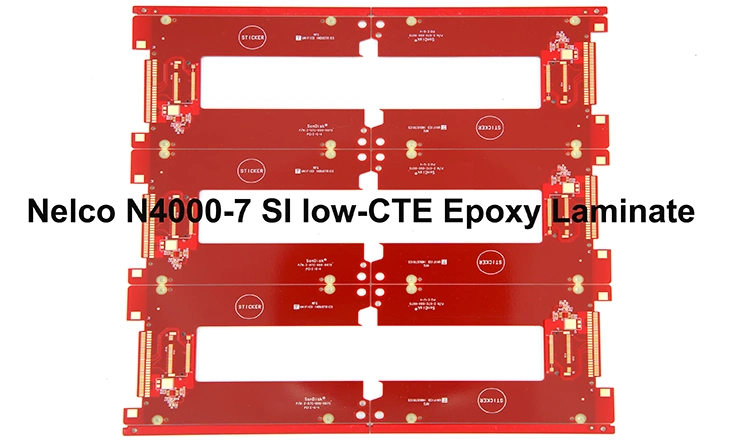

For circuit board engineers, selecting the right materials is crucial to ensure optimal performance and reliability of electronic designs. The Nelco N4000-7 SI low-CTE (Coefficient of Thermal Expansion) epoxy laminate has emerged as a game-changing solution, empowering circuit board engineers to push the boundaries of innovation. This article explores the exceptional characteristics and advantages of the N4000-7 SI laminate, showcasing how it unleashes the design potential for circuit board engineers and enables the creation of cutting-edge electronic systems.

Nelco N4000-7 SI PCB Laminate: Introduction

The Nelco® N4000-7 SI low-CTE epoxy laminate and prepreg system offers a highly cost-effective solution for a wide range of multilayer PCB designs that require exceptional thermal stability, minimal Z-axis expansion, and superior integrity of hole walls.

Key Features and Benefits:

1. Superior Z-axis stability, ensuring reliable performance and signal integrity.

2. Excellent thermal stability, enabling the PCB to withstand varying temperature conditions without compromising its functionality.

3. Enhanced hole-wall integrity, ensuring robust connections and minimizing the risk of failure.

4. Specifically designed for automotive testing, meeting the stringent requirements of this industry.

5. SI (Signal Integrity) option available, ensuring optimal signal transmission and minimizing signal loss.

6. Resistant to CAF (Conductive Anodic Filament) formation, enhancing the reliability and longevity of the PCB.

7.Cost-effective solution that allows for standard FR-4 processing, reducing manufacturing costs without sacrificing quality.

Technical Specifications for N4000-7 SI PCB Substrates

The Nelco® N4000-7 SI laminate system is compatible with various materials, each offering specific thickness or layer options for different application requirements.

The N4000 Series comprises three glass grades: 1.5 mm, 1.2 mm, and 0.6 mm. These glass cloths, combined with an epoxy resin in a binder system, exhibit exceptional toughness and color stability. Moreover, they possess remarkable thermal shock resistance and high-temperature capability, ensuring reliable performance in demanding environments.

Technical Specifications for N4000-7 SI PCB Substrates:

Standard Roll Sizes:

The N4000-7 SI PCB substrates are conveniently available in standard roll sizes to facilitate efficient manufacturing processes. These standard rolls have a length of 185 feet (approximately 56.4 meters) or 115 meters and are available in two width options: 25 inches (approximately 64 centimeters) and 50 inches (approximately 127 centimeters).

The standardized roll sizes ensure compatibility with industry-standard equipment and processes, enabling manufacturers to streamline their operations and achieve consistent results. However, it’s worth noting that custom dimensions for the N4000-7 SI PCB substrates can be accommodated upon request. This flexibility allows for tailoring the substrate dimensions to specific project requirements, further enhancing design possibilities and manufacturing efficiency.

CAF Resistant:

The N4000-7 SI substrate material is resistant to Conductive Anodic Filament (CAF) formation, ensuring long-term reliability and preventing electrical failures caused by conductive paths forming within the material.

RoHS Compliant:

The N4000-7 SI PCB substrates meet the requirements of the Restriction of Hazardous Substances (RoHS) directive, ensuring that they are free from hazardous substances such as lead, mercury, cadmium, and certain flame retardants.

Lead-Free Assembly Compatible:

The N4000-7 SI substrates are compatible with lead-free assembly processes, allowing for environmentally friendly and compliant manufacturing practices.

Low CTE FR-4 Epoxy:

The N4000-7 SI laminate system features a low Coefficient of Thermal Expansion (CTE) FR-4 epoxy material. This characteristic minimizes dimensional changes in the substrate due to temperature variations, ensuring stability and reliability in diverse operating conditions.

SI (Signal Integrity) Option: The N4000-7 SI substrate offers a Signal Integrity (SI) option, which is specifically designed to meet the requirements of high-speed digital and RF applications. This option helps maintain signal integrity, reduce signal loss, and minimize electromagnetic interference (EMI).

Outstanding Z-axis, Thermal Stability, and Hole Wall Integrity:

The N4000-7 SI substrate system exhibits exceptional performance in terms of Z-axis expansion, thermal stability, and hole wall integrity. These properties are crucial for maintaining the structural integrity of the PCB, ensuring reliable electrical connections, and preventing issues such as delamination, warping, or dimensional changes over time.

When selecting the appropriate material for a PCB design, the N4000-7 SI laminate system provides flexibility in terms of thickness or layer options. These options enable PCB engineers to tailor the design to meet specific project needs, ensuring optimal performance and reliability.

Overall, the N4000-7 SI PCB substrates offer a comprehensive set of technical specifications that make them suitable for a wide range of applications, including automotive, wireless, and fine-line designs.

The Difference Between N4000 Series and Other Fr4 Laminates

The N4000 Series FR-4 laminates offer compatibility with various types of prepregs, including standard woven glass cloth prepregs and similar options like Spectra™ Glass and SCS Laminate. These laminates have a denser pattern compared to conventional laminates, resulting in parallel plies rather than crosswise plies.

In terms of weave pattern, the N4000 Series laminates consist of three layers of 0.6 mm glass cloth on the outside and 1.2 mm on the inside, with a total fillet area of 0.7 sq ft / 65 sq cm. The prepregs used with N4000 Series laminates have a nominal width of 3 inches / 76 µm and an effective area of 0.35 sq ft / 32 sq cm.

Furthermore, the N4000 Series FR-4 laminates are compatible with prepregs from other manufacturers, such as JarnisTech PCB & Assembly. These laminates can work well with prepregs that are thinner and have a finer pattern compared to modern woven glass cloth prepregs.

Additionally, the N4000 Series laminates can be used with heavier and thicker fabrics, such as 2.5 mm (68 µm) or 3.0 mm (84 µm) different fabric unidirectional prepregs. This compatibility allows for flexibility in design and manufacturing, accommodating a wide range of material options to meet specific project requirements.

Overall, the N4000 Series FR-4 laminates provide compatibility with various prepregs, offering versatility and adaptability in PCB fabrication processes.

Considering Factors of Choose N4000-7 SI in PCB Design

When choosing the Nelco N4000-7 SI laminate for PCB design, several factors should be taken into consideration:

1. Thermal Stability: The N4000-7 SI laminate offers low CTE, ensuring excellent thermal stability. This is crucial for PCBs that are subjected to temperature variations during operation, preventing issues such as warping, delamination, and solder joint failures.

2. Signal Integrity: The N4000-7 SI laminate provides high-speed signal integrity, making it suitable for applications that require reliable transmission of high-frequency signals. Its low loss tangent and controlled dielectric constant contribute to minimal signal distortion and improved overall performance.

3. Compatibility: Consider the compatibility of the N4000-7 SI laminate with the manufacturing processes and materials used in your PCB assembly. Ensure that it is compatible with the chosen prepregs, solder masks, and surface finishes to ensure smooth production and assembly.

4. RoHS Compliance: The N4000-7 SI laminate is designed to meet RoHS (Restriction of Hazardous Substances) standards, making it environmentally friendly and compliant with regulations. This is important for manufacturers aiming to produce sustainable and compliant electronic products.

5. Application-Specific Requirements: Evaluate the specific requirements of your PCB design application. Consider factors such as frequency, power dissipation, mechanical strength, and dimensional stability to ensure that the N4000-7 SI laminate meets the specific needs of your project.

6. Reliability and Performance: Assess the track record and reputation of the N4000-7 SI laminate in terms of reliability and performance. Look for testimonials, case studies, and reliability data to ensure that the laminate has a proven track record in delivering consistent performance and reliability.

By considering these factors, circuit board engineers can make an informed decision and confidently choose the Nelco N4000-7 SI laminate for their PCB designs, ensuring optimal performance, reliability, and compatibility with their specific requirements.

Applications/Qualifications

1. Wireless Handsets: Ideal for PCB designs used in wireless handset devices, ensuring reliable wireless communication.

2. Wireless Infrastructure: Suitable for PCB designs in wireless infrastructure systems, ensuring stable and efficient network connectivity.

3. Digital Broadband Multilayers: Well-suited for PCB designs in digital broadband applications, providing reliable signal transmission.

4. Automotive: Meets the demanding requirements of the automotive industry, ensuring durability and reliability in automotive electronic systems.

5. Underhood Automotive: Designed to withstand the challenging conditions of underhood environments, maintaining performance and reliability.

6. Backplanes: Suitable for PCB designs in backplane applications, ensuring high-speed and reliable data transmission.

7. Fine-Line Multilayers: Ideal for PCB designs that require fine-line traces, enabling high-density interconnections.

8. Fine Pitch BGA Multilayers: Suitable for PCB designs with fine pitch BGA components, ensuring reliable connections and signal integrity.

9. Direct Chip Attach: Well-suited for PCB designs that utilize direct chip attachment, providing reliable electrical connections.

10. RoHS Compliant: Meets the requirements of RoHS (Restriction of Hazardous Substances) regulations, ensuring environmental compliance.

11. Meets IPC-4101/98 Specifications: Compliant with IPC-4101/98 specifications, ensuring adherence to industry standards.

Conclusion

The Nelco N4000-7 SI low-CTE epoxy laminate has revolutionized the landscape of electronic manufacturing. Its outstanding material properties, including low CTE, high-speed signal integrity, and compatibility with various prepregs, empower electronic manufacturers to create cutting-edge products with superior performance and reliability. By incorporating the N4000-7 SI laminate into their manufacturing processes, companies can enhance their competitiveness, meet stringent industry standards, and exceed customer expectations. Embrace the power of the Nelco N4000-7 SI laminate and unlock new possibilities in electronic manufacturing.