In the realm of product design, engineers constantly seek materials that can enhance the performance, reliability, and aesthetics of their creations. ITEQ IT-170GRA1 PCB laminate emerges as a game-changing solution, offering a myriad of benefits that empower product design engineers to push the boundaries of innovation.

This article explores the remarkable features of ITEQ IT-170GRA1 from the perspective of PCB design engineers, highlighting its ability to unlock new design possibilities and elevate the quality of electronic products.

Overview of ITEQ Corporation

ITEQ Corporation is a leading global supplier of high-performance copper-clad laminate and prepreg materials for the printed circuit board (PCB) industry. Founded in 2000 and headquartered in Taiwan, ITEQ has established itself as a trusted provider of advanced materials for the electronics industry.

The company’s product portfolio includes a wide range of materials such as standard FR-4, high-speed digital, high-frequency, and high-reliability laminates and prepregs. These materials are used in various electronic applications, including telecommunications, automotive, consumer electronics, and industrial equipment.

ITEQ Corporation is committed to innovation and sustainability, with a focus on developing environmentally friendly and high-performance materials. The company’s products are designed to meet the evolving demands of the PCB industry, offering high thermal resistance, low signal loss, and reliable performance in high-speed and high-frequency applications.

With a global presence and a strong commitment to quality and customer satisfaction, ITEQ Corporation continues to be a preferred partner for PCB manufacturers and electronic device designers worldwide. The company’s dedication to research and development, as well as its emphasis on technical support and customer service, has solidified its reputation as a leading provider of advanced PCB materials.

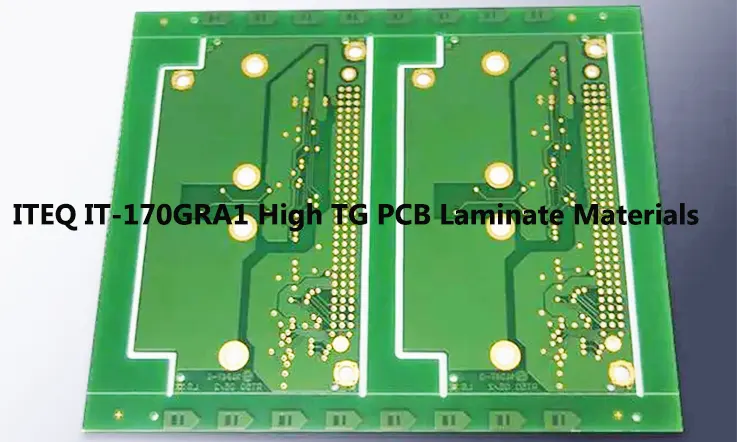

What is ITEQ IT-170GRA1?

High Tg / Halogen Free / Mid-Loss Laminate & Prepreg

ITEQ IT-170GRA1 is a high Tg (180°C by DSC) PCB material that is halogen-free and specifically designed for industrial PC and 3S (server/storage/switch) applications. This material offers low mid-loss, high thermal reliability, low CTE, and CAF resistance. It is a green material that provides aggressive cost savings without sacrificing performance, making it an ideal choice for demanding PCB applications.

Performance Characteristic of IT-170GRA1

ITEQ IT-170GRA1 is a high-performance PCB material with the following characteristics:

1.High Tg (180°C) and Halogen-Free:

The material offers a high glass transition temperature and is free from halogen, making it suitable for applications requiring high thermal resistance and environmental friendliness.

2.Low Dielectric Constant (Dk) and Dissipation Factor (Df):

With a Dk of less than 3.9 at 10GHz and a Df of less than 0.010 at 10GHz, IT-170GRA1 provides low mid-loss, making it suitable for high-frequency applications.

3.Compatibility with High Tg Standard FR-4 Processes:

The material is compatible with standard FR-4 processes, allowing for ease of integration into existing manufacturing processes.

4.High Thermal and CAF Resistance Reliability:

IT-170GRA1 offers high thermal reliability and resistance to CAF (Conductive Anodic Filament) formation, ensuring long-term performance and durability in demanding environments.

5.Laminate Properties:

The material exhibits excellent laminate properties, making it suitable for industrial PC and 3S (server/storage/switch) applications, where high reliability and performance are essential.

Limitations and Challenges for using ITEQ IT-170GRA1

While ITEQ IT-170GRA1 high TG PCB substrate offers many advantages, there are also some limitations and challenges associated with its use:

1. Cost: High TG materials can be more expensive compared to standard PCB substrates, which can impact overall production costs.

2. Processing: High TG materials may require specialized processing techniques and equipment, which can add complexity and cost to the manufacturing process.

3. Design considerations: The use of high TG materials may require adjustments to the PCB design to accommodate the material’s specific properties, such as thermal expansion and conductivity.

4. Availability: Depending on the region, availability of high TG materials may be limited compared to standard PCB substrates, which can impact supply chain and lead times.

5. Material handling: High TG materials may have specific handling requirements to prevent damage or contamination, which can add complexity to the manufacturing process.

6. Compatibility: Ensuring compatibility with other materials and components in the PCB assembly process can be a challenge when using high TG substrates.

7. Environmental impact: Some high TG materials may contain substances that could have environmental implications, requiring proper disposal and handling procedures.

Overall, while ITEQ IT-170GRA1 high TG PCB substrate offers numerous benefits, careful consideration of the limitations and challenges is important when selecting this material for a specific application. Working closely with material suppliers and manufacturers can help address these challenges and ensure successful implementation.

ITEQ IT-170GRA1: Higher Cost Analysis

The higher cost of ITEQ IT-170GRA1 laminates compared to other PCB laminates can be attributed to several factors:

1.High-TG (Glass Transition Temperature) Material:

ITEQ IT-170GRA1 is designed to withstand higher operating temperatures, making it suitable for demanding applications such as automotive, aerospace, and high-power electronics. The use of high-TG materials involves specialized manufacturing processes and materials that contribute to higher production costs.

2.Advanced Properties:

ITEQ IT-170GRA1 laminates offer advanced properties such as improved thermal performance, low dielectric loss, and high reliability. Achieving these properties often requires the use of more sophisticated manufacturing techniques and higher quality raw materials, which can drive up the cost.

3.R&D and Innovation:

Developing high-performance laminates like ITEQ IT-170GRA1 involves significant research and development efforts to create materials with specific performance characteristics. The investment in R&D and ongoing innovation contributes to the higher cost of the final product.

4.Quality and Certification:

High-performance laminates often undergo rigorous testing and certification processes to ensure they meet industry standards and performance requirements. The additional quality assurance and certification processes can add to the overall cost of the material.

5.Specialized Applications:

ITEQ IT-170GRA1 is targeted at specialized applications that demand high-performance materials, such as high-frequency, high-speed, and high-reliability PCBs. The niche nature of these applications can result in lower production volumes, which may contribute to higher per-unit costs.

While ITEQ IT-170GRA1 laminates may have a higher initial cost, their advanced properties and performance characteristics can provide long-term benefits in terms of reliability, durability, and overall performance in demanding electronic applications. It’s essential for purchasers to weigh the higher cost against the specific needs and requirements of their PCB applications to determine the overall value proposition.

How to Test the Quality of ITEQ IT-170GRA1 PCB Laminate?

There are several ways to test the quality of ITEQ IT-170GRA1 PCB laminate. Here are some common methods:

1. Visual Inspection: Conduct a visual examination of the PCB laminate for any visible defects such as cracks, delamination, voids, or uneven surfaces.

2. Dimensional Measurement: Measure the dimensions of the PCB laminate, including thickness, length, and width, to ensure they meet the specified tolerances.

3. Mechanical Testing: Perform mechanical tests such as tensile strength, flexural strength, and impact resistance to assess the material’s mechanical properties and its ability to withstand various stresses.

4. Thermal Analysis: Conduct thermal tests to evaluate the laminate’s thermal conductivity, coefficient of thermal expansion (CTE), and its ability to dissipate heat effectively.

5. Electrical Testing: Perform electrical tests to determine the laminate’s dielectric constant, loss tangent, electrical insulation properties, and impedance control.

6. Chemical Resistance Testing: Assess the laminate’s resistance to various chemicals, including solder fluxes, cleaning agents, and other substances commonly encountered during PCB assembly and operation.

7. Moisture Absorption Testing: Measure the laminate’s ability to absorb moisture over time, as excessive moisture absorption can affect its electrical and mechanical performance.

8. Environmental Testing: Subject the PCB laminate to environmental conditions such as temperature and humidity cycling, thermal shock, and exposure to harsh chemicals to evaluate its long-term reliability and performance under different operating conditions.

9. Peel Strength Testing: Determine the adhesive strength between the laminate layers by conducting peel strength tests, which assess the bond integrity and adhesion quality.

10. Aging and Reliability Testing: Perform accelerated aging and reliability tests to simulate the laminate’s performance over an extended period, evaluating its stability, durability, and resistance to degradation.

It’s important to note that the specific testing methods may vary depending on the requirements and industry standards applicable to ITEQ IT-170GRA1 PCB laminate.

Applications of ITEQ IT-170GRA1 PCB Laminates

ITEQ IT-170GRA1 PCB laminates are well-suited for a variety of high-performance applications, including:

1. Server/Storage/Switch: The high thermal reliability and low mid-loss characteristics of IT-170GRA1 make it an ideal choice for use in server, storage, and switch applications where high-speed data processing and reliability are crucial.

2. Routers: IT-170GRA1 is suitable for routers due to its high Tg, low Dk, and low Df properties, enabling efficient signal transmission and reliability in high-speed networking devices.

3. Backplane: The material’s high Tg and compatibility with standard FR-4 processes make it suitable for backplane applications, where high-speed data transfer and signal integrity are essential.

4. Telecom: ITEQ IT-170GRA1 is well-suited for telecom equipment, offering high thermal reliability and CAF resistance to ensure long-term performance in demanding telecommunications environments.

5. Base Station: The material’s high Tg and low mid-loss properties make it suitable for use in base station equipment, where reliable signal transmission and high thermal resistance are critical for continuous operation.

Overall, ITEQ IT-170GRA1 PCB laminates find applications in high-speed, high-reliability electronic devices across various industries, where performance and durability are paramount.

Conclusion

ITEQ IT-170GRA1 PCB laminate emerges as a game-changer for product design engineers, unlocking a world of possibilities in creating innovative and high-quality electronic products. With its exceptional properties and versatile compatibility, ITEQ IT-170GRA1 empowers engineers to achieve superior functionality, reliability, and aesthetics in their designs. By harnessing the potential of ITEQ IT-170GRA1, product design engineers can create products that captivate users, outperform competitors, and shape the future of the electronics industry.