Printed circuit board, widely recognized as PCB, are pivotal parts in the electronics fabrication industry, presenting themselves in diverse dimensions and forms. While rectangular and square PCB dominate the scene, you can also find non-standard geometrical forms such as octagonal and round PCB in the marketplace.

The need for unconventional PCB shapes arises due to the requirement to fit them into specific enclosures, which is vital in achieving the intended application of the PCB. Despite being less common, round PCB are becoming increasingly demanded, mostly due to the continual advancements in technology.

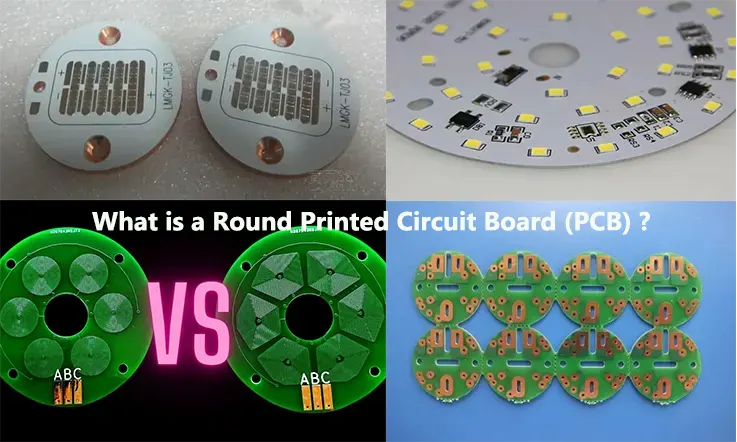

What is Round PCB?

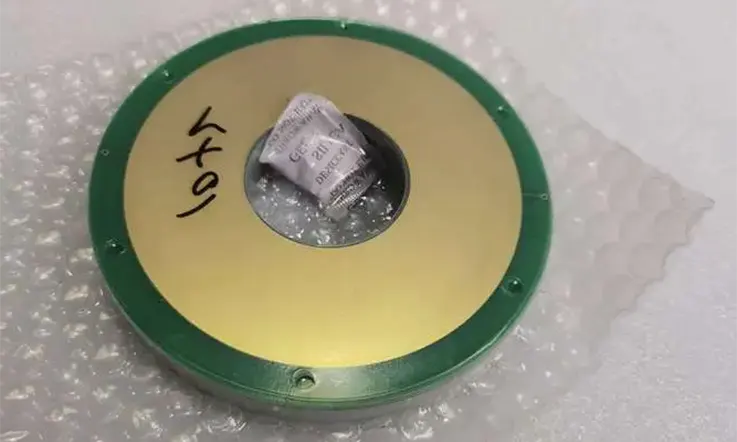

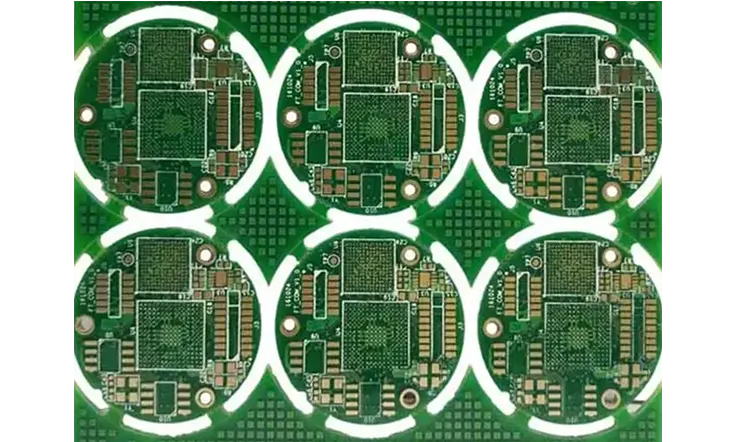

A round PCB, identifiable by its circular form, functions to establish electrical connectivity to circuits. Their usage spans across diverse gadgets, inclusive of consumer electronics and LED PCBA, and they are favored for both household and business applications. Nevertheless, their creation demands a complex routing process, which subsequently escalates their cost.

PCB manufacturers pay close attention to the fabrication process of round PCBs, as it is a complex procedure. These boards feature electronic components, traces, and varying widths and are commonly used in wearable devices. Unlike rectangular PCB, a round PCB provides ample board space, making them a preferred choice for certain applications.

Therefore, round PCBs are a valuable component in electronics manufacturing, offering unique capabilities and benefits for specific applications.

Types of Round PCB

Round circuit boards are different kinds of printed circuit boards exist, such as single sided double sided and multilayer boards. Each type has its purpose and is crafted based on the specific needs of a PCB project.

● Single Sided Round PCB:

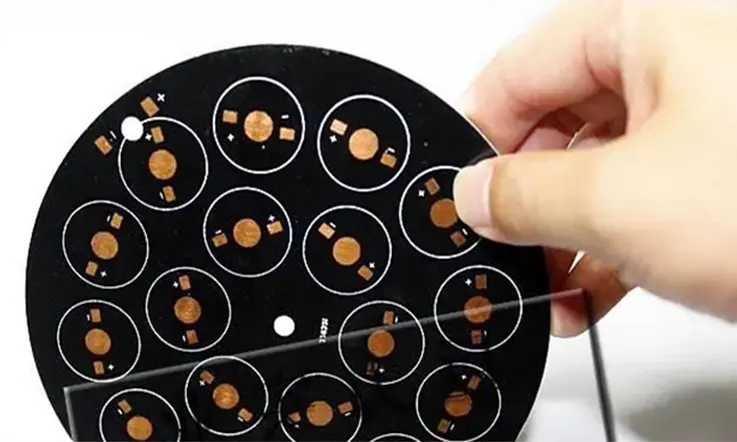

A single-sided round PCB comes with only one conductive copper layer, establishing its place as one of the most frequently employed types of round PCB. Owing to its utilization of substrates as the main material, this PCB type finds its presence across an array of applications. With components housed on one side and conductor patterns on the opposing one, single-sided round PCB effectively cater to low-density designs.

Single-sided round PCBs stand out due to their advantage of low-cost and straightforward production process, rendering them a budget-friendly solution for electronics manufacturers. The production of this type of PCB can be successfully carried out using either through-hole technology or surface mount technology.

● Double-sided Round PCB:

Double-sided round PCBs are characterized by the presence of conductive layers on each side of the board, positioning them as a viable alternative to their single-sided counterparts. Their inherent capacities have found favor across numerous applications and for specific designs, they are deemed more advantageous than single-sided boards.

Double-sided round PCBs find wide-ranging use in diverse applications such as lighting systems, wearable technology, and consumer electronics, aptly serving as dependable, high-performing alternatives for these devices. In comparison with single-sided PCB, these double-sided round circuit boards present an enlarged board space and higher component density. As a result, they rank high as a preferred option whenever manufacturing compact devices is on the agenda.

● Multilayer Round PCB:

The design of a multilayer round PCB accommodates more than two layers of conductive materials– a feature that renders it considerably suitable for high-speed applications. The advantages of this kind of round PCB are manifold, among which an enhanced assembly density and a superior capacity stand out. These qualities make multilayer round PCB particularly fitting for scenarios where a greater board space is a necessity.

On the contrary, the manufacture of a multi layer round PCB is somewhat more intricate compared to single or double-sided PCB. The production process demands meticulous layer alignment in addition to a precise bonding of all layers so as to guarantee structural integrity. Regardless of the advanced complexities inherently associated with the making of a multilayer round PCB, their imperative role in the realm of contemporary electronics remains indubitable

Advantages of Round PCBs Over other Shapes

Here are some advantages of Round PCB over other shapes:

● Space Efficient

● Reduced EMI noise

● Better Thermal Management

● Aesthetically Pleasing

● Better Signal Integrity

Consequently, the benefits of employing round PCBs as opposed to other forms hinge upon the unique demands stipulated by a distinct application. Such needs may encompass space limitations, thermal management requirements, a necessity to reduce electromagnetic interference, or considerations of aesthetic value.

Round PCB Design

Designing a round printed circuit board can be a more intricate process compared to the typical rectangular layout due to the constraints imposed by the manufacturing process. This is majorly attributed to the constraints imposed by the manufacturing methodology. To be specific, the outer edge of a round PCB can only be formed using straight line segments. This fundamental characteristic mandates thoughtful attention and strategic planning in the preliminary design phase.

To create a circular shape for the perimeter of the board, a circle can be added to the silkscreen layer. A diverse spectrum of software instruments exists which are catered to the design of round PCBs, each harboring its own distinct set of unique features and capabilities.

It should be noted that break routing is the only separation method available for a round PCB, which further adds complexity to the design process. Consequently, a profound comprehension of the software, in conjunction with meticulous attention to the minutiae, is crucial in certifying a successful outcome.

Round Circuit Board Design Rules:

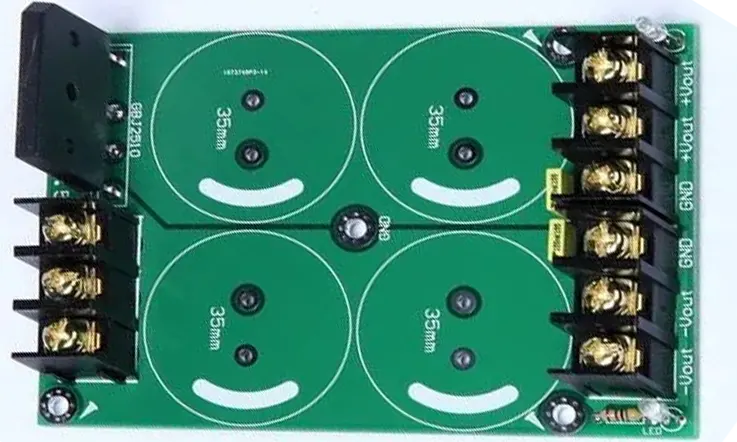

When using CAD tools to design a round printed circuit board, the first step is to draw the board’s shape in the CAD software. For high-speed appliances, a multilayered PCB is recommended, with separate layers defining the power and ground planes. A polygon editor is useful for defining the shape of these planes, and some software also allows customizing them.

Designing round circuit boards also requires panelization schemes, and break routing is a common method used for this purpose. It is crucial to maintain a minimum clearance of 10 mm between circuit boards, although this can be increased using a larger routing tool.

Regarding component mounting technology, both Surface Mount Technology (SMT) and Through Hole Technology (THT) can be used, although SMT is better suited.

How to Use Eagle CAD to Make Round PCB?

Eagle CAD is a widely-used software for the design of electronic circuit schematics and layouts. Circuit schematics depict how different electronic components connect, and the layout is an exact image of the circuit’s appearance on a Printed Circuit Board (PCB). By default, many designers create rectangular circuit board layouts, but Eagle CAD offers a “MITER” command that transforms the square layout into a circular one.

To employ Eagle CAD for your design, initially, you’d want to access the layout file by navigating to “File” and opting for “Open.” In scenarios where a pre-existing layout file is non-existent, there exists the possibility to originate a new file, you’d achieve this by heading to “File” and pressing “New,” then naming the file as per your requirements.

You will need to modify the board outline’s size to match the intended PCB size. The board outline typically appears as a square, and you can adjust its size by clicking on either side and dragging it left or right. Ensure that the board outline remains square, preventing it from taking an oval shape when attempting to transform it into a circle.

To actualize a circular layout, it is pivotal to align each side of the square with the circle’s diameter. Input “MITER 2” atop the layout and submit by pressing “Enter.” The icon will transition into a plus symbol. Trigger a left-click on the corner of the square, this will result in it rounding off. Should the corner appear overly diminutive, make use of “MITER 3” or above, whereas, if it’s excessively large, diminish the MITER value. This procedure needs to be replicated, bestowing the MITER command onto all corners, until the point they collectively embody a circular form.

Manufacturing Process for Round PCBs

The manufacturing process for round PCB is similar to that of other PCB shapes but has some specific steps.

● PCB Design: Utilize PCB blueprint software to develop a schematic followed by a layout of the PCB.

● Panelization: Multiple round PCBs are typically fabricated in unison on extensive panel boards, allowing for modulated manufacturing and diminished costs.

● Layer Stacking: Copper trace-filled layers are piled atop one another.

● Substrate Preparation: The PCB’s substrate material receives a coat of a photosensitive layer.

● Imaging: A photosensitive mask is generated from the layout and then implemented to expose the photosensitive layer via a process involving UV exposure and development.

● Etching: The etching phase eliminates the bare copper areas, leaving behind the final copper traces.

● Drilling: Obligatory through-holes or via holes are drilled into the PCB.

● Plating: Copper plating is supplemented to the holes and surface to establish electrical connectivity amongst the layers.

● Solder Mask Application: The solder mask substance is applied and cured to insulate the copper traces and protect them from environmental factors.

● Silk Screening: A concluding layer of ink-like substance is enforced to label the constituents and essential information.

● Final Inspection: The concluding inspection verifies that all the connections are operative, devoid of any short or open circuits, and the board conforms to the required specifications.

● Separating the PCB: The solitary PCBs are disengaged from the larger panel board, marking the cessation of the manufacturing process.

Applications of Round PCBs in Various Industries

Round circuit boards are utilized in an applications of sectors:

Consumer electronics

Automotive industry

Medical equipment

Aerospace sector

Industrial automation

Military and defense

Lighting industry

In short the adaptable nature of circular PCBs and their capacity to be accommodated in compact spaces make them a preferred option for various applications, in different industries

How to Choose the Best Round PCB Manufacturer

When it comes to the production of round PCB boards, it can be a complex process that requires careful selection of a manufacturer that delivers quality. Since Many select of manufacturers available, there are several pivotal elements to consider during decision-making. Opting for the appropriate round PCB manufacturer is vital in guaranteeing the triumphant production of top-quality products.

● Experience:

The primary criteria to contemplate when opting for a round PCB manufacturer is the eminence of the products they provide. A desirable manufacturer offers exceptional product quality whilst upholding a professional echelon of service delivery. It’s judicious to go with a manufacturer boasting profound experience in the domain as they are likely to possess the necessary proficiency for manufacturing top-tier round PCBs. One can probe into the manufacturer’s offerings and services to evaluate their appropriateness. Hence, it is crucial to carry out an exhaustive investigation and assessment prior to committing to a specific manufacturer to ensure their products and services recognize the requisite norms.

● Quality:

Round PCB manufacturers typically conduct several tests to ensure that their products meet the requisite quality for optimal performance.. The most credible manufacturers are distinguished by executing a series of quality checks on the round PCBs. Such checks may encompass the E-test, thermal stress test, microsection assessment, among other tests. Through these examinations, flaws and inadequacies on the circuit board can be promptly detected. The employment of top-notch materials in the manufacturing process is equally vital in ensuring the production of superior-quality circuit boards. A ideal manufacturer should give precedence to the utilization of prime materials to assure the prolonged lifespan and durability of the circuit boards manufactured.

● Turnaround Time:

Another critical factor when choosing a round PCB manufacturer is the consideration of turnaround time. This refers to the time frame within which a manufacturer concludes and dispatches a product to the client. It’s essential to select a manufacturer who can adhere to specific delivery schedules and ensure timely product delivery.

● Customer service:

It is worth noting that certain round PCB manufacturers are committed to supporting the research and development endeavors of their clients. These manufacturers prioritize their client’s demands by being readily available to provide exceptional service. The ideal manufacturer should be able to provide a quick response to inquiries regarding quotations, professional technical support, and customized service. It is advisable to conduct thorough research on potential manufacturers by analyzing reviews and feedback from past clients.

Why Choose JarnisTech?

● Boasting a rich tenure of over two decades in the industry, we have anchored our position as a forefront PCB fabricating corporation. Our fully-furnished infrastructures are adept at handling the most complex and detailed designs of Round PCB. Our dedication towards furnishing superior-quality products at economically viable prices has been the bedrock of our establishment’s evolution and triumph. We esteem quality and earmark the integration of state-of-the-art technology in our manufacturing operations to guarantee the conveyance of first-rate products to our clients.

● At JarnisTech, we pride ourselves on delivering reliable and high-performing Round PCB to our clients. Our products are calibrated for swift integration into devices, ensuring that they meet and exceed clients’ performance expectations. We subject all our products to rigorous E-test and functional tests, including Surface Mount Technology (SMT) application, to guarantee optimal performance.

● We understand the critical role that Round PCB play in our clients’ operations, which is why we use only standardized and high-quality PCB materials. Our raw material suppliers meet international standards, ensuring that our clients receive products that are durable and long-lasting.

● In the event of any issues, our skilled team can conduct a comprehensive 8D analysis to identify the root cause and promptly provide appropriate solutions. Our customer service representatives are fully trained to respond to clients’ queries through various communication channels and offer complete service to address all their requests.

● We are well-equipped to handle bulk orders to manage large orders from different sectors and provide a variety of PCB types such, as Embedded PCB, Laser Cut PCB, USB PCB and more. As a result our customers can anticipate their orders being safely delivered to the location promptly.

For all your Round PCB needs and other PCB requirements, please contact us today, and we will be delighted to offer our expertise.

Frequently Asked Questions

Which Type of Mounting Technology is Best for Round PCBs?

For component placement on round PCB, two techniques are at one’s disposal: Surface Mount Technology and Through Hole Technology. Among these, SMT is considered the superior choice for component placement. Being an automated process, SMT simplifies the fabrication process while boosting productivity. Furthermore, the application of SMT on round PCB mitigates stress levels, culminating in an end-product of greater quality.

How do I Panelize Round PCBs?

When panelizing round PCBs, break routing is the suggested technique. Upholding a clearance of 10mm between the round circuit boards is vital for achieving superior results, particularly when utilizing diminutive routing tools. Nevertheless, this clearance can be enlarged when employing larger routing instruments. Maintaining this clearance at a suitable degree is paramount to avoid inflicting any harm to the boards or the components during the operation.

Conclusion

The prevalence of round PCBs has escalated in multiple sectors due to their advantageous traits encompassing space-effectiveness, improved thermal management, curtailed EMI disturbances, and strengthened signal reliability. Their striking circular form also enhances the aesthetic appeal of products.

Though the manufacturing process for round PCBs is similar to other PCB shapes, special steps are executed due to their circular form.

As the ongoing inclination for device miniaturization and the escalating requirement for compact, mutually connected electronic apparatuses, the utilization of round PCB is projected to persistently grow. Technological progress within the PCB production industry, coupled with the continuous evolution of innovative design software, is also expected to augment the popularity of round PCB. Furthermore, the integration of cutting-edge materials such as high-functioning ceramics is predicted to build upon the advantages provided by round PCBs even more.

At JarnisTech, we dedicate ourselves to supply esteemed customers with premium round PCB coupled with stellar customer assistance. Our knowledgeable team is always ready to support and improve our clients’ products to meet their demanding electronics assembly needs. We present economical solutions and diligently work towards guaranteeing our patrons’ gratification. To acquire further insights on our top-tier products and services, kindly browse our website at www.jarnistech.com.

Related Posts:

1.How to Build a Heater PCB Circuit Boards?

3.Waterproof PCBs: Everything You Should Know