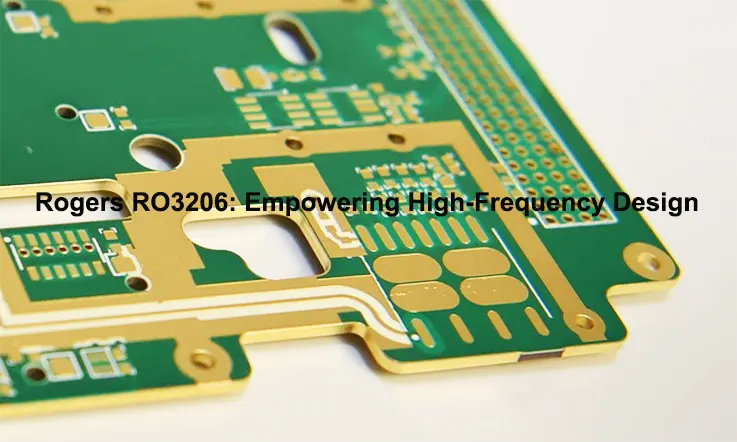

Rogers RO3206 is a high-performance PCB material that has gained popularity in the electronics industry for its exceptional characteristics and reliability. Designed specifically for high-frequency applications, RO3206 offers engineers and designers a versatile solution to meet the demanding requirements of modern electronic systems. In this article, we will explore the key features and benefits of Rogers RO3206 PCB materials, highlighting their importance in empowering high-frequency design.

What is Rogers RO3206?

Rogers RO3206 is an advanced laminate that belongs to the RO3000 series, renowned for its exceptional properties in the field of PCB design and manufacturing. This particular laminate stands out due to its remarkable mechanical stability, making it a preferred choice among designers.

RO3206, like other members of the RO3000 family, is a ceramic-filled composite that is reinforced with woven fiberglass. This unique combination of materials imparts outstanding mechanical and electrical characteristics to the laminate, meeting the stringent requirements of high-performance applications.

Engineered specifically for RF and microwave applications, RO3206 exhibits excellent performance in high-frequency circuits. Its composition, comprising ceramic-filled composites and woven fiberglass reinforcement, ensures optimal signal integrity and reliability in demanding environments.

With a dielectric constant of 6.15 and a dissipation factor of 0.0027, the electrical properties of RO3206 are truly exceptional. These values indicate superior electrical stability, enabling precise signal transmission and minimizing signal loss. Moreover, the material’s mechanical stability further enhances its overall performance, ensuring reliable operation under varying conditions.

Properties Feature of Rogers RO3206 PCB Materials

Rogers RO3206 PCB material possesses a range of notable properties that contribute to its exceptional performance in high-frequency applications. Here are some key features of RO3206:

1.Advanced Dielectric Properties:

RO3206 exhibits a dielectric constant of 6.15, which ensures precise signal transmission and minimizes signal loss. This property is crucial for maintaining signal integrity in high-frequency circuits.

2.Low Dissipation Factor:

With a dissipation factor of 0.0027, RO3206 offers minimal energy loss during signal transmission. This characteristic enables efficient power delivery and helps to maintain signal quality.

3.Excellent Electrical Stability:

RO3206 provides excellent electrical stability over a wide range of frequencies, making it suitable for high-frequency and microwave applications. This stability ensures consistent performance and reliable signal transmission.

4.Superior Mechanical Stability:

One of the standout features of RO3206 is its exceptional mechanical stability. This laminate is designed to withstand mechanical stresses and maintain its structural integrity under various operating conditions. This stability contributes to the long-term reliability of PCBs using RO3206.

5.Ceramic-Filled Composite:

RO3206 is a ceramic-filled composite material that combines the benefits of ceramics and woven fiberglass reinforcement. This composition enhances the laminate’s mechanical strength, dimensional stability, and thermal performance.

6.Woven Fiberglass Reinforcement:

The woven fiberglass reinforcement in RO3206 provides additional strength and rigidity to the laminate, making it resistant to bending and flexing. This reinforcement contributes to the overall durability and reliability of PCBs fabricated with RO3206.

7.Compatibility with High-Frequency Applications:

RO3206 is specifically engineered for high-frequency and microwave applications. Its unique properties enable efficient signal transmission, low loss, and excellent performance in these demanding applications.

Applications of Rogers RO3206

Rogers RO3206 finds applications in various high-frequency fields. Here are some specific applications where RO3206 is commonly used:

1. LMDS Broadband: RO3206 is well-suited for Local Multipoint Distribution Service (LMDS) broadband applications. It provides the required electrical and mechanical properties for reliable signal transmission in high-frequency wireless communication systems.

2. Wireless Telecommunication Systems: RO3206 is utilized in wireless telecommunication systems, including cellular networks, where high-frequency signals need to be transmitted and received efficiently with minimal loss.

3. Microstrip Patch Antennas: RO3206 is often employed in the construction of microstrip patch antennas. Its low loss and excellent electrical stability make it an ideal choice for these high-frequency antenna applications.

4. Satellites for Direct Broadcasts: RO3206 is used in satellite systems for direct broadcasts, where it helps ensure reliable signal transmission and reception in high-frequency bands.

5. Automotive GPS Antennas: RO3206 is suitable for automotive GPS antennas, enabling accurate positioning and navigation in vehicles. Its mechanical stability and high-frequency performance make it an excellent choice for these applications.

6. Remote Meter Readers: RO3206 is utilized in remote meter reading systems, where it enables the wireless transmission of meter data over high-frequency channels.

7. Infrastructure for Base Stations: RO3206 is employed in the construction of base station infrastructure, including antennas and RF modules, to support high-frequency wireless communication networks.

8. Automotive Collision Avoidance Systems: RO3206 is used in automotive collision avoidance systems, such as radar systems, where it enables the reliable transmission and reception of high-frequency signals for enhanced safety features.

9. Power Backplanes: RO3206 can be found in power backplanes, which are used in high-frequency power distribution systems. Its electrical stability and mechanical strength make it suitable for these applications.

These are just a few examples of the applications where Rogers RO3206 is commonly utilized. Its combination of electrical performance, mechanical stability, and compatibility with high-frequency designs make it a preferred choice in various industries that require reliable and efficient signal transmission in the high-frequency spectrum.

Key Considerations for Selecting Rogers RO3206 Material

When choosing Rogers RO3206 for a specific application, there are several factors to consider:

1. Frequency Range: Determine the frequency range required for your application. RO3206 is designed for high-frequency applications, but it’s important to ensure that the frequency range of the material aligns with the operating frequencies of your circuit.

2. Dielectric Constant (Dk): The dielectric constant of RO3206 is 6.15. Consider whether this value is suitable for your application’s impedance requirements and signal integrity needs. Higher dielectric constants generally result in smaller dimensions for the same impedance, but they can also introduce higher signal loss.

3. Loss Tangent (Dissipation Factor): RO3206 has a low loss tangent, which contributes to low signal loss. However, it’s important to evaluate the dissipation factor and determine if it meets your application’s requirements for signal integrity.

4. Mechanical Stability: Assess the mechanical stability of RO3206 for your specific application. Consider factors such as thermal cycling, vibration, flexing, and bending that the material may encounter. RO3206 is known for its excellent mechanical stability, but it’s important to ensure it can withstand the environmental conditions of your application.

5. Thermal Performance: Evaluate the thermal performance of RO3206, especially if your application involves high-power components or operates in thermally demanding environments. Consider the material’s ability to dissipate heat effectively and its coefficient of thermal expansion (CTE) to ensure compatibility with your application’s thermal requirements.

6. Fabrication and Assembly: Consider the ease of fabrication and assembly when choosing RO3206. Evaluate factors such as the material’s compatibility with standard PCB fabrication processes, ease of drilling, routing, and soldering.

7. Cost: Assess the cost of RO3206 and compare it with your budget. Consider the overall value and performance that the material offers for your application.

8. Application-Specific Requirements: Consider any specific requirements of your application, such as dimensional constraints, environmental considerations, and regulatory compliance. Ensure that RO3206 meets these requirements and can deliver the necessary performance.

Design Guidelines When Use Ro3206 In PCB Manufacturing

When using Rogers RO3206 in PCB manufacturing, there are several design guidelines that can help ensure optimal performance and reliability. Here are some key considerations:

Dielectric Constant and Thickness:

RO3206 has a specific dielectric constant (Dk) and thickness. It is important to accurately define these parameters in your design to achieve the desired electrical properties. Pay attention to the tolerances specified by the manufacturer.

Controlled Impedance:

RO3206 is often used in high-frequency applications where controlled impedance is crucial. Follow the manufacturer’s guidelines for trace width, spacing, and layer stack-up to achieve the desired impedance values. Be aware of the Dk variation with frequency and temperature.

Ground and Power Planes:

For signal integrity and noise reduction, incorporate dedicated ground and power planes in your design. These planes provide shielding and help maintain signal integrity by minimizing electromagnetic interference (EMI) and reducing power supply noise.

Thermal Considerations:

RO3206 has good thermal conductivity properties, making it suitable for applications with high heat dissipation requirements. Ensure proper heat sinking and thermal vias to dissipate heat efficiently. Consider the thermal coefficient of expansion (CTE) when designing for temperature variations.

Vias and Pads:

When designing for RO3206, pay attention to via and pad sizes to maintain signal integrity and ensure good solderability. Follow the manufacturer’s recommendations for minimum via and pad sizes, especially for high-frequency designs.

Copper Foil:

RO3206 is compatible with both rolled copper and electrodeposited (ED) copper foils. Consider the thickness and roughness of the copper foil based on your application requirements and the manufacturing capabilities.

Routing and Trace Placement:

Optimize trace routing to minimize signal loss, crosstalk, and EMI. Use proper trace widths and spacing, especially for high-frequency signals. Maintain separation between sensitive signals and high-speed digital or power lines to minimize interference.

Design for Manufacturability:

Consider the manufacturability aspects of your design. Ensure that the PCB layout complies with the capabilities and limitations of your chosen fabrication process. Avoid tight spaces, sharp angles, and complex geometries that may be challenging to manufacture.

Design Validation and Simulation:

Utilize simulation and modeling tools to validate your design before fabrication. Perform signal integrity analysis, impedance matching, and thermal simulations to identify and address potential issues early in the design process.

Consult Manufacturer’s Guidelines:

Always refer to the manufacturer’s datasheet, application notes, and design guidelines specific to RO3206. These documents provide valuable information on material properties, recommended design practices, and limitations.

Final Thoughts

Rogers RO3206 PCB materials have revolutionized high-frequency design by providing engineers and designers with a reliable and versatile solution. With its excellent electrical performance, low loss tangent, and mechanical stability, RO3206 enables the efficient transmission of high-frequency signals while ensuring signal integrity and minimizing losses.

Whether it’s for wireless communication systems, radar applications, or high-speed digital circuits, RO3206 empowers engineers to push the boundaries of high-frequency design. By leveraging the unique properties of RO3206, designers can achieve optimal performance, improved signal integrity, and reliable operation in their electronic systems. With Rogers RO3206 PCB materials, the possibilities for high-frequency design are limitless.

Our services

Rogers PCB Laminates & Series

Other services

Call us to get a free quote now

Nullam pulvinar blandit ullamcorper. Pellentesque venenatis felis quis risus posuere, a luctus neque consectetur.

Aliquam dictum diam ex, eget eleifend purus finibus sed. Etiam faucibus accumsan ligula ut iaculis. In nibh tellus, mollis eget iaculis id, aliquet vel elit. Nulla mollis ut mauris et venenatis. Nulla metus nisl, maximus ut congue vel, malesuada eu mi. Nullam tempus viverra mauris nec volutpat. Sed turpis tortor, lobortis at tristique sed, interdum nec neque. Mauris aliquam, erat nec luctus suscipit, nulla turpis mattis velit, non vehicula magna erat ac enim. Aliquam facilisis ullamcorper dui, ut euismod eros molestie ac.

Donec venenatis

sodales lacus sit amet scelerisque

Integer mattis condimentum laoreet. Nullam non dignissim est, interdum ornare arcu. Morbi dignissim a ipsum in dignissim. Cras semper magna nec suscipit fermentum. Nulla iaculis dolor eu finibus imperdiet. Donec rhoncus varius eros, sed tincidunt libero commodo a. Vestibulum tincidunt ligula sed orci lobortis congue. Vivamus posuere tempor mauris iaculis convallis. In id ullamcorper felis. Suspendisse potenti.