When designing high-performance electronics, the choice of PCB laminate can significantly impact the overall system’s performance, durability, and efficiency. MEGTRON-7, a premium laminate material, stands out for its superior properties in high-speed and high-frequency applications. As electronic devices become more complex, the demand for reliable signal integrity and thermal stability in PCBs has intensified. MEGTRON-7 answers this need, providing unmatched low-loss characteristics and exceptional thermal performance, making it the material of choice for advanced PCB designs, particularly in industries like telecommunications, aerospace, and automotive. In this article, we explore why MEGTRON-7 is the go-to choice for manufacturers looking to push the boundaries of high-performance PCB design.

Why Reimagining Your PCB Design with MEGTRON-7?

About high-speed, high-frequency PCB design, staying ahead of the curve requires cutting-edge materials that can meet the growing demands of modern electronics. For many years, FR4 was the standard choice for general-purpose PCBs. However, as technology advances, traditional materials are no longer sufficient to handle the complexity and performance requirements of today’s designs. Enter MEGTRON-7 PCB laminate, a material built to meet the new challenges in next-generation electronics.

What sets MEGTRON-7 apart is its ability to perform exceptionally well in high-speed and high-frequency applications. Specifically engineered for environments that require strong signal integrity and stable thermal performance, MEGTRON-7 is ideal for use in 5G communications, IoT devices, and other advanced electronic systems where reliable and efficient operation is a must.

Beyond Conventional Laminates: What Makes MEGTRON-7 Stand Apart

For many years, traditional laminates were sufficient for less demanding applications. However, the demands of modern-day electronics, particularly in high-frequency communication systems, have exposed the limitations of these older materials. MEGTRON-7 has been specifically developed to address the shortcomings of traditional laminates and provides the necessary performance to handle today’s high-speed, high-frequency demands.

One standout feature of MEGTRON-7 is its low dielectric constant (Dk), which helps minimize signal loss. As high-frequency signals travel faster, they need careful handling to avoid degradation. MEGTRON-7 ensures these signals maintain their integrity across the PCB layers, significantly lowering the chances of failure. Its stable electrical characteristics also mean that the PCB will continue performing reliably under varying conditions. This makes it a solid option for demanding applications such as 5G networks, satellite communications, and high-speed data transfer.

The Science Behind MEGTRON-7’s Unique Electrical and Thermal Properties

MEGTRON-7 excels in providing low-loss electrical performance and exceptional thermal management. These features are indispensable when designing advanced, high-speed circuits that must function at peak efficiency. Whether it’s maintaining signal integrity or handling thermal challenges, MEGTRON-7 delivers the necessary properties for demanding applications where reliability matters most.

Low-Dielectric Constant and Signal Integrity-

The low Dk of MEGTRON-7 is one of its most significant features. Signal integrity is essential in any high-frequency application, and MEGTRON-7 minimizes signal degradation due to its low dielectric loss. This property is particularly useful in circuits designed for 5G technology, where maintaining clarity and precision of signals is non-negotiable. By providing consistent, low Dk values, MEGTRON-7 ensures that the signals are transferred with minimal delay and without distortion, enabling reliable communication for both wired and wireless systems.

Thermal Stability for Dense Designs-

MEGTRON-7 stands out for its ability to manage heat effectively, making it a solid choice for designs with high power densities. As circuits become more complex, managing the heat produced by densely packed components is essential. MEGTRON-7 is designed to withstand high temperatures without experiencing material breakdown, ensuring that your high-density designs maintain structural integrity even under demanding conditions. Therefore, This material is a strong fit for demanding applications like 5G base stations, autonomous vehicle sensor systems, and high-performance computing, where reliable thermal management is needed.

MEGTRON-7’s Contribution to Design Evolution in High-Speed PCBs

As PCB design continues to evolve, the demand for materials that can handle high-speed, high-frequency signals has grown significantly. MEGTRON-7 offers a level of performance and reliability that empowers human’s designers to push the boundaries of their designs.

Optimizing Impedance Control-

In high-speed digital circuits, maintaining stable impedance is necessary to prevent signal degradation. MEGTRON-7 is engineered to keep impedance consistent across a broad range of frequencies, ensuring smooth signal transmission. This feature proves valuable in applications such as networking, satellite communications, and high-definition video streaming, where high-frequency signals need to move through various components without interference or data loss.

Ensuring Signal Integrity at High Frequencies-

Signal integrity is at the heart of high-speed PCB design. MEGTRON-7 addresses this concern by offering low signal loss and maintaining electrical consistency across a broad frequency range. This ensures that high-frequency signals—such as those used in telecommunications equipment or 5G systems—maintain their clarity without experiencing unnecessary degradation.

Thermal Management for Complex Designs-

As the density of PCBs increases, managing heat becomes a top priority. MEGTRON-7 delivers superior thermal performance, ensuring that even the most complex and power-hungry designs can operate at optimal levels. For instance, designs used in autonomous driving or aerospace applications, where heat is a constant challenge, benefit greatly from the material’s thermal stability. MEGTRON-7 allows us to create high-density boards without worrying about heat-induced failures or material degradation.

Key Features and Performance of MEGTRON-7 PCB Laminate

When designing high-performance circuits, selecting the right PCB laminate is a fundamental step. MEGTRON-7 PCB laminate sets a new benchmark for high-speed and high-frequency PCB designs. So, if you’re working on 5G infrastructure, autonomous vehicle systems, or advanced medical electronics, the need for signal integrity, thermal stability, and impedance control is greater than ever.

This section will examine MEGTRON-7’s unique electrical, thermal, and impedance control properties that make it an ideal choice for next-generation PCB manufacturing. This material’s advanced characteristics optimize performance in high-frequency applications, ensuring that circuits stay stable even in demanding environments. Whether you are designing HDI PCBs, low-loss circuits, or high-speed interconnects, MEGTRON-7 is built to meet the challenges of modern electronics.

Electrical Performance: Why MEGTRON-7 is Ideal for High-Speed and High-Frequency PCB Design

In high-speed PCB design, maintaining signal integrity is a must. MEGTRON-7 stands out by ensuring reliable signal transmission even at high frequencies. This feature is especially beneficial for applications like 5G networks, RF communications, and high-speed data processing, where even the smallest amount of signal loss can compromise system performance.

The Importance of Signal Integrity in High-Frequency Circuits-

In high-frequency PCBs, signals travel at fast speeds. Any disruption—no matter how small—can result in corrupted signals, leading to malfunction or communication failure. MEGTRON-7’s low-loss characteristics ensure that signals travel efficiently, with minimal loss over extended traces or dense layer stacks.

For example, in 5G systems, low-loss PCBs are necessary to maintain the high data transfer rates required by the technology. Without a material like MEGTRON-7, signal clarity would degrade, affecting overall system performance.

Performance Features of MEGTRON-7-

●Low Dielectric Constant (Dk): A low Dk ensures minimal signal attenuation, making MEGTRON-7 highly suited for high-frequency applications.

●Low Loss Tangent (Df): This property guarantees that energy loss remains low during signal transmission, suitable for RF and microwave applications.

●Stable Performance: MEGTRON-7 consistently delivers exceptional electrical performance across a wide frequency and temperature range, ensuring signal fidelity in demanding applications.

Unlike FR4, which tends to have higher Dk and Df, MEGTRON-7 reduces signal loss, making it an ideal material for high-performance applications such as 5G base stations and automated control systems, where precise signal integrity is required. The following table demonstrates how MEGTRON-7 performs against other materials like FR4 and standard high-speed laminates.

| Property | MEGTRON-7 | Traditional FR4 | Other High-Speed Laminates |

| Dielectric Constant (Dk) | 3.61-3.63 | 4.5 | 3.4 – 3.8 |

| Loss Tangent (Df) | 0.002 | 0.020 | 0.005 – 0.010 |

| Thermal Conductivity (W/m°C) | 0.70 | 0.25 | 0.50 – 0.60 |

| Glass Transition Temp (Tg) | 180°C | 140°C | 170°C – 180°C |

Key Takeaways:

1.The high Tg of MEGTRON-7 makes it more thermally stable, allowing for reliable performance in high-temperature environments.

2.Thermal conductivity ensures that the laminate efficiently dissipates heat, preventing performance bottlenecks due to heat buildup.

Thermal Management with MEGTRON-7: Ensuring Stability in High-Speed Applications

Effective thermal management is just as important as electrical properties in ensuring PCB performance. As circuits become more complex and power consumption increases, the heat generated by components needs to be properly managed to avoid performance issues or thermal damage. MEGTRON-7 offers excellent thermal stability, allowing designs to perform well even in high-density, high-speed applications.

Why Thermal Management is Key-

In high-speed PCBs, the heat generated by densely packed components can cause thermal expansion that may compromise the integrity of the circuit. Excessive heat also leads to signal degradation and potentially permanent damage to components. MEGTRON-7 provides superior thermal stability due to its high glass transition temperature (Tg) and low coefficient of thermal expansion (CTE), which prevent heat-related issues in high-frequency designs.

Key Thermal Features of MEGTRON-7-

●High Tg (Glass Transition Temperature): MEGTRON-7 maintains its structural integrity at higher temperatures compared to many standard laminates, allowing it to perform reliably in demanding environments.

●Low Coefficient of Thermal Expansion (CTE): This reduces the risk of warping or cracking in high-density, high-heat situations.

●Efficient Heat Dissipation: MEGTRON-7 helps to prevent hot spots, ensuring that the circuit maintains stable performance even when subjected to high power or temperature variations.

Therefore, MEGTRON-7 shines here with its exceptional thermal stability and thermal conductivity, outperforming traditional materials like FR4 and other high-performance laminates.

| Material | Tg (°C) | CTE (ppm/°C) | Thermal Conductivity (W/m°C) |

| MEGTRON-7 | 180 | 17 | 0.70 |

| FR4 | 130 – 140 | 20 – 50 | 0.25 |

| Megtron 6 | 170 | 18 | 0.50 |

So, we can see that the thermal conductivity at 0.70 W/m°C is ideal for high-density circuits, preventing heat accumulation that could affect signal quality and performance.

Example Applications-

●Automotive Electronics: Autonomous vehicles rely on advanced electronic systems, where maintaining signal integrity and managing thermal conditions are necessary. MEGTRON-7 supports these systems by ensuring reliable performance, preventing overheating, and optimizing efficiency, even under demanding conditions.

●5G Base Stations: In 5G infrastructure, high-power components often operate at elevated temperatures. With MEGTRON-7, these components remain within thermal limits, improving system reliability over the long term.

Impedance Control and Low Loss in MEGTRON-7 PCBs

In high-speed PCB design, maintaining consistent impedance is necessary to ensure proper signal transmission. If impedance is not managed correctly, it can lead to signal reflection, which can impair performance and potentially cause failures. MEGTRON-7 excels in high-frequency, HDI PCBs, where precise impedance control supports signal clarity across the layers.

What Impedance Control Means for High-Speed PCB Design-

Impedance control ensures that the resistance to signal flow is uniform across the PCB traces, reducing the chances of reflection or signal loss. Without proper impedance control, signals can reflect back and cause signal interference, especially in high-speed designs. With MEGTRON-7, you get the precision needed to design high-performance circuits that deliver clear and accurate signals.

How MEGTRON-7 Supports Impedance Control-

●Stable Dielectric Properties: MEGTRON-7’s consistent dielectric constant (Dk) allows for uniform impedance control across a wide frequency spectrum.

●Low-Loss Design: The low-loss characteristics of MEGTRON-7 minimize signal reflection, ensuring that energy is efficiently transmitted with minimal loss.

High-Density Interconnect (HDI) PCBs-

For HDI PCBs, which are often used in smartphones, wearable devices, and other compact electronics, MEGTRON-7 is the material of choice. It supports high-precision impedance control in designs that incorporate microvias and fine traces. Whether you’re developing 5G devices or next-gen consumer electronics, MEGTRON-7 offers the performance needed to ensure optimal signal integrity and efficient energy transfer.

Let’s see how MEGTRON-7 compares to other PCB materials in terms of impedance control and low-loss performance.

| Material | Impedance Control (Ω) | Signal Loss at 1 GHz (dB/in) | Maximum Frequency (GHz) |

| MEGTRON-7 | ±5% | 0.01 | 40+ |

| FR4 | ±10% | 0.05 | 2-3 |

| Teflon (PTFE) | ±5% | 0.02 | 30+ |

●MEGTRON-7 ensures tighter impedance control (±5%), which is crucial for HDI PCBs and complex circuit designs.

●The low signal loss at 1 GHz and the ability to handle frequencies over 40 GHz make MEGTRON-7 good for RF applications, including 5G networks and high-performance radar systems.

●Compared to FR4, MEGTRON-7 shows a significantly lower signal loss, ensuring more consistent performance in high-speed applications.

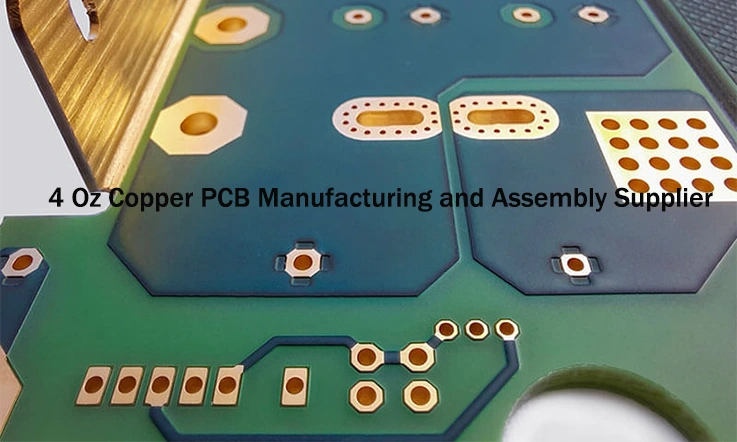

Manufacturing PCB Circuit Boards for Use with MEGTRON-7 PCB Laminate

When it comes to fabricating high-performance PCB circuit boards using MEGTRON-7 laminate, the process is more than just a typical PCB design. It involves sourcing premium materials, applying state-of-the-art fabrication techniques, and ensuring rigorous testing for maximum reliability. This section takes a deep dive into the core aspects of this process, showing how to leverage the advanced features of MEGTRON-7 in PCB production.

Sourcing and Quality Control of MEGTRON-7 PCB Laminate

Sourcing the right material is the first step in ensuring that your high-performance PCBs meet the demanding standards of modern electronic applications. For MEGTRON-7 laminate, selecting the right supplier and ensuring top-notch quality control are crucial steps in the manufacturing process. The best suppliers not only provide MEGTRON-7 but also ensure that the material meets the precise specifications necessary for high-speed and high-frequency PCB applications.

Sourcing MEGTRON-7 involves collaborating directly with trusted PCB laminate suppliers who maintain steady supply chains and adhere to rigorous quality control procedures. Additionally, it’s essential to have documentation that tracks the material’s composition, ensuring it’s free from defects and meets the exacting standards required in military, aerospace, and telecommunications applications. This transparency helps to guarantee reliability, especially when the stakes are high.

| Material Specification | MEGTRON-7 | Standard Laminate |

| Dielectric Constant (Dk) | 3.61-3.63 | 4.5 |

| Loss Tangent (Df) | 0.002 | 0.020 |

| Glass Transition Temperature (Tg) | 180°C | 130°C |

| Thermal Conductivity (W/m°C) | 0.70 | 0.25 |

Advanced Fabrication Techniques for MEGTRON-7 in HDI and Multilayer PCBs

Fabricating high-performance PCBs with MEGTRON-7 laminate requires advanced methods that exceed traditional PCB manufacturing techniques. For applications such as HDI and multilayer PCBs, achieving precision in the fabrication process is a must. These designs often include intricate geometries and fine-pitch traces, demanding careful attention to layer stacking, via drilling, and impedance matching to guarantee the best results. Each step in the process must be meticulously controlled to maintain consistency and ensure the desired performance across all layers.

To handle the demanding performance requirements, MEGTRON-7 must be processed using specialized equipment. For instance, laser direct imaging (LDI) and plasma etching techniques are ideal for creating fine lines and traces that can carry high-frequency signals with minimal loss. Multilayer PCBs made with MEGTRON-7 often require advanced pressing technologies to bond the layers together without compromising the material’s thermal stability or signal integrity.

| Fabrication Technique | MEGTRON-7 | Traditional FR4 | Other Advanced Laminates |

| Laser Direct Imaging (LDI) | Yes | No | Yes |

| Plasma Etching | Yes | No | Yes |

| Layer Bonding | Advanced pressing | Standard pressing | Advanced pressing |

| Fine Trace Width | 3 mils | 6 mils | 4 mils |

●Using MEGTRON-7 in HDI PCBs requires precise process control to avoid material distortion and maintain electrical performance.

●The high Tg (180°C) of MEGTRON-7 helps ensure that your multilayer designs can withstand the high temperatures typical in high-density PCB fabrication.

●By combining MEGTRON-7 with cutting-edge PCB fabrication techniques, you can achieve superior performance in designs for 5G, aerospace, and automotive applications.

Rigorous Testing and Validation of MEGTRON-7 PCBs for Reliability

After MEGTRON-7 PCBs are fabricated, the next step involves comprehensive testing to ensure the boards endure under harsh conditions. Testing and validation help verify that high-frequency performance remains intact, and the PCB can operate dependably throughout its lifespan. The testing process covers various phases, such as high-speed signal assessments, thermal cycling, stress tests, and reliability checks, each designed to simulate real-world scenarios. These tests guarantee that the final product can meet the demands of its operating environment without issues, ensuring reliable long-term performance.

The signal integrity of MEGTRON-7 PCBs can be validated using time-domain reflectometry (TDR) or vector network analyzers (VNA) to ensure that the signals pass with minimal distortion. Thermal reliability is tested by subjecting the PCBs to thermal cycling tests to simulate real-world conditions where temperature variations might lead to material degradation.

| Test Type | MEGTRON-7 | Traditional FR4 | Other High-Speed Laminates |

| Signal Integrity Testing | Passes >40 GHz | Passes <3 GHz | Passes <20 GHz |

| Thermal Cycling (TCT) | 1000 cycles @ -40°C to 125°C | 500 cycles @ -40°C to 125°C | 700 cycles @ -40°C to 125°C |

| Flexural Strength Testing | 110 MPa | 70 MPa | 90 MPa |

●MEGTRON-7 passes high-frequency testing at frequencies over 40 GHz, making it suitable for modern 5G and RF communication applications.

●Thermal cycling tests show that MEGTRON-7 can endure over 1000 cycles, proving it can handle extreme temperature shifts without compromising its structural or electrical integrity.

●Flexural strength testing demonstrates that MEGTRON-7 retains its structural stability even under mechanical stress, which is particularly necessary for applications like automotive electronics.

Therefore, put MEGTRON-7 to the test and ensure that your PCB designs will not only meet industry standards but exceed them when it comes to signal quality and thermal performance.

What Factors Should Be Considered When Using MEGTRON-7 PCB Laminate in PCB Design?

Designing with MEGTRON-7 PCB laminate is a meticulous process that requires an understanding of its unique properties and how they impact high-speed, high-frequency PCB applications. As the demand for high-performance circuits continues to rise, MEGTRON-7 stands out for its low-loss characteristics, thermal stability, and exceptional signal integrity. However, selecting this laminate isn’t just about its superior performance; designers need to consider how it interacts with other materials, the complexity of the design, and the specific needs of the application.

Let’s explore the key design factors when working with MEGTRON-7 to make sure your PCB design is built for success.

Key Design Factors in MEGTRON-7 PCB for High-Speed Circuit Applications

When designing PCBs for high-speed circuits, several factors must be accounted for to ensure that the board performs optimally at the required frequencies. MEGTRON-7, with its low dielectric constant and low loss tangent, is a top contender for high-frequency designs. But it’s not just the material properties that matter—there are other considerations that play a role in maximizing performance.

●Signal Integrity and Material Compatibility: When working with MEGTRON-7, maintaining signal integrity is the focus. This means ensuring high-frequency signals pass through the PCB with minimal degradation. MEGTRON-7’s low Dk and low loss properties help reduce signal reflection and attenuation, which is especially effective in designs for 5G and data-heavy applications like HD video and automotive sensors. With these characteristics, the material ensures signals stay sharp and reliable throughout their journey, even in demanding environments.

●Trace Width and Spacing: High-frequency circuits require precise trace width and spacing control. MEGTRON-7 allows for narrower trace designs without losing signal integrity, enabling higher-density interconnects and compact layouts that meet the demands of modern IoT devices and wearables. This material helps achieve miniaturization while ensuring consistent performance in dense designs.

| Design Factor | MEGTRON-7 | Traditional FR4 |

| Dielectric Constant (Dk) | 3.61-3.63 | 4.5 |

| Loss Tangent (Df) | 0.002 | 0.020 |

| Signal Attenuation | Low | Higher |

| Impedance Matching | Excellent | Challenging |

Overcoming Design Challenges in High-Density PCB Designs with MEGTRON-7

High-density PCB designs are becoming more common as the demand for miniaturization grows in consumer electronics, automotive systems, and medical devices. MEGTRON-7, with its superior thermal stability and low-loss properties, is ideally suited to tackle the unique challenges these complex designs present.

●Impedance Matching and Signal Integrity: One of the primary challenges in high-density PCBs is ensuring impedance matching. MEGTRON-7 provides exceptional impedance stability, making it an best choice for high-speed, multi-layer, high-density circuit designs. . For instance, using MEGTRON-7 can help mitigate the risks of signal distortion that typically arise in multi-layer PCBs where the signal paths are complex and traces run parallel for long distances.

●Thermal Management in Dense Designs: Another significant challenge is thermal management. As circuit densities increase, so do the heat levels. MEGTRON-7’s high Tg (180°C) and thermal conductivity ensure that the material can handle the higher operating temperatures found in high-density designs without risking thermal degradation or performance loss.

| Design Challenge | MEGTRON-7 Solution | Traditional FR4 Solution |

| Impedance Matching | Excellent signal integrity | More complex, higher risk |

| Thermal Stability | High Tg, better heat dissipation | Lower thermal resistance |

| Signal Integrity in HDI | Low signal loss, minimal distortion | Higher signal degradation |

Cost-Effective Design Strategies for High-Performance MEGTRON-7 PCBs

While MEGTRON-7 PCB laminate offers impressive performance, it’s possible to design cost-effective solutions that maintain its high standards for demanding applications. Striking the right balance between performance and cost can be a challenge, but MEGTRON-7 makes it possible to tap into its excellent properties without pushing the budget to the limit. This approach helps to meet the needs of high-performance applications while ensuring that costs remain manageable, offering a solid value proposition in the process.

●Material Selection and Layer Optimization: An effective strategy involves optimizing the arrangement of layers and choosing the right materials. For example, MEGTRON-7 can be utilized for the signal layers that require superior performance, while a more economical material can be selected for the power and ground layers. This approach helps reduce overall material costs while maintaining the required performance levels for the design. By making thoughtful material choices, you can balance both cost-efficiency and high performance in your PCBs.

●Advanced Manufacturing Techniques for Cost Efficiency: With MEGTRON-7, advanced fabrication techniques like laser direct imaging (LDI) and fine-pitch etching can help reduce overall manufacturing costs. These processes allow us to create smaller, more densely packed circuits that require fewer materials and lower assembly costs while still achieving high-frequency performance.

| Cost-Effective Strategy | MEGTRON-7 Impact | Traditional PCB Laminate Impact |

| Layer Optimization | Lower overall cost | Higher material use |

| Advanced Fabrication | Reduced manufacturing costs | Higher costs, more material waste |

| Material Selection | High performance, low cost | Trade-off between performance and cost |

NOTE:

●MEGTRON-7’s low-loss factor and high-frequency performance make it better for high-end designs without the premium price tag typically associated with advanced materials.

●By strategically utilizing MEGTRON-7 only in the critical parts of your design, you can keep your high-speed PCB cost-effective and maintain top-tier performance.

Megtron 7 vs. Isola 370HR PCB Laminate: A Comparative Analysis for High-Performance Applications

When it comes to high-performance PCB laminates, Megtron 7 and Isola 370HR are two leading choices in the industry. Both materials are engineered to meet the demands of modern high-speed and high-frequency circuit designs, but their properties cater to different needs. Understanding the specific strengths and use cases of both laminates is necessary for selecting the right material. In this section, we’ll dive into the technical characteristics of Megtron 7 and Isola 370HR, comparing how they perform across various factors. This will help in making the right decision based on your project’s needs.

Megtron 7: High-Frequency and Thermal Stability for Demanding Applications

Megtron 7 has built a strong reputation in the high-frequency PCB market, thanks to its excellent performance in signal integrity and thermal management. Let’s explore why Megtron 7 stands out when dealing with high-speed circuit designs.

High-Frequency Performance-

Megtron 7 is specifically designed for high-speed and high-frequency applications, making it good for 5G communication, high-definition video, and RF circuits. The material’s low dielectric constant (Dk) and dissipation factor contribute to its outstanding ability to maintain signal integrity at elevated frequencies. These features ensure that signal loss is minimized and that the signals remain stable over long transmission lines, even at GHz speeds.

Low Dielectric Constant and Dissipation Factor-

The low dielectric constant of Megtron 7 enhances signal transmission speed, as lower Dk results in a faster signal propagation. This property is essential in high-performance applications, where even slight signal degradation can impact functionality. Similarly, its low dissipation factor reduces heat generation during operation, contributing to overall system efficiency.

Thermal Stability for Harsh Environments-

Thermal stability is another standout feature of Megtron 7. With a high Tg (glass transition temperature), it performs reliably in temperature-sensitive environments. Megtron 7 can handle elevated temperatures without compromising its structural integrity or electrical properties. This makes it suitable for applications in industries such as automotive, aviation, and military, where reliability under extreme conditions is a must.

Cost Consideration for High-Performance Design-

Megtron 7 stands out for its impressive performance while offering a solid balance of cost-efficiency compared to other laminates with similar specifications. Its performance-to-cost ratio makes it an appealing choice for both mass production and custom designs, where staying within budget without sacrificing quality is just as important as meeting technical requirements. This makes Megtron 7 a practical option for projects that require both high performance and financial consideration, providing value without cutting corners.

Isola 370HR: A Strong Contender for High Tg and Mechanical Strength

Isola 370HR is a well-regarded laminate that is commonly chosen for its high glass transition temperature and mechanical properties, especially in environments requiring robust physical characteristics. Let’s break down the attributes of Isola 370HR and understand its advantages in comparison to Megtron 7.

High Tg for Enhanced Temperature Resistance-

A standout feature of Isola 370HR is its high Tg, which indicates the temperature at which the material transitions from a rigid to a more flexible, molten state. A higher Tg enhances the laminate’s ability to handle temperature changes and prolonged exposure to high heat without losing mechanical strength. This makes Isola 370HR especially suitable for applications in environments with fluctuating temperatures, such as automotive electronics, where the material needs to perform reliably under harsh conditions.

Mechanical Strength and Dimensional Stability-

Compared to Megtron 7, which emphasizes electrical performance, Isola 370HR stands out for its mechanical strength. Known for its dimensional stability, this laminate is suited for applications where precise tolerances are needed. Its ability to maintain its structure under stress makes it a solid choice for designs involving heavier components or situations requiring stability during the PCB manufacturing process. This makes Isola 370HR a dependable option for mechanically demanding applications.

Compatibility with Lead-Free Processing-

Isola 370HR is compatible with lead-free soldering processes, which aligns well with the growing demand for environmentally-friendly manufacturing practices. As environmental regulations continue to tighten, materials that support lead-free soldering are becoming more widely adopted. This laminate’s ability to meet these requirements makes it a common selection for industries focused on sustainability and eco-conscious production. It is a reliable option for businesses looking to adhere to green manufacturing standards while ensuring stable performance.

Comparing Performance: Choosing Between Megtron 7 and Isola 370HR

The decision between Megtron 7 and Isola 370HR largely depends on the specific requirements of the application. Here is a comparison of the key attributes to help with your decision:

| Feature | Megtron 7 | Isola 370HR |

| High-Frequency Performance | Excellent, with low Dk and dissipation factor | Moderate, suitable for lower frequency ranges |

| Thermal Stability | High thermal stability, excellent for harsh conditions | High Tg, good for temperature-sensitive designs |

| Mechanical Strength | Moderate, focuses on electrical performance | High, ideal for robust, heavy-duty applications |

| Signal Integrity | Superior, minimizes signal loss | Good, but not as optimized for high-speed signals |

| Compatibility with Lead-Free | Compatible | Lead-free soldering compatible |

| Cost-Effectiveness | Generally more affordable for high-performance | Higher cost due to mechanical properties |

The choice between Megtron 7 and Isola 370HR hinges on the specific requirements of the PCB application. If your focus is on high-frequency performance with low-loss and superior thermal stability, Megtron 7 might be the best option. On the other hand, if your project requires a higher Tg for temperature resistance and mechanical strength, especially in heavy-duty applications, Isola 370HR could be the better choice.

Why Choose Us for Manufacturing Your High-Performance PCB?

At JarnisTech, we specialize in high-performance PCB manufacturing, offering solutions for high-speed, high-frequency applications using advanced materials such as Megtron 7. This laminate ensures solid signal integrity and thermal stability, even under demanding conditions. Our team’s expertise in HDI and multilayer PCB fabrication ensures that your projects meet the required standards for industries like telecommunications and automotive, where design complexity is paired with strict performance expectations. Whether you’re focused on custom or large-scale production, our approach blends high-quality materials with expert manufacturing processes to deliver reliable and efficient results.

1.Expertise in Advanced Materials and High-Frequency Applications

We understand the critical importance of selecting the right PCB material for your project. Our team is well-versed in Megtron 7 PCB laminate—a high-performance material known for its low dielectric constant (Dk) and dissipation factor (Df), making it suitable for applications that require high-frequency performance and minimal signal loss. So, if you’re designing 5G circuits, high-speed digital boards, or data center components, we offer customized solutions that optimize performance without compromising reliability.

2.Precision Manufacturing with Industry-Leading Techniques

Our facility is equipped with state-of-the-art fabrication and assembly technologies, including the latest multilayer PCB and HDI PCB processes, to ensure your designs are precisely crafted. Using Megtron 7 and other top-tier laminates, we handle complex routing, fine-line widths, and impedance matching to guarantee that your circuits perform optimally, even under the most demanding conditions. Whether your design calls for intricate layer stacking or specialized routing for high-frequency applications, our team brings deep technical expertise and proven experience to every project.

3.Commitment to Quality and Reliability

At our company, we don’t just focus on delivering high-quality PCBs—we ensure that every board is meticulously tested for performance and durability. We conduct comprehensive electrical testing, thermal analysis, and mechanical stress testing to validate the integrity and signal performance of your Megtron 7 PCBs. Our rigorous testing process ensures that your products are ready for high-performance applications, with stable thermal properties and reliable signal transmission even under extreme conditions.

4.Cost-Efficient Solutions Without Compromising Performance

At JarnisTech, we recognize that managing project costs is always a top consideration. Our goal is to provide cost-effective PCB manufacturing without compromising quality. Thanks to our efficient manufacturing processes and our extensive experience with Megtron 7 laminate, we provide competitive pricing without sacrificing the performance and durability required for high-end designs. We work closely with you to offer flexible solutions that align with your project’s requirements and budget.

5.Seamless Customer Support and Expertise

Choosing us means more than just receiving exceptional PCBs. We offer hands-on customer support throughout the entire design and manufacturing process. From initial consultation and material selection to post-production support, our team is here to provide expert advice, share insights, and ensure your project’s success. Therefore, if you need guidance on signal integrity or assistance with thermal management for your high-frequency PCBs, we’re here to help.

FAQs about MEGTRON-7 PCB Laminate

1. Is MEGTRON-7 compatible with lead-free soldering?

Yes, MEGTRON-7 works well with both traditional and lead-free soldering processes.

2. How does MEGTRON-7 support PCB miniaturization?

Its low dielectric constant allows for finer traces, helping reduce PCB size without sacrificing signal quality.

3. Can MEGTRON-7 be used for flexible PCBs?

MEGTRON-7 is mainly used in rigid PCBs, though some variants are available for flexible applications.

4. What’s the recommended processing temperature for MEGTRON-7?

MEGTRON-7 can handle processing temperatures up to 180°C, making it suitable for high-heat environments.

5. How does MEGTRON-7 manage high-frequency noise?

Its low dissipation factor minimizes high-frequency noise, better for noise-sensitive applications.