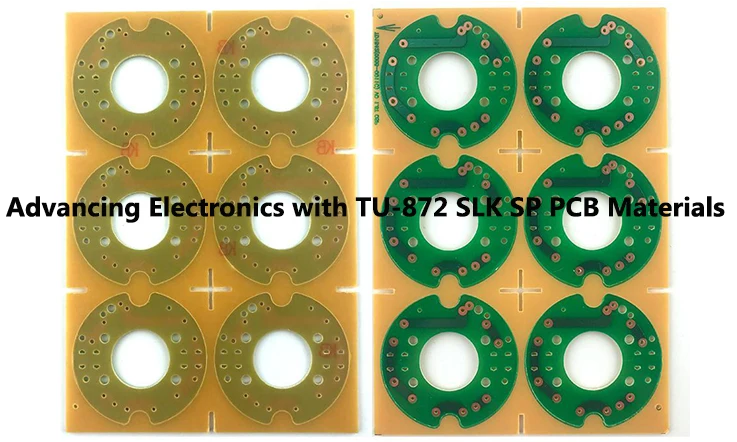

In the high-tech world of PCB manufacturing, staying ahead means embracing materials that combine technical sophistication with practical reliability. Enter TUC TU-872 SLK SP PCB laminates—a cutting-edge material tailored to meet the high-speed, high-frequency demands of today’s electronics. If you’re someone who deals with advanced applications like 5G telecommunications, automotive electronics, or radar systems, this laminate is designed to be your go-to choice.

Below, we’ll explore every facet of TUC TU-872 SLK SP, breaking down its properties, manufacturing insights, and real-world applications. Let’s dive deep and uncover what makes this material a standout in the industry.

An Introduction to TUC TU-872 SLK SP PCB Laminates

When it comes to designing and manufacturing high-performance printed circuit boards (PCBs), the choice of laminate material is fundamental. For industries like telecommunications, automotive electronics, and aerospace, reliability and efficiency are non-negotiable. TUC TU-872 SLK SP PCB Laminates stands out as a robust solution for these demanding applications, offering an exceptional balance between performance and durability.

This material is engineered with advanced technology to provide superior electrical and mechanical properties, making it suitable for use in high-speed, high-frequency applications. By integrating the latest in epoxy resin systems and reinforced glass fiber fabrics, TUC TU-872 SLK SP delivers the ideal combination of reliability and signal integrity required by modern PCB manufacturers.

Let’s dive deeper into the specifics of why TUC TU-872 SLK SP is becoming the preferred choice for PCB professionals, especially in industries that require precision and advanced performance.

What Makes TUC TU-872 SLK SP Unique?

TUC TU-872 SLK SP PCB laminate is a unique product that’s specially engineered to meet the high demands of industries requiring fast, reliable, and precise electronic circuits. This laminate stands out for its combination of material properties, including a specially modified epoxy resin FR-4 and advanced glass fiber cloth.

●Epoxy Resin FR-4 provides an excellent balance of mechanical strength, electrical performance, and thermal stability. This is especially useful when dealing with high-frequency applications like radar, wireless communication, and even space exploration equipment, where signal loss must be minimized, and performance must be consistent. Unlike standard epoxy resins that may not perform well under extreme conditions, the modified FR-4 in TUC TU-872 SLK SP maintains its stability across a broader temperature range, ensuring reliability even in tough environments.

●The advanced glass fiber cloth used in TUC TU-872 SLK SP laminates helps ensure dimensional stability. This reinforced material is built to endure mechanical stress, ensuring the structural integrity of high-density PCBs. In high-speed applications, thermal stress can lead to performance issues, but this glass fiber cloth helps minimize that risk. Think of it as an added layer of protection for your PCBs, reducing the chances of thermal-related problems. Whether dealing with multiple layers or demanding circuit requirements, this cloth helps keep everything intact under high temperatures.

Key Features of TUC TU-872 SLK SP PCB Laminates

Now that we’ve explored what makes TUC TU-872 SLK SP stand out, it’s time to dig deeper into the features that truly make this laminate a favorite among both PCB designers and manufacturers. These features offer exceptional value and elevate performance, especially in applications where reliability and precision are non-negotiable. With TUC TU-872 SLK SP, you’re not just getting a material — you’re investing in a solution that helps streamline your design process and manufacturing workflow, all while boosting your product’s durability and signal integrity.

| Property | Value | Implications for Use |

| Dielectric Constant (Dk) | 3.0-3.2 | Low Dk ensures minimal signal loss for high-speed applications. |

| Dissipation Factor (Df) | 0.002-0.004 | Low Df contributes to efficient signal transmission with reduced energy loss. |

| Thermal Coefficient of Expansion (CTE) | 40-50 ppm/°C | Minimizes dimensional changes with temperature fluctuations, supporting stable performance. |

| Glass Transition Temperature (Tg) | 180°C-220°C | High Tg ensures reliable operation under lead-free soldering temperatures and harsh environments. |

| CAF Resistance | Excellent | Prevents conductive anodic filament failure, extending PCB lifespan. |

Why TUC TU-872 SLK SP is the Right Choice for High-Speed Digital Circuits?

The combination of low dielectric constant (Dk), low dissipation factor (Df), and thermal reliability makes TUC TU-872 SLK SP the material of choice for high-speed and high-frequency applications. Let’s break down why TUC TU-872 SLK SP is a go-to solution for applications where precision, speed, and durability are non-negotiable.

| Feature | TUC TU-872 SLK SP | Standard FR-4 | Implications for PCB Design |

| Signal Integrity | High, due to low Dk/Df | Moderate | Essential for high-speed digital and RF applications. |

| Mechanical Strength | High, due to advanced glass fiber reinforcement | Moderate | Ensures durability in multilayer PCBs and harsh conditions. |

| Temperature Stability | Excellent (up to 220°C Tg) | Moderate (up to 130°C Tg) | Necessary for lead-free soldering and high thermal environments. |

1.Signal Integrity-

TUC TU-872 SLK SP’s low Dk and Df are core factors that help maintain signal integrity in high-speed digital and RF applications. Whether it’s for communication systems, radar, or automotive electronics, TUC TU-872 SLK SP ensures the signal quality remains stable throughout the transmission, reducing the risk of interference or data loss.

2.Thermal Reliability and Lead-Free Compatibility-

TUC TU-872 SLK SP’s impressive thermal reliability and compatibility with lead-free soldering processes make it a standout choice in today’s eco-conscious manufacturing environment. As the industry moves toward RoHS-compliant production, this laminate ensures that modern PCBs can meet lead-free standards without compromising on performance or durability. With TUC TU-872 SLK SP, you’re getting a material that not only aligns with sustainability goals but also delivers dependable, top-tier quality for the long haul.

Example: When assembling PCBs for 5G base stations or other infrastructure that requires lead-free solder, TUC TU-872 SLK SP ensures your boards will perform reliably in the field, under extreme conditions, without warping or thermal stress.

3.Reduced Risk of Failure-

CAF resistance is another standout feature of TUC TU-872 SLK SP. CAF (Conductive Anodic Filament) failure can lead to shorts between PCB layers, and it’s an issue that has historically plagued many high-performance PCBs. With TUC TU-872 SLK SP, this risk is significantly reduced, ensuring longer-lasting and more durable PCBs.

4.Customization and Versatility-

One of the great advantages of TUC TU-872 SLK SP is its ability to be tailored to specific application needs. Whether you’re designing a multilayer PCB or a flexible PCB, this laminate can be customized to meet unique electrical, thermal, and mechanical specifications. This versatility allows manufacturers to meet a wide range of demands across various sectors.

Example: Manufacturers in medical electronics can use TUC TU-872 SLK SP to design compact, high-density boards that fit within small enclosures, all while maintaining the reliability required for life-saving devices.

Material Composition and Core Properties of TUC TU-872 SLK SP PCB Laminates

When you’re designing a printed circuit board, the material you use is everything. It directly impacts performance, reliability, and even longevity of the finished product. The TUC TU-872 SLK SP PCB laminates offer high-performance features that make them an ideal choice for advanced, high-frequency electronic applications. These laminates are built from a unique blend of modified epoxy resin FR-4 and advanced glass fiber cloth—each material selected with precision to achieve the best balance of electrical, mechanical, and thermal properties.

Let’s break down how TUC TU-872 SLK SP sets itself apart from the competition. In this section, we’ll look into its dielectric properties, how the glass fiber integration enhances its toughness, and the laminate’s built-in anti-CAF capability, which increases its reliability over time.

Dielectric Properties of TUC TU-872 SLK SP PCB Laminates

One of the first things to know about TUC TU-872 SLK SP is that it has an excellent set of dielectric properties that make it ideal for high-speed, high-frequency applications. Dielectric constant (Dk) and dissipation factor (Df) are the two factors in determining how well a material performs in high-speed signal transmission.

| Property | TUC TU-872 SLK SP | Standard FR-4 | Implications for Use |

| Dielectric Constant (Dk) | 3.0-3.2 | 4.0-4.5 | Low Dk ensures minimal signal loss, crucial for high-speed applications. |

| Dissipation Factor (Df) | 0.002-0.004 | 0.015-0.030 | Low Df allows for efficient signal transmission with reduced heat generation. |

Why does this matter-

The low dielectric constant (Dk) and low dissipation factor (Df) of TUC TU-872 SLK SP ensure quicker, more dependable signal transmission. This is particularly beneficial for high-demand technologies like 5G, radar systems, and advanced communication devices, where minimizing signal degradation and heat is a top priority. With its efficient Dk/Df characteristics, TUC TU-872 SLK SP helps maintain crisp, reliable signals and reduces unnecessary energy consumption, delivering a boost in performance while keeping power usage in check.

Let’s look at this practically: When you’re building a high-frequency RF system for telecommunications, keeping your signals sharp over long distances or during data transfer is a must. TUC TU-872 SLK SP’s low Dk/Df comes through by helping signals stay consistent and travel without losing strength or clarity. This means your system can perform better, even when dealing with heavy data loads or long-range transmissions, boosting reliability across the board. It’s all about delivering high-quality, uninterrupted performance—no compromises.

Advanced Glass Fiber Cloth Integration

The performance of a PCB isn’t just about the electrical properties—it’s also about how well the material holds up physically. The advanced glass fiber cloth integrated into TUC TU-872 SLK SP serves as the secret weapon for increasing both mechanical toughness and dimensional stability.

Here’s the kicker: When you’re designing high-density PCBs that need to withstand mechanical stresses and temperature fluctuations, you want a laminate that can take the heat—literally. Glass fiber helps to ensure that your PCB doesn’t warp, twist, or deform under high thermal or mechanical pressure.

| Property | TUC TU-872 SLK SP | Standard FR-4 | Implications for Use |

| Glass Fiber Reinforcement | Advanced integration | Standard integration | Provides higher mechanical strength, reducing the likelihood of PCB failure under thermal or physical stress. |

| Thermal Expansion (CTE) | 40-50 ppm/°C | 50-70 ppm/°C | Lower CTE minimizes dimensional changes with temperature fluctuations, providing better long-term reliability. |

What does this mean for your applications? Well, if you’re designing for automotive electronics, where temperature changes are frequent, or aerospace electronics, where both mechanical strength and precision are essential, the glass fiber cloth in TUC TU-872 SLK SP ensures the laminate will stay true to its original dimensions, regardless of the conditions it faces.

Example: Think about a PCB inside an electric vehicle that needs to endure both high temperatures and mechanical vibrations. The TUC TU-872 SLK SP PCB laminate, with its enhanced glass fiber structure, keeps your board intact and free from physical failures, even under challenging circumstances.

Anti-CAF Capability for Long-Term Reliability

In the PCB world, CAF (Conductive Anodic Filament) failure is a sneaky issue that can sneak up and cause significant problems if not addressed. TUC TU-872 SLK SP laminates come with built-in anti-CAF protection, shielding your PCBs from this hidden danger. This extra layer of defense helps ensure your designs last longer, work more reliably, and avoid costly failures down the road. By reducing the risk of CAF, you’re ensuring a more durable and stable performance over time.

What’s CAF, and why does it matter-

CAF is a phenomenon where the conductive material inside the PCB can form tiny, but dangerously conductive filaments between the PCB layers due to high humidity or voltage. Over time, these filaments can lead to short circuits and cause failure in the device. With TUC TU-872 SLK SP, the material is designed to resist this issue, providing a long-term reliable performance even in harsh environments.

| Property | TUC TU-872 SLK SP | Standard FR-4 | Implications for Use |

| CAF Resistance | Excellent | Moderate | Reduces the risk of conductive anodic filament formation, ensuring better reliability over time. |

Technical Performance Benchmarks of TUC TU-872 SLK SP PCB Laminates

When it comes to PCB laminates, performance is everything. As electronic systems demand faster speeds, greater signal integrity, and enhanced thermal stability, TUC TU-872 SLK SP PCB laminates have set a new standard for high-performance applications. With their optimized dielectric properties, exceptional thermal reliability, and resistance to harsh environmental conditions, these laminates are becoming the go-to choice for cutting-edge designs.

Thermal Reliability in Extreme Conditions

When it comes to PCB manufacturing, one of the toughest challenges is ensuring thermal stability. As electronic devices continue to become more powerful and compact, heat dissipation becomes an even more pressing concern. Thankfully, TUC TU-872 SLK SP is engineered to excel in extreme thermal environments, providing superior thermal reliability and long-term stability under high temperatures.

In demanding applications like automotive electronics, 5G systems, and aerospace technologies, where heat can cause warping, delamination, and performance degradation, TUC TU-872 SLK SP maintains its structural integrity. Thanks to its advanced resin formulation and glass fiber integration, it remains highly stable even under high thermal stress.

| Feature | Standard PCBs | TUC TU-872 SLK SP | Impact on High-Temperature Applications |

| Thermal Stability | Prone to warping and delamination | Exceptional thermal reliability | Ensures long-term operational stability |

| Glass Transition Temperature (Tg) | Typically < 170°C | High (>180°C) | Maintains structural integrity at high temperatures |

| Coefficient of Thermal Expansion (CTE) | High CTE can cause delamination | Low CTE | Reduces thermal stress and minimizes failure rates |

Chemical Resistance and Durability

PCB laminates need to endure a variety of environmental factors that can degrade their performance over time. From chemical exposure to moisture, TUC TU-872 SLK SP has been engineered to offer superior chemical resistance and long-term durability, making it the perfect solution for industrial and commercial applications.

Therefor, whether you’re designing automotive PCBs, medical devices, or industrial control systems, the laminate’s resistance to chemicals like solvents, oils, and acids ensures that it can withstand harsh working conditions without compromising its mechanical properties.

| Feature | Standard PCBs | TUC TU-872 SLK SP | Impact on Chemical Exposure |

| Chemical Resistance | Susceptible to degradation | High resistance to solvents, oils, acids | Ensures long-lasting durability in harsh environments |

| Moisture Absorption | High moisture absorption | Very low moisture uptake | Prevents delamination and circuit failure |

| Corrosion Resistance | Vulnerable to corrosion | Resistant to corrosive agents | Ensures consistent performance over time |

TUC TU-872 SLK SP doesn’t just handle the normal wear-and-tear; it’s built for extreme durability in industries where chemical exposure and environmental stresses are inevitable.

Comparing TUC TU-872 SLK SP PCB Laminates with Other TUC Materials

Choosing the right PCB laminate directly impacts how well your design performs, stays cost-effective, and holds up over time. TUC TU-872 SLK SP offers distinct electrical and mechanical features, setting it apart from other materials in the TUC lineup. Comparing it to options like TU-872 LK and TU-872 SLK reveals the subtle differences that matter most for high-performance applications. Let’s dig into these comparisons to help you find the perfect match for your next project, ensuring a smart, well-informed choice for your design needs.

In this section, we will delve into the differences between TU-872 LK, TU-872 SLK, and TU-872 SLK SP, and highlight why TUC TU-872 SLK SP is often the go-to material for cutting-edge designs that demand the best in signal integrity, thermal stability, and overall reliability.

Differences Between TU-872 LK, TU-872 SLK, and TU-872 SLK SP

Let’s break down how TUC TU-872 SLK SP stacks up against its counterparts. These PCB laminates from the TUC series offer a variety of unique advantages depending on the specific needs of your application. Here’s how TU-872 LK, TU-872 SLK, and TU-872 SLK SP compare in terms of key properties such as dielectric constants, dissipation factors, and application-specific advantages.

| Property | TU-872 LK | TU-872 SLK | TU-872 SLK SP | Benefits for High-Performance Applications |

| Dielectric Constant (Dk) | 3.5-3.7 | 3.2-3.5 | 3.0-3.2 | Lower Dk in TU-872 SLK SP improves signal transmission and reduces signal loss. |

| Dissipation Factor (Df) | 0.010-0.020 | 0.008-0.018 | 0.002-0.004 | TU-872 SLK SP has a significantly lower Df, leading to better signal fidelity in high-speed operations. |

| Thermal Conductivity | 0.30 W/m·K | 0.32 W/m·K | 0.30 W/m·K | Thermal performance is consistent across the range, providing stability for high-frequency circuits. |

| Glass Fiber Content | 235 gsm | 245 gsm | 260 gsm | Higher glass fiber content in TU-872 SLK SP offers improved mechanical toughness and dimensional stability. |

As you can see, TUC TU-872 SLK SP offers exceptional performance for high-speed digital circuits, with a lower dielectric constant and dissipation factor compared to its counterparts. This makes it particularly suitable for applications that require low-loss characteristics and high-frequency performance, such as telecommunications and data processing systems.

Why Choose TUC TU-872 SLK SP for High-Performance Applications?

When designing for high-performance applications, balancing cost, reliability, and signal performance is a delicate act. TUC TU-872 SLK SP PCB laminates provide an ideal combination of these attributes.

●Cost-Efficiency: While TUC TU-872 SLK SP offers top-tier performance, its cost remains competitive, making it a reliable option for manufacturers who need high-quality materials without overspending.

●Signal Performance: The low dielectric constant (Dk) and low dissipation factor (Df) of TU-872 SLK SP ensure minimal signal degradation during high-frequency operations.

●Reliability: TUC TU-872 SLK SP is designed to withstand extreme conditions, offering excellent thermal stability and mechanical strength.

| Property | TU-872 SLK SP | Standard Materials | Advantages for High-Performance Designs |

| Thermal Expansion | 30-50 ppm/°C | 60-80 ppm/°C | Low CTE ensures better layer-to-layer bonding in multilayer designs. |

| Mechanical Strength | High Flexural Strength | Moderate | Stronger materials resist warping and delamination during high-temperature operations. |

| Environmental Compatibility | Lead-Free Compatible | Lead-Based Options | TU-872 SLK SP offers lead-free compatibility, meeting modern environmental standards. |

TUC TU-872 SLK SP offers the perfect balance of cost, reliability, and signal performance, making it an ideal choice for next-generation high-performance systems.

Application Scenarios for TUC TU-872 SLK SP PCB Laminates

Identifying the industries and applications where TUC TU-872 SLK SP truly excels can help guide your material selection process. This laminate is tailored for environments demanding robust performance, including high-speed circuits, next-generation communication networks, and high-frequency electronic systems. Its advanced composition ensures it can handle the heat—both literally and figuratively—making it an excellent choice for projects where precision, efficiency, and durability are non-negotiable.

Here are some of the most prominent application scenarios where TUC TU-872 SLK SP PCB laminates truly shine:

| Industry | Key Application | Why TUC TU-872 SLK SP Works |

| Telecommunications | 5G Antenna and Network Designs | Low Dk/Df ensures strong signal transmission in high-frequency circuits. |

| Automotive Electronics | Advanced Control Systems | Excellent thermal conductivity ensures reliable operation in extreme environments. |

| Aerospace and Defense | Radar and Navigation Systems | High mechanical strength and dimensional stability make it ideal for harsh conditions. |

| Consumer Electronics | High-Speed Consumer Devices | Ensures low-loss and reliable signal transmission for high-performance electronics. |

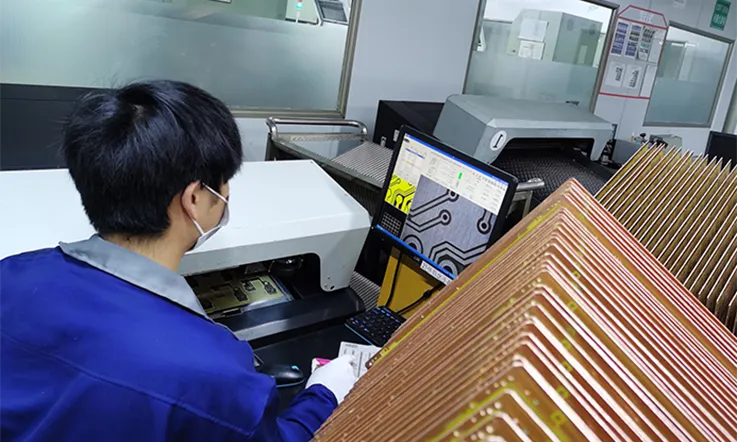

Enhancing Manufacturing Efficiency with TUC TU-872 SLK SP PCB Laminates

In the world of PCB manufacturing, streamlining production processes is just as important as ensuring high-quality end products. TUC TU-872 SLK SP PCB laminates provide an excellent balance between performance and manufacturability, making them an outstanding choice for companies looking to optimize their workflows. With the ability to integrate seamlessly into existing FR-4 processes, deliver cost-effective high-performance solutions, and withstand the thermal stresses of manufacturing, TUC TU-872 SLK SP has become a go-to material for many in the industry.

Let’s take a closer look at how this material boosts efficiency across the manufacturing process.

Compatibility with FR-4 Processes

One of the standout features of TUC TU-872 SLK SP is its ability to integrate smoothly into traditional FR-4-based manufacturing processes. This is a huge benefit for manufacturers who want to make the switch to high-performance PCB laminates without needing to overhaul their existing equipment or workflows.

FR-4 (Flame Retardant 4) is the most widely used PCB material due to its cost-effectiveness and versatility. Many manufacturers are already familiar with its processing methods, which makes introducing TUC TU-872 SLK SP to their workflow an easy transition. Here’s why TUC TU-872 SLK SP works so well with FR-4 processes:

| Property | FR-4 Process Compatibility | TUC TU-872 SLK SP Compatibility |

| Temperature Resistance | Can handle standard processing temps | Excellent stability at higher processing temperatures |

| Mechanical Workability | Standard cutting and drilling methods | No extra steps required for shaping or cutting |

| Pre-preg Laminate Handling | Typical epoxy resin handling | Seamlessly integrates with FR-4 prepregs for multi-layer boards |

| Curing Time | Standard curing time | Comparable curing times with FR-4 materials |

This compatibility ensures TUC TU-872 SLK SP can be used for multilayer PCBs, high-frequency boards, and complex circuit designs without adding complexity or extra steps to the manufacturing process. we can maintain the same efficiency while reaping the benefits of advanced materials.

Cost-Effective High-Performance Solutions

Finding ways to trim costs without compromising on quality or performance is a constant challenge in any design process. TUC TU-872 SLK SP strikes a sweet spot by offering a well-balanced mix of affordability and top-tier capabilities. This material proves to be a smart pick for high-performance applications that demand both reliability and budget-friendly solutions. It’s like getting champagne performance on a beer budget—ideal for those who want to deliver exceptional results while keeping an eye on the bottom line.

By switching to TUC TU-872 SLK SP, we can achieve high-speed signal integrity and low-loss characteristics, without the premium cost associated with some other high-performance PCB laminates. The laminate offers reliable performance over time, even in demanding environments, which reduces the need for costly rework or replacement.

| Feature | FR-4 | TUC TU-872 SLK SP | Cost Benefits |

| Signal Integrity | Good, but limited at higher frequencies | Excellent for high-speed circuits | Reduces need for signal boosting, saving on components |

| Thermal Stability | Can be prone to thermal fatigue | Excellent thermal stability | Reduces failure rates in extreme environments |

| Production Efficiency | Standard PCB manufacturing | No additional steps required | Lower production costs due to no need for extra processing |

| Material Cost | Low to moderate | Competitive with standard options | Offers high performance at a lower cost |

All in all, TUC TU-872 SLK SP offers the performance boost you need for high-frequency and high-speed applications without driving up the production costs. It’s a win-win for manufacturers looking to balance budget and performance.

Thermal Stability During Manufacturing

Thermal stability is a consideration in PCB manufacturing. With the demands of modern electronics, PCBs are often exposed to extreme temperatures during both the manufacturing process and throughout their operational life. TUC TU-872 SLK SP performs exceptionally well under thermal stress, ensuring that your PCB manufacturing remains smooth and your designs are thermally stable.

High temperatures during lamination, drilling, and soldering can lead to warping, delamination, or layer misalignment. With TUC TU-872 SLK SP, you can expect consistent quality and robust performance, even under high-temperature conditions.

| Property | FR-4 | TUC TU-872 SLK SP | Thermal Benefits |

| Coefficient of Thermal Expansion (CTE) | Higher (around 50-80 ppm/°C) | Lower (30-50 ppm/°C) | Ensures better dimensional stability under thermal cycling |

| Thermal Conductivity | 0.30 W/m·K | 0.35 W/m·K | Helps to dissipate heat more efficiently, preventing thermal damage |

| Thermal Fatigue Resistance | Moderate | High | Reduces the risk of delamination or warping during high-temperature processes |

By reducing the risks associated with thermal cycling and ensuring that TUC TU-872 SLK SP maintains its integrity through high temperatures, we benefit from higher yields and fewer rejected boards. This enhances overall manufacturing efficiency and minimizes the need for rework or rejection rates.

Why High-Speed Digital Applications use TUC TU-872 SLK SP PCB Laminates?

As the demand for high-speed digital devices continues to soar, the need for PCBs that can support faster data rates without compromising reliability has never been greater. TUC TU-872 SLK SP PCB laminates meet this demand by providing exceptional performance for high-speed digital circuits, offering critical properties such as low signal loss, enhanced signal integrity, and thermal management. Whether you’re designing telecommunications systems, data processing units, or high-frequency components, TUC TU-872 SLK SP is engineered to perform in the most challenging digital environments.

In this section, we’ll explore how TUC TU-872 SLK SP PCB laminates excel in supporting signal integrity, minimizing energy loss during high-frequency operations, and ensuring compatibility with multilayer PCB manufacturing for scalable and efficient designs.

Signal Integrity in High-Speed Circuits

In high-speed circuits, maintaining signal integrity is the top priority. As signals travel through a PCB, they are subjected to various physical challenges that can cause degradation, including reflection, crosstalk, and attenuation. TUC TU-872 SLK SP laminates stand out for their ability to minimize these issues, ensuring that the transmitted signal remains strong and clear, even at high frequencies.

Therefore, the ability of TUC TU-872 SLK SP PCB laminates to provide superior signal integrity translates into better performance and reliability for applications such as 5G communications, satellite technology, and high-speed computing. With minimized signal degradation, these laminates ensure that high-speed circuits can operate at their full potential without interference or data loss.

Low-Loss Characteristics of TUC TU-872 SLK SP PCB Laminates

For high-frequency applications, keeping energy loss to a bare minimum is non-negotiable. TUC TU-872 SLK SP PCB laminates are crafted to deliver exceptionally low dielectric loss, making them a top-tier choice for designs where every watt and signal matters. Whether it’s powering telecommunications systems, managing data transfers, or operating radar equipment, this low-loss feature ensures your signals stay sharp and your energy use stays efficient. It’s like running a marathon with the lightest sneakers—optimized for peak performance without weighing you down.

| Property | TUC TU-872 SLK SP | Standard FR-4 | Benefits for High-Frequency Operations |

| Dissipation Factor (Df) | 0.002-0.004 | 0.015-0.030 | Low Df ensures that less energy is lost in the form of heat, allowing for more efficient data transmission. |

| Thermal Conductivity | 0.30 W/m·K | 0.25 W/m·K | Enhanced thermal conductivity prevents overheating, ensuring stable operation during high-frequency operations. |

| Insertion Loss | Low | High | Lower insertion loss improves overall circuit efficiency, ensuring minimal signal degradation over distance. |

With TUC TU-872 SLK SP, the lower Df ensures that the board can handle high-speed data transmission with fewer losses, ensuring your high-frequency systems run with optimal performance and minimal heat generation.

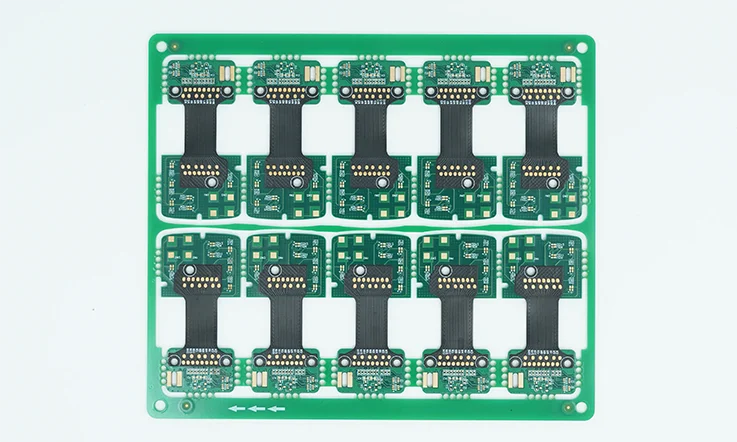

Compatibility with Multilayer PCB Manufacturing

When working with multilayer PCB designs, choosing a laminate that blends seamlessly with stacked layers while efficiently managing heat is a smart move. TUC TU-872 SLK SP laminates are crafted to handle the demands of intricate multilayer configurations. Their superior heat dissipation and mechanical stability ensure your boards perform consistently, even under challenging conditions.

| Property | TUC TU-872 SLK SP | Standard FR-4 | Advantages for Multilayer PCBs |

| Thermal Coefficient of Expansion (CTE) | 40-50 ppm/°C | 50-70 ppm/°C | A lower CTE helps reduce warping or stress in multilayer PCBs, ensuring better interlayer connectivity and reliability. |

| Thermal Conductivity | 0.30 W/m·K | 0.25 W/m·K | Higher thermal conductivity aids in the efficient dissipation of heat across multiple layers, preventing overheating. |

| Flexural Strength | 220 MPa | 180 MPa | Stronger materials contribute to enhanced mechanical performance and durability, reducing the likelihood of warping during the manufacturing process. |

The compatibility of TUC TU-872 SLK SP with multilayer PCB manufacturing allows for scalable designs that do not compromise on thermal performance or mechanical strength. This is particularly valuable in industries like automotive, aviation, and consumer electronics, where multilayer PCBs are often required to handle complex and high-power designs.

Innovations in High-Speed PCB Design with TUC TU-872 SLK SP PCB Laminates

As we venture into the future of high-speed PCB design, the demand for high-performance laminates that can handle emerging technologies is growing rapidly. TUC TU-872 SLK SP PCB laminates stand at the forefront of this trend, offering solutions that align with both the technological shifts in electronics and the specific demands of modern, high-speed digital circuits.

These laminates aren’t just about enhancing speed; they enable PCB manufacturers to produce boards that meet the growing challenges of increased frequency and higher bandwidth. Let’s dive into how TUC TU-872 SLK SP is shaping the future of high-speed circuit design.

Future Trends in High-Speed Digital Circuits

The world of high-speed digital circuits is on the fast track, pushing the boundaries of both signal processing and data transmission. TUC TU-872 SLK SP PCB laminates are engineered to meet the growing demands of advanced telecommunications, high-frequency systems, and data centers. As IoT devices, 5G networks, and AI-powered technologies continue to gain momentum, the need for PCBs that can support these technologies will only increase.

TUC TU-872 SLK SP is engineered to meet the demands of modern PCB designs, offering low-loss properties, high-speed signal integrity, and thermal stability. These attributes support circuits handling gigabit-level speeds and advanced communication systems. Whether you’re working with high-speed data transmission or next-generation wireless technologies, this material helps keep your designs efficient and dependable, ensuring smooth performance in complex applications.

| Feature | Traditional PCBs | TUC TU-872 SLK SP | Implication for High-Speed Designs |

| Dielectric Constant (Dk) | Higher (usually around 4.5) | Low (around 3.3) | Minimizes signal loss, enabling higher data rates |

| Dissipation Factor (Df) | Higher (up to 0.02) | Low (typically 0.004) | Lowers signal attenuation during high-speed operation |

| Thermal Stability | Limited at high temperatures | Excellent thermal management | Ensures reliable operation under extreme conditions |

As digital circuits continue to push into faster and more complex domains, TUC TU-872 SLK SP is designed to support these future-forward technologies by offering better thermal handling and low-loss signal integrity that keep speed up and signal distortion down.

Advancements in High-Frequency PCB Applications

In the high-frequency PCB applications, TUC TU-872 SLK SP takes the lead in offering unmatched performance for systems operating at microwave frequencies and beyond. With the increasing demand for multi-gigabit communication, 5G infrastructure, and broadband satellites, traditional PCB materials often fall short in supporting these applications.

TUC TU-872 SLK SP brings several advancements that make it a go-to material for high-frequency applications:

●Low Dielectric Constant (Dk)

●Low Dissipation Factor (Df)

●Improved Impedance Control

| Feature | Standard PCB Materials | TUC TU-872 SLK SP | Impact on High-Frequency Systems |

| Dielectric Constant (Dk) | Higher (4.2 – 5.0) | Low (3.3) | Improves signal transmission for high-frequency circuits |

| Dissipation Factor (Df) | Higher (0.01 – 0.03) | Low (0.004) | Reduces signal attenuation during long-distance transmission |

| Impedance Control | Standard, with limited control | Tight impedance control | Ensures stable performance at high frequencies |

With TUC TU-872 SLK SP, you can support new frequencies and expanded bandwidths, ensuring that the circuit’s performance remains stable and reliable even as the demands on the design increase.

Signal Integrity Challenges and Solutions

When it comes to signal integrity in high-speed PCB designs, there are several challenges to overcome, such as signal loss, reflection, and cross-talk. These issues are particularly pronounced in high-frequency circuits, where even minor imperfections can compromise performance.

Here’s where TUC TU-872 SLK SP shines—by offering low-loss characteristics and superior thermal stability, this material helps reduce the challenges often encountered in high-speed signal integrity.

1.Minimized Signal Loss: With a low Dk and Df, TUC TU-872 SLK SP ensures that signals travel efficiently with minimal loss, making it ideal for high-speed digital designs.

2.Reduced Cross-Talk: The material’s high-quality glass fiber integration helps to minimize unwanted interactions between signal traces, enhancing overall signal fidelity.

3.Thermal Management: The advanced thermal properties of TUC TU-872 SLK SP reduce heat build-up, which can otherwise lead to signal degradation or circuit failure.

| Challenge | Standard PCBs | TUC TU-872 SLK SP | Solution for High-Speed Designs |

| Signal Loss | High due to high Dk/Df | Low due to optimized Dk/Df | Reduces signal attenuation over long distances |

| Cross-Talk | Likely in high-density designs | Minimized with advanced fiber integration | Ensures clearer signal transmission |

| Thermal Stress | Poor heat dissipation | Excellent thermal management | Prevents signal degradation due to excessive heat |

FAQs & TUC TU-872 SLK SP PCB Laminates

1. How does TUC TU-872 SLK SP improve signal integrity?

Its low dissipation factor (Df) and optimized dielectric properties help minimize signal loss, ensuring better signal integrity in high-frequency circuits.

2. Can TUC TU-872 SLK SP be used for multilayer PCB manufacturing?

Yes, TUC TU-872 SLK SP is highly compatible with multilayer PCB processes, ensuring efficient stacking and superior thermal management.

3. Does TUC TU-872 SLK SP offer thermal stability?

Yes, it provides excellent thermal stability, resisting warping and delamination under high-temperature conditions, ensuring durability over time.

4. How does TUC TU-872 SLK SP reduce the risk of CAF?

Its unique material properties help reduce conductive anodic filament (CAF) formation, which enhances long-term reliability in high-density circuits.

5. What is the cost-effectiveness of TUC TU-872 SLK SP compared to other laminates?

While offering high-performance capabilities, TUC TU-872 SLK SP balances cost-efficiency with reliability, making it a great value for manufacturers looking for quality without compromising performance.

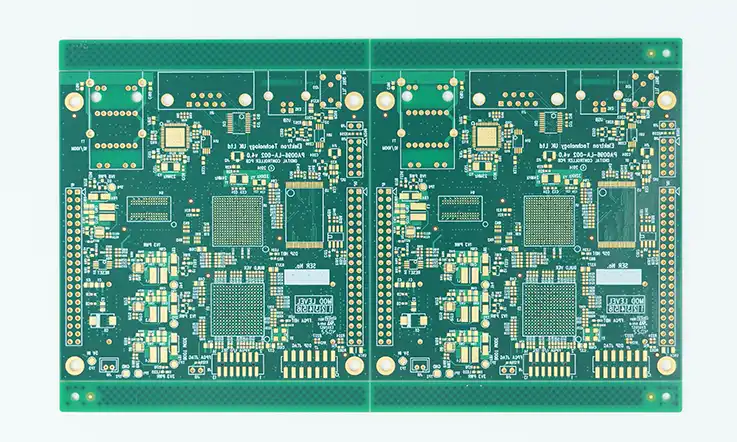

Why Choose Us for Manufacturing TUC PCBs with TU-872 SLK SP PCB Laminates?

At JarnisTech, we know that the performance, longevity, and consistency of your printed circuit boards play a huge role in the success of your projects.. That’s why we use TUC TU-872 SLK SP PCB laminates—a material engineered to meet the evolving demands of today’s high-speed, high-frequency applications. With its exceptional dielectric properties, thermal stability, and chemical resistance, TU-872 SLK SP provides a solid foundation for delivering top-tier PCBs that excel in even the most challenging environments.

Here’s why choosing us for your PCB manufacturing needs will elevate your product designs and help you stay ahead of the curve:

1. Advanced Material Selection for Superior Performance

When designing high-performance PCBs, TUC TU-872 SLK SP stands out by offering a low dielectric constant (Dk) and dissipation factor (Df). These features help ensure signal integrity in high-speed applications like 5G communications, telecommunications, and data processing. By opting for this advanced material, you can count on faster signal transmission, reduced signal loss, and better overall performance. It’s a great choice for systems that demand precision and reliability, ensuring your designs meet the high standards of modern technology. Our commitment to using this cutting-edge material ensures that your designs benefit from faster signal transmission, lower signal loss, and better overall performance.

Additionally, with its thermal reliability and resistance to extreme temperatures, TU-872 SLK SP outperforms traditional laminates in applications that experience high thermal stress, such as automotive electronics, medical devices, and aerospace technologies. Our team is equipped to leverage these unique features to manufacture PCBs that offer long-term stability under even the harshest conditions.

2. Expertise in High-Frequency and High-Speed Applications

With the rise of IoT, 5G, and high-frequency RF circuits, choosing the right materials for your PCB designs is a must. TUC TU-872 SLK SP is designed to support high-frequency applications by offering a low-loss, high-speed platform for seamless signal transmission. Its low Dk ensures minimal signal drop, making it perfect for high-precision and high-speed systems in sectors like telecommunications, data centers, and military tech. If you’re aiming for top-notch performance in fast-paced industries, TU-872 SLK SP delivers the goods, keeping your designs sharp and on track for success.

By choosing us, you gain access to a team of experts, we understand how to best utilize TU-872 SLK SP to deliver PCBs that maintain signal integrity while offering high-frequency stability. Whether your application involves 5G infrastructure, microwave communication, or high-speed digital circuits, we ensure your PCBs can perform at their peak.

3. Unmatched Durability and Reliability

In industries like automotive, medical, and industrial control, durability is non-negotiable. TUC TU-872 SLK SP provides outstanding chemical resistance, making it an excellent choice for PCBs that are exposed to moisture, solvents, oils, and harsh chemicals. With minimal moisture absorption and exceptional corrosion resistance, our PCBs continue to deliver long-lasting performance, even in the most demanding environments.

Furthermore, TUC TU-872 SLK SP offers superior thermal stability, resisting warping and delamination even in extreme temperature conditions. Whether you’re working with automotive electronics that need to withstand high-heat environments or medical devices that demand constant reliability, our PCBs will continue to function flawlessly over time.

4. Cost-Effective Solutions Without Compromising Quality

While high-performance materials like TUC TU-872 SLK SP offer superior advantages, we believe in delivering these top-tier benefits without breaking your budget. At JarnisTech, we optimize manufacturing processes to provide cost-effective solutions that don’t sacrifice quality. By working closely with you to understand the specifics of your project, we offer the perfect balance between performance and cost-efficiency.

5. Seamless Integration and Manufacturing Expertise

We specialize in FR-4 processes, making it easy to integrate TUC TU-872 SLK SP laminates into your existing workflows. From single-layer to multilayer PCB manufacturing, our team ensures that the transition to high-performance materials is smooth and hassle-free. Thanks to our advanced manufacturing capabilities, we can create custom PCBs that align with your unique specifications and standards, all while maintaining high-quality control throughout the process.

Let Us Power Your Next Project

By choosing JarnisTech, we not only understands the complexities of PCB manufacturing but also has the expertise to push the boundaries of what’s possible with materials like TUC TU-872 SLK SP. Whether your project requires high-speed digital circuits, high-frequency signal transmission, or extreme environmental resilience, we’re here to provide the reliable, high-performance PCBs that will meet and exceed your expectations.

Are you ready to take your PCB designs to the next level? Contact us today and discover how we can help you create cutting-edge solutions with TUC TU-872 SLK SP PCB laminates!

Our services

TUC PCB Laminate & Materials Series