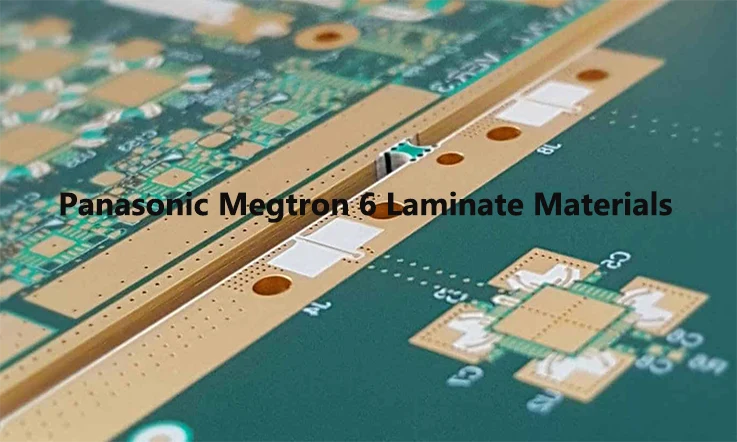

Megtron 6 by Panasonic is an innovative material designed specifically for high-speed network equipment, back panels, HDI boards, high speed/frequency measuring equipment, and RF designs. It offers a wide range of cloth and hydrocarbon resin options, catering to different requirements. Available in various thicknesses starting from 50 μm, Megtron 6 provides excellent performance even at higher temperatures. This unique feature enables the development of multilayer RF designs using standard FR4 equipment. Furthermore, it allows for the integration of RF multilayer designs with commonly used FR4 core material, leading to significant cost savings.

What is MEGTRON 6?

MEGTRON 6 is an advanced material specifically designed for applications such as high-speed network equipment, mainframes, IC testers, and high-frequency measuring instruments. It possesses key characteristics including a low dielectric constant, low dielectric dissipation factors, minimal transmission loss, and exceptional heat resistance, with a thermal decomposition temperature (Td) of 410°C (770°F).

MEGTRON 6 conforms to IPC specification 4101 / 102 / 91, meeting the required standards for quality and performance. As the future implementation of the fifth-generation mobile communication system “5G” approaches, data communication is anticipated to advance further, emphasizing the need for large-capacity and high-speed transmission.

In this evolving landscape, multi-layer substrate materials play a significant role in supporting the backbone of communication networks, including servers and routers. Beyond enabling high-capacity and high-speed transmission, these materials must also meet environmental specifications by being halogen-free.

Through a combination of innovative resin design technology and blending techniques, our company has successfully commercialized multi-layer substrate materials for communication infrastructure equipment. These materials are halogen-free and deliver exceptional performance with low transmission loss, sustained heat resistance, and high reliability.

Benefits Of Panasonic Megtron 6 Laminates

Megtron 6 substrates offer a wide range of advantages across various applications. Their key benefits are as follows:

Enhanced Through Hole Reliability:

Megtron 6 substrates excel in providing exceptional durability and reliability for through-hole components, making them well-suited for specialized applications. These substrates can withstand environmental strains, such as elevated temperatures, and ensure robust interconnections between layers. This capability is particularly advantageous in prototyping and testing scenarios that require components like connectors to endure mechanical stress.

Improved Efficiency:

By utilizing Megtron 6 substrates, precise outcomes can be achieved while maintaining high-performance standards for high-frequency applications. These laminates enable efficient operation with reduced disruptions from environmental and operational factors, ensuring optimal performance.

Exceptional Durability:

In addition to efficiency and reliability, Megtron 6 substrates possess exceptional durability. Their robustness allows them to maintain performance over extended periods, maximizing their utility. Furthermore, they can withstand physical, mechanical, and chemical stresses, instilling confidence in their reliability for critical projects.

High Thermal and Electrical Conductivity:

Megtron 6 substrates possess excellent insulation properties that optimize the flow of electrical current and minimize leakage in both thermal and electric applications. Additionally, these laminates facilitate superior conduction of heat and electric currents, leading to increased efficiency and productivity.

Properties of Panasonic Megtron 6

Gaining a comprehensive understanding of the characteristics of this printed circuit board (PCB) material is essential as it provides valuable insights into its functionality and performance.

High Decomposition Temperature:

This material demonstrates a high resistance to chemical decomposition under elevated temperatures, with a decomposition temperature of 410°C. This attribute enables the PCB to maintain excellent performance. However, it is crucial to avoid exposing the material to temperatures exceeding 410°C, as it can trigger chemical decomposition.

Low Dielectric Constant:

The PCB material, specifically MEGTRON 6 R-5775, exhibits an impressively low dielectric constant (DK). At 1 GHz, the DK value measures 3.71, and at 10 GHz, it records 3.61. Importantly, the DK value remains stable across different frequencies and temperatures, making it an ideal choice for applications requiring high-frequency transmission.

High Glass Transition Temperature:

With a glass transition temperature of 185°C, the MEGTRON 6 R-5775 PCB material is categorized as having a high glass transition temperature. This characteristic highlights its exceptional performance, particularly in applications subject to varying temperatures.

Low Dissipation Factor:

The MEGTRON 6 R-5775 PCB material demonstrates remarkable stability and an extremely low dissipation factor (Df). At 1 GHz, it records a Df value of 0.002, and at 10 GHz, it measures 0.004. The dissipation factor, which measures electrical loss during discharge in the insulator, is a crucial consideration when selecting insulating materials. The PCB material’s low Df value minimizes electrical signal loss, thereby improving overall efficiency.

High Peel Strength:

The MEGTRON 6 R-5775 PCB material exhibits robust bonding properties, as evidenced by its strong tensile strength of 0.8 kN/m, measured according to IPC-TM-650 2.4.8 standards. This high peel strength ensures reliable and secure bonding of the PCB’s components.

How Many Types Megtron6 PCB Laminate Thickness?

Megtron 6 laminates offer a wide range of options to accommodate different requirements. They are available in 18 thicknesses, complemented by a diverse selection of prepreg thicknesses and glass styles. Specifically, tightly woven, flat-glass styles are offered to minimize impedance variation caused by fiber-weave effects, with the resin evenly coating the surface of these weaves. Additionally, for several Megtron 6 prepreg glass styles, it is possible to choose from three different percentages of resin content.

One notable advantage of Megtron 6 laminates is their compatibility with conventional FR-4 materials. They can be laminated in the same manner without the need for incompatible pressures, temperatures, movements, or cure times. Hybrid boards can be constructed using a single lamination process, incorporating inner layers made of relatively affordable FR-4 materials and outer layer(s) of Megtron 6. This flexibility allows for foil construction or cap construction. Moreover, the availability of a wide selection of Megtron 6 core and prepreg thicknesses, along with different resin content options, simplifies the development of stackups and facilitates impedance control.

The demand for PCB materials with stable dissipation factor (Df) values, typically around 0.003 up to at least 10 GHz, arises from the need to meet channel loss budgets in high-speed digital applications, such as network line cards for data rates of 40 Gbit/s and higher. While various materials, commonly used in RF circuit boards, possess low enough Df values to satisfy loss budgets for high-speed signal paths, these materials usually come at a higher cost compared to regular FR-4 laminates. As a result, hybrid stackups are commonly employed, allocating low-loss layers of high-speed nets on materials with low Df values, while less critical circuits are placed on FR-4 layers for cost-effectiveness.

Applications of Megron 6

MEGTRON 6 by Panasonic is an advanced laminate material specifically engineered for high-speed applications including network equipment, mainframes, IC testers, and high-frequency measuring instruments.

One of the prominent features of Panasonic MEGTRON 6 material is its low dielectric constant and dielectric dissipation factors, which contribute to enhanced electrical performance. Additionally, the material offers low transmission loss, ensuring minimal signal degradation, and exhibits high heat resistance, allowing it to operate reliably under demanding conditions.

How to Store the Panasonic M6 Laminates?

Proper storage conditions are essential to maintain the quality of Panasonic circuit board materials used in printed circuit board production. Here are the key guidelines to follow:

Flat Storage: It is crucial to prevent bending and scratching of the laminate. Store the Panasonic substrate in a flat position, ensuring it remains flat throughout the storage period. This helps to maintain its structural integrity.

Controlled Environment: Create a storage environment that is dry and cool. Avoid exposure to excessive humidity or moisture, as it can adversely affect the substrate’s performance and lead to possible delamination.

Original Container: Preserve the original container provided by the manufacturer to store the Panasonic substrate. The container is specifically designed to protect the material from external factors that could compromise its quality.

Suitable Environment: Store the laminate in a suitable environment that complies with the recommended temperature and humidity conditions for long-term storage. Aim for a cool and dry environment to minimize the risk of damage or degradation.

By adhering to these storage guidelines, you can help ensure the longevity and quality of Panasonic circuit board materials during the printed circuit board production process.

Why Choose JarnisTech to Manufacturing your Megtron 6 PCB

JarnisTech takes pride in offering cutting-edge MEGTRON 6 PCB products developed through advanced production techniques, backed by ISO and UL approvals. Our commitment to quality is reflected in our utilization of modern PCB testing methods such as E-test and solderability test, ensuring the delivery of high-quality PCBs and PCB assemblies.

Key Features of JarnisTech’s MEGTRON 6 PCBs:

●Authentic, state-of-the-art ultra-low loss material.

●Well-suited for HDI applications in the telecommunications and computer sectors.

●Sourced from Panasonic, a reputable vendor known for original PCB standards.

●Tg 195 is one of the standout features of our MEGTRON 6 products.

We offer personalized design solutions, incorporating your input to meet specific requirements.

In addition to providing top-notch MEGTRON 6 components that enhance your projects, JarnisTech offers competitive pricing, ensuring value for your investment. We pride ourselves on being a reliable and reputable company.

By choosing our MEGTRON 6 PCBs, you can rely on dependable components that align with your budgetary needs. We are committed to helping your business thrive, presenting you with the best options to improve profitability. Our MEGTRON 6 Layer PCBs are manufactured in a secure environment, mitigating the risk of device failures.

To ensure customer satisfaction, we offer a free sample before large-quantity orders, ensuring flawless performance without concerns. We have vast experience working with esteemed clients and supply parts to major consumer brands, consistently meeting their expectations. Should a third-party audit be required, we are willing to provide the necessary documentation, as trust from our customers is of utmost importance.

JarnisTech stands as a reliable PCB manufacturer with extensive industry experience. Choose our MEGTRON 6 PCBs and associated products today. Reach out to us now to initiate the process!

Final Thoughts

When seeking a suitable low-loss material that offers optimal performance and cost-effectiveness for your specific requirements, the decision-making process goes beyond comparing laminate data sheets and prices alone. At JarnisTech, we understand this complexity and are here to assist you in making the right choice.

A trusted partner of JarnisTech, provides exceptional service in the PCB industry. We have a team of professionals who possess in-depth knowledge and expertise in guiding customers through material selection processes, ensuring that you find the ideal solution for your needs. This is particularly important as there is a growing demand for specialized materials like Megtron 6.

We recognize the importance of launching flawless prototypes with consistent performance. Rest assured, our experts will collaborate closely with you to ensure that your new prototype not only meets but exceeds your expectations. With our dedication to providing high service levels and industry-leading expertise, JarnisTech is your reliable partner throughout the PCB material selection journey.