The production process for Printed Circuit Boards (PCBs) starts with the design phase, handled by an electronics engineer. Following this, PCB manufacturers produce the board as per the design specifications, after which an assembler inserts the electronic components onto the board. A quality control testing process is the final step in ensuring that the end […]

Read more

Carbon ink is a type of ink that contains conductive carbon particles, typically in the form of carbon black, mixed with a binder material. The carbon black particles are small and form a dense and continuous network, making the ink electrically conductive. When applied to a non-conductive substrate such as paper, plastic, or even a […]

Read more

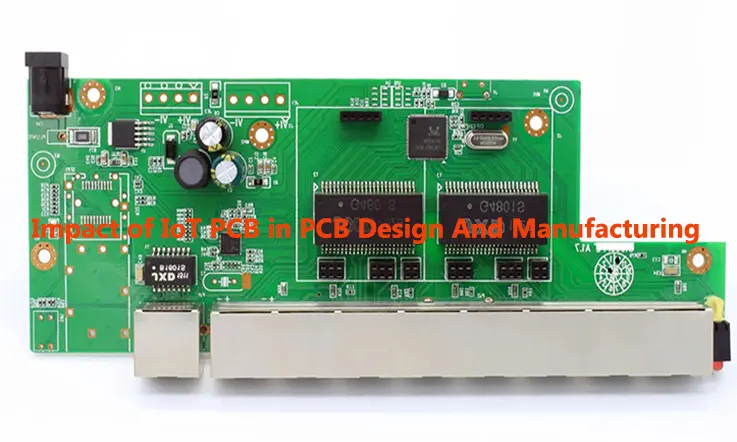

As a PCB designer, it is important to acknowledge that the manufacturing of IoT devices necessitates a specialized breed of circuit boards that pose unique design and manufacturing challenges. Unlike conventional electronic products, IoT devices push the boundaries of manufacturers and designs. Manufacturers have been facing difficulties keeping up with the rapid-scale adoption of new […]

Read more

As an electronic manufacturer, you may have encountered inquiries regarding the relevance of a 94v0 circuit board. This type of circuit board is sometimes compared to conventional PCBs, leading to questions about its advantages. These uncertainties usually arise from a lack of understanding of the 94v0 circuit board. In demanding environments with fluctuating temperatures, engineers […]

Read more

In the world of technology, electronic devices and advances go hand in hand. As a result, the significance of circuit boards has gained substantial importance, making it an essential aspect that every professional in the electronic industry- including students, engineers, designers, and hobbyists- must grasp. A comprehensive understanding of printed circuit boards is crucial for […]

Read more

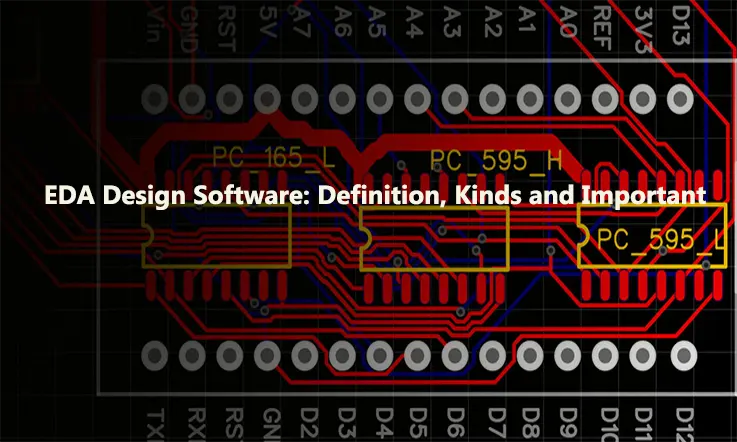

The Electronic Design Automation (EDA) market segment encompasses specialized software, hardware, and services geared towards supporting the complete lifecycle of semiconductor device manufacturing. This includes aiding in the definition, planning, design, implementation, verification, and final manufacturing of these devices, also referred to as “chips.” The primary service providers in the semiconductor manufacturing space are semiconductor […]

Read more

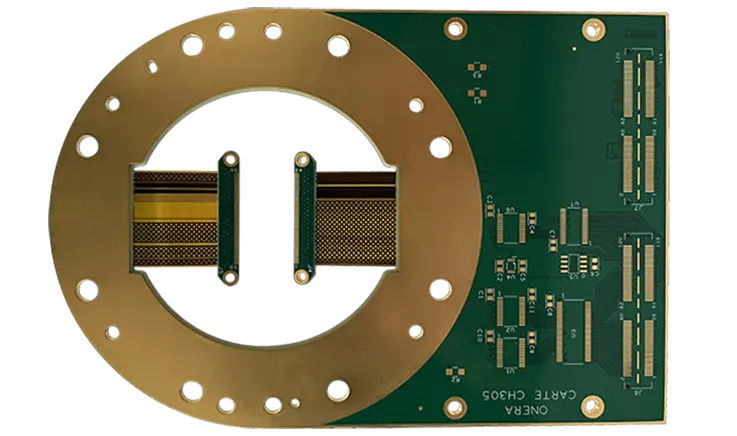

In today’s world, electronic devices often require higher component and trace densities, and as a result, vias are gradually shrinking while simultaneously increasing in aspect ratio.There are more microvias in multilayer PCB boards because these boards have smaller traces, sometimes as thin as 3 mil (0.075 mm). When it comes to the production of high […]

Read more

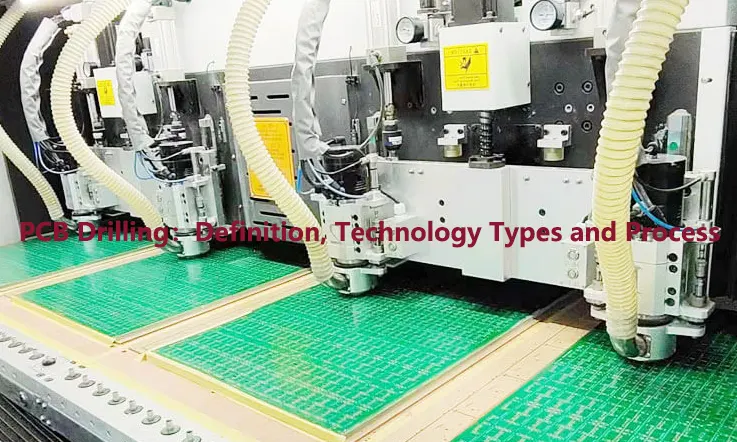

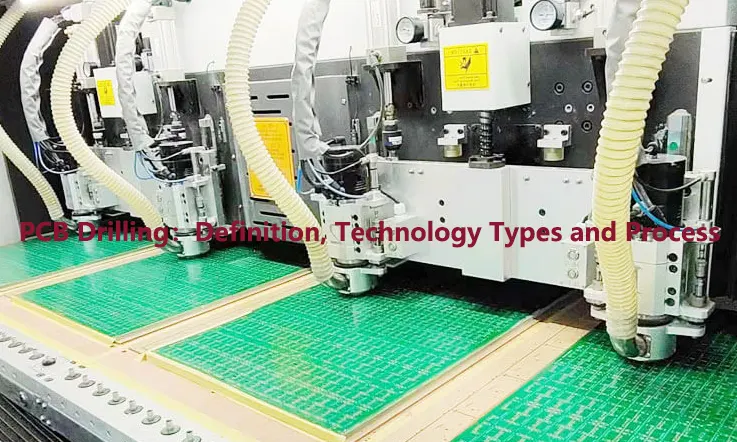

The drilling process is the most time-consuming and labor-intensive step in the fabrication of boards.The process of drilling PCBs needs to be carried out with extreme caution because the slightest mistake might result in a significant financial loss.It is generally agreed that the drilling process is the most important and time-consuming part of the fabrication […]

Read more

The term “PI” refers to a specific type of polyimide resin material, which is a material that has very good performance and is being utilized in a variety of industries due to its widespread applicability. Some people consider PI to be a ground-breaking substance that has the potential to foster the reform of electronic devices. […]

Read more

Do you ever find yourself pondering the meaning behind the many colors on your PCB? Or are you undecided regarding the color of the printed circuit board (PCB) that you should use for your circuit board? The answers to these questions can be found in the article that you are currently reading. We’ll also learn […]

Read more