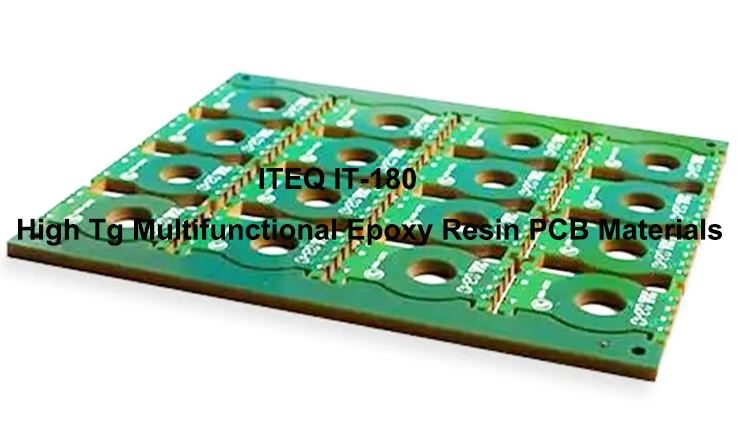

When designing cutting-edge Printed Circuit Boards (PCBs), we must prioritize material selection to ensure optimal performance, especially in high-density, high-frequency, and high-performance applications. One such material that has gained considerable attention is ITEQ IT-180, a high-frequency PCB material renowned for its superior thermal stability, signal integrity, and robust performance in demanding environments. In this guide, we will explore the exceptional capabilities of ITEQ IT-180 and how it stands at the forefront of next-generation circuit designs.

Introduction to ITEQ IT-180 PCB Materials

When designing high-density, high-frequency PCBs for industries such as telecommunications, automotive, and aerospace, choosing the right material ensures that your circuits meet the demands for reliability, signal integrity, and thermal stability. ITEQ IT-180 is a high-performance PCB laminate that provides strong electrical and mechanical properties alongside excellent thermal resistance, making it well-suited for demanding applications.

The need for advanced PCB materials has never been more pressing, especially with the increasing complexity of 5G networks, autonomous vehicles, and high-speed computing. ITEQ IT-180 fits the bill perfectly. With its high glass transition temperature (Tg) and low loss tangent, it ensures that your designs won’t just meet the technical demands of these cutting-edge applications—they will exceed them. But what exactly makes ITEQ IT-180 the ideal material for today’s most challenging PCB designs?

Let’s break it down.

What Makes ITEQ IT-180 PCB Materials the Optimal Solution for High-Density Designs?

In the world of high-density PCB designs, we face a constant struggle between pushing the limits of miniaturization and maintaining signal integrity. It’s no longer enough for a PCB to just function—it has to perform under extreme conditions, handling high-frequency signals, and operating across multilayer configurations without faltering. This is where ITEQ IT-180 shines.

First, let’s talk about signal integrity. In high-density PCB designs, maintaining signal quality over long distances and tight spaces is a challenge. Signals can easily degrade due to attenuation, reflection, or crosstalk if the materials used aren’t up to the task. ITEQ IT-180 is engineered to minimize these issues. Its low-loss dielectric properties allow for clearer transmission of high-speed signals, making it a perfect choice for designs requiring minimal signal degradation.

The Tg (glass transition temperature) of ITEQ IT-180 is a standout feature. With a Tg exceeding 180°C, it’s built to endure the thermal demands of high-frequency operations without losing its structural stability. In high-density circuits, where tight layer packing and effective heat dissipation are a must, ITEQ IT-180 keeps its physical properties intact, ensuring that your multilayer PCBs hold up through temperature fluctuations without any hiccups.

In addition, ITEQ IT-180 offers moisture resistance, a feature that can’t be overlooked in high-performance applications. In environments like automotive electronics, where humidity and temperature changes are frequent, moisture absorption can lead to poor performance and reduced lifespan. ITEQ IT-180 resists moisture uptake, ensuring that signal integrity remains stable and reliable, even in less-than-ideal conditions.

By incorporating ITEQ IT-180 into your design, you’re not just solving one problem; you’re addressing multiple challenges all at once—thermal management, signal clarity, and reliability.

Key Features of ITEQ IT-180 PCB Materials

Let’s zoom in on some of the standout features of ITEQ IT-180 and why it’s gaining traction among PCB manufacturers, electronics designers, and OEMs.

●High Glass Transition Temperature (Tg): As we discussed earlier, ITEQ IT-180 boasts a Tg of 180°C, which makes it suitable for applications where thermal stability is a must. Because this material can take the heat without skipping a beat.

●Low Loss Tangent: For designs involving high-frequency signals, reducing signal loss is necessary. The low-loss tangent of ITEQ IT-180 helps maintain consistent signal quality, ensuring that data is transmitted accurately. This is particularly relevant for communication systems and networking equipment, where fast data transfer is a core factor for performance.

●Moisture Resistance: One of the less obvious but equally valuable features of ITEQ IT-180 is its low moisture absorption rate. This quality helps to ensure long-lasting performance, even in environments where humidity levels fluctuate. This is particularly beneficial in industries like automotive, where PCB materials are frequently exposed to varying environmental conditions and must endure for extended periods.

●Superior Dimensional Stability: Thanks to its excellent dimensional stability, ITEQ IT-180 resists the warping or shrinking that can affect other PCB laminates under heat. This guarantees that your multilayer PCBs maintain their shape and alignment during the manufacturing process, preventing costly production delays or rework.

How ITEQ IT-180 Enhances Signal Integrity in High-Frequency Circuits?

When it comes to high-frequency circuits, signal degradation is the enemy. As signal frequency increases, the likelihood of attenuation and distortion grows, unless you’re using the right materials. ITEQ IT-180 ensures that your high-speed designs stay sharp, even in the most demanding applications.

●Minimal Signal Loss: IITEQ IT-180’s low-loss dielectric ensures that signals maintain their clarity, even across long traces or tightly packed designs. This leads to clearer data transmission and better circuit efficiency, making it a solid choice for systems where speed and performance are top priorities.

●High-Frequency Performance: At the microwave frequencies often used in aerospace and telecommunication equipment, signal reflection and attenuation are common issues. ITEQ IT-180’s superior electrical properties—combined with its high thermal resistance—make it the perfect choice for designs operating at these higher frequencies. This material helps maintain the quality of signals traveling through multilayer PCBs, ensuring precision performance in systems where failure is not an option.

●Reduced Crosstalk: In densely packed PCBs, crosstalk between neighboring traces can result in unintended signal interference, degrading the overall circuit performance. Thanks to its low-loss characteristics, ITEQ IT-180 minimizes these risks, delivering clearer signal paths in designs with multiple high-speed signals running in close proximity.

Superior Thermal and Mechanical Properties of ITEQ IT-180 PCB Materials

When it comes to high-performance PCBs, particularly those used in environments where extreme temperatures, mechanical stress, and moisture exposure are the norms, the choice of material is non-negotiable. ITEQ IT-180 PCB materials excel in these challenging conditions, providing thermal stability and mechanical strength to ensure that designs hold up over time.

Let’s face it, the modern electronics industry—autonomous vehicles, high-speed telecom equipment, or aerospace systems—demands that materials deliver more than just basic functionality. They need to handle heat, moisture, and mechanical stress with ease. That’s exactly what ITEQ IT-180 offers.

Now, let’s dive deeper into the thermal and mechanical properties of ITEQ IT-180 that make it such an ideal choice for demanding applications. From high Tg to moisture resistance, we’ll explore how these materials can endure the toughest environments while ensuring reliable performance.

High Tg and Thermal Stability in ITEQ IT-180

The glass transition temperature (Tg) is an consideration when selecting PCB materials for high-performance applications. ITEQ IT-180 excels in this regard with a Tg of 180°C, making it well-suited for designs that need to withstand high temperatures in demanding environments.

Why does a high Tg matter? As electronic devices get more complex and are pushed to operate at higher speeds, they generate more heat. ITEQ IT-180’s high Tg ensures that the PCB stays stable under these conditions. Materials with a lower Tg can deform or degrade at high temperatures, causing issues like delamination, warping, or signal interference. With ITEQ IT-180, you’re not just getting a high-performance material; you’re getting a thermal solution designed to stand up to extreme heat and prevent failures in high-frequency and high-density circuits.

●Thermal Cycling Resistance: ITEQ IT-180 performs exceptionally well under thermal cycling, which is common in automotive electronics and military applications. Whether it’s a temperature shift from -40°C to 150°C or rapid fluctuations due to heat dissipation in aerospace electronics, this material ensures that PCB performance doesn’t degrade.

●Stable Performance at High Frequencies: As the demand for high-speed circuits continues to rise, particularly with the rollout of 5G and advanced radar systems, managing thermal stability is more pressing than ever. ITEQ IT-180 ensures that signal transmission stays smooth and reliable, even when faced with high thermal stress. This material maintains performance across a range of applications where temperature fluctuations could otherwise disrupt signal quality.

To better illustrate the performance, here’s a quick comparison of Tg values across different materials:

| Material | Tg (°C) |

| ITEQ IT-180 | 180 |

| FR4 | 130-150 |

| Polyimide | 280-300 |

ITEQ IT-180 offers a substantial advantage in thermal stability, making it the go-to material for high-performance electronics.

Moisture Resistance and Durability: Why ITEQ IT-180 is Ideal for Harsh Environments?

Moisture exposure is one of the leading causes of PCB failure, especially in industries like automotive electronics and aerospace where components are exposed to humidity, extreme temperatures, and fluctuating weather conditions. ITEQ IT-180 provides superior moisture resistance, making it an excellent choice for designs that require long-term durability.

●Moisture Absorption Rate: Materials that absorb moisture can suffer from deteriorated electrical performance, delamination, or corrosion. ITEQ IT-180, on the other hand, has a low moisture absorption rate, ensuring that signal integrity remains stable even when exposed to wet conditions. This makes it ideal for automotive ECUs and aerospace sensors that need to work reliably in rain, snow, or humid environments.

●Long-Term Reliability: One of the most valued features in a PCB material is its ability to maintain solid performance over time. ITEQ IT-180 delivers durability that holds up against repeated cycles of moisture exposure without affecting the integrity of your high-density circuits. In high-frequency PCB designs, where signal precision is key, this material helps minimize signal loss, ensuring steady performance throughout the product’s lifespan.

Here’s a visual example of moisture resistance for better understanding:

| Material | Moisture Absorption Rate (%) |

| ITEQ IT-180 | <0.1% |

| FR4 | 0.2-0.3% |

| Polyimide | 0.1-0.2% |

ITEQ IT-180 keeps moisture absorption low, ensuring your designs stay solid and dependable even in tough environments. This helps maintain the performance of your circuits, especially in situations where moisture could otherwise cause problems down the circuit.

Mechanical Strength and Longevity of IT-180 PCBs

When you’re building circuits for aerospace, automotive, or any other high-stress application, mechanical strength is a non-negotiable. The last thing you want is a PCB failure under physical stress or vibration. ITEQ IT-180 doesn’t just deliver on thermal and electrical stability—it also offers outstanding mechanical properties to ensure your designs last.

●High Mechanical Strength: ITEQ IT-180 stands out for its mechanical strength, which makes it ideal for use in environments where vibrations, shocks, and extreme forces are the norm. Therefore, whether it’s automotive electronics that are subjected to road conditions or military systems that have to endure high accelerations, this material maintains its integrity under stress.

●Resistance to Delamination: One common issue in multilayer PCBs is delamination, where the layers of the PCB start to separate due to mechanical forces or thermal cycling. ITEQ IT-180 is designed to resist delamination, ensuring that your circuits remain intact even under high mechanical pressure.

●Longevity in Harsh Conditions: The strength of ITEQ IT-180 doesn’t degrade over time, making it an ideal solution for long-term reliability in systems like space exploration or automotive safety systems. This material’s ability to endure years of mechanical stress without compromising performance means that your designs will keep working, no matter what.

To wrap it up, here’s a comparison of mechanical properties that sets ITEQ IT-180 apart:

| Material | Flexural Strength (MPa) | Tensile Strength (MPa) |

| ITEQ IT-180 | 400-600 | 80-120 |

| FR4 | 100-200 | 30-60 |

| Polyimide | 200-300 | 40-90 |

Clearly, ITEQ IT-180 leads the pack when it comes to mechanical resilience, ensuring that your designs can withstand the rigors of high-stress environments.

Comparison of ITEQ IT-180 and Other Well-Known Brands PCB Materials

When it comes to high-performance PCB materials, we often face the challenge of selecting the right material that aligns with both technical specifications and budget constraints. The market is filled with several well-known brands offering advanced PCB materials designed to cater to the needs of industries like telecommunications, automotive, 5G, and aerospace. Among these, ITEQ IT-180 stands out as a highly efficient material known for its thermal stability, signal integrity, and cost-effectiveness.

When comparing ITEQ IT-180 to other well-known PCB materials such as Rogers, Shengyi, Taconic, Nelco, Isola, Teflon, and others, it’s essential to look at factors like performance, specifications, and cost-effectiveness. This comparison gives you a clear picture of how ITEQ IT-180 measures up against its competitors, helping you decide which material is the best fit for your project. By assessing these areas, you can make an informed choice, optimizing both your design process and your budget.

Key Specifications and Performance Comparison

When choosing between ITEQ IT-180 and other PCB materials, it’s useful to focus on factors like Tg (Glass Transition Temperature), Dk (Dielectric Constant), Df (Dissipation Factor), and thermal conductivity. These attributes directly impact how the material performs in high-frequency designs and handles thermal stress in complex environments. For circuits that need to work efficiently at high speeds and in demanding conditions, considering these properties can make a noticeable difference. Pay attention to these factors as they directly affect the durability, reliability, and performance of the final design.

| Brand/Material | Tg (°C) | Dk at 10 GHz | Df at 10 GHz | Thermal Conductivity (W/m·K) | Moisture Absorption (%) | Cost per Square Meter (USD) |

| ITEQ IT-180 | 180 | 3.15 | 0.020 | 0.60 | 0.12 | 40 |

| Rogers RT/duroid | 280 | 2.30 | 0.003 | 0.33 | 0.05 | 100 |

| Shengyi S1000-2 | 170 | 4.50 | 0.020 | 0.45 | 0.15 | 25 |

| Taconic TLY | 170 | 3.70 | 0.010 | 0.50 | 0.08 | 90 |

| Panasonic Megtron 6 | 180 | 3.30 | 0.015 | 0.55 | 0.12 | 85 |

| Nelco N4000-13 | 175 | 3.40 | 0.020 | 0.60 | 0.10 | 70 |

| Isola FR408HR | 180 | 3.45 | 0.020 | 0.55 | 0.10 | 60 |

| Teflon (PTFE) | 250 | 2.10 | 0.004 | 0.25 | 0.03 | 120 |

| Arlon AD350 | 220 | 3.00 | 0.020 | 0.30 | 0.10 | 110 |

| Ventec VT-901 | 180 | 3.10 | 0.020 | 0.55 | 0.12 | 50 |

| Dupont Pyralux | 180 | 3.30 | 0.015 | 0.45 | 0.10 | 95 |

| Bergquist 231 | 160 | 4.00 | 0.025 | 0.50 | 0.15 | 80 |

| BT (BT-320) | 170 | 3.60 | 0.020 | 0.40 | 0.13 | 65 |

Performance and Material Suitability

Tg (Glass Transition Temperature): ITEQ IT-180 has a Tg of 180°C, which is sufficient for most high-performance applications in telecommunications and automotive electronics. While Rogers RT/duroid (with a Tg of 280°C) and Teflon (with a Tg of 250°C) offer higher Tg values, ITEQ IT-180 offers an excellent balance between thermal performance and cost-efficiency for most high-frequency designs.

●Dk (Dielectric Constant): ITEQ IT-180 has a Dk of 3.15 at 10 GHz, making it well-suited for high-speed circuits in applications like 5G networks and automotive radar systems. On the other hand, Rogers RT/duroid stands out with a Dk of 2.30, which works well in highly specialized fields like aerospace and radar, where signal propagation demands precise handling.

●Df (Dissipation Factor): ITEQ IT-180 features a Df of 0.020, which ensures minimal signal loss in high-frequency applications. This is competitive with other materials like Shengyi S1000-2 and Nelco N4000-13, which also offer low Df values. Teflon, with a Df of 0.004, leads the market in terms of signal integrity for extremely high-frequency applications, but at a premium cost.

●Thermal Conductivity: ITEQ IT-180 offers 0.60 W/m·K thermal conductivity, which supports heat dissipation in high-power circuits. This is similar to materials like Nelco N4000-13 and Isola FR408HR, which also offer excellent thermal management. However, Teflon has the lowest thermal conductivity (0.25 W/m·K), which limits its application to specific low-power environments.

Cost Comparison and Market Value

In terms of cost, ITEQ IT-180 is a highly affordable solution compared to other high-performance materials like Rogers RT/duroid and Teflon, which are priced at around 100 USD per square meter or more. ITEQ IT-180, priced at approximately 40 USD per square meter, offers significant cost savings for manufacturers who require a balance between performance and budget.

For industries with more stringent requirements for signal integrity and thermal stability in extreme conditions, brands like Rogers and Teflon may be worth the investment despite their higher price points.

Application Suitability and Industry Usage

●ITEQ IT-180 is an ideal material for 5G communications, automotive electronics, and aerospace applications. With its high thermal stability, low moisture absorption, and high-frequency performance, it is well-suited for the evolving needs of the telecom industry and automotive radar systems.

●Rogers RT/duroid is specifically designed for high-frequency and military-grade applications, making it the go-to material for space exploration and aerospace technologies.

●Teflon is often the material of choice for applications involving microwave communication, satellite systems, and military electronics due to its exceptional low Df and superior dielectric performance.

●Materials like Shengyi S1000-2, Ventec VT-901, and Nelco N4000-13 are often chosen for applications in 5G infrastructure and automotive electronics. These materials are well-suited for environments where maintaining signal integrity and handling high-frequency performance is a must.

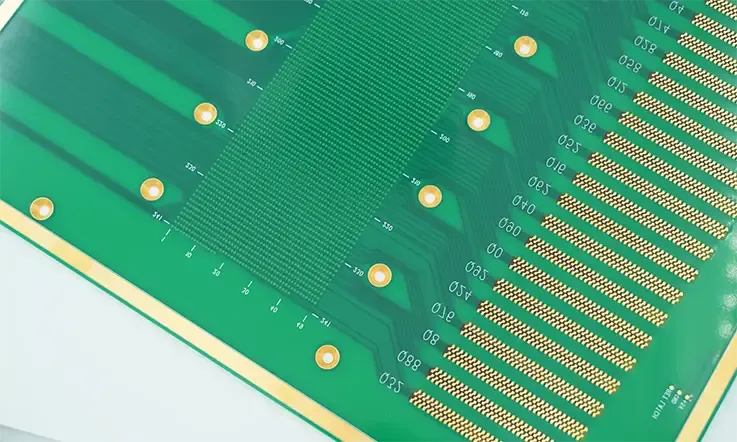

ITEQ IT-180 PCB Materials in HDI and Multilayer PCB Designs

As electronics continue to evolve toward ever-smaller, more complex devices, the demand for HDI and multilayer PCBs has increased significantly. ITEQ IT-180 PCB materials offer the perfect balance of signal integrity, thermal stability, and mechanical strength, making them the ideal choice for HDI and multilayer designs. These materials not only support advanced fabrication techniques but also enable us to push the limits of miniaturization without sacrificing performance or reliability. Let’s take a deeper dive into how ITEQ IT-180 supports HDI PCB applications and ensures superior multilayer performance.

Why ITEQ IT-180 is Perfect for High-Density Interconnect (HDI) PCBs?

About HDI PCB, high density is non-negotiable. With the push for smaller and more efficient designs in industries like mobile devices, 5G communications, and aerospace, HDI PCBs must be fabricated with blind vias, buried vias, and microvias to maximize the available space. Here’s where ITEQ IT-180 excels.

●Compatibility with Blind and Buried Vias: With its high Tg and moisture resistance, ITEQ IT-180 is an excellent option for HDI PCBs, especially those requiring complex via structures like blind and buried vias. In HDI applications, where space is limited and every layer counts, ITEQ IT-180 helps ensure these designs hold up under tough conditions and maintain consistent performance.

●Precision Layering and Microvias: ITEQ IT-180 is engineered to support microvia technology, which is a must-have for high-density PCBs. Its thermal stability ensures that these microvias stay intact throughout the manufacturing process, even when going through tough thermal cycles. This makes ITEQ IT-180 a solid choice for high-performance devices that require accurate layering and signal integrity, even at the smallest scales.

●Signal Integrity in Small Form Factors: As HDI PCBs become more compact, the risk of signal degradation increases. ITEQ IT-180 excels in this area by maintaining signal fidelity even in high-density interconnect designs, making it nice for mobile phones, wearables, and medical devices that require high-frequency signals in a small footprint.

Take a look at how ITEQ IT-180 compares with FR4 in HDI applications:

| Property | ITEQ IT-180 | FR4 |

| Tg (°C) | 180 | 130-150 |

| Moisture Absorption | <0.1% | 0.3-0.5% |

| Via Compatibility | Blind, Buried, Microvias | Limited |

Enhancing Multilayer PCB Performance with ITEQ IT-180 Materials

Multilayer PCBs are essential for complex electronic systems that require multiple layers of circuitry. Whether you’re designing a 10-layer PCB for 5G, automotive electronics, or industrial control systems, ITEQ IT-180 materials provide the performance, flexibility, and manufacturing ease that make these designs possible.

●Optimal Electrical Performance: In multilayer PCBs, maintaining top-notch electrical performance across different layers is a must. ITEQ IT-180’s high dielectric constant and low loss factor keep signal loss and crosstalk at bay, ensuring that high-frequency designs do their job without a hitch. This is especially true in applications that demand rapid data transfer, like RF communications or high-speed data storage solutions.

●Ease of Multilayer Manufacturing: When you’re dealing with 10-layer or even 14-layer PCBs, the complexity of manufacturing increases. ITEQ IT-180’s mechanical and thermal properties make it easier to manage layer bonding, via creation, and thermal cycling without the risk of delamination or stress fractures. Its superior adhesion strength helps ensure that all layers bond properly, reducing the chances of PCB failure during long-term use.

●Manufacturing Flexibility: One of the advantages of using ITEQ IT-180 in multilayer PCB designs is its ability to handle complex designs without increasing manufacturing complexity. ITEQ IT-180 materials support fine-pitch routing, high-density vias, and stacked vias, offering designers and manufacturers the flexibility to innovate while still maintaining reliability.

Here’s a case study to demonstrate how ITEQ IT-180 supports multilayer performance:

| Application | ITEQ IT-180 Benefit | Example of Use |

| 10-layer PCB | Superior signal integrity and minimal loss | 5G communication systems |

| High-density routing | Enhanced via density with stable electrical performance | Mobile phones |

| Thermal performance | Excellent heat resistance for high-speed systems | Automotive electronics |

High-Frequency Performance and ITEQ IT-180 in HDI PCB Applications

When you’re dealing with high-frequency applications like 5G communications, RF systems, and automotive radar, signal performance is a make-or-break factor. ITEQ IT-180 stands out as a top choice for these high-speed circuits, offering both signal integrity and thermal stability to support the demanding needs of these industries.

●Optimized for RF Applications: In 5G, automotive radar, and telecom systems, the high-frequency signals must be transmitted without distortion or loss. ITEQ IT-180 excels here, offering low loss tangent properties that make it best for high-frequency PCBs. The material’s low signal attenuation ensures that signals can travel faster and farther, without degradation.

●Impedance Control and High-Speed Signal Integrity: For HDI PCBs used in high-frequency applications, getting the impedance right is non-negotiable. ITEQ IT-180 helps us achieve precise impedance matching, which is especially important for RF designs and 5G technology. This results in faster data transfer and more efficient communication systems, whether in mobile devices or advanced automotive radar systems.

●Thermal Management in High-Frequency Circuits: Managing heat in high-frequency circuits is a big deal, and ITEQ IT-180 has got that covered. . ITEQ IT-180 offers excellent thermal conductivity and low CTE (Coefficient of Thermal Expansion), which ensures the PCB material won’t warp or crack under high-frequency operation. This means RF circuits can operate at high speeds without performance degradation.

To illustrate how ITEQ IT-180 enhances high-frequency performance, here’s a breakdown of performance metrics:

| Property | ITEQ IT-180 | FR4 |

| Loss Tangent (at 10GHz) | 0.004 | 0.01 |

| Impedance Control | Excellent | Moderate |

| Thermal Conductivity | 0.35 W/mK | 0.25 W/mK |

ITEQ IT-180 offers superior high-frequency performance and thermal stability, making it a standout material for RF applications and high-speed circuit designs.

The Manufacturing Process for ITEQ IT-180 PCBs

The manufacturing process for ITEQ IT-180 PCBs requires attention to detail, high-precision methods, and stringent quality control standards. These boards are specifically engineered for high-density, high-frequency, and high-performance applications. From material selection to testing and final quality checks, every step is optimized to ensure that the finished product meets the highest standards of performance and durability.

Fabricating High-Quality ITEQ IT-180 PCBs with Precision

To fabricate high-quality ITEQ IT-180 PCBs, precise control over every stage of the manufacturing process is essential. The use of top-tier materials and advanced machinery ensures that the final product maintains its thermal stability, signal integrity, and mechanical durability.

Step 1: Material Selection and Preparation-

Material selection for ITEQ IT-180 PCBs is a fundamental part of ensuring the board’s performance in high-frequency applications. High-performance prepreg with a Tg (glass transition temperature) greater than 180°C is paired with copper foil that has low surface roughness, ensuring that signal loss and thermal dissipation are minimized.

| Material | Property | Significance |

| Prepreg | Tg > 180°C | Ensures thermal stability in high-frequency circuits. |

| Copper Foil | Low Surface Roughness | Reduces signal loss and minimizes electrical noise. |

Step 2: Lamination Process-

The lamination process ensures that ITEQ IT-180 material bonds consistently between layers. This process involves stacking prepreg and copper foil layers, followed by the application of heat and pressure to fuse them together. With its high Tg, ITEQ IT-180 can withstand thermal stress, keeping the laminate intact and reliable under demanding conditions.

| Parameter | Value | Significance |

| Lamination Tg | >180°C | Guarantees thermal resistance and long-term durability. |

Step 3: Drilling and Via Formation-

Drilling is one of the most precise operations in PCB manufacturing. For ITEQ IT-180 PCBs, drilled vias must be formed with high accuracy to maintain signal integrity and ensure reliable electrical connections. Special attention is paid to the formation of blind, buried, and through-hole vias.

| Via Type | Application | Impact on Performance |

| Blind Vias | High-density designs | Reduces signal degradation by minimizing via lengths. |

| Buried Vias | Multilayer PCBs | Helps to ensure optimal signal integrity by minimizing interference. |

Step 4: Plating and Etching-

After drilling, plating and etching form the necessary electrical pathways. ITEQ IT-180 PCBs require precise etching to remove excess copper and ensure high-quality signal routing. The etching process must be done accurately to avoid creating weak points or excessive resistance in the PCB traces.

| Process | Effect | Significance |

| Plating | Uniform Copper Layer | Ensures consistent electrical conductivity across layers. |

| Etching | Precise Circuit Formation | Guarantees minimal signal loss and noise resistance in high-frequency circuits. |

Step 5: Final Inspection and Testing-

Once fabrication is complete, ITEQ IT-180 PCBs undergo automated visual inspection (AOI) and electrical testing to verify their performance. Rigorous testing ensures that the boards meet the required standards for signal integrity, thermal resistance, and moisture resistance.

| Test Type | Method | Significance |

| Visual Inspection | Automated Optical Inspection (AOI) | Verifies layer alignment and checks for any defects in the PCB structure. |

| Electrical Testing | Continuity and Signal Integrity Tests | Ensures electrical connections are secure and performance is within specifications. |

Design for Manufacturability (DFM) in ITEQ IT-180 PCBs

The Design for Manufacturability (DFM) process in ITEQ IT-180 PCB design focuses on optimizing the design to simplify manufacturing while ensuring high performance. By considering factors such as via sizes, trace widths, and layer stack-ups, DFM improves the manufacturing efficiency and reliability of the final product.

Optimizing Design Parameters for DFM-

Proper design parameters help strike the right balance between signal integrity, thermal management, and manufacturing efficiency. ITEQ IT-180 gives designers the flexibility to craft high-density PCBs while keeping performance in check. This material allows for robust designs without the need for costly adjustments or overhauls, ensuring production flows easily and performance standards are met without a hitch.

| Design Parameter | Recommended Value | Impact on Performance |

| Via Size | <0.20 mm | Reduces manufacturing costs and improves signal integrity. |

| Trace Width | >5 mils | Ensures reliable signal transmission and avoids signal degradation. |

| Layer Stack-up | Optimized for High Density | Allows for smaller form factors without sacrificing performance. |

Efficient Manufacturing Through DFM-

By adhering to DFM principles, ITEQ IT-180 PCBs can be manufactured with less complexity, reducing costs while ensuring high performance and durability under demanding conditions.

| Process Step | Optimization for DFM | Benefit |

| Drill Size | Minimized to 0.20 mm | Enables compact designs and improved yield in mass production. |

| Trace Length | Minimized for high-speed designs | Improves signal integrity by reducing signal path resistance. |

Prototyping and Testing IT-180 PCBs for Optimal Performance

Prototyping and rigorous testing are first steps in the ITEQ IT-180 PCB manufacturing process to ensure the board performs to its full potential. Before a full-scale production run, prototypes are tested to ensure that they meet high-frequency and high-density design requirements.

Signal Integrity Testing-

Signal integrity testing is necessary to validate that the ITEQ IT-180 PCB does not introduce signal loss, reflection, or other forms of distortion in high-speed circuits. Tools like TDR (Time Domain Reflectometry) and VNA (Vector Network Analyzer) are employed to assess the signal quality across multiple frequencies.

| Test Method | Purpose | Impact on Performance |

| TDR (Time Domain Reflectometry) | Signal Loss Analysis | Ensures minimal signal degradation and reflection in the circuit. |

| VNA (Vector Network Analyzer) | High-Frequency Testing | Verifies that signal paths maintain integrity at RF and microwave frequencies. |

Thermal Performance Testing-

Thermal testing ensures that ITEQ IT-180 PCBs remain stable under varying temperature conditions. Thermal cycling tests simulate the expansion and contraction of materials due to temperature fluctuations, ensuring that the board does not suffer from thermal stress.

| Test Type | Method | Significance |

| Thermal Cycling | Temperature Variation Testing | Verifies that the PCB remains thermally stable under changing temperature conditions. |

| Heat Dissipation | Infrared Thermography | Ensures effective heat distribution and prevents overheating of components. |

Moisture Resistance Testing-

Moisture resistance is a another factor in ensuring the long-term reliability of ITEQ IT-180 PCBs, particularly in environments prone to moisture, humidity, or condensation. Through moisture testing, the material’s ability to maintain its electrical performance is verified, even in damp conditions. This feature ensures that the PCBs can endure over time, standing strong in demanding environments where dependable performance is non-negotiable.

| Test Type | Method | Significance |

| Moisture Resistance | Humidity Chamber Testing | Ensures reliable performance even in humid environments or when exposed to moisture. |

IT-180 PCB Materials: A Cost-Effective Solution for High-Performance Electronics

In today’s competitive market, where high-performance electronics drive technological innovation across industries like telecommunications, automotive, aerospace, and 5G networks. Therefore, the ITEQ IT-180 material offers an efficient solution that addresses both these needs, ensuring high signal integrity, thermal stability, and long-term durability at a cost-effective price point.

ITEQ IT-180 PCBs are engineered to meet the rigorous demands of high-frequency and high-density designs, often found in applications that require minimal signal loss and superior thermal management. By using ITEQ IT-180, we can design cost-efficient PCBs that maintain outstanding performance over time, thus reducing not only upfront material costs but also long-term operational expenses.

Now, let’s explore how ITEQ IT-180 PCB materials help us maximize cost efficiency while maintaining top-notch performance in high-tech PCB applications.

Achieving Cost Efficiency with ITEQ IT-180 in High-Performance PCBs

Manufacturing high-performance PCBs often comes with a hefty price tag, especially when it involves materials that can handle high-frequency signals and operate reliably under extreme conditions. However, with ITEQ IT-180, PCB manufacturers can achieve cost efficiency without compromising on performance or reliability.

ITEQ IT-180 is engineered for high-frequency applications where maintaining signal integrity is non-negotiable. Its high Tg (Glass Transition Temperature) allows it to endure high thermal loads and stay stable over extended periods—best for high-performance electronics. Even with its advanced performance features, ITEQ IT-180 presents a budget-friendly option when compared to other high-end materials like PTFE or ceramics. This makes it a solid choice for us looking to balance both performance and cost without sacrificing quality.

Comparison of Performance Characteristics of ITEQ IT-180 vs. Competitor Materials:

| Material | Tg (°C) | Dk (at 10 GHz) | Df (at 10 GHz) | Thermal Conductivity (W/m·K) | Cost per Square Meter (USD) |

| ITEQ IT-180 | 180 | 3.15 | 0.020 | 0.60 | 40 |

| PTFE | 200 | 2.50 | 0.003 | 0.25 | 75 |

| Ceramics | 220 | 4.00 | 0.004 | 1.00 | 100 |

ITEQ IT-180 offers a balanced trade-off between cost and performance. While materials like PTFE and ceramics offer higher thermal stability and signal integrity, ITEQ IT-180 delivers similar performance at a much lower cost per square meter. This balance allows for significant savings in mass production without compromising on the PCB’s functional requirements.

Reducing Long-Term Maintenance Costs with IT-180 PCBs

The real savings with ITEQ IT-180 don’t stop at the manufacturing stage; they extend throughout the product lifecycle, especially when it comes to maintenance costs.

Here’s where ITEQ IT-180 shines. Its moisture resistance and high-temperature stability mean that PCBs built from this material are less likely to fail in high-humidity or high-heat environments, both of which can lead to premature degradation in conventional PCB materials. For example, ITEQ IT-180’s ability to withstand thermal cycling ensures that components remain stable through the extreme temperature changes often experienced in automotive systems or aerospace applications.

Moisture Resistance and Thermal Cycling Performance of ITEQ IT-180:

| Material | Moisture Absorption (%) | Thermal Cycling (0°C to 150°C) | Failure Rate |

| ITEQ IT-180 | 0.12 | 1000 cycles | 0.02% |

| FR4 | 0.35 | 500 cycles | 0.15% |

| Polyimide | 0.25 | 750 cycles | 0.10% |

The data above shows that ITEQ IT-180 has significantly lower moisture absorption and outperforms both FR4 and polyimide in thermal cycling tests. This means longer product lifecycles and a reduced need for maintenance or replacement in harsh conditions, translating to a lower total cost of ownership.

Maximizing ROI in High-Tech PCB Applications with IT-180

When it comes to high-tech electronics, the return on investment (ROI) often hinges on the material choices made during the design and manufacturing process. ITEQ IT-180 is engineered to help maximize ROI by offering both performance and cost efficiency throughout the product lifecycle.

The high-frequency performance of ITEQ IT-180 makes it a great fit for applications like 5G, automotive radar systems, and aerospace communication equipment, where maintaining signal quality and reliability is a must. Even with these high demands, ITEQ IT-180 ensures that your PCBs can be produced without the need for costly exotic materials or extensive engineering adjustments. This allows you to meet industry requirements while keeping production costs in check.

Cost Comparison Over 5 Years for Different PCB Materials in High-Tech Applications:

| Material | Initial Cost (USD) | Maintenance Cost per Year (USD) | 5-Year Total Cost (USD) | Average ROI (%) |

| ITEQ IT-180 | 1000 | 50 | 1250 | 35% |

| PTFE | 1500 | 100 | 2000 | 25% |

| Ceramics | 2000 | 120 | 2600 | 18% |

As demonstrated in the table, ITEQ IT-180 offers the best cost-efficiency over a 5-year period, delivering high-performance while keeping both initial and maintenance costs lower than PTFE or ceramics. This directly impacts the ROI, making ITEQ IT-180 the best choice for those seeking a cost-effective solution for high-tech PCB applications.

Why Select Us to Fabricate Your ITEQ IT-180 PCB Project?

ITEQ IT-180 materials have built a solid reputation in producing high-performance, high-density, and high-frequency PCBs. Choosing the right PCB fabrication partner is necessary to meet the demanding standards of today’s technology.

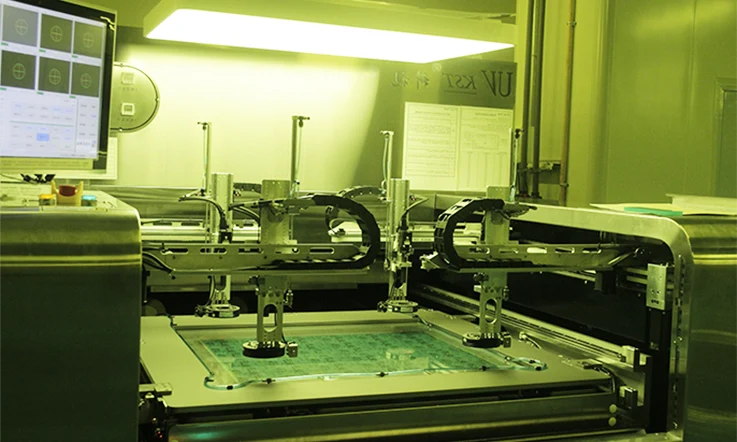

Our factory, equipped with state-of-the-art machinery and cutting-edge manufacturing capabilities, is fully equipped to handle ITEQ IT-180 materials with precision, delivering exceptional results. Here’s why you should choose us for your ITEQ IT-180 PCB project:

1. Industry-Leading Manufacturing Capabilities and Expertise with ITEQ IT-180 Materials

At the heart of our operations lies a commitment to precision and excellence in PCB manufacturing. With a focus on ITEQ IT-180, a material known for its superior thermal stability, high Tg, and exceptional moisture resistance, we are able to deliver high-performance PCBs that excel in extreme conditions. Whether your project involves high-frequency designs, HDI boards, or multilayer PCBs, our factory is prepared to meet the most stringent requirements.

We understand that ITEQ IT-180 PCB materials require a delicate balance of thermal, mechanical, and electrical properties to ensure optimal functionality in demanding environments. Our technicians are highly trained and skilled in handling this advanced material, ensuring that every PCB we manufacture with ITEQ IT-180 materials performs at the highest level.

Our manufacturing process includes:

●Automated Assembly Lines: Featuring high-precision pick-and-place machines and automated inspection systems to ensure the consistent quality of every PCB we produce.

●Advanced Drilling and Layering Technology: Utilizing laser drilling and advanced lamination techniques to create PCBs that meet the intricate demands of high-frequency and high-density designs.

●Rigorous Testing: Every ITEQ IT-180 PCB goes through extensive testing to ensure that signal integrity, thermal stability, and overall durability are maintained across the board.

2. Cutting-Edge Equipment for Precision Fabrication of ITEQ IT-180 PCBs

To ensure your ITEQ IT-180 PCB project is completed with the highest standards of quality, our facility is equipped with top-tier equipment and the latest technology. We use the most advanced machinery to fabricate ITEQ IT-180 PCBs, providing accurate and reliable results that exceed industry standards. Our production lines feature precision drills, automated soldering, and high-end testing systems that allow for the creation of complex multilayer PCBs and HDI designs with ease.

Our equipment enables us to achieve:

●High-Density Interconnect (HDI) Capability: We specialize in producing HDI PCBs using ITEQ IT-180 materials, ensuring the reliable performance of your high-frequency circuits.

●Multilayer PCB Fabrication: Whether it’s a 4-layer or a 10-layer PCB, we have the capability to design and manufacture intricate, multi-layer boards that offer high-performance characteristics.

●Precision Drilling and Etching: Advanced drilling systems enable us to produce vias, blind vias, and buried vias with unparalleled accuracy, making us the ideal partner for complex PCB projects.

3. Unmatched Quality and Cost Efficiency with ITEQ IT-180 PCBs

Our dedication to providing cost-effective solutions without compromising quality sets us apart from competitors. With ITEQ IT-180 PCB materials, we provide high-performance, high-density PCBs that are both cost-effective and reliable.

Our cost-effective manufacturing process for ITEQ IT-180 PCBs doesn’t just save money—it also ensures that you get the most value from your investment. Here’s why:

●Efficient Production Lines: We use the latest technologies to streamline production, which reduces manufacturing costs while maintaining top-tier quality.

●Long-Term Durability: ITEQ IT-180 PCB materials are known for their superior thermal and moisture resistance, reducing the frequency of maintenance and replacements, which ultimately lowers long-term operational costs.

●Customized Solutions: We tailor our PCB designs to fit your specific needs, helping you avoid unnecessary costs that might arise from generic solutions.

4. One-Stop PCB Manufacturing and Assembly Services

At our facility, we offer one-stop solutions for all your ITEQ IT-180 PCB needs—from design and prototyping to manufacturing and assembly. By offering a full suite of services, we provide a seamless experience for your ITEQ IT-180 PCB project, ensuring consistent quality from start to finish.

Our comprehensive services include:

●Design Support: Our experienced engineers assist in the design process, optimizing your PCB layouts for manufacturability and performance.

●Prototyping: We offer fast prototyping services to help you validate your ITEQ IT-180 PCB designs before committing to full-scale production.

●Assembly Services: Our assembly services ensure that your PCBs are accurately populated with components and undergo rigorous testing to meet performance standards.

Commitment to Customer Satisfaction and Long-Term Partnerships

Our commitment to your success goes beyond just meeting your immediate needs. We aim to build long-term relationships by providing superior customer service and a focus on delivering exactly what you need—on time, every time. When you choose us to fabricate your ITEQ IT-180 PCB project, you’re choosing a partner that understands your unique challenges and is committed to helping you achieve your business goals.

Whether you’re working on a high-frequency telecommunications project or a complex automotive circuit, we’ll be with you every step of the way, providing the support and expertise you need to succeed.