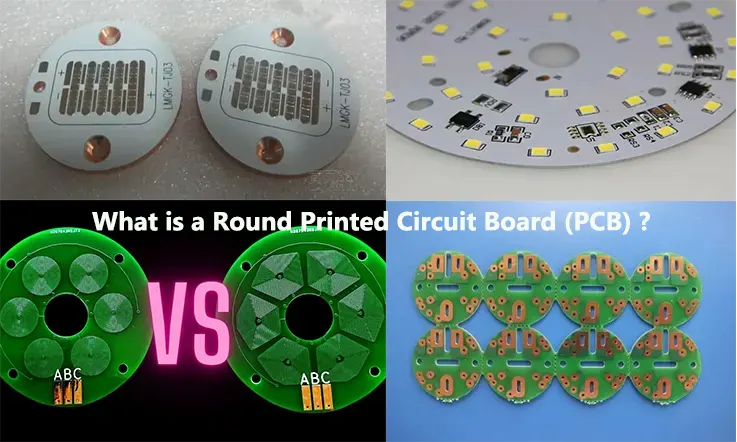

Printed circuit board, widely recognized as PCB, are pivotal parts in the electronics fabrication industry, presenting themselves in diverse dimensions and forms. While rectangular and square PCB dominate the scene, you can also find non-standard geometrical forms such as octagonal and round PCB in the marketplace. The need for unconventional PCB shapes arises due to […]

Read more

When the various components of a circuit board are subjected to tap water, it might result in short-circuits or lower the efficiency of the circuit. Thus, there’s an eminent need to shield these components from moisture and corrosion. At first, we need to must be done is to check and see if the fundamental circuitry […]

Read more

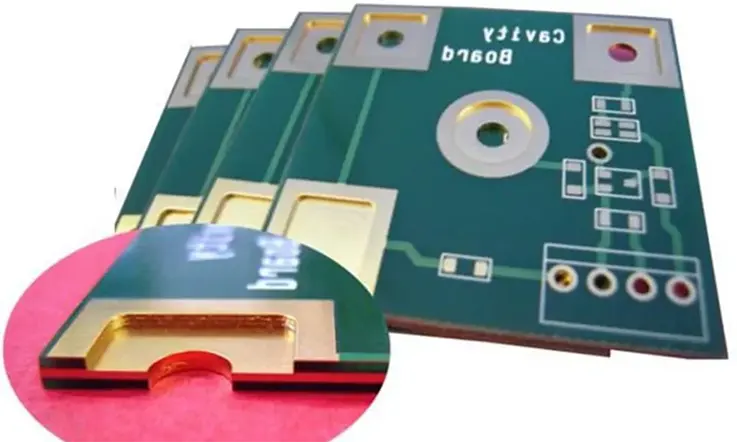

JarnisTech, a renowned Chinese manufacturer, has established a strong presence in the heater PCB industry for numerous years. Our unwavering commitment to delivering exceptional quality has been affirmed by countless satisfied clients worldwide. With an unyielding focus on customer satisfaction, we consistently strive to provide unparalleled services to our esteemed clientele. At JarnisTech, we take […]

Read more

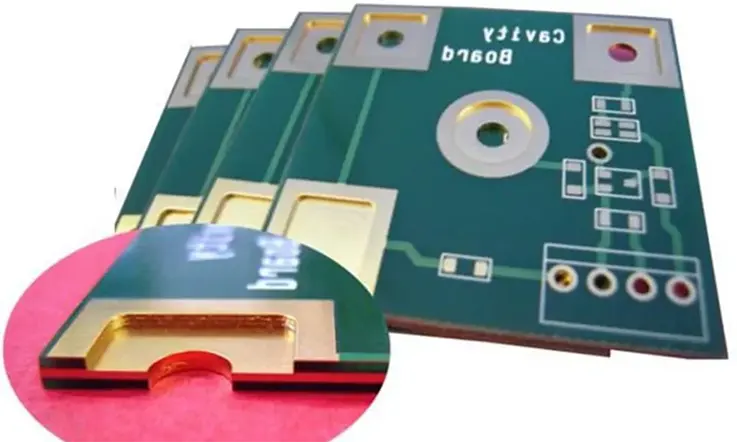

The copper layers embedded within a PCB function as pathways for electrical current, underscoring the importance of selecting an optimal copper thickness to ensure the assembly’s performance is not detrimentally affected. A comprehensive grasp of the relationship between copper weight, its efficacy in signal transmission, and the implications for PCB manufacturing costs is essential. It […]

Read more

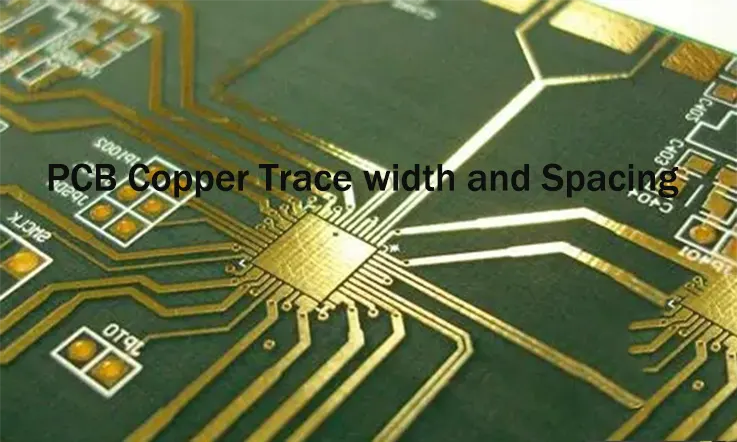

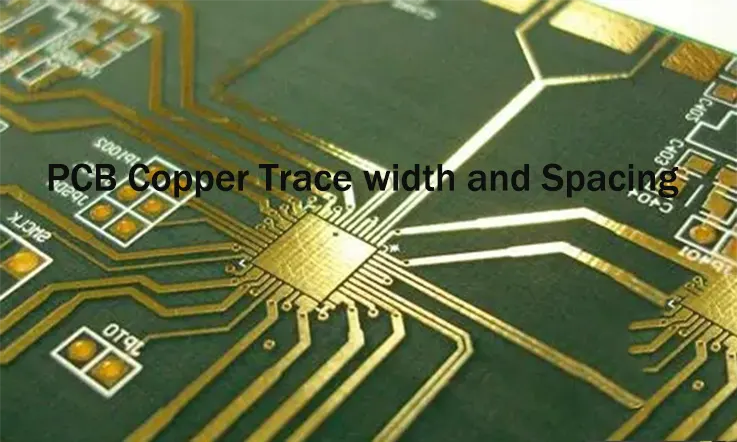

Within the discipline of printed circuit board (PCB) design, engineers often engage in the practice of making informed estimations concerning numerous facets of their design schematics. Among these critical design considerations is a parameter commonly identified as “Trace and Space.” The “Trace” component refers to the width of a designated copper pathway, whereas “Space” delineates […]

Read more

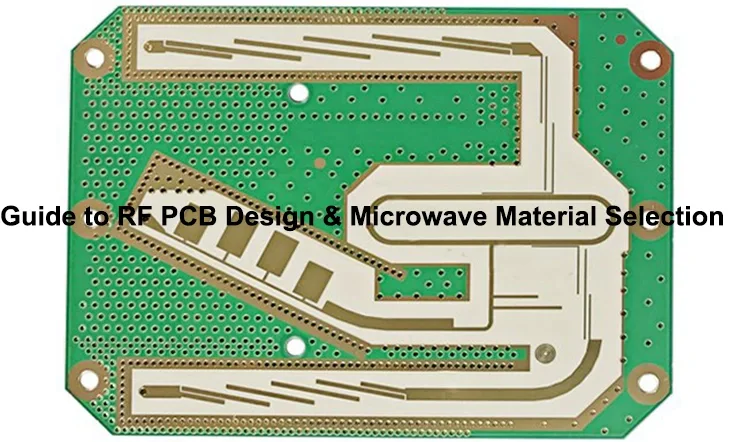

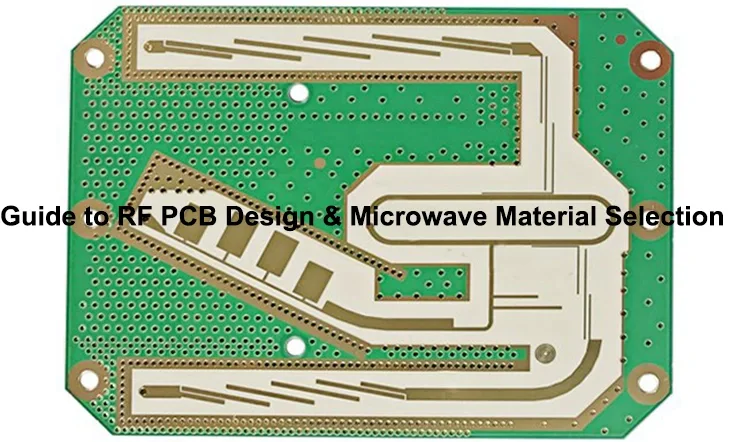

The choice of materials plays a pivotal role in the design and performance of RF PCBs. RF (Radio Frequency) circuits operate at high frequencies, demanding specific material properties to ensure optimal signal integrity, impedance control, and overall system performance. In this informative article, we aim to offer a thorough and all-encompassing set of instructions for […]

Read more

Radio Frequency (RF) amplifiers play a role in modern communication systems by boosting radio frequency signals for wireless communication over long distances. They are commonly used in devices like cell phones Wi Fi routers, radar systems and scientific research tools. When designing RF amplifiers engineers need to consider factors such as gain, bandwidth, efficiency, stability, […]

Read more

In the world of high speed communication systems and electronic gadgets RF multiplexers are essential for enhancing signal transmission and organization. As the need, for data transfer speeds, better network performance and improved communication features continues to grow RF multiplexers have become vital elements in a wide range of industries. What is a RF Multiplexer ? […]

Read more

HDMI, an acronym for High Definition Multimedia Interface, is a connection type that permits high-quality audio and visual signal transmission amongst a spectrum of devices such as televisions, Blu-ray players, gaming consoles, and computers. HDMI cables are notably appreciated for their proficiency in concurrently transporting definition audio and visual signals via a singular cable. Conversely, […]

Read more

In contemporary times, the lexicon of electronics hobbyists and novices has seen the increasing use of terms such as DFM (Design for Manufacture), DFA (Design for Assembly), and more broadly, DFX (Design for Excellence). To alleviate any confusion, our aim is to establish the term PCBA Design for Assembly (PCBA DFA) as a prominent concept, […]

Read more