In recent years, the field of electronics has experienced significant advancements, particularly in the very large scale integration (VLSI) industry. Starting with the invention of the transistor and progressing to the development of the integrated circuit and application-specific integrated circuit, technology has advanced at an impressive pace. Furthermore, the advent of programmable logic devices (PLDs) […]

Read more

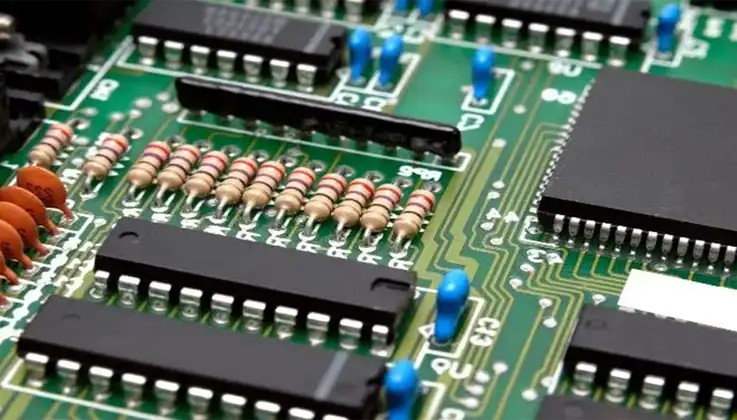

The demand for carrier printed circuit boards (PCBs) is increasing in tandem with the growing complexity and miniaturization of electronic equipment and systems, as well as the need for improved signal integrity, lower power consumption, and higher data rates. Carrier PCBs serve as a stable and reliable platform for configuring and interconnecting multiple electronic components, […]

Read more

In today’s highly competitive industrial landscape, engineers are constantly seeking out innovative means of reducing the cost of their products without compromising on quality. Printed Circuit Boards (PCBs) are a crucial component of electronic and electrical engineering hardware, and their cost has a substantial impact on the price of the final product. Therefore, selecting a […]

Read more

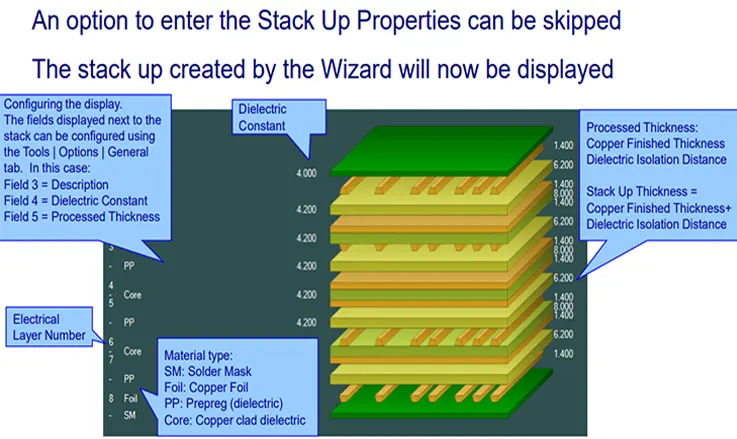

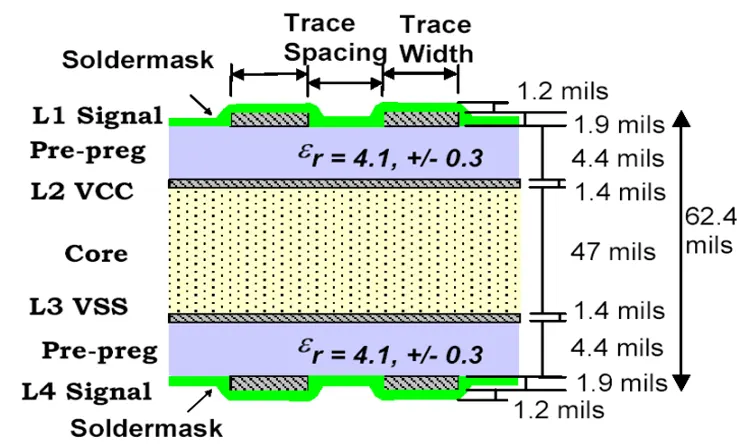

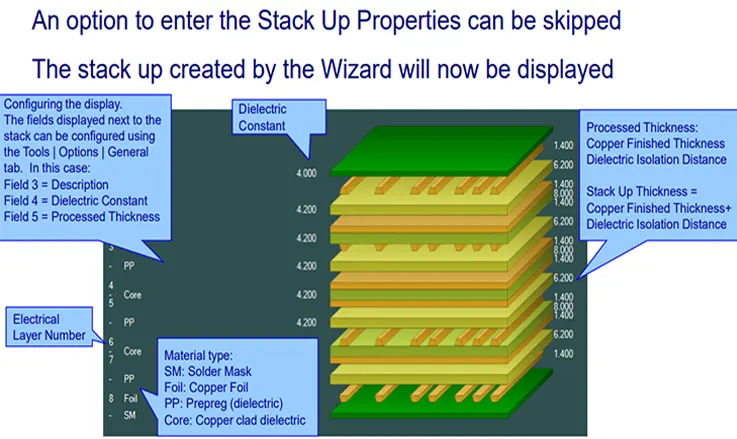

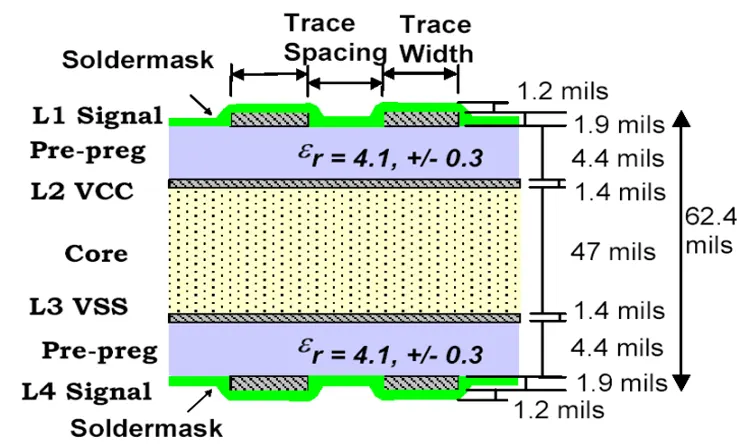

In modern times, electronic manufacturing companies are designing increasingly complex printed circuits with multiple layers, causing a surge in the importance of PCB stackup design. It is common knowledge that a well-designed stackup is crucial for reducing radiation from PCB loops and associated connections. Conversely, a poorly designed stackup can significantly increase radiation levels, posing […]

Read more

For any electronic manufacturing company, the utilization of turnkey printed circuit board assembly services is crucial to their function. Therefore, it is essential to identify an appropriate business partner who can fulfill your manufacturing requirements. JarnisTech offers turnkey PCB assembly services that enable you, the customer, to focus on the design and development of your […]

Read more

The manufacturing process of PCBs is influenced by multiple factors, with the thickness being a key variable. The electrical conductivity and resistance of a PCB are significantly impacted by its thickness. Therefore, it is crucial for PCB manufacturers to carefully choose the appropriate thickness to ensure an optimal fit for a given application. Precision and […]

Read more

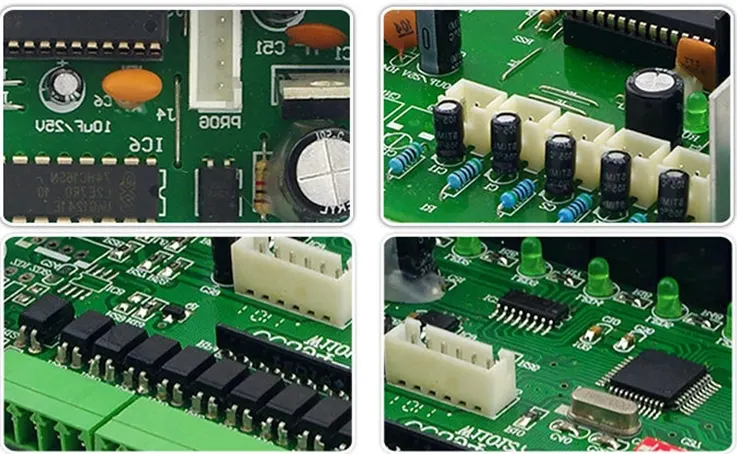

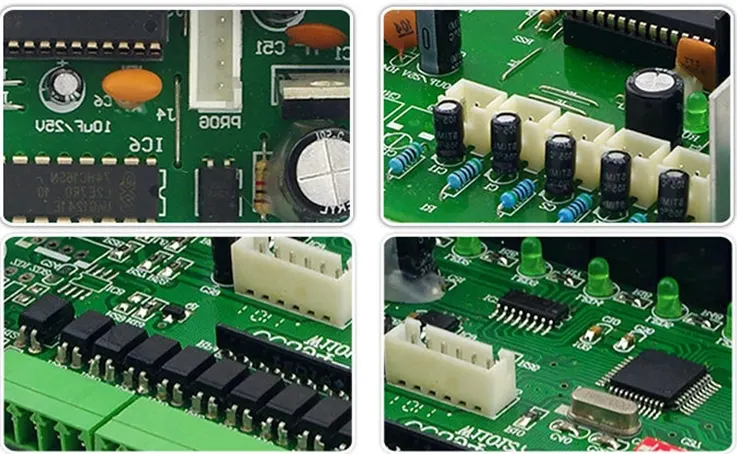

Printed Circuit Board (PCB) Assembly is the process of mounting electronic components onto a circuit board. PCBs are used extensively in the manufacturing of electronic equipment, and their assembly involves a combination of manual and automatic processes, such as soldering, inspection, testing, and more. It is important to note that the PCB Assembly process is […]

Read more

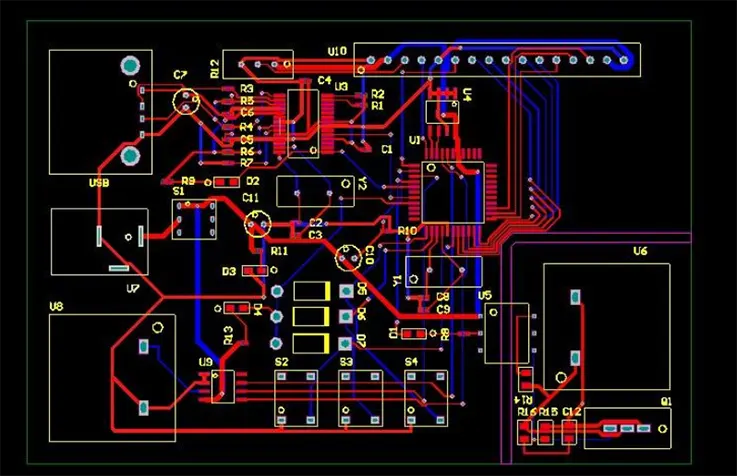

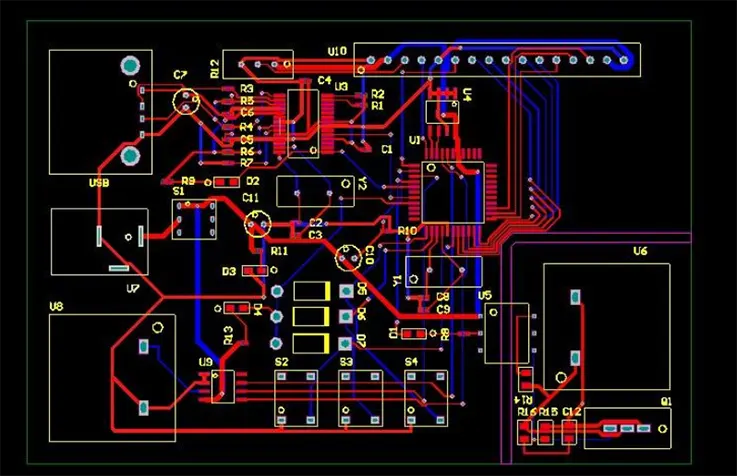

A PCB layout engineer knows that a well-crafted PCB layout is the cornerstone of producing a reliable and cost-effective end product. Although circuit design and component selection are important factors, dedicating sufficient time and expertise to the PCB layout process is crucial to achieve a successful outcome. This is especially true as boards become more […]

Read more

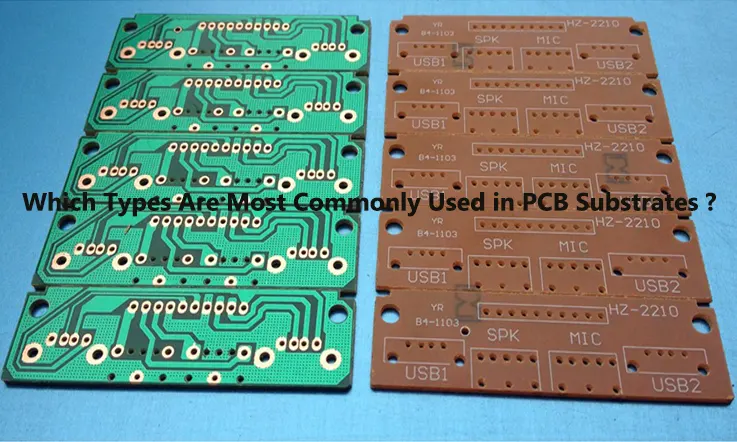

Printed circuit boards (PCBs) are a fundamental component in modern electronic devices, and their material selection is dependent on the specific role they play in the final product. Common PCB materials include aluminum, Rogers, copper, metal, HDI, and FR-4, with FR-4 being the most prevalent choice. FR-4, a popular choice for PCB construction, is well-known […]

Read more

The performance of substrate material is a critical factor that significantly influences the fundamental attributes of Printed Circuit Boards (PCBs). PCB manufacturers understand that in order to enhance the performance of circuit boards, they must first optimize the substrate material’s performance. In response to the demand for compatibility with market trends and new technologies, numerous […]

Read more