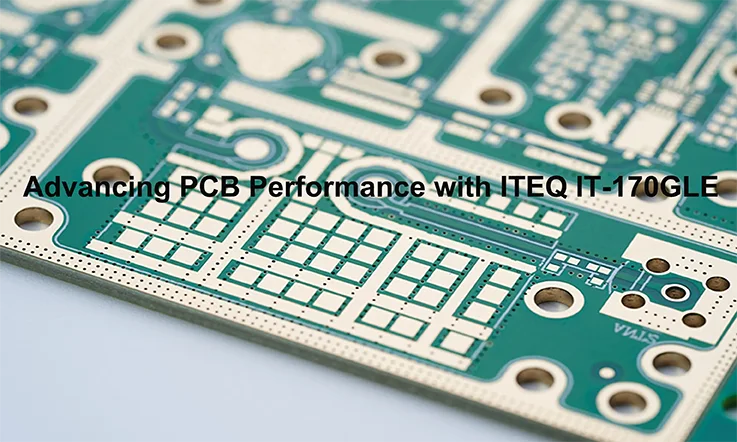

As electronic systems evolve, the demand for PCB materials with superior thermal stability, electrical performance, and environmental compliance continues to rise. ITEQ IT-170GLE, a high-Tg, halogen-free laminate, meets these stringent requirements, making it a preferred choice for industries such as 5G communication, automotive electronics, and aerospace technology. With its low dielectric loss, excellent thermal reliability, and strong mechanical properties, IT-170GLE ensures stable performance in high-frequency circuits, high-density interconnects (HDI), and harsh operating conditions.

This article explores the fabrication processes, reliability testing, cost-effectiveness, and industry applications of IT-170GLE, providing a comprehensive understanding of how this material enhances PCB performance across various cutting-edge technologies.

Understanding ITEQ IT-170GLE and Its Advantages in PCB Manufacturing

The electronics industry never slows down. Every new device demands more from circuit boards—better heat resistance, lower signal loss, and materials that align with strict environmental standards. That’s where ITEQ IT-170GLE steps in.

This high-Tg, halogen-free laminate has gained recognition across industries that rely on multilayer PCBs, high-frequency applications, and advanced thermal management solutions. From 5G infrastructure to automotive electronics, medical imaging systems, and aerospace navigation, ITEQ IT-170GLE delivers where traditional FR-4 struggles.

To fully appreciate what this material brings to the table, let’s take a deep dive into its composition, compliance with global regulations, and the technical benefits that set it apart.

What is ITEQ IT-170GLE and Why Are PCB Manufacturers Making the Switch?

Every circuit board material has a temperature threshold, known as glass transition temperature (Tg)—the point where the resin softens. ITEQ IT-170GLE, with its high-Tg properties, provides a sturdy foundation for PCBs that must perform under heat-intensive conditions.

Comparing Tg Ratings Across PCB Materials-

| PCB Material | Tg (Glass Transition Temperature) | Halogen-Free | Signal Loss Performance |

| Standard FR-4 | ~130°C | No | Moderate |

| High-Tg FR-4 | ~150°C | No | Moderate |

| ITEQ IT-170GLE | ~170°C | Yes | Low loss |

| Panasonic Megtron 6 | ~200°C | Yes | Ultra-low loss |

Unlike standard FR-4, ITEQ IT-170GLE minimizes expansion at elevated temperatures, reducing stress on vias and solder joints. This makes it a suitable material for high-layer count PCBs used in automotive control units, satellite communication systems, and 5G base stations.

Halogen-Free PCB Material: Environmental Benefits and Compliance Standards

Modern electronics must align with international environmental regulations, and ITEQ IT-170GLE checks all the boxes. Many older PCB materials contain halogen-based flame retardants, which can release harmful gases when exposed to fire.

Why the Shift to Halogen-Free PCBs?

As global regulations tighten, human are looking for PCB materials that meet safety and sustainability requirements without sacrificing performance. ITEQ IT-170GLE is built to handle demanding applications while staying compliant with industry standards.

Key Compliance Standards Met by ITEQ IT-170GLE:

●RoHS (Restriction of Hazardous Substances) – Eliminates lead, mercury, and other hazardous materials

●REACH (Registration, Evaluation, Authorization of Chemicals) – Ensures safer chemical use in manufacturing

●WEEE (Waste Electrical and Electronic Equipment Directive) – Supports recycling and responsible disposal

●UL 94V-0 Flame Retardancy – Provides flame resistance without the use of halogens

Industry Adoption Example:

A telecommunications equipment manufacturer in the U.S. transitioned to ITEQ IT-170GLE to ensure compliance with RoHS and WEEE directives. As a result, their PCBs passed environmental audits without material redesign, keeping production timelines on track.

Properties That Make ITEQ IT-170GLE a Standout in High-Reliability PCB Applications

When selecting a PCB material, we will evaluate multiple factors: thermal performance, signal transmission, and durability under mechanical stress. ITEQ IT-170GLE meets all these demands while maintaining cost efficiency.

Handling Heat Without Material Breakdown-

Electronics that run under extreme temperatures—such as engine control modules (ECMs) and power conversion units—need PCB materials that won’t warp or degrade over time.

Real-World Case Study:

An automotive electronics manufacturer upgraded from standard FR-4 to ITEQ IT-170GLE for their electric vehicle battery management systems (BMS). The shift cut thermal expansion issues by 40%, reducing failure rates in high-vibration environments.

Reliable Signal Transmission for High-Frequency Circuits-

High-speed PCB design requires materials with low dielectric constant (Dk) and low dissipation factor (Df) to prevent unwanted signal loss. ITEQ IT-170GLE excels in this aspect, making it an excellent choice for RF, microwave, and high-speed data applications.

Dielectric Performance Comparison:

| PCB Material | Dielectric Constant (Dk) | Dissipation Factor (Df) @ 1GHz |

| Standard FR-4 | 4.6 | 0.020 |

| ITEQ IT-170GLE | 4.2 | 0.009 |

| Rogers 4350B | 3.5 | 0.004 |

With a lower Dk than traditional FR-4, ITEQ IT-170GLE ensures stable impedance and minimal signal distortion, which is especially valuable for PCBs in 5G antennas, radars, and high-performance computing systems.

Built for Reliability in Harsh Conditions-

PCBs used in aerospace, military, and industrial automation systems must withstand constant mechanical stress, high humidity, and exposure to chemicals. ITEQ IT-170GLE’s robust resin system and enhanced interlayer adhesion ensure long-term durability, even in challenging environments.

Example:

A medical imaging device manufacturer adopted ITEQ IT-170GLE for their MRI scanning units to reduce circuit board failures caused by electromagnetic interference (EMI). The low Df properties helped stabilize signal transmission, leading to clearer imaging results.

Electrical Performance of ITEQ IT-170GLE for High-Speed and RF PCBs

As electronic devices push into higher frequencies and faster processing speeds, the demand for low-loss, high-performance PCB materials is at an all-time high. Designing circuit boards for 5G infrastructure, high-speed computing, aerospace, and RF applications requires careful material selection to maintain signal clarity, impedance control, and electromagnetic compatibility.

ITEQ IT-170GLE steps up to the challenge by offering a well-balanced dielectric profile, superior thermal stability, and excellent signal transmission properties. This material supports consistent electrical behavior across multiple layers, making it a better choice for engineers looking to build robust, high-frequency circuits.

Let’s explore how ITEQ IT-170GLE helps achieve outstanding electrical performance in high-speed and RF PCB designs.

Low Dielectric Constant (Dk) and Low Loss Tangent (Df) for Signal Integrity

For high-frequency and high-speed digital circuits, dielectric properties directly impact signal speed, propagation delays, and overall circuit reliability. A high dielectric constant (Dk) can cause unwanted capacitance, slowing down signals, while a high dissipation factor (Df) leads to energy loss, weakening transmission strength.

Dielectric Performance Comparison-

| PCB Material | Dielectric Constant (Dk) | Loss Tangent (Df) @ 1GHz | Ideal Applications |

| Standard FR-4 | 4.6 | 0.020 | General-purpose PCBs |

| ITEQ IT-170GLE | 3.14~3.33 | 0.0095~0.0108 | High-speed digital, RF and microwave PCB |

| Rogers 4350B | 3.48 ± 0.05 | 0.0031~0.0037 | Ultra-high-frequency RF/microwave |

ITEQ IT-170GLE is engineered with a low and stable Dk, ensuring faster signal travel across PCB traces. Additionally, its low loss tangent (Df) minimizes power dissipation, preserving signal clarity over longer distances.

How ITEQ IT-170GLE Enhances Signal Performance-

●Consistent Dk across frequency ranges, preventing impedance fluctuations

●Reduced signal attenuation, allowing high-speed data to move efficiently

●Minimized dielectric loss, ensuring power reaches its destination with minimal waste

This balance allows RF engineers and PCB designers to achieve cleaner signal transmission, supporting applications like wireless communications, satellite systems, and data centers.

Impedance Control and High-Frequency Performance in ITEQ IT-170GLE-Based PCBs

In high-speed multilayer PCBs, impedance mismatches can cause signal reflections, power dissipation, and lower transmission efficiency. Keeping impedance tightly controlled helps ensure reliable data flow and maintains signal integrity in RF, microwave, and high-speed computing systems.

Impedance Performance in High-Speed PCBs-

| PCB Material | Impedance Variation (%) | Signal Loss (dB/m @ 10 GHz) | Frequency Suitability |

| Standard FR-4 | ±10% | -1.5 dB/m | Up to 2 GHz |

| ITEQ IT-170GLE | ±5% | -0.8 dB/m | Up to 15 GHz |

| Megtron 6 | ±3% | -0.4 dB/m | Above 20 GHz |

ITEQ IT-170GLE is designed to support precise impedance matching, offering reliable performance across high-frequency circuits. With its consistent electrical properties and excellent lamination compatibility, we can confidently design controlled impedance traces that align with industry standards.

Why ITEQ IT-170GLE Stands Out for Impedance Control-

●Stable dielectric behavior, ensuring uniform impedance across PCB layers

●High-frequency signal retention, reducing reflections and unwanted distortion

●Improved reliability for RF, 5G, and ultra-fast digital circuits

By incorporating ITEQ IT-170GLE into PCB stack-ups, we can design low-loss, impedance-matched circuits that support seamless data flow in high-frequency applications.

EMI/EMC Reduction Strategies Using ITEQ IT-170GLE in PCB Design

Electromagnetic interference (EMI) is a major concern in wireless communication systems, high-speed computing, and RF applications. Uncontrolled EMI can cause signal cross-talk, disrupt circuit performance, and lead to regulatory compliance issues.

ITEQ IT-170GLE offers inherent properties that help minimize electromagnetic disturbances, making it a strong choice for EMI-sensitive designs.

How ITEQ IT-170GLE Contributes to Lower EMI and Better EMC Compliance-

●Optimized dielectric properties, reducing unintentional radiation

●Consistent interlayer adhesion, limiting unwanted capacitive coupling

●Reliable impedance stability, helping to prevent unwanted reflections

With better EMI shielding and controlled impedance, ITEQ IT-170GLE allows us to meet electromagnetic compatibility (EMC) standards while enhancing overall signal quality.

Thermal and Mechanical Properties of ITEQ IT-170GLE in Multilayer PCBs

High-reliability PCBs are exposed to intense thermal cycling, mechanical stress, and stringent manufacturing processes. Selecting the right laminate material determines how well a PCB can handle heat dissipation, expansion mismatches, and physical deformation over time.

ITEQ IT-170GLE is designed to meet the toughest engineering demands in automotive, aerospace, telecommunications, and industrial control applications. Let’s break down how its thermal and mechanical characteristics contribute to long-term stability and performance.

High Glass Transition Temperature (Tg) and PCB Reliability Under Heat Stress

Glass transition temperature (Tg) is a fundamental parameter in PCB materials, defining the temperature at which the laminate shifts from a rigid state to a more flexible one. Higher Tg values ensure better resistance to thermal deformation, particularly during soldering, assembly, and prolonged high-temperature operation.

ITEQ IT-170GLE’s Tg Performance-

ITEQ IT-170GLE features a Tg above 170°C, making it highly effective in lead-free soldering environments where reflow profiles often exceed 260°C.

●Prevents softening and dimensional distortion during reflow soldering

●Supports high-current applications by maintaining structural consistency under prolonged heat exposure

●Reduces the risk of resin decomposition, ensuring long-term material stability

For PCBs subjected to continuous heating and cooling cycles, using a high-Tg material like ITEQ IT-170GLE prevents layer separation, via cracking, and mechanical degradation over time.

Coefficient of Thermal Expansion (CTE) and Its Impact on PCB Performance

As temperatures fluctuate, PCB materials expand and contract at different rates. A high coefficient of thermal expansion (CTE) can lead to:

●Increased stress on plated through-holes (PTHs), causing fractures

●Layer misalignment in HDI and multilayer stackups

●Weakened solder joints due to uneven expansion

ITEQ IT-170GLE’s Controlled CTE for Dimensional Stability-

ITEQ IT-170GLE is engineered with low X-Y axis expansion, ensuring tight registration accuracy during fabrication.Additionally, its controlled Z-axis expansion helps mitigate barrel cracking and via failures caused by repeated thermal cycling.

CTE Performance Breakdown (Typical Values)-

| Property | ITEQ IT-170GLE | Standard FR-4 |

| Tg (°C) | >170°C | 130–150°C |

| Z-Axis Expansion (50-260°C, %) | 2.9-3.2% | 4.0-5.0% |

| X-Y Expansion (ppm/°C) | 12-14 ppm/°C | 16-18 ppm/°C |

With these attributes, ITEQ IT-170GLE significantly reduces expansion mismatches between copper and the substrate, leading to better reliability in high-temperature environments.

Mechanical Strength and Warpage Control in ITEQ IT-170GLE Substrates

In high-layer-count PCBs, warpage and mechanical flexing can cause issues during assembly, depaneling, and in-field operation. Warped boards can lead to:

●Misaligned components and poor solder joint connections

●Cracking of large BGAs and fine-pitch packages

●Difficulties in automated assembly due to uneven surfaces

ITEQ IT-170GLE’s Reinforced Resin System-

The fiberglass-to-resin ratio in ITEQ IT-170GLE is designed to minimize board deformation, providing:

●Superior flexural strength to withstand mechanical stress during fabrication

●Optimized rigidity, reducing handling-related fractures

●Consistent thickness control, improving high-density PCB stacking

This makes ITEQ IT-170GLE a solid choice for multilayer PCBs used in telecommunications, data servers, and automotive control modules, where flatness and mechanical durability are non-negotiable.

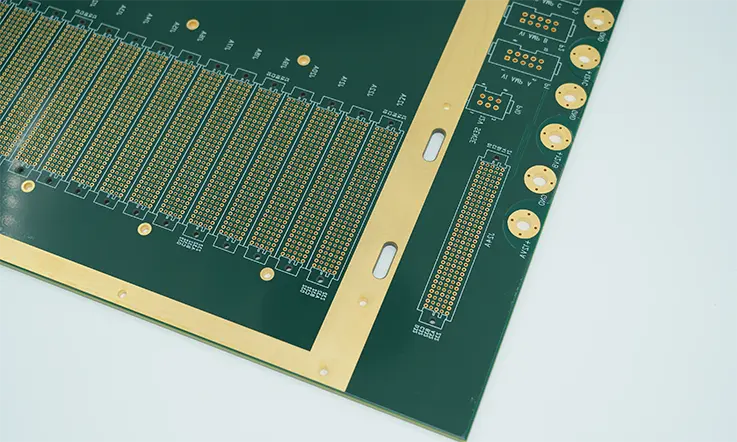

Optimizing PCB Stack-Up with ITEQ IT-170GLE for Multilayer and HDI PCBs

As PCB designs become increasingly complex, layer count, material performance, and signal integrity take center stage. Multilayer and HDI (High-Density Interconnect) PCBs demand fine-tuned stack-ups that balance electrical, thermal, and mechanical properties without compromising manufacturability.

ITEQ IT-170GLE is engineered to support densely packed, high-speed circuits by offering stable dielectric properties, controlled expansion characteristics, and robust lamination performance. Therefore, if you’re working with high-layer-count server motherboards, compact IoT devices, or RF-driven telecom applications, getting the stack-up right is the foundation of a reliable PCB.

Material Selection for High-Density Interconnect (HDI) and Rigid PCBs

When designing for HDI and high-layer-count PCBs, the choice of prepregs and core laminates significantly influences:

●Signal integrity at high frequencies

●Layer registration and drilling accuracy

●Reliability under thermal cycling and mechanical stress

Why ITEQ IT-170GLE Stands Out in HDI and Multilayer PCBs-

ITEQ IT-170GLE’s low dielectric constant (Dk) and low dissipation factor (Df) make it a preferred choice for high-speed signal transmission. These characteristics allow for shorter rise times, reduced signal distortion, and better impedance matching, which are all essential for HDI, RF, and high-speed digital applications.

Additionally, its high Tg and controlled coefficient of thermal expansion (CTE) provide dimensional stability, ensuring that vias remain structurally sound across multiple thermal cycles.

Prepreg and Core Laminates: Optimizing ITEQ IT-170GLE in PCB Fabrication

Balancing prepreg and core laminates is a fine art when stacking up a rigid or HDI PCB. ITEQ IT-170GLE prepregs and cores offer a reliable resin-to-glass ratio, helping:

●Minimize resin starvation and excess flow, preventing delamination

●Ensure proper dielectric thickness for controlled impedance traces

●Enhance via reliability by maintaining uniform lamination pressure

Prepreg and Core Selection for ITEQ IT-170GLE-Based PCBs-

| Stack-Up Configuration | Prepreg Type | Core Type | Dielectric Thickness (µm) | Application |

| Standard Multilayer (8-12 layers) | IT-170GLE PP-1080 | IT-170GLE Core | 50-75 | General high-speed digital PCBs |

| High-Frequency (RF & mmWave) | IT-170GLE PP-2116 | IT-170GLE Core | 75-125 | Impedance-controlled RF circuits |

| HDI with Microvias | IT-170GLE PP-106 | IT-170GLE Thin Core | 25-50 | Stacked and staggered microvias |

| Power Integrity Focused (Low Noise) | IT-170GLE PP-7628 | IT-170GLE Core | 150-200 | Embedded capacitance and power integrity |

Lamination Considerations for ITEQ IT-170GLE-

●For multilayer PCBs, a consistent press cycle with controlled heat-up rates and pressure distribution prevents resin squeeze-out and air entrapment.

●In HDI builds, the thin prepreg layers of ITEQ IT-170GLE support laser-drilled microvias, allowing precise stacking of sub-laminates without creating unnecessary thickness.

●For RF and high-frequency PCBs, selecting the right dielectric thickness ensures optimal impedance matching across signal layers.

Embedded Capacitance and Power Integrity in ITEQ IT-170GLE PCB Designs

As signal speeds increase and power rails tighten, embedded capacitance layers are becoming a go-to strategy for managing power delivery and noise suppression in high-performance PCBs.

ITEQ IT-170GLE allows for ultra-thin power and ground planes, reducing the distance between them and effectively:

●Lowering power distribution network (PDN) impedance

●Minimizing simultaneous switching noise (SSN) in dense BGA layouts

●Improving transient response for high-frequency circuits

How ITEQ IT-170GLE Enhances Embedded Capacitance-

●Using ultra-thin cores with high-Dk dielectric layers enables better charge storage and power stability

●Minimizing plane separation lowers loop inductance, reducing voltage fluctuations

●Tighter lamination tolerances maintain consistent capacitance across the board

Impact of Embedded Capacitance Using ITEQ IT-170GLE-

| Power Plane Spacing (µm) | Capacitance Density (nF/cm²) | Power Noise Reduction (%) | Application |

| 100 | 4.5 | 15 | General Digital PCBs |

| 75 | 6.8 | 22 | High-Speed Computing |

| 50 | 9.2 | 30 | Signal Integrity Sensitive Circuits |

| 25 | 13.5 | 42 | RF and Ultra-Low Noise Designs |

For engineers pushing the limits of signal and power integrity, incorporating ITEQ IT-170GLE into embedded capacitance stack-ups results in lower noise, improved efficiency, and fewer power-related design challenges.

PCB Fabrication Processes and Compatibility with ITEQ IT-170GLE

Handling high-Tg laminates like ITEQ IT-170GLE demands precise fabrication control. From multilayer lamination to etching and final surface finishing, each process step affects electrical performance, mechanical integrity, and long-term durability.

Fine-tuning parameters like lamination pressure, copper foil adhesion, and surface roughness can influence everything from interconnect reliability to high-frequency signal transmission.

Lamination, Etching, and Manufacturing Considerations for High-Tg PCBs

Lamination is one of the most main stages in multilayer PCB fabrication, particularly for high-Tg materials like ITEQ IT-170GLE. The resin system within the laminate must fully cure while maintaining uniform flow, ensuring strong interlayer adhesion and minimal voids.

Process Optimization for ITEQ IT-170GLE Lamination-

| Parameter | ITEQ IT-170GLE | Standard FR4 | Engineering Consideration |

| Tg (°C) | 170 | 130-140 | Affects thermal stability during reflow soldering |

| Lamination Pressure (psi) | 275-350 | 250-300 | Must be optimized to prevent resin starvation or excessive squeeze-out |

| Curing Temperature (°C) | 180-200 | 160-170 | Ensures proper cross-linking for thermal reliability |

| CTE (Z-axis, ppm/°C pre-Tg) | 55 | 70-80 | Reduces via fatigue and minimizes expansion mismatch |

For multilayer designs, glass weave selection and prepreg flow characteristics should be considered to prevent resin starvation or excess accumulation in specific areas.

During etching, maintaining trace integrity is necessary for high-frequency and impedance-controlled PCBs. The use of low-profile copper foil can improve etching precision, reducing signal losses due to surface roughness.

Fine-tuning lamination pressure and curing profiles helps prevent delamination and ensures consistent dielectric performance.

Copper Foil Adhesion and Surface Roughness Control in ITEQ IT-170GLE Boards

The adhesion between copper foil and the resin system affects signal transmission efficiency and mechanical stability. The goal is to achieve strong adhesion while minimizing conductor losses, especially for high-frequency applications.

Copper Surface Roughness and Electrical Loss Considerations-

| Copper Type | Surface Roughness (Ra, µm) | Electrical Impact | Use Case |

| Standard ED Copper | 1.5-2.0 | Higher conductor loss due to rough interface | General-purpose PCBs |

| Low-Profile ED Copper | 0.8-1.2 | Moderate improvement in signal integrity | High-speed digital designs |

| Reverse-Treated Foil (RTF) | 0.5-0.9 | Reduced insertion loss | RF and high-speed PCBs |

| Ultra-Low Profile (ULP) Copper | <0.4 | Best performance in minimizing signal loss | 5G, RF, and mmWave PCBs |

A higher surface roughness (Ra >1.5µm) can introduce impedance variations, affecting signal transmission in GHz-frequency circuits.

For high-speed and RF PCBs, selecting RTF or ULP copper ensures minimal conductor losses while maintaining sufficient adhesion strength.

Surface Finish Compatibility: ENIG, Immersion Silver, and OSP for ITEQ IT-170GLE

The choice of surface finish affects solderability, oxidation resistance, and signal integrity. Given ITEQ IT-170GLE’s high-Tg composition, surface finish selection must account for thermal cycles and corrosion resistance.

Surface Finish Selection Based on Application Needs-

| Surface Finish | Coating Thickness (µm) | Solderability | Electrical Performance | Suitable Applications |

| ENIG (Electroless Nickel Immersion Gold) | Ni: 3-6, Au: 0.05-0.1 | Excellent | Low loss at high frequencies | HDI, RF, and high-speed PCB designs |

| Immersion Silver | 0.1-0.3 | Good | Moderate | High-frequency and power-sensitive PCBs |

| OSP (Organic Solderability Preservative) | 0.2-0.5 | Moderate | Best for cost-sensitive high-speed designs | Cost-efficient high-speed PCBs |

ENIG provides excellent oxidation resistance and maintains stable electrical contact performance, making it good for HDI and RF circuits.

Looking for the best balance between solderability and signal transmission? ENIG is a solid choice for high-Tg laminates like ITEQ IT-170GLE.

Quality Control, Reliability Testing, and Certifications of ITEQ IT-170GLE PCBs

Ensuring a printed circuit board (PCB) meets industry standards is not just about manufacturing precision; it involves rigorous testing, adherence to global certifications, and material stability under real-world conditions. ITEQ IT-170GLE, as a high-Tg laminate, is designed to comply with multiple international regulations while undergoing extensive reliability assessments.

How does this material hold up in demanding applications? Let’s explore the certification requirements, environmental stress testing, and long-term performance evaluations.

Compliance with IPC-4101, UL-94 V-0, and Other Industry Standards

PCB laminates must conform to strict industry guidelines to ensure consistent performance across different applications. ITEQ IT-170GLE meets internationally recognized specifications, making it suitable for sectors where high-temperature resistance, flame retardancy, and electrical reliability are non-negotiable.

●IPC-4101 Compliance: Ensures the material meets thermal stability, dielectric properties, and mechanical integrity requirements for high-reliability electronics.

●UL-94 V-0 Rating: Verifies that the laminate demonstrates flame-retardant properties, self-extinguishing within 10 seconds without dripping molten material.

●RoHS Compliance: Confirms the absence of hazardous substances like lead and halogens, aligning with environmental safety regulations.

●ISO 9001 Manufacturing Standards: Guarantees a controlled production process with consistent material quality.

Choosing a PCB laminate that aligns with these certifications reduces the risk of material degradation and ensures compatibility with stringent application demands.

Reliability Testing: Thermal Cycling, Moisture Resistance, and Long-Term Aging

Reliability assessments are not based on theoretical claims; they require real-world simulation under extreme conditions. ITEQ IT-170GLE undergoes a series of accelerated stress tests to validate its performance in environments where exposure to heat, humidity, and mechanical stress is unavoidable.

●Thermal Cycling: The material is subjected to repeated temperature transitions between -40°C and 125°C for 1,000 cycles to assess its resistance to thermal expansion and contraction.

●Moisture Resistance: High-humidity storage at 85°C and 85% RH over extended periods tests the laminate’s ability to maintain its electrical insulation and prevent delamination.

●Long-Term Aging: Continuous exposure to elevated temperatures at 150°C helps evaluate the laminate’s ability to retain its mechanical strength and Tg stability.

A PCB material that maintains structural integrity under extreme conditions ensures a longer operational lifespan and minimizes failure risks in applications requiring high reliability.

How ITEQ IT-170GLE Ensures High-Reliability PCB Performance in Demanding Applications?

High-performance electronics, such as automotive control systems, 5G communication hardware, and aerospace components, demand PCB laminates that remain stable despite fluctuating temperatures, vibration, and prolonged usage. ITEQ IT-170GLE has demonstrated its capability to support such applications by maintaining dimensional stability, reducing signal loss, and offering low moisture absorption.

●Automotive Electronics (ECU, ADAS, Power Modules): The low coefficient of thermal expansion (CTE) prevents warpage and ensures proper alignment in multilayer assemblies.

●5G High-Frequency Circuits: Its controlled dielectric properties support high-speed signal transmission with minimal loss.

●Industrial Control Systems: With a low moisture absorption rate, the material remains resistant to environmental fluctuations in manufacturing environments.

●Aerospace and Defense Applications: Passing extensive thermal and mechanical stress tests confirms its ability to withstand extreme operational conditions.

A laminate that delivers stable electrical and mechanical performance ensures that electronic systems operate reliably even in challenging conditions.

Cost-Effectiveness and Performance Comparison: Why Choose ITEQ IT-170GLE?

Selecting the right PCB laminate requires a careful evaluation of material properties, manufacturing efficiency, and long-term durability. ITEQ IT-170GLE provides an alternative to standard FR-4 and other high-Tg PCB laminates, offering improved thermal stability, electrical performance, and mechanical reliability.

To better understand its advantages, let’s examine how it compares to other materials, its impact on manufacturing costs, and how it influences the overall expenses over a product’s lifecycle.

Comparing ITEQ IT-170GLE vs. Standard FR-4 and Other High-Tg Laminates

The choice of laminate affects every stage of PCB performance, from fabrication to long-term use. ITEQ IT-170GLE stands out by offering improved heat resistance and signal integrity, making it suitable for applications where standard FR-4 may fall short.

●Glass Transition Temperature (Tg): Standard FR-4 materials typically range between 130-140°C, while IT-170GLE provides a higher threshold (~170°C), making it more stable under elevated temperatures.

●Thermal Conductivity: With better heat dissipation than conventional FR-4, IT-170GLE helps manage high-power applications more effectively.

●Electrical Properties: The lower dielectric loss ensures that signals maintain integrity, especially in high-frequency designs.

●Mechanical Performance: A lower coefficient of thermal expansion (CTE) enhances dimensional stability, reducing the risk of misalignment in multilayer PCBs.

Long-Term Durability and Cost-Savings in PCB Manufacturing with ITEQ IT-170GLE

The longevity of a PCB depends on how well the laminate material withstands repeated thermal cycles, mechanical stress, and environmental exposure. ITEQ IT-170GLE reduces material fatigue, lowers defect rates, and supports consistent performance over time.

●Lower Scrap and Rework Rates: The improved adhesion between copper and the laminate minimizes delamination, leading to fewer manufacturing defects.

●Better Resistance to Thermal Stress: Unlike conventional FR-4, which can degrade under repeated heating and cooling, IT-170GLE remains structurally stable.

●Extended Operational Lifespan: PCBs using IT-170GLE exhibit higher reliability in applications where temperature fluctuations and mechanical stress are frequent.

Total Cost of Ownership (TCO) and ROI for ITEQ IT-170GLE-Based PCB Solutions

The initial cost of a laminate is only part of the equation. The long-term expenses associated with failures, maintenance, and production inefficiencies must also be considered when evaluating material selection.

●Material Cost vs. Performance Benefits: While IT-170GLE may have a slightly higher upfront cost than standard FR-4, it compensates through improved durability and manufacturing efficiency.

●Assembly Compatibility: IT-170GLE supports various surface finishes (ENIG, immersion silver, OSP), allowing flexibility in production processes.

●Lower Failure Rates: Industries such as automotive, telecommunications, and industrial electronics benefit from fewer field failures, reducing warranty claims and unexpected downtime.

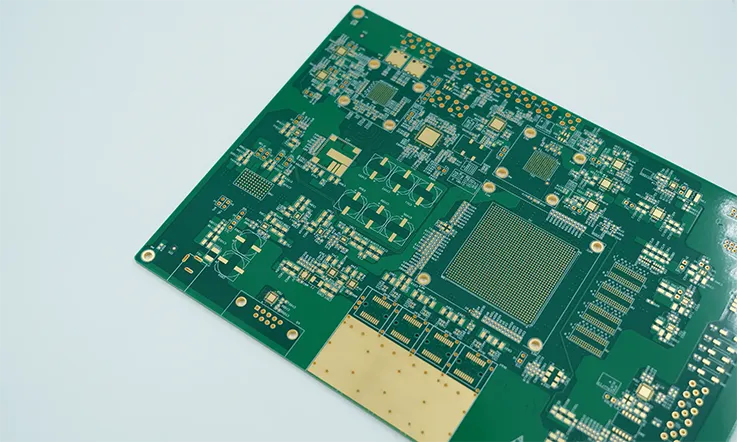

Applications of ITEQ IT-170GLE in High-Tech Industries

Advanced electronics require PCB materials that can handle high frequencies, extreme temperatures, and demanding mechanical stresses. ITEQ IT-170GLE has become a trusted choice across industries where precision and durability are non-negotiable. From 5G base stations to autonomous vehicles and aerospace systems, this high-Tg laminate meets the strict performance demands of modern technology.

Let’s explore how ITEQ IT-170GLE enhances electronic systems in telecommunications, automotive, and aerospace applications.

ITEQ IT-170GLE in 5G Base Stations and High-Frequency Communication Systems

5G networks push the limits of PCB materials, requiring low-loss, high-frequency laminates that can handle multi-gigahertz signals without interference. ITEQ IT-170GLE stands out with its stable dielectric properties, low dissipation factor, and superior thermal performance, making it well-suited for RF circuits and antenna modules.

●Consistent Dielectric Constant (Dk): Minimizes impedance fluctuations across different frequency bands, ensuring signal clarity.

●Low Dissipation Factor (Df): Minimizes energy loss in high-speed data transmission, helping to sustain network performance.

●Thermal Stability: Withstands prolonged exposure to heat generated by high-power RF components, preventing material degradation.

●Mechanical Strength: Supports fine-line etching and dense circuit layouts, optimizing board real estate in compact 5G infrastructure.

Automotive PCB Materials: ITEQ IT-170GLE for ADAS, EV, and Autonomous Vehicles

Modern vehicles rely on electronic systems that must endure vibration, temperature swings, and long operational lifetimes. ITEQ IT-170GLE supports automotive PCBs used in advanced driver assistance systems (ADAS), electric vehicles (EVs), and autonomous platforms.

●High-Tg and Low CTE: Provides dimensional stability, preventing layer separation and microcracks in high-temperature environments.

●Moisture Resistance: Reduces the risk of dielectric breakdown in humid or high-condensation conditions.

●Reliable Copper Adhesion: Prevents delamination, extending the lifespan of automotive control units and sensor circuits.

●Superior Heat Dissipation: Supports power electronics in EV battery management systems, helping to manage heat dissipation and improve reliability.

Aerospace and Defense PCB Solutions Using ITEQ IT-170GLE for Harsh Environments

PCBs in aerospace and defense applications face some of the toughest operating conditions—from extreme temperatures to high radiation exposure. ITEQ IT-170GLE provides the stability and durability required for core electronics used in satellites, avionics, and military-grade communication systems.

●Radiation and Thermal Endurance: Ensures prolonged functionality in space applications where materials must resist atomic oxygen and radiation-induced degradation.

●Low Outgassing: Meets aerospace material standards, preventing contamination in vacuum environments.

●Mechanical Resilience: Absorbs shock and vibration in defense applications, reducing the risk of electrical failure.

●Consistent Electrical Performance: Supports high-frequency radar, GPS, and secure military communications without signal loss.

FAQ About ITEQ IT-170GLE

1.How does ITEQ IT-170GLE perform in high-altitude environments?

The material performs well in high-altitude environments due to its excellent moisture resistance and stable electrical properties, even at lower air pressures.

2.What is the CTE (Coefficient of Thermal Expansion) of ITEQ IT-170GLE?

ITEQ IT-170GLE typically has a CTE of around 12-14 ppm/°C, ensuring minimal expansion and contraction with temperature fluctuations, especially in multilayer designs.

3.Can ITEQ IT-170GLE be used in mixed-material PCBs with copper or aluminum substrates?

Yes, ITEQ IT-170GLE can be successfully used in mixed-material designs, including those with aluminum or copper substrates, for effective heat dissipation.

4.What is the maximum number of layers typically achievable with ITEQ IT-170GLE?

IT-170GLE is well-suited for high-layer-count PCBs, commonly used in 8 to 12 layers, depending on the complexity of the design.

5.Does ITEQ IT-170GLE support fine-pitch components and microvias?

Yes, IT-170GLE supports fine-pitch components and microvia technologies, making it’s best for HDI and high-density designs.

6.Is ITEQ IT-170GLE suitable for wearable device PCBs?

Yes, due to its robust mechanical properties and ability to handle temperature cycling, ITEQ IT-170GLE is suitable for PCB designs used in wearable electronics.