PCBs are essential components used in electronic devices to provide mechanical support and electrical connections between various components. While traditional PCBs are commonly made of fiberglass or other materials, single-sided aluminum PCBs have gained popularity due to their excellent thermal conductivity and cost-effective manufacturing process.

In this article, we will explore the structure and design considerations of single-sided aluminum PCBs. We will delve into the manufacturing process, highlighting the steps involved in creating these PCBs, such as substrate preparation, copper trace application, etching, drilling, and surface finishing. Furthermore, we will discuss the advantages and applications of single-sided aluminum PCBs, including their improved heat dissipation properties and their relevance in various industries.

Definition of Single Sided Aluminum PCB

Single-sided aluminum PCBs are a type of metal-core printed circuit board that have a conductive layer only on one side. The base material is aluminum, which provides excellent heat dissipation properties.

The structure of a single-sided aluminum PCB consists of a single layer of aluminum as the substrate material, with a thin layer of copper traces applied to one side. This single-layer design simplifies the manufacturing process and reduces production costs compared to multi-layer or double-sided PCBs. Additionally, the use of aluminum as the substrate provides superior thermal management capabilities, making single-sided aluminum PCBs especially suitable for applications where heat dissipation is crucial.

Properties and Characteristics

Here are some of the characteristics of single-sided aluminum PCBs:

Composition: They consist of three layers – the base layer (aluminum), the dielectric layer (insulating material), and the circuit layer (copper).

Thermal Conductivity: Due to the aluminum base, these PCBs offer better thermal conductivity compared to traditional FR-4 PCBs, which can be crucial in high-power and high-temperature applications.

Mechanical Rigidity: They have a high level of mechanical durability and stability.

Lightweight: Despite their durability, aluminum PCBs are relatively lightweight, which can be advantageous in many applications.

Cost-Effective: Single-sided aluminum PCBs are generally more cost-effective to manufacture than double-sided or multi-layered PCBs.

Advantages of Single-sided Aluminum PCBs

Below are some advantages of single-sided aluminum PCBs:

Improved Heat Dissipation: Aluminum has good thermal conductivity, so these PCBs are excellent at dissipating heat, which can prolong the life of the circuit components.

High Mechanical Strength: They have high mechanical strength making them suitable for rugged applications.

Cost-Effective: They are less expensive to produce compared to multi-layered or double-sided PCBs.

Environmentally Friendly: Aluminum is recyclable, making these PCBs more environmentally friendly than some alternatives.

Applications of Single Layer Aluminum Circuit Board

Single-sided aluminum PCBs are used in a variety of applications where efficient heat dissipation and cost-effectiveness are important. Some examples include:

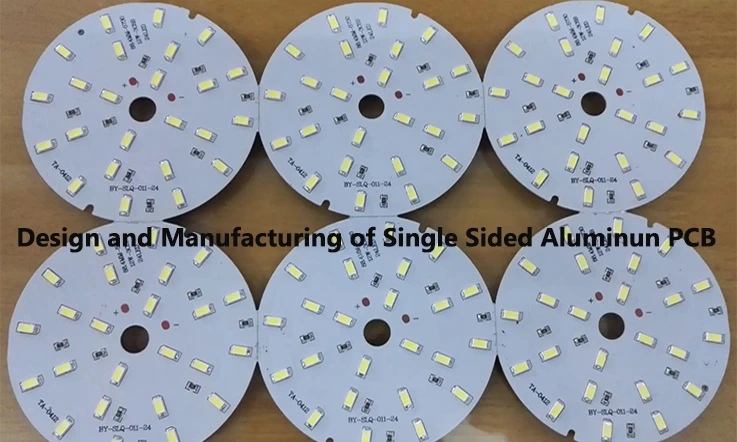

LED Lighting: High-power LED applications often use single-sided aluminum PCBs due to their ability to dissipate heat effectively.

Power Supplies: These PCBs are commonly used in power supply products due to their thermal characteristics and mechanical rigidity.

Automotive Systems: In automotive electronics, where heat dissipation and durability are crucial, these PCBs are often used.

Consumer Electronics: They’re also used in various consumer electronics like power amplifiers, electronic switchgear, and audio equipment.

Computing & Storage Devices: In computers and storage devices, aluminum PCBs are often used to manage heat generated by high-speed, high-power components.

All in All, single-sided aluminum PCBs offer a host of advantages, particularly in applications where heat management and durability are key considerations.

What are the Limitations of Single-sided Aluminum Substrate?

Here are some of the main limitations and challenges with using single-sided aluminum substrates for PCBs:

Lower conductivity

Aluminum has about 60% the conductivity of copper, which means wider traces are needed to carry the same amount of current. This can limit trace density and routing options.

More prone to oxidation

Aluminum oxidizes readily compared to copper which can degrade performance over time. Special coatings or preparations are needed.

CTE mismatch

The coefficient of thermal expansion differs between aluminum and common PCB substrates like FR4, which can induce mechanical stresses and reliability issues.

Limited component options

Not all leaded or SMD components are readily available or rated for direct attachment to aluminum boards. Special packaging or isolators may be needed.

Soldering challenges

The high thermal conductivity of aluminum can make soldering more difficult. Special solders, fluxes or underside heating are often needed.

Via and hole plating issues

It is hard to get reliable plated through holes with aluminum, limiting interconnect options.

Thermal management

While the high thermal conductivity helps, thermal expansion differences compared to chips can still make thermal design difficult.

Component bonding

Adhesives and epoxies may not adhere as well to oxides on aluminum surfaces. Special surface preparations are required.

Supply chain maturity

Aluminum PCB fabrication is still a niche industry segment with fewer capable manufacturers compared to traditional FR4 PCBs.

So in summary, electrical, mechanical, thermal and fabrication factors need to be considered to properly leverage aluminum PCB technology. The applications need to be well matched to aluminum’s unique properties.

Design Considerations of Single-sided Aluminum PCBs

Here are some key design considerations when working with single-sided aluminum PCBs:

Trace Sizing

Aluminum has lower conductivity than copper, so traces need to be designed wider to carry equivalent current. Generally increase trace widths by 60% compared to copper.

Trace Spacing

Increased trace widths mean you need to account for greater spacing to avoid shorts. Higher voltage designs require more spacing as well.

Vias

Plated through holes are challenging with aluminum, so designs should avoid vias or use other connection methods like wire bonding.

Board Layout

Group high current components together to minimize the length of power distribution traces. Use large heat sink pads for power semiconductors.

Thermal Management

Use large thermal pads and thermal vias to dissipate heat. Allow sufficient air flow for cooling. Consider underside cooling options.

Component Selection

Choose components rated for aluminum board mounting. Pay attention to temperature ratings and coefficients of thermal expansion.

Protective Coatings

An insulating solder mask and protective silicone or acrylic coating helps minimize aluminum oxidation over time.

Mechanical Reinforcement

Consider adding a rigid backing layer or metal stiffeners. This helps minimize board flexing which can crack thin aluminum.

Testing and Inspection

Verify electrical connectivity, insulation resistance and dielectric strength during testing. Check for signs of corrosion or flaws in the aluminum layer.

Following Manufacturing Guidelines

Work closely with your board shop and comply with their design rules, capabilities and limitations.

By considering these factors early in the design process, you can help ensure a successful and reliable aluminum printed circuit board design.

Single Sided Aluminum PCB Plate Manufacturing Process

Single-sided aluminum PCBs, also known as metal core PCBs (MCPCBs), are widely used in applications that require efficient heat dissipation, such as LED lighting, power supplies, and automotive electronics. Here is a general overview of the manufacturing process for single-sided aluminum PCB plates:

Design:

Start by designing the PCB layout using a PCB design software. Consider the placement of components, traces, and the heat dissipation requirements.

Substrate Selection:

Choose an aluminum-based substrate for the PCB. Aluminum provides good thermal conductivity and helps dissipate heat efficiently. The thickness of the aluminum substrate depends on the application requirements.

Preparing the Aluminum Substrate:

Clean the aluminum substrate to remove any impurities or contaminants. Then, apply a layer of thermally conductive dielectric material on the aluminum surface. This dielectric layer helps with insulation and provides a smooth surface for the circuitry.

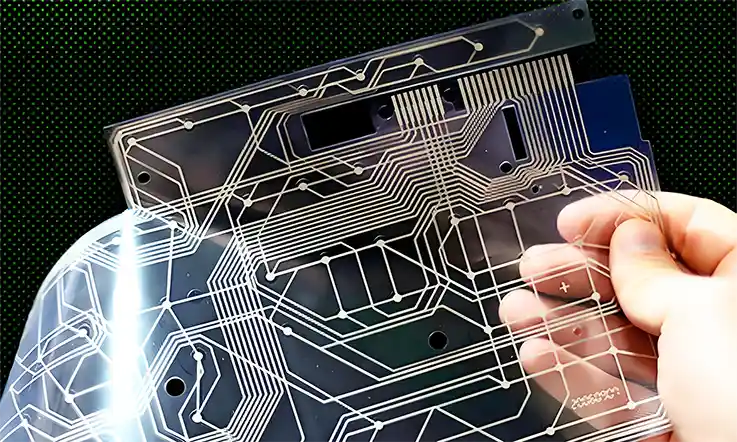

Imaging and Etching:

Apply a photosensitive layer called a photoresist on the dielectric layer. Use a photomask or a photographic negative to expose the photoresist to UV light. The exposed areas become soluble, while the unexposed areas remain insoluble. Develop the photoresist to remove the soluble areas, revealing the underlying dielectric layer.

Copper Cladding:

After imaging and etching, apply a thin layer of copper to the exposed areas of the dielectric layer using a process such as electroless copper plating or sputtering. The copper layer will form the conductive traces and pads of the PCB.

Etching and Stripping:

Remove the remaining photoresist and unwanted copper from the non-conductive areas using an etching solution. This step leaves behind the desired copper traces and pads.

Solder Mask Application:

Apply a solder mask layer to protect the copper traces and pads, except for the areas where soldering is required. The solder mask is typically green, but it can be of different colors.

Silkscreen Printing:

Optionally, add component markings, logos, and other information using silkscreen printing. This step helps with component placement and identification.

Surface Finish:

Apply a surface finish to protect the exposed copper surfaces and prevent oxidation. Common surface finishes for aluminum PCBs include HASL (Hot Air Solder Leveling), OSP (Organic Solderability Preservative), ENIG (Electroless Nickel Immersion Gold), and immersion tin.

Testing and Inspection:

Perform electrical testing and visual inspection to ensure the PCB meets the design specifications and quality standards.

Component Assembly:

Once the single-sided aluminum PCB plates are manufactured, they can be populated with electronic components using standard PCB assembly techniques, such as surface mount technology (SMT) or through-hole technology (THT).

It’s important to note that the actual manufacturing process may vary depending on the specific requirements, equipment, and technologies used by the PCB manufacturer.

Single-sided Aluminum Based Circuit Boards Vs Other PCB Boards

Single-Sided Aluminum Based Circuit Boards and other types of Printed Circuit Boards (PCBs) have several differences, which include their material composition, thermal properties, cost, and usage contexts. Here are some key differences:

Material Composition

Single-Sided Aluminum Based Circuit Boards: These are a type of Metal Core PCB (MCPCB). They have a base metal material as aluminum for the heat spreader portion of the board. They are called single-sided because the conductive copper layer is only on one side of the board.

Other PCBs: These could be made from a variety of materials, including FR-4 (a glass-reinforced epoxy laminate material), polyimide, Rogers, etc. These materials may not have as high thermal conductivity as aluminum.

Thermal Properties

Single-Sided Aluminum Based Circuit Boards: These PCBs are designed for their superior ability to dissipate heat. Aluminum can transfer heat away from critical board components and therefore, is useful in high power and tight tolerance applications.

Other PCBs: Standard PCBs, such as those made from FR-4, do not have as good heat dissipation properties. However, they can be used in a wide range of applications owing to their flexibility, cost-effectiveness, and other properties.

Cost

Single-Sided Aluminum Based Circuit Boards: These are typically more expensive to manufacture due to the cost of aluminum and the specialized process needed to create these boards.

Other PCBs: Standard FR-4 PCBs are generally cheaper to produce, which makes them a popular choice for a wide variety of applications.

Usage Contexts

Single-Sided Aluminum Based Circuit Boards: Because of their excellent thermal properties, these boards are often used in LED lighting systems, power converters, and any other system where heat dissipation can be a concern.

Other PCBs: Other types of PCBs are used in a wide range of electronic devices, from computers to radios, to TVs, etc. The type of PCB chosen largely depends on the specific needs of the project or device.

Remember that the best type of PCB for a project depends on a variety of factors, including its intended function, the environment in which it will be used, and cost considerations.

In conclusion

Single-sided aluminum PCBs provide a compelling alternative to traditional PCB designs. Their unique structure, superior thermal management capabilities, and cost-effective manufacturing process make them an attractive choice for various electronic applications. By examining their structure, manufacturing process, advantages, challenges, and future trends, we can gain a comprehensive understanding of the potential of single-sided aluminum PCBs in the ever-evolving world of electronics.