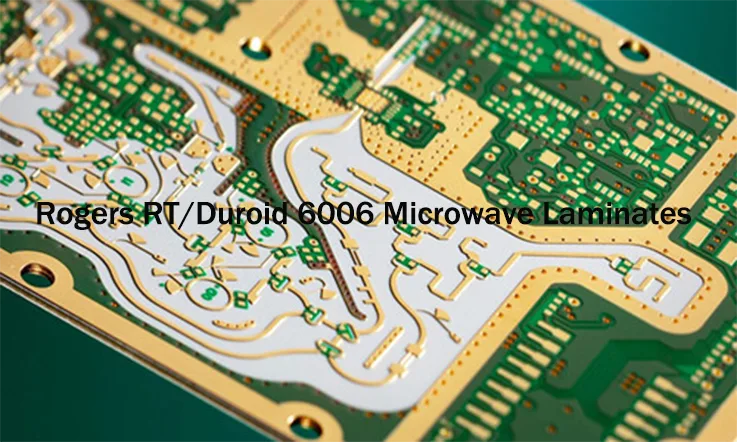

Today. When it comes to high-frequency applications, the materials that make up a printed circuit board (PCB) can have a massive impact on performance. If you’re in the PCB manufacturing world, you know that precision, reliability, and efficiency are the three pillars that keep everything running smoothly. Rogers RO6006 PCB Laminates have become a go-to solution for those looking to elevate their high-frequency designs. But what makes this laminate stand out in a sea of options?

Let’s dive into what sets Rogers RO6006 apart, how it performs in various applications, and why it’s the preferred choice for engineers and manufacturers in industries like aerospace, telecommunications, and beyond. Whether you’re designing RF circuits or preparing your next big project in 5G, this article will guide you through everything you need to know.

The Evolution of High-Frequency PCB Materials: From Standard to Superior

Over the years, the demand for materials capable of handling higher frequencies and delivering consistent performance has pushed the boundaries of PCB technology. Traditional materials like FR4 were once sufficient for most designs, but as technology advanced, especially with the advent of 5G and other high-speed systems, there was a critical need for materials that could keep up. Rogers RO6006 PCB Laminates were specifically engineered to meet this demand, offering unmatched high-frequency stability and reliability.

Origins of High-Frequency PCB Laminates

Before we take a deep dive into Rogers RO6006 PCB Laminates, let’s understand how we got here. The world of high-frequency PCBs has evolved significantly over the past few decades. As wireless communications advanced and industries like aerospace, automotive, and telecom grew, the demand for specialized materials that could handle higher frequencies while maintaining performance became more evident.

Rogers Corporation, a name synonymous with cutting-edge PCB materials, took this challenge head-on. Their RO6006 laminate was developed specifically for high-frequency, high-performance applications, setting a new standard in the industry. But what exactly makes it different? Let’s break it down.

The Science Behind Rogers RO6006 PCB Laminates

Rogers RO6006 PCB laminates are crafted from a unique ceramic-filled PTFE (polytetrafluoroethylene) composite. This smart mix of materials provides a high dielectric constant, low signal loss, and exceptional thermal stability. These qualities make RO6006 a top pick for high-frequency applications where maintaining signal integrity and minimizing loss is a must. Whether you’re designing cutting-edge RF circuits or high-speed data lines, this laminate keeps the performance high and the losses low, ensuring your systems stay sharp and reliable over time.

The dielectric constant of 6.15 is a standout feature, as it allows for tighter routing and smaller component placement. Whether you’re working with millimeter-wave frequencies or RF circuits, the material’s low dissipation factor means less signal degradation. Simply put, Rogers RO6006 PCB Laminates are built for precision in demanding environments.

Real-World Impact of Rogers RO6006

So, what does this mean for industries relying on high-performance PCBs? Simply put, Rogers RO6006 is a standout in real-world applications. Whether it’s aerospace systems needing to perform under tough conditions or telecom networks demanding speed and rock-solid reliability, this laminate material has proven itself as a go-to solution. It’s been pushing the envelope, helping industries hit new milestones in performance and efficiency. For companies looking to stay ahead of the game, RO6006 offers the durability and precision to keep everything working at peak performance, no matter the challenge.

Overview of Rogers RO6006 PCB Laminates and Their Unique Properties

When it comes to high-frequency applications, Rogers RO6006 PCB Laminates are the go-to material for us looking for reliability and performance. Unlike standard materials like FR4, Rogers RO6006 is engineered specifically for demanding environments where signal integrity, low loss, and high-frequency stability are non-negotiable.

Material Composition of Rogers RO6006 PCB Laminates

At the heart of Rogers RO6006 is a robust combination of PTFE (Polytetrafluoroethylene), a highly stable polymer, and carefully engineered ceramic fillers. This mix gives the laminate its superior dielectric properties, making it an excellent candidate for high-frequency applications. The ceramic fillers not only enhance the dielectric constant but also contribute to the laminate’s ability to minimize signal loss.

●PTFE (Polytetrafluoroethylene): PTFE is well-known for its insulating properties, making it an ideal match for RO6006, especially in high-heat and high-frequency environments. It helps the laminate hold strong even when things heat up or get demanding. Whether you’re working with harsh conditions or extreme temperatures, PTFE keeps things solid, maintaining stability and performance. When it comes to ensuring reliable functionality under tough circumstances, this material helps keep everything in check, so you don’t have to worry about disruptions or degradation.

●Ceramic Fillers: These are blended into the material to control its dielectric properties. The fillers work hand-in-hand with PTFE to provide the desired balance between low loss and high permittivity (dielectric constant).

This unique composition creates a laminate that minimizes energy loss during signal transmission, making it an excellent fit for high-speed data and RF systems. The low dissipation factor ensures that the signals keep their integrity across long distances, without unnecessary drop-offs. When you’re dealing with fast-paced signals in RF or microwave systems, this means clearer and more efficient transmission, with less energy going to waste. It’s all about delivering signals as they were meant to be, without any unwanted interference slowing things down.

Key Specifications of Rogers RO6006 PCB Laminates

Let’s break down the specs that make Rogers RO6006 a standout in the world of high-frequency PCBs:

| Specification | Details |

| PCB Material | Ceramic-PTFE composite (RT/duroid 6006) |

| Dielectric Constant | 6.15 ±0.15 (process), 6.45 (design) |

| Layer Count | 1 Layer, 2 Layer, Multilayer |

| Copper Weight | 0.5oz (17 µm), 1oz (35 µm), 2oz (70 µm), etc. |

| PCB Thickness | 10mil (0.254mm), 25mil (0.635mm), 50mil (1.27mm), 75mil (1.90mm), etc. |

| PCB Size | ≤400mm X 500mm, etc. |

| Solder Mask Colors | Green, Black, Blue, Yellow, Red, etc. |

| Surface Finish Options | Bare copper, HASL, ENIG, Immersion Tin, Immersion Silver, OSP, etc. |

| Loss Tangent (Df) | 0.0025 |

| Thermal Coefficient of Expansion (TCE) | 14 ppm/°C |

| Surface Resistivity | 7X107 |

| Volume Resistivity | 2X107 |

This table provides a concise and clear overview of the key characteristics of the RT/duroid 6006 PCB material, useful for reference and comparison.

●Dielectric Constant (Dk): With a Dk of 6.15, Rogers RO6006 offers a higher dielectric constant than many conventional PCB materials, making it ideal for tightly packed designs and high-speed signal transmission. This is a huge benefit when it comes to reducing PCB size without sacrificing performance.

●Loss Tangent (Df): The low loss tangent of 0.0025 helps keep signal attenuation in check. This is a big deal when you’re working with high-frequency applications, where maintaining top-notch signal integrity is everything. Whether you’re designing for RF or microwave circuits, less loss means clearer transmission and fewer headaches down the road. With RO6006, you’re ensuring your signals travel with minimal disruption, giving you the edge when precision matters most.

●Thermal Coefficient of Expansion (TCE): With a low TCE of 14 ppm/°C, RO6006 ensures that the laminate will remain dimensionally stable under thermal stress, an essential characteristic for devices operating in dynamic temperature environments.

These specifications make Rogers RO6006 a preferred choice in high-frequency designs such as 5G antennas, radar systems, and satellite communication equipment.

Comparison of Rogers RO6006 PCB Laminates with Alternative Materials

When you stack Rogers RO6006 up against alternative materials like FR4, RO3006, and RO3010, the advantages become clear—especially when it comes to high-frequency performance.

RO6006 vs. FR4-

●FR4 is the standard material for most PCBs but it’s simply not built for high-speed or high-frequency applications. The dielectric constant of FR4 typically ranges from 4.0 to 5.0, meaning it can’t handle as dense designs as Rogers RO6006. FR4 also has a much higher loss tangent, leading to significant signal attenuation at higher frequencies.

●Rogers RO6006 offers a Dk of 6.15, which allows for much more efficient signal transmission and the ability to design PCBs with closer component placements.

RO6006 vs. Other Rogers Laminates-

●Compared to other materials like RO3006 or RO3010, Rogers RO6006 excels in both thermal performance and dielectric consistency. While RO3006 is great for some high-frequency applications, RO6006 provides a better balance of low loss and higher permittivity, making it a superior option for 5G applications where signal integrity is non-negotiable. Moreover, Rogers RO6006 provides a broader operating temperature range, contributing to better performance in extreme conditions.

Advantages of Rogers RO6006 PCB Laminates in High-Frequency Applications

In the world of high-frequency applications, Rogers RO6006 PCB Laminates are a solid choice for designers aiming for top-tier performance and miniaturization. Whether you’re developing high-speed communication systems, RF circuitry, or aerospace tech, Rogers RO6006 offers several compelling advantages that set it apart from conventional PCB materials like FR4. Let’s dive into the specifics of why RO6006 is the go-to material for your next big project.

High Dielectric Constant for Compact Designs

As the demand for miniaturization and efficiency increases, especially in high-frequency environments, designers are facing new challenges. With the surge in 5G, IoT, and wearable tech, packing more capabilities into smaller spaces is a must. That’s where Rogers RO6006 really stands out. It offers superior performance in compact, high-frequency designs, making it an excellent choice for those looking to optimize space while maintaining top-notch signal integrity. This laminate keeps things running smoothly, even in the smallest, most demanding applications.

Rogers RO6006 offers a dielectric constant of 6.15, significantly higher than traditional materials like FR4, which typically has a Dk of around 4.5. This higher Dk enables designers to reduce the size of the PCB and increase the density of components without sacrificing performance. For example, in high-speed, high-density circuit designs, a higher Dk allows for tighter spacing between traces while still maintaining signal integrity.

In layman’s terms? You can fit more functionality into a smaller footprint, all while ensuring the performance doesn’t drop off. Whether you’re designing 5G antennas, RF modules, or high-frequency circuits, Rogers RO6006 makes it possible to maximize space without compromising on the high-frequency stability you need.

| Material | Dielectric Constant (Dk) | Loss Tangent (Df) |

| Rogers RO6006 | 6.15 | 0.0025 |

| FR4 | 4.5 | 0.02 |

| Rogers RO3010 | 10.2 | 0.003 |

Exceptional Signal Integrity with Rogers RO6006 PCB Laminates

When designing PCBs for high-frequency and RF/microwave applications, signal integrity is a top concern. Rogers RO6006 laminate stands out in this area with its low loss tangent and top-notch material composition, making it a solid choice for those seeking reliable performance. This laminate helps reduce signal loss during transmission, which is a big win when working with high-speed signals. Whether you’re designing for RF power amplifiers or microwave circuits, RO6006’s characteristics make sure the signals stay sharp and clear.

So, what does this mean for you? With a loss tangent of just 0.0025, Rogers RO6006 keeps signal attenuation and distortion to a minimum during transmission. This becomes especially useful when handling high-frequency signals, where even small losses can affect system performance. Whether you’re working with RF power amplifiers, microwave circuits, or high-speed data transmission lines, a lower loss tangent helps keep the signal clear and steady, ensuring your system functions smoothly.

In simple terms, a lower loss tangent means your high-frequency signals waste less energy as they travel, allowing for more efficient signal transmission over longer distances. This can be a big deal in fields like satellite communications, where clear and steady signals are a non-negotiable. It’s all about minimizing signal degradation to ensure smooth and reliable communication, even across vast distances.

Example:

A 5G base station uses Rogers RO6006 to transmit high-frequency signals at gigahertz frequencies. The laminate ensures that the signal quality remains intact across the entire transmission path, enabling fast, reliable communication. In comparison, a typical FR4 board would result in signal loss, degrading the overall performance of the base station.

Dimensional Stability Under Thermal Stress

When you’re designing high-frequency PCBs, thermal stress is something you cannot afford to overlook. Whether it’s changes in the environment, fluctuations in power, or inherent heat generation from the PCB itself, ensuring dimensional stability under varying thermal conditions is a must.

This is where Rogers RO6006 stands out from the crowd. With a low coefficient of thermal expansion (CTE) of 14 ppm/°C, RO6006 maintains its structural integrity and dimensions even under significant temperature variations. This is particularly advantageous in aerospace, automotive, and military applications, where equipment is often subjected to extreme temperatures, from freezing cold to intense heat.

Unlike FR4, which tends to expand or contract significantly with temperature changes, RO6006 ensures that the traces and vias on the PCB stay aligned and maintain consistent performance. It’s this kind of thermal stability that guarantees the longevity and durability of high-frequency circuits in the long run.

| Material | CTE (Coefficient of Thermal Expansion) |

| Rogers RO6006 | 14 ppm/°C |

| FR4 | 17 ppm/°C |

For example, in an automotive radar system, the RO6006 PCB can withstand extreme temperature shifts without warping or affecting the circuitry. In contrast, FR4 might suffer from inconsistent thermal behavior, causing malfunction or failure in the circuit under demanding conditions.

Manufacturing Considerations for Rogers RO6006 PCB Laminates

When it comes to fabricating PCBs with Rogers RO6006 Laminates, the process demands more than just technical know-how—attention to detail at every step is a must. Whether you’re working with high-frequency circuits, RF designs, or microwave applications, RO6006 offers tremendous benefits. But to unlock its full potential, it’s essential to follow best practices in every stage of the manufacturing process. Let’s dive into the must-know tips for ensuring your Rogers RO6006 PCB builds are up to the task.

Best Practices for PCB Fabrication with Rogers RO6006

When fabricating Rogers RO6006 PCBs, you’ll want to pay careful attention to several aspects of the process, from stack-up design to via placement. Ensuring optimal performance at high frequencies requires a bit more than the standard approach used for conventional materials like FR4. Here are some best practices for fabricating RO6006-based boards:

1.Stack-Up Design: With Rogers RO6006, maintaining a consistent dielectric constant throughout the PCB is a consideration. When stacking the PCB layers, make sure the materials around RO6006 are properly matched for impedance control. Disparities between layers can cause signal integrity issues. Generally, it’s a good idea to combine RO6006 with other low-loss laminates for layers requiring high-speed signal routing.

2.Via Placement: The placement and design of vias are a game-changer for PCB performance, especially when dealing with high-frequency applications. With RO6006, the goal is to reduce via inductance and optimize the via-to-pad ratio. For microwave and RF applications, minimizing the impact of vias on signal transmission can make all the difference in ensuring the product’s reliability and top-notch performance. It’s all about fine-tuning the design to keep the signals flowing strong and uninterrupted, just the way you want them.

3.Drilling Techniques: Because Rogers RO6006 has a higher thermal conductivity compared to FR4, proper drilling techniques are necessary to prevent material damage during the fabrication process. Laser drilling is a good choice to ensure accuracy when working with small vias or microvias, ensuring minimal stress on the material.

By following these fabrication best practices, you’ll optimize Rogers RO6006’s unique properties, enhancing the PCB’s overall performance, especially in high-frequency designs.

| Fabrication Aspect | Recommendation |

| Stack-Up Design | Ensure matching materials around RO6006 for impedance control |

| Via Placement | Minimize via inductance and ensure proper via-to-pad ratios |

| Drilling Techniques | Use laser drilling for precision and avoid material stress |

Storage and Handling Recommendations

To ensure the long-term stability and performance of Rogers RO6006, proper storage and handling are non-negotiable. Here’s what you need to keep in mind to protect the material and maintain its superior dielectric properties and signal integrity:

1.Storage Conditions: Rogers RO6006 should be stored in a cool, dry environment with temperatures ranging from 18-22°C (64-72°F). Humidity should be kept at 50% or lower to prevent any moisture absorption that could compromise the laminate’s integrity. Additionally, it’s essential to store the material in its original packaging until use to prevent environmental exposure.

2.Handling: When handling RO6006, always use gloves to prevent oils or moisture from your hands from contaminating the surface of the laminate. Surface contamination can result in defects during the lamination process or negatively affect the electrical performance of the board.

3.Shelf Life: While RO6006 has an excellent shelf life, it’s essential to follow the manufacturer’s recommendations regarding the expiration dates. If the material has been stored for an extended period, it’s a good idea to test the laminate for any potential degradation in its electrical properties before use.

By following these storage and handling guidelines, you ensure that Rogers RO6006 remains in optimal condition, avoiding any potential issues during fabrication and ensuring the long-lasting performance of your PCBs.

Post-Fabrication Testing for Rogers RO6006 PCBs

After the PCB is fabricated, it’s important to conduct thorough post-fabrication testing to verify that the RO6006 PCB meets the required performance standards for high-frequency applications. The testing process will ensure that the signal integrity and thermal stability of the PCB remain intact.

1.Impedance Control Testing: RO6006 is specifically designed to offer a stable dielectric constant across a wide range of frequencies, making it an ideal choice for impedance-controlled designs. After the PCB is fabricated, it’s a smart move to perform impedance testing using tools like time-domain reflectometry (TDR) or network analyzers. This ensures the integrity of the traces and guarantees that the signal stays strong, with no degradation as it travels through the PCB.

2.Thermal Stress Testing: Given the thermal conductivity of Rogers RO6006, you should perform thermal cycling tests to ensure that the PCB remains stable under varying temperatures. Rogers RO6006 is designed to perform well under thermal stress, but testing is still necessary to simulate real-world conditions, such as aerospace and automotive applications where temperature fluctuations are common.

3.Signal Integrity Testing: S-parameters are commonly used to evaluate signal integrity in high-frequency designs. Running vector network analyzers (VNA) tests will allow you to see how well the PCB transmits signals across a wide range of frequencies, ensuring that the RO6006 laminate is performing as expected in microwave, 5G, and RF applications.

By incorporating these post-fabrication tests, you ensure the Rogers RO6006 PCB performs at its best, especially in demanding high-frequency applications.

| Test Type | Purpose | Testing Method |

| Impedance Testing | Verify signal integrity and controlled impedance | TDR or Network Analyzers |

| Thermal Stress | Ensure stability under temperature fluctuations | Thermal Cycling Tests |

| Signal Integrity | Verify minimal signal loss at high frequencies | S-parameters with VNA |

Technical Benefits of Rogers RO6006 PCB Laminates

If you’re working with high-frequency applications or looking to create RF circuits, Rogers RO6006 PCB laminates should be at the top of your list. Why? Because it comes packed with a suite of technical benefits that make it the go-to choice for advanced PCBs. Let’s dive into some of the standout features that make this laminate perfect for your high-performance needs, from low loss to thermal management. Keep reading to see why RO6006 could be your next favorite material!

Low Loss for High-Frequency Performance

When designing PCBs for high-frequency applications, keeping signal loss in check is a must. That’s where Rogers RO6006 really stands out. The material’s low loss tangent is one of its features. So, what does this mean in simple terms? A low loss tangent means less energy is lost as signals pass through the laminate. For microwave and RF signals, this is a big deal. Less loss translates to stronger signals and clearer transmissions, making it perfect for high-performance applications.

●Signal Attenuation: When it comes to RF signals and microwave communication, signal attenuation can lead to distorted or weak signals, negatively affecting the performance of your circuit. By choosing RO6006, you ensure that your design minimizes attenuation, maintaining signal quality over longer distances and at higher frequencies.

●Perfect for High-Speed Designs: Think of it this way—RO6006 gives your designs the edge, particularly when working with 5G, satellite communications, or high-speed digital applications. This means faster, clearer, and more reliable communications.

Here’s a quick breakdown of the signal loss characteristics of Rogers RO6006 versus FR4:

| Material | Loss Tangent (at 10 GHz) | Dielectric Constant |

| RO6006 | 0.0025 | 6.15 |

| FR4 | 0.020 | 4.4 |

With RO6006, you experience reduced signal loss and enhanced performance, making it an excellent option for high-frequency applications that demand reliable signal transmission. This material minimizes attenuation, ensuring strong and consistent signal integrity throughout.

Thermal Conductivity for Efficient Heat Management

Next up, let’s talk about heat. If you’re designing high-power systems, thermal management is one of the most core aspects of maintaining reliability and performance. Rogers RO6006 provides exceptional thermal conductivity, allowing heat to dissipate more efficiently than traditional PCB materials like FR4.

●Efficient Heat Dissipation: The thermal conductivity of RO6006 is 0.67 W/m·K, which is considerably higher than FR4 and other low-loss laminates. This means that heat generated from high-power applications such as 5G circuits, radar systems, and aerospace equipment can be quickly absorbed and transferred away from sensitive components, reducing the risk of overheating and improving the longevity of your high-frequency PCBs.

●Handling Thermal Stress: High-frequency PCBs are often subject to fluctuating temperatures due to power surges or environmental changes. RO6006’s superior thermal stability ensures that your designs can withstand these changes without affecting their performance.

Here’s a comparison between Rogers RO6006 and FR4 in terms of thermal conductivity:

| Material | Thermal Conductivity |

| Rogers RO6006 | 0.67 W/m·K |

| FR4 | 0.25 W/m·K |

With RO6006, thermal management is no longer an afterthought. Whether you’re dealing with high-power RF or microwave circuits, this laminate keeps things cool and efficient, which is a win for both performance and reliability.

Moisture Resistance and Environmental Stability

If you’re dealing with harsh environments—whether it’s aerospace, automotive, or military applications—environmental stability is key. Rogers RO6006 is highly resistant to moisture and extreme environmental conditions, making it a solid choice for demanding designs.

●Moisture Absorption Resistance: RO6006 has a much lower moisture absorption rate compared to FR4, meaning it maintains its electrical properties even in high humidity environments. Moisture can affect dielectric constant and signal integrity, but with RO6006, you don’t have to worry about performance degradation over time.

●Long-Term Durability: RO6006 is also known for its high dimensional stability, even in the face of thermal cycling and moisture exposure. For military-grade or aerospace electronics, this material offers unmatched reliability, ensuring your PCBs perform consistently over the long haul.

●Environmental Resistance: In addition to moisture resistance, RO6006 is highly resilient against chemicals, UV light, and temperature extremes, making it suitable for outdoor and industrial applications where other laminates might fail.

Here’s a quick snapshot of moisture absorption compared to FR4:

| Material | Moisture Absorption Rate |

| Rogers RO6006 | 0.04% |

| FR4 | 0.10% |

Choosing Rogers RO6006 means you can count on environmental stability, whether you’re building automotive sensors, communications equipment, or satellite systems. It resists the elements, ensuring your high-frequency PCBs stay reliable in the toughest environments.

Comparing Rogers RO6006 PCB Laminates with Rogers RT/duroid 6010

When it comes to high-frequency applications and microwave communications, Rogers RO6006 and Rogers RT/duroid 6010 are two of the top laminate choices in the game. Both materials are widely used in RF and microwave circuit designs, but they offer different characteristics that suit different needs. Let’s dive into the details and compare them head-to-head, so you can make the best decision for your PCB manufacturing needs.

Material Differences and Performance Impacts

At the core of any decision between RO6006 and RT/duroid 6010 are the material properties. While both materials are known for their low loss, they each have their unique strengths that can influence your high-frequency designs.

Dielectric Constant-

●RO6006 features a dielectric constant of 6.15 at 10 GHz, making it ideal for designs that require good signal transmission with controlled impedance. This makes it suitable for high-speed digital designs, 5G circuits, and military applications.

●On the flip side, RT/duroid 6010 boasts a lower dielectric constant of 10.2 at 10 GHz, which results in higher impedance. This characteristic makes it an excellent choice for designs where maintaining signal integrity at even higher frequencies is a must, providing a solid foundation for top-tier performance in such applications.

Here’s a quick comparison of the dielectric constants for these materials at 10 GHz:

| Material | Dielectric Constant (10 GHz) | Loss Tangent | Thermal Conductivity |

| Rogers RO6006 | 6.15 | 0.0025 | 0.67 W/m·K |

| RT/duroid 6010 | 10.2 | 0.0023 | 0.60 W/m·K |

●Loss Tangent: Both materials feature an exceptionally low loss tangent, which helps maintain strong signal integrity over long distances, particularly in RF applications. RO6006 has a slight advantage with a loss tangent of 0.0025, just a bit lower than RT/duroid 6010’s 0.0023. This slight difference results in less signal loss in specific cases, ensuring better performance in demanding scenarios.

●Thermal Properties: The thermal conductivity of RO6006 is slightly higher (0.67 W/m·K) than that of RT/duroid 6010 (0.60 W/m·K), making RO6006 a better choice for designs with higher power dissipation, such as 5G mobile devices, aerospace equipment, and military radars.

Cost-Effectiveness for High-Performance Applications

When considering which material to use for your PCB design, cost is always a factor. While both Rogers RO6006 and RT/duroid 6010 offer excellent high-frequency performance, they come with different price points, and the cost-effectiveness varies depending on your application.

●Rogers RO6006 is more affordable compared to RT/duroid 6010, making it the go-to option for projects where cost control is a priority without compromising performance. Whether you’re designing consumer electronics or telecommunication systems, RO6006 provides an excellent balance between cost and performance.

●RT/duroid 6010, on the other hand, offers higher impedance and dielectric constant, which can be beneficial for certain specialized applications. However, due to its higher dielectric constant and lower loss tangent, RT/duroid 6010 can be more expensive. It’s typically used in more demanding projects, such as space communications and high-power military systems, where performance takes precedence over cost.

Cost-Effectiveness Summary-

| Material | Price Range | Best Use Case |

| Rogers RO6006 | Moderate | Consumer electronics, Telecommunication systems, 5G applications |

| RT/duroid 6010 | Higher | Aerospace, Military radar, Satellite communications |

Recommendations for Choosing the Right Material

Selecting the right material depends on the specific needs of your project. Let’s take a closer look at the scenarios in which Rogers RO6006 and RT/duroid 6010 excel:

Go with Rogers RO6006 if you’re designing-

●5G Networks: With its lower dielectric constant, RO6006 excels in 5G designs that require high-frequency performance and efficient signal transmission over short to medium distances.

●RF/Microwave Circuits: Perfect for designs that demand low loss and stable performance at microwave frequencies. Whether you’re developing cellular communication systems or radar technologies, RO6006 delivers excellent signal integrity.

●Consumer Electronics: If you’re working with consumer-grade products that require high-frequency and thermal performance, RO6006 strikes the right balance between cost and performance.

Go with RT/duroid 6010 if you’re designing-

●High-Impedance Systems: When designing systems that demand a higher impedance for signal routing or high-frequency signal processing, RT/duroid 6010 offers a dielectric constant that caters to these needs.

●Aerospace and Military Applications: RT/duroid 6010 is commonly used in high-performance applications within aerospace and military sectors, where extremely high-frequency performance is required. This material ensures the reliability of space communications, satellite systems, and radar equipment, consistently delivering reliable results even under demanding conditions.

●Precision Instrumentation: In fields requiring extreme precision and low loss, such as medical electronics or scientific instruments, RT/duroid 6010 provides the accuracy and signal clarity needed for microwave frequencies.

Customization Options for Rogers RO6006 PCB Laminates

When it comes to high-performance applications, the Rogers RO6006 PCB laminate stands out as a reliable choice for RF and microwave designs. However, one of the standout features of RO6006 is the ability to customize its properties to suit a wide range of unique design needs. Let’s dive into the various customization options available to help you get the most out of Rogers RO6006.

Thickness and Configuration Choices

One of the main advantages of Rogers RO6006 PCB laminates is the variety of thickness options that cater to different design requirements. Whether you’re building a thin-profile PCB for a compact device or a high-layer count PCB for a high-power application, the material can be adjusted to fit your exact needs.

●Thickness Options: RO6006 is available in several standard thicknesses, typically ranging from 0.005” to 0.020”. For projects that require high-density interconnects (HDI) or microvia designs, thinner laminates provide greater flexibility. Thicker options can be chosen for heavy power systems or high-impedance signal routing.

●Layer Configuration: Whether you’re designing a single-layer PCB, multi-layer PCB, or complex HDI board, RO6006 accommodates different stack-up designs. By adjusting the number of layers, you can optimize signal routing, reduce interference, and manage heat dissipation more effectively. This flexibility is ideal for applications in consumer electronics, automotive systems, and medical technologies.

For example, In a 5G application, where miniaturization and high-frequency performance are needed, selecting a thinner laminate (around 0.008”) helps create a compact, high-performing PCB while reducing signal loss.

Surface Finishes and Compatibility

When it comes to selecting the right surface finish for your RO6006 PCBs, you’re making a decision that can seriously impact both long-term reliability and the ease of assembly. The finish doesn’t just affect how well your solder bonds—it also plays a part in the overall electrical performance of your PCB. Here are the most common options that are compatible with Rogers RO6006 and their benefits:

●ENIG (Electroless Nickel Immersion Gold): This is one of the most widely used finishes for high-frequency applications because it provides excellent flatness and solderability, ensuring consistent electrical performance across your design. ENIG also offers corrosion resistance, making it ideal for harsh environments such as aerospace and automotive applications.

●Immersion Silver: Another popular option, immersion silver offers excellent thermal conductivity and electrical properties, making it an excellent choice for high-frequency circuits. It’s also more cost-effective compared to ENIG, though it might not offer the same level of long-term corrosion protection.

●OSP (Organic Solderability Preservative): For those on a tighter budget, OSP is a more affordable finish, though it’s better suited for low-volume or less demanding applications. This finish prevents oxidation during storage, ensuring reliable solder joints when you’re ready for assembly.

| Surface Finish | Benefits | Best Use Case |

| ENIG | Excellent flatness, corrosion-resistant, reliable solderability | Aerospace, medical devices, consumer electronics |

| Immersion Silver | Good electrical and thermal properties, cost-effective | 5G circuits, RF devices, telecommunications |

| OSP | Cost-effective, preserves solderability | Low-volume PCB runs, consumer devices |

Special Design Features for Unique Applications

When designing custom PCBs for demanding applications, it’s often necessary to go beyond the standard configurations. Rogers RO6006 offers a variety of specialized design options that ensure your PCB performs at its best in unique environments. Whether you’re working with high-frequency signals, high-power designs, or space-constrained applications, these special features can make your designs more efficient and reliable.

●Tailored Impedance Control: Rogers RO6006 gives our designers the flexibility to fine-tune the impedance of their PCBs for high-speed signals with impressive accuracy. In high-demand applications like 5G networks and military radar systems, where signal loss can throw a wrench in the works, maintaining optimal impedance is non-negotiable. With RO6006, you’re able to achieve precise impedance control, ensuring your signal integrity stays solid—even when conditions get tough.

●Thermal Management: For designs involving high-power devices such as automotive circuits or industrial equipment, Rogers RO6006 provides excellent thermal stability and heat dissipation properties. By utilizing multiple layers and optimizing the thermal vias, we can direct heat away from sensitive components, improving the lifespan of the PCB and preventing overheating.

●Custom Hole Sizes and Via Configurations: Depending on the application, you might need microvias or blind/buried vias to handle high-density interconnects. Rogers RO6006 is highly adaptable when it comes to custom via configurations, offering better support for HDI designs than many other materials.

Special Features Summary-

| Design Feature | Benefits | Ideal Application |

| Impedance Control | Precise impedance matching, essential for high-speed and RF signals | 5G networks, microwave systems, satellite communications |

| Thermal Management | Effective heat dissipation, extends PCB lifespan | Automotive electronics, industrial equipment, power systems |

| Custom Vias & Hole Sizes | High-density interconnects and flexible design options | HDI boards, medical devices, communications equipment |

Why Choose Us for Manufacturing Your Rogers RO6006 PCB?

When it comes to Rogers RO6006 PCB manufacturing, partnering with the right provider – JarnisTech can make all the difference. With a track record built on decades of industry expertise, advanced manufacturing capabilities, and a commitment to delivering high-quality solutions, we stand out as a trusted choice for your high-frequency PCB needs. Let’s break down why we’re the go-to source for your next project, and how we can help you meet your engineering goals.

Decades of Expertise in High-Frequency PCB Manufacturing

We bring over 25 years of experience in crafting precision-driven PCBs using Rogers RO6006 laminates. Our deep understanding of RF (Radio Frequency) and microwave circuits sets us apart from the competition, ensuring that we deliver PCBs that maximize performance and reliability for every project.

With years of work in industries like telecommunications, aerospace, automotive, and medical, we know what it takes to meet stringent requirements in high-frequency signal integrity and thermal management. Our expert engineers have refined every process to guarantee that each Rogers RO6006 PCB meets your specific performance criteria and can withstand the demands of challenging environments.

JarnisTech’s Example:

In one recent project, we worked with a 5G network provider to create custom Rogers RO6006 PCBs for their base station equipment. Thanks to our experience and knowledge, we were able to deliver PCBs that minimized signal loss and thermal issues, while also meeting the tight design constraints they faced.

Advanced Manufacturing Capabilities for Rogers RO6006

To produce high-quality Rogers RO6006 PCBs, you need more than just a standard manufacturing setup—you need state-of-the-art fabrication. That’s why our manufacturing process integrates cutting-edge technology with industry-leading quality control. We use automated processes combined with manual oversight to ensure the accuracy and reliability of every board we produce.

●Advanced Drilling: Our laser drilling and mechanical drilling systems ensure precise hole placement and via creation that are perfect for high-density designs and HDI (high-density interconnects).

●Automated Lamination: Using advanced automated lamination equipment, we ensure that every layer of your Rogers RO6006 PCB is bonded with precision, maintaining the structural strength and thermal stability of your design. This consistent lamination process helps prevent potential weak spots, keeping your PCB solid even under tough conditions. Whether you’re dealing with complex high-frequency circuits or high-power applications, we take care to ensure each layer performs as it should, so your PCB can take on whatever challenges come its way without a hitch.

●High-Precision Routing: Whether you need intricate shapes for microvias or a custom layer stack-up, our advanced routing systems ensure precise cutouts and edge definitions, keeping your design true to the original concept.

| Manufacturing Process | Benefits | Ideal Application |

| Laser Drilling | High precision, ideal for small vias and tight spacing | High-density PCBs, RF designs, telecommunications |

| Automated Lamination | Consistent material bonding for durability | 5G networks, aerospace systems, automotive electronics |

| High-Precision Routing | Exact cutouts for custom shapes and designs | Medical devices, consumer electronics |

Comprehensive Engineering Support for PCB Design

Designing a high-performance PCB isn’t just about creating a layout and sending it for production. It’s about collaboration to optimize the design at every stage of the process. That’s where our engineering support comes into play. We don’t just manufacture your Rogers RO6006 PCB—we work closely with your team to ensure your design performs at its best.

●Design Consultation: Our experienced engineers are available to help with stack-up design, impedance matching, and signal integrity analysis. We work alongside your design team to identify potential performance bottlenecks before they become an issue during manufacturing.

●Thermal Optimization: When working on high-frequency designs, managing heat is a must. We help you pick the right thermal vias, copper thickness, and material configurations to make sure your PCB stays stable, even when it’s under heavy load. With the right setup, your design can handle demanding conditions without breaking a sweat, ensuring long-term performance in tough environments. Whether you’re working with high-power systems or high-frequency circuits, we’ve got the solutions to keep things running without overheating.

●Design for Manufacturability (DFM): We ensure that your designs are not only technically sound but also easy and cost-effective to manufacture. Our DFM reviews identify potential production challenges early in the design phase, allowing us to make adjustments before they impact timelines or budgets.

JarnisTech’s Example:

One of our recent collaborations with a medical technology company involved designing a high-frequency PCB for a wearable health monitoring device. By working closely with their engineering team, we were able to streamline the design, reduce potential sources of interference, and optimize thermal management, resulting in a product that met both performance requirements and production cost targets.

Ready to Take Your Design to the Next Level?

Choosing us for your Rogers RO6006 PCB manufacturing needs means partnering with a team that understands high-frequency applications and is committed to providing exceptional quality at every step of the process. Whether it’s our decades of industry experience, advanced manufacturing capabilities, or comprehensive engineering support, we’re here to help you bring your designs to life.

Don’t settle for anything less than the best—contact us today to discuss your Rogers RO6006 PCB needs and let’s work together to create a product that performs and excels.

FAQ & Rogers RO6006 PCB Laminates

How does Rogers RO6006 compare to other PCB materials?

It outperforms standard FR4 in high-frequency performance, offering better signal integrity and thermal stability.

What is the typical thickness of Rogers RO6006?

Common thicknesses range from 10mil (0.254mm) to 75mil (1.90mm), depending on design requirements.

Can Rogers RO6006 be used in multilayer PCBs?

Yes, Rogers RO6006 is available in multilayer configurations to meet complex design needs.

What are the surface finishes compatible with Rogers RO6006?

Compatible finishes include ENIG, HASL, immersion silver, and OSP.

How does Rogers RO6006 handle thermal stress?

Rogers RO6006 offers excellent thermal stability, making it suitable for high-power applications that require efficient heat dissipation.

Our services

Rogers PCB Laminates & Series