailored Solutions for OEMs

If you’re an OEM looking for a custom PCB design, you’re in the right place. At JarnisTech, we don’t just make PCBs—we design and manufacture them to your exact needs. Whether you’re building something simple or cutting-edge, we’ll tailor the perfect solution to match. From the drawing board to the finished product, you’ll have a custom-designed PCB that fits your specifications down to the finest details.

We understand that OEMs need flexibility, and we’re here to provide it. Need to mass-produce a new design? We’ve got the capacity. Need small runs for prototypes? We’ve got you covered. No matter the quantity, we can scale quickly to meet your demand, while keeping things on track for on-time delivery.

| OEM Requirement | Nancy PCB Solution | Example |

| Custom Design | Tailored PCB layouts and designs | Custom PCB for Medical Device |

| Mass Production | High-volume production capabilities | Automotive Electronics |

| Prototypes & Low Volume | Flexible production runs for prototypes | Consumer Electronics |

High-Volume Production with Speed and Precision

When it’s time to ramp up production, we’ve got the chops to handle high-volume orders. Whether it’s for consumer electronics, automotive, or telecommunication, we ensure that your order is processed quickly and with precision.

Don’t worry about sacrificing quality for speed. Our advanced systems and skilled team make sure that each PCB we ship meets the strictest standards of performance, even in mass production. It’s all about giving you exactly what you need, when you need it—on budget and without compromise.

Example: We recently helped an automotive company scale up their PCB production to meet a spike in demand. Thanks to our automated manufacturing systems, we were able to produce thousands of PCBs in record time, with zero defects. This allowed our client to meet their launch deadline and avoid costly delays.

| Project Type | Production Speed | Manufacturing Process |

| Automotive Electronics | 10,000 units/month | Automated Soldering, Laser Cutting |

| Consumer Electronics | 5,000 units/week | High-speed CNC Drilling, SMT |

| Telecommunication Devices | 20,000 units/month | Multi-layer PCB assembly |

Reliability and On-Time Delivery

As an OEM, the last thing you need is a late delivery or a PCB failure that messes up your production schedule. That’s where we shine. From the very first stages of manufacturing, we maintain a steady flow with our streamlined processes. And with strong partnerships across the supply chain, we’re able to ensure on-time delivery for every order.

We’ve got your back. If there’s one thing we guarantee, it’s that you’ll never be left hanging—whether you need urgent orders or large volumes, we’ll make sure you get what you need, on time, every time.

Example: One of our clients in the medical device industry came to us with an urgent order. They were facing a supply chain delay, and needed a fast turnaround on a batch of HDI PCBs. We stepped up to the plate, prioritized the order, and delivered the PCBs on schedule. The client was able to meet their regulatory submission deadline, and they’ve been working with us ever since.

| Client Type | Turnaround Time | Delivery Performance |

| Medical Device Manufacturer | 5-day turnaround | 100% on-time delivery rate |

| Consumer Electronics OEM | 7-day turnaround | On-time delivery, no delays |

| Telecommunications Supplier | 10-day turnaround | 99% on-time delivery rate |

PCB Prototyping and Customization Services at JarnisTech

At JarnisTech, we know that prototyping is more than just a step in the process—it’s a critical moment where innovation meets reality. We’re not just in the business of creating boards; we’re in the business of helping you turn your ideas into tangible, reliable prototypes that pave the way for full-scale production. Whether you’re looking for rapid prototyping or custom design services, we’ve got you covered with quick turnarounds, top-notch quality, and the flexibility to meet your unique needs.

Rapid Prototyping for Quick Testing

Time’s ticking, and we get it—every second counts when it comes to prototypes. That’s why we offer rapid prototyping services that make it easy to test and validate your designs quickly. No more waiting around—just fast, reliable results that help you keep moving and avoid delays. Whether you’re testing new features or need a quick turnaround for a trade show demo, we deliver with the speed and precision that keeps you ahead of the competition.

Example: We recently worked with a client in the consumer electronics sector who needed a quick turnaround on a prototype for a wearable device. They were on a tight deadline, but thanks to our rapid prototyping capabilities, we had the first iteration ready for testing in just 48 hours. The result? They had the prototype they needed and were able to proceed to mass production without a hitch.

| Project Type | Prototyping Speed | Client Deadline |

| Wearable Device | 48 hours | 2-day turnaround |

| IoT Product | 72 hours | 3-day turnaround |

| Consumer Electronics | 24 hours | 1-day turnaround |

Flexible Customization Options

Every project has its own personality—and that means customization. At JarnisTech, we offer a wide range of options to make sure your PCB is tailored to your exact specs. From choosing specialized materials to adjusting the design layout, we’re here to help you fine-tune every detail. Whatever your vision is, we’ve got the tools and expertise to make it happen.

We understand that one size does not fit all, so whether you need a high-frequency board for telecom or a flexible PCB for a wearable device, we’re ready to make it work. You dream it—we build it.

| Customization Feature | Available Options | Example |

| Material Selection | FR4, Polyimide, PTFE | Medical-grade PCB |

| Board Thickness | From 0.2mm to 3.0mm | Custom wearable PCB |

| Surface Finish | HASL, ENIG, OSP | Automotive electronics |

From Prototype to Full-Scale Production

Once your prototype is ready and tested, we can seamlessly transitions you into full-scale production without skipping a beat. We’re here to ensure that the high quality and precision of your prototype carry through to the final product. From the first prototype to the mass production phase, we make sure that the consistency and reliability you expect are maintained every step of the way.

We don’t just stop at prototyping—we’re your partner for the entire journey. Whether you’re scaling up for a new product launch or ready to meet growing demand, we’ll ensure your product remains top-quality at any volume.

Example: A client in the automotive industry needed to transition from a prototype PCB for an electronic control unit (ECU) to large-scale production. After rigorous testing, we ensured that the final product met all the required industry standards and performance specs. They received on-time delivery with zero defects, and now we’re their go-to PCB supplier.

| Phase | Client Need | Nancy PCB Action |

| Prototype Stage | Functional testing | 48-hour turnaround |

| Testing & Validation | Rigorous durability tests | 5-day testing cycle |

| Full-Scale Production | 10,000+ units, tight deadline | Delivered in 3 weeks |

Don’t settle for less—partner with us and turn your ideas into real-world products!

Why OEMs and Procurement Teams Choose Nanya PCB?

When it comes to choosing a PCB supplier, OEMs and procurement teams don’t settle for anything less than reliability, quality, and efficiency. JarnisTech has built a strong reputation for meeting those needs, and we’re proud to be the go-to supplier for many top-tier manufacturers. Let’s take a closer look at why we’re the preferred choice for companies worldwide.

The Value of Building Long-Term Relationships with Nanya PCB

At JarnisTech, we understand that strong partnerships don’t happen overnight—they’re built on trust, consistency, and a shared vision. That’s why we take a long-term approach with every client we work with. When you choose us, you’re not just picking a supplier; you’re choosing a reliable partner who will be there every step of the way, from prototype to mass production.

We’ve been working with OEMs across industries for years, and we know that our clients expect top-notch service every time. Our dedicated account managers work closely with you to understand your unique needs and ensure the success of your projects. This collaboration leads to smoother processes and quicker resolutions, making us an irreplaceable asset in your supply chain.

Example: We recently worked with an automotive client who came to us for a long-term partnership to produce their electric vehicle PCB assemblies. By continuously improving the design and production process, we not only met their quality standards but also helped them reduce lead times by 15%. This strengthened our relationship and showed the real value of a long-term partnership.

| Client Type | Partnership Duration | Outcome |

| Automotive OEM | 5+ years | 15% reduction in lead times |

| Consumer Electronics | 3 years | Ongoing improvements & success |

| Medical Devices | 7 years | Continuous product upgrades |

High-Quality Standards and Compliance Across All Nanya PCB Products

We don’t cut corners—ever. At JarnisTech, we uphold strict quality standards across all our products to make sure that each PCB meets the rigorous demands of industries like automotive, medical, telecommunications, and more. Our boards go through extensive testing to ensure that they meet global compliance regulations and industry-specific certifications, so you can trust that your products will perform flawlessly.

From UL certifications to ISO 9001, we keep our quality in check so that you don’t have to worry. Whether you’re creating a medical device or a consumer gadget, our PCBs are built to meet the highest standards.

Example: A recent project for a medical device client involved creating PCBs that needed to meet FDA standards. We conducted several rounds of testing and passed with flying colors, helping our client bring their life-saving device to market on time.

| Industry | Compliance Standard | Outcome |

| Medical Devices | FDA, ISO 13485 | Passed compliance with ease |

| Automotive | ISO 9001, TS 16949 | Flawless product performance |

| Consumer Electronics | UL, RoHS | Industry-leading quality |

Flexible Procurement Solutions with Nanya PCB for OEMs and Manufacturers

At JarnisTech, we know that flexibility is key when it comes to procurement. Whether you need to scale up production quickly or adjust to tight timelines, our team is always ready to adapt to your needs. From low-volume runs to high-volume mass production, we work with you to create tailored solutions that fit your business.

We offer flexible lead times, customized payment terms, and just-in-time delivery to ensure you’re never left in the lurch. Our goal is to make procurement as smooth and stress-free as possible, so you can focus on what you do best: building products that move the market forward.

Example: A telecommunications company approached us with a tight deadline for a new product launch. By offering flexible payment terms and accelerating the production timeline, we helped them deliver the finished product ahead of schedule, beating their competition to market.

| Client Type | Procurement Needs | Nanya PCB Action |

| Telecom OEM | High volume, tight deadline | Accelerated production timeline |

| Medical OEM | Low volume, customized parts | Tailored procurement solution |

| Consumer Goods | Flexible lead times | Just-in-time delivery |

Cost-Effective Solutions for PCB Procurement with Nanya PCB

At JarnisTech, we know that getting the best deal is just as important as getting the best quality. That’s why we’ve worked hard to create solutions that bring you both top-tier performance and affordability. When it comes to PCB procurement, our focus is simple: deliver exceptional quality at a price that doesn’t break the bank.

Let’s dive into how we make this happen and how it benefits you.

How Nanya PCB Balances Quality and Affordability?

About Nanya PCB, we focus on providing top-quality solutions without stretching your budget. By selecting the best materials, refining production methods, and ensuring strict quality control throughout, we can offer affordable yet high-performance PCBs. Our approach guarantees that you get exceptional results while keeping costs in check. We aim to provide value and reliability from start to finish, making sure you get the most out of your investment with every project we take on.

We leverage the latest in manufacturing technology and materials to optimize efficiency while maintaining top-notch quality standards. From design to testing, every step is geared toward minimizing waste and reducing costs, so we can pass those savings on to you.

Example: For a consumer electronics client, we helped them reduce PCB costs by 12% while enhancing the board’s performance and durability. The key? Strategic use of advanced manufacturing techniques that streamline production without compromising quality.

| Production Step | Cost-Reducing Strategy | Result |

| Material Selection | Smart sourcing of components | Reduced material costs by 8% |

| Design Optimization | Using modular designs | Lowered design time and cost |

| Testing & Quality Control | Efficiency in testing processes | Reduced test overhead by 15% |

Bulk Ordering with Nanya PCB for Long-Term Cost Savings

When you’re scaling up production, bulk ordering isn’t just about volume; it’s about long-term savings. We make sure that bulk Manufacturing Nanya PCB circuit boards translate into real savings over time. Our team works closely with you to plan for the future and secure competitive pricing on large orders.

By ordering in bulk, you can lock in favorable rates and reduce per-unit costs, leading to long-term savings for your business. Plus, we’ll ensure that the quality remains top-notch, no matter the size of the order.

Example: A medical device manufacturer ordered a bulk run of PCBs for a new product launch. With a customized bulk pricing plan, they saved 18% on their order, all while receiving PCBs that met their exacting standards.

| Order Type | Savings | Customer Benefit |

| Bulk Orders | 18% savings | Significant long-term cost cuts |

| Standard Orders | 5% savings | Affordable yet high quality |

| Custom Orders | Tailored savings | Tailored pricing solutions |

Transparent Pricing for High-Quality Nanya PCB Production

Transparency is key when it comes to pricing. We believe in being upfront with our clients about costs and fees—no hidden charges, no surprises. Our transparent pricing model ensures that you know exactly what you’re paying for, whether it’s for prototype designs, small batch runs, or full-scale production.

We’ll break down every step of the cost—material, labor, testing, shipping—so that you can make the most informed decision for your budget and business needs.

Example: One of our OEM clients needed a breakdown of costs for a new batch of multilayer PCBs. We provided them with a detailed price sheet that outlined every cost element involved, helping them optimize their budget without compromising quality.

| Cost Element | Price Breakdown | Client Benefit |

| Materials | Component cost breakdown | Clear understanding of costs |

| Labor | Hourly production rates | Cost-efficient production |

| Shipping & Handling | Transparent delivery costs | No hidden fees |

Looking for cost-effective solutions that don’t sacrifice quality? Let JarnisTech be your go-to partner for affordable PCB procurement. With our transparent pricing, bulk order discounts, and quality commitment, we’ll help you get the best deal on top-quality Nanya PCBs. Let’s talk and start saving today!

Difference Between Nanya PCB and Other High-Performance PCBs

When comparing Nanya PCBs with other high-performance PCBs, there are several key distinctions that set Nanya apart in terms of material quality, performance under various conditions, and reliability.

Nanya PCBs: A Solid Foundation for Diverse Applications

Nanya laminates, such as CEM-3, FR-4, and NPGN, stand out because of their well-rounded performance across a range of environments. Whether you’re working with consumer electronics, wearable tech, or automotive devices, Nanya’s flexibility in performance and cost make it a favorite for many OEMs.

| Material | Main Use | Benefit |

| CEM-3 | General electronics | Affordable, reliable |

| FR-4 | Telecommunications | High electrical insulation |

| NPGN | Wearable tech, automotive | Durability, heat resistance |

Comparing to Other High-Performance PCBs

Other high-performance PCBs used in more specialized industries—such as military, medical, and aerospace—often utilize advanced materials like ceramic PCBs or PTFE-based laminates. These materials tend to offer better thermal stability and signal integrity at higher frequencies, but at a higher cost.

For instance, PTFE-based PCBs perform exceptionally well in high-speed data transmission scenarios, often seen in telecommunications or high-frequency circuits. However, their manufacturing is more expensive and less flexible in comparison to Nanya’s options.

| Material | Main Use | Benefit |

| PTFE-based | Telecom, high-frequency | Superior signal integrity, costlier |

| Ceramic PCBs | Medical, aerospace | Excellent thermal management |

Which One Fits Your Project Best?

When it comes to choosing between Nanya PCBs and other high-performance PCBs, it ultimately depends on the project’s requirements—budget and application demands. If you need a cost-effective solution with solid performance across many industries, Nanya PCBs are the way to go. If you’re looking for extreme performance in highly specialized fields, investing in PTFE or ceramic materials might be your best bet.

Frequently Asked Questions About Nanya PCB

What is Nanya PCB?

Answer: Nanya PCB specializes in manufacturing high-quality PCBs using cutting-edge materials like Nan Ya laminates.

How Does Nanya PCB Ensure Quality and Reliability?

Answer: Nanya PCB follows stringent quality control standards, using advanced testing techniques for thermal, electrical, and environmental reliability to ensure every PCB meets industry certifications.

What Makes Nan Ya Laminates Ideal for Nanya PCB Products?

Answer: Nan Ya laminates offer superior thermal stability, excellent electrical performance, and long-term reliability, making them a preferred material for complex and high-performance PCB applications.

How Can I Request a Quote for Nanya PCB’s Services?

Answer: To get a quote for your custom PCB needs, you can contact JarnisTech’s sales team directly through our website or by phone to discuss your specifications and project requirements.

What Are the Lead Times for Nanya PCB’s Manufacturing and Prototyping Services?

Answer: Lead times vary depending on the complexity and volume of the order. Typically, rapid prototyping can be delivered within a few days, while large-scale production may take 3-4 weeks.