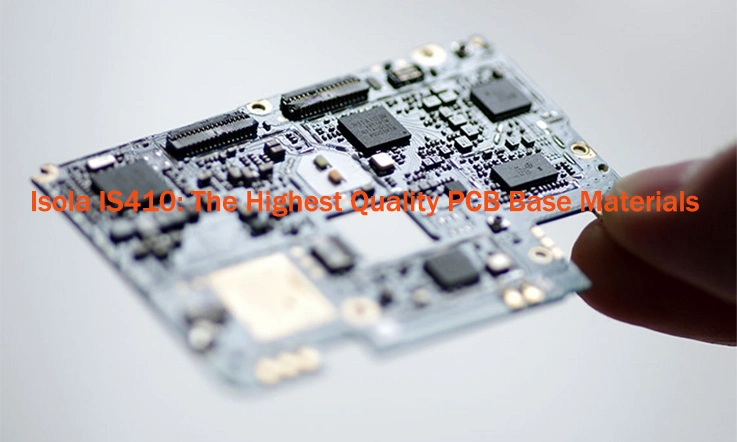

Printed circuit boards (PCBs) are at the heart of modern electronics, facilitating the integration of complex electronic systems. As technology progresses, the demands for reliable, high-performance PCB materials have grown exponentially. Among these materials, Isola IS410 PCB Materials have emerged as a standout choice for multi-layer PCBs requiring excellent thermal stability and signal integrity. Let’s take a deep dive into what makes Isola IS410 a top-tier choice for electronics professionals and how it caters to the needs of high-tech industries.

Comprehensive Overview of Isola IS410 PCB Materials

When it comes to designing high-performance printed circuit boards, selecting the right materials is half the battle. Isola IS410 PCB Materials are designed to meet the most demanding requirements in modern electronics. This high-Tg laminate material is specifically tailored for multi-layer PCBs that need to withstand extreme conditions, such as high temperatures and electrical interference. If you’re in the business of manufacturing cutting-edge devices—whether for telecommunications, automotive, or aerospace—you’ll appreciate how Isola IS410 can take your designs to the next level.

What Makes Isola IS410 Unique?

Isola IS410 stands out from the pack with its unique advantages over conventional PCB materials. While standard materials suffice for everyday uses, IS410 delivers outstanding performance, reliability, and durability in demanding environments. Engineered for superior thermal stability, excellent electrical properties, and long-term dependability, it’s the ideal choice for applications where subpar performance just won’t cut it. Whether it’s enduring tough operating conditions or meeting stringent industry standards, IS410 proves itself to be the go-to material for manufacturers aiming for excellence. So, if you’re looking for a material that delivers top-tier performance without the drama, IS410 has you covered.

The Role of High-Tg Laminates in Modern PCBs-

High-Tg laminates allow modern PCBs to endure higher temperatures without deforming. This feature becomes necessary when designing complex electronics, as managing heat can be tricky. With a Tg of 180°C, Isola IS410 maintains its structure under thermal stress, even during soldering. Whether handling high-speed circuits or multi-layer designs, it performs reliably under demanding conditions.

Key Differentiators of Isola IS410 PCB Materials-

Isola IS410 is engineered with a blend of innovative materials that deliver outstanding mechanical, thermal, and electrical performance. What sets this laminate apart is its ability to maintain low loss factors at high frequencies, making it a solid choice for industries requiring high-speed signal integrity. It also offers a balance between cost and performance, ensuring that we can benefit from a premium product without breaking the bank.

Here’s why Isola IS410 stands out in a crowded field of PCB materials:

●Superior Signal Integrity: The laminate’s low dielectric constant (Dk) helps keep signal loss to a bare minimum, making it a solid choice for high-frequency applications. By reducing interference and maintaining signal integrity, it ensures consistent performance, even when dealing with demanding circuit designs. This feature comes in handy when you need reliable results without the headache of signal degradation.

●Thermal Stability: Its high glass transition temperature allows it to maintain performance under heat stress, reducing the risk of component failure.

●Mechanical Strength: Using an advanced resin system combined with high-quality glass cloth, Isola IS410 delivers robust durability and reliability, making it a go-to choice for complex multi-layer stack-ups. This material handles the demands of intricate designs, ensuring consistent layer alignment and long-term stability.

Benefits of Using Isola IS410 in Multi-Layer PCBs

Multi-layer PCBs are widely used in electronics design, and Isola IS410 proves to be a great match for complex, high-performance applications. Whether developing advanced data center systems or next-generation automotive electronics, this material delivers dependable performance and handles demanding designs with ease.

Enhanced Durability and Performance in Demanding Environments-

Multi-layer PCBs face a range of challenges like thermal expansion, mechanical stress, and signal loss. Isola IS410 is built to take on these demands with ease. Its excellent thermal stability allows it to handle temperature fluctuations, making it a solid option for tough environments. Whether in the heat of a car engine or in the tough conditions of aerospace, IS410 stands up to the task and keeps things on track.

Reduced Signal Loss and Electrical Interference-

When it comes to high-frequency applications, signal loss and electrical interference are serious concerns. Isola IS410 is engineered with low dielectric loss, ensuring that signals maintain their integrity over long distances and at high speeds. For example, in telecommunications, this means clearer signals and faster data transmission—no more worrying about data being garbled or lost during transmission. This material is a trusted choice for 5G infrastructure and data center connections, where reliability is a must.

Technical Properties of Isola IS410 PCB Materials

In the competitive landscape of PCB design and manufacturing, choosing the right material directly impacts reliability and performance. Isola IS410 is known for its excellent thermal, electrical, and mechanical properties. To offer a clearer view, we compare Isola IS410 with other popular materials such as Rogers, Shengyi, Taconic, and Panasonic. This comparison provides us with the necessary details to make the best material choice for our specific applications, helping us meet their design goals efficiently.

Glass Transition Temperature (Tg) and Thermal Stability

When designing for environments with fluctuating or high temperatures, the glass transition temperature (Tg) becomes a factor to keep in mind. Materials with a higher Tg offer better stability under heat, helping to prevent deformation and extend the material’s lifespan. Isola IS410, with a Tg of 180°C, provides a reliable option for multilayer PCB designs. This makes it a strong choice for designs that need to endure extreme conditions over time.

How High Tg Improves PCB Reliability-

High Tg laminates help prevent thermal damage in demanding applications such as automotive engine controls or industrial robotics. For example, Isola IS410’s performance is highly reliable during soldering processes and under repeated thermal cycling, making it suitable for high-reliability designs.

Comparison of Isola IS410 with Standard FR4 Laminates-

Let’s break it down further by comparing Isola IS410 with other laminates:

| Material | Tg (°C) | Applications |

| Isola IS410 | 180 | Multilayer PCBs, automotive electronics |

| Rogers RO4835 | 280 | RF and microwave applications |

| Shengyi S1000H | 180 | Consumer electronics, telecommunication |

| Panasonic Megtron 6 | 175 | Data center and networking infrastructure |

While Isola IS410 doesn’t reach the extreme Tg of materials like Rogers RO4835, it balances affordability and reliable performance, making it an excellent choice for many industrial applications.

Electrical Properties: Dielectric Constant (Dk) and Dissipation Factor (Df)

For applications with high frequencies and fast data rates, electrical properties like dielectric constant (Dk) and dissipation factor (Df) are essential to consider. Materials with low Dk and Df help cut down on signal loss and boost performance in high-speed designs. Isola IS410’s excellent electrical properties make it a solid choice for high-frequency applications, ensuring your circuits maintain precision and reliability under demanding conditions.

Low Dk and Df for High-Frequency Applications-

The Dk of Isola IS410 is 3.87~3.96, while its Df is 0.0149~0.023. These values ensure minimal signal distortion, enabling high-speed data transfers. For instance, in applications like 5G base stations or high-speed communication devices, such properties ensure reliable signal integrity.

Signal Integrity Advantages in High-Speed Designs-

When compared to standard FR4 materials, Isola IS410 offers superior signal integrity. For reference:

| Material | Dk @ 1 GHz | Df @ 1 GHz | Applications |

| Isola IS410 | 3.9 | 0.0189 | High-speed communication devices |

| Taconic TLY-5 | 2.2 | 0.0015 | Satellite communication, 5G networks |

| Rogers RO4003C | 3.38 | 0.0027 | Microwave antennas |

| Shengyi S1170 | 4.0 | 0.016 | Consumer electronics |

By maintaining low dissipation and dielectric values, Isola IS410 ensures signal quality without the premium costs of specialized materials like Rogers or Taconic laminates.

Mechanical Strength and Stress Resistance

PCBs often face mechanical stress due to assembly processes, vibration, and environmental conditions. A material’s mechanical properties determine its ability to withstand these challenges without degrading over time. Isola IS410’s mechanical robustness makes it a reliable choice for designs requiring long-term durability.

Performance Under Thermal Cycling-

Thermal cycling, common in automotive and aerospace applications, can lead to material fatigue and failure. Isola IS410 is engineered to resist such stress, maintaining its structural integrity even after prolonged thermal exposure.

Long-Term Reliability in Harsh Conditions-

Applications like industrial robotics and oil exploration demand materials that can endure not only physical stress but also harsh environments. Let’s compare Isola IS410 with other materials in terms of mechanical performance:

| Property | Isola IS410 | Ventec VT-47 | Shengyi S1000-2 |

| Tensile Strength (MPa) | 400 | 350 | 320 |

| Peel Strength (N/mm) | 1.2 | 1.1 | 1.0 |

| Z-Axis Expansion (%) | 3.2 | 3.5 | 4.0 |

These properties demonstrate why Isola IS410 is a trusted choice for complex multilayer designs. Its balance of tensile strength, peel strength, and thermal expansion ensures it performs well across a range of applications, from automotive systems to industrial control boards.

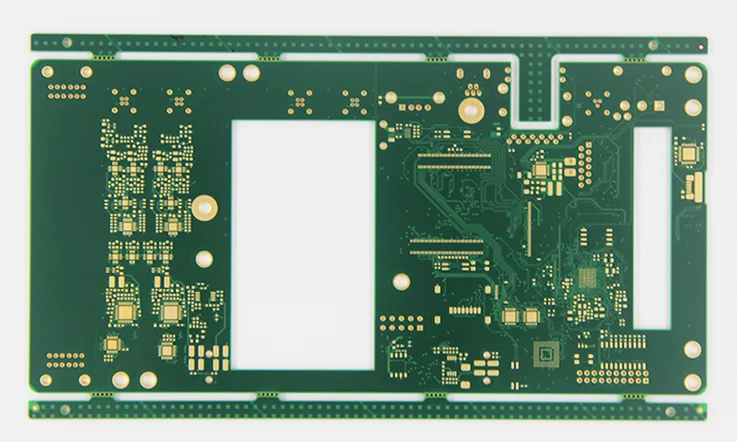

Designing Multi-Layer PCBs with Isola IS410 PCB Materials

Creating efficient and reliable multi-layer PCBs requires a fine balance of engineering precision, material performance, and manufacturing expertise. Isola IS410 PCB materials stand out in this space for their ability to enhance performance in high-speed, high-frequency designs. From proper stack-up configurations to tackling prototyping challenges, these materials empower our designers to push the boundaries of innovation. In this section, we’ll explore best practices for using Isola IS410, tackle prototyping challenges, and discuss strategies to maintain signal integrity and suppress EMI interference.

Best Practices for PCB Stack-Up with Isola IS410

Effective PCB stack-up is the cornerstone of robust design, especially in multilayer boards where signal layers, ground planes, and power planes need careful alignment. Isola IS410’s consistent performance ensures us can achieve precise layer configurations without compromising functionality.

Layer Alignment and Material Selection Tips-

When using Isola IS410, consider the layer structure and dielectric thickness to balance electrical and thermal performance. Proper alignment of signal layers adjacent to ground planes minimizes crosstalk and improves impedance control. For example:

| Layer Type | Recommended Material | Purpose |

| Signal Layer | Isola IS410 | High-speed signal transmission |

| Ground Plane | Copper foil | EMI shielding and signal return |

| Power Plane | Copper foil | Stable power delivery |

| Dielectric Prepreg | Isola FR406 | Insulation and layer bonding |

Signal Integrity Optimization Techniques-

Designers aiming for high-speed performance can benefit from Isola IS410’s low dielectric constant (Dk) and dissipation factor (Df). Strategies include:

1.Maintaining uniform trace widths to achieve consistent impedance.

2.Minimizing stub lengths by carefully drilling vias.

3.Using Isola IS410 laminates with low Dk values to reduce signal delay.

The result? A smooth pathway for high-speed signals, even in dense multilayer layouts.

Prototyping Challenges and Solutions

Prototyping multilayer PCBs comes with its fair share of hurdles. Common issues include misaligned layers, delamination, and signal loss due to material inconsistencies. Leveraging Isola IS410 materials helps mitigate these risks, but there are still some best practices to follow.

Common Issues During Multi-Layer PCB Prototyping-

1.Thermal Mismatch: If materials with mismatched coefficients of thermal expansion (CTE) are used, it can cause warping. Isola IS410’s low CTE minimizes this risk.

2.Delamination: Insufficient lamination pressure or thermal stress can cause layers to separate. Using Isola IS410’s high Tg properties reduces this problem.

3.Signal Crosstalk: Inadequate ground planes or poorly routed traces can lead to interference. Proper stack-up design mitigates this.

Ensuring Quality with Isola IS410 Materials-

Adopting stringent quality checks during prototyping ensures success in production runs. For instance:

| Prototyping Step | Best Practice with Isola IS410 |

| Lamination | Use proper pressure and temperature settings. |

| Drilling | Optimize drill speed to avoid cracking. |

| Impedance Control | Test with controlled dielectric materials. |

With these practices, we can produce prototypes that mirror final production quality while saving costs and time.

Signal Integrity and EMI Shielding

Signal integrity and EMI shielding are top priorities in multi-layer PCB designs. Without addressing these aspects, performance can degrade significantly, especially in high-speed or RF applications. Isola IS410 materials provide a reliable solution, offering low dielectric properties and thermal stability to minimize signal disruption.

The Role of Isola IS410 in Minimizing Signal Loss-

Isola IS410’s low Dk ensures signals travel at consistent speeds, reducing timing mismatches. Additionally, the low Df minimizes power dissipation, allowing signals to retain their strength over long traces. For instance, in a 5G networking application, Isola IS410 materials ensure data flows with minimal interference, even at gigabit rates.

Strategies for Effective EMI Interference Prevention-

1.Ground Plane Placement: Surrounding signal layers with ground planes improves EMI shielding.

2.Via Stitching: Adding via fences around sensitive signal paths reduces electromagnetic leakage.

3.Material Selection: Isola IS410’s consistent dielectric performance provides an inherent advantage in suppressing EMI.

To illustrate, here’s a comparative table of EMI performance:

| Material | EMI Shielding Efficiency | Applications |

| Isola IS410 | High | High-speed, multi-layer designs |

| Rogers RO4350 | Very High | RF and microwave circuits |

| Ventec VT-42 | Moderate | Consumer electronics |

Isola IS410 offers a balance of performance and cost, making it accessible for a wide range of projects.

Thermal and Electrical Performance of Isola IS410 PCB Materials

The performance of advanced PCBs hinges not only on their ability to handle high-speed signals but also on how effectively they manage heat and maintain structural integrity under thermal stress. Isola IS410 laminates excel in balancing thermal management and electrical performance, offering a dependable choice for cutting-edge designs in telecommunications, automotive systems, and aerospace applications. In this section, we delve into the advantages Isola IS410 brings to thermal management, high-speed signal transmission, and lead-free soldering.

Thermal Management in Advanced PCBs

Managing heat dissipation is a major design challenge in modern PCBs, especially in high-power or high-frequency applications. Materials that can handle thermal stress without compromising performance are indispensable. Isola IS410 is engineered with high Tg (Glass Transition Temperature) and robust thermal conductivity, making it an excellent choice for applications demanding superior thermal stability.

Managing Heat Dissipation with Isola IS410 Laminates-

When devices operate under intense workloads, excess heat can cause circuit failures, delamination, or material degradation. Isola IS410 mitigates these risks through its ability to:

1.Withstand temperatures up to 180°C.

2.Maintain mechanical integrity during repeated thermal cycling.

3.Offer low Z-axis expansion, reducing stress on plated through-holes (PTHs).

Real-World Examples of Thermal Stability Benefits-

Take the example of a 5G base station. Its multi-layer PCB, built using Isola IS410 laminates, operates at high power levels continuously. Isola’s thermal resilience ensures stable performance, reduced failure rates, and a longer lifespan for the equipment.

| Material | Thermal Conductivity (W/m·K) | Max Operating Temperature (°C) |

| Isola IS410 | 0.85 | 180 |

| Rogers RO4350 | 0.69 | 150 |

| Taconic TLY-5 | 0.71 | 150 |

High-Speed Electrical Performance

With the rise of technologies like 5G, IoT, and autonomous vehicles, the need for high-speed signal transmission is skyrocketing. A material’s dielectric properties can make or break its ability to handle those high-frequency signals. Isola IS410 laminates step up to the plate by keeping the dielectric constant (Dk) and dissipation factor (Df) low, so you get minimal signal distortion. This makes it a solid option for designers who need reliable performance without the hassle.

Supporting High-Frequency Signal Transmission-

Isola IS410 excels in:

1.Signal integrity: Low Dk values reduce signal delay, making it best for high-speed data lines.

2.Power efficiency: Low Df minimizes energy loss, allowing signals to retain their strength over long distances.

For instance, in high-speed server boards, Isola IS410 ensures data transmission rates remain consistent across multiple layers, even in densely packed designs.

Compatibility with RF and Microwave Designs-

Isola IS410 is a reliable choice for RF and microwave designs, thanks to its low dielectric constant (Dk). This helps maintain stable impedance matching, which is a must for RF circuits. When you need a material that can handle the heat and still deliver consistent performance, Isola IS410 doesn’t disappoint—it’s built to keep things on track without any fuss.

| Material | Dielectric Constant (Dk @ 10 GHz) | Dissipation Factor (Df @ 10 GHz) |

| Isola IS410 | 3.7 | 0.017 |

| Rogers RO4350 | 3.48 | 0.0037 |

| Taconic RF-35 | 3.5 | 0.0018 |

Lead-Free Soldering Compatibility

With environmental regulations pushing for lead-free manufacturing processes, PCB materials must endure higher soldering temperatures without compromising their performance. Isola IS410 rises to the occasion with its high thermal reliability and excellent dimensional stability under extreme conditions.

Ensuring Durability Under Lead-Free Soldering Processes-

Lead-free soldering typically requires reflow temperatures above 260°C, which can cause delamination or warping in standard PCB materials. Isola IS410’s high Tg (180°C) ensures the laminate remains intact and stable during repeated soldering cycles.

How Isola IS410 Outperforms Alternative Laminates-

When you stack up Isola IS410 against other high-performance laminates, it offers a solid mix of cost-effectiveness, durability, and reliable electrical performance. This material can take the heat, literally, without losing its electrical punch, making it a go-to choice for applications like consumer electronics, where cost matters, and aerospace systems, where durability and precision are non-negotiable. Whether you’re dealing with high temperatures or intricate designs, Isola IS410 holds up under pressure, keeping things solid and stable when it counts.

| Material | Tg (°C) | CTE (Z-axis, ppm/°C) | Lead-Free Soldering Compatibility |

| Isola IS410 | 180 | 45 | Excellent |

| Panasonic Megtron 6 | 180 | 50 | Very Good |

| Shengyi S1000-2 | 170 | 65 | Good |

What Technology is Required to Manufacture High-End PCBs Using Isola IS410 Materials?

Building high-quality PCBs with Isola IS410 materials requires precision, the right tools, and a deep understanding of the material’s unique qualities. As the demand for durable and advanced electronic products continues to climb, materials like Isola IS410 are becoming more and more of a go-to solution. To create multi-layer PCBs that are both reliable and cost-effective, it’s all about using the right tech that can take full advantage of what Isola IS410 brings to the table, like top-notch thermal stability, signal integrity, and solid mechanical strength. With the right approach, you can stay ahead of the curve and produce boards that won’t let you down.

Advanced Design Software for PCB Layouts

Before starting the manufacturing process, a solid PCB design is necessary. When building high-end PCBs with Isola IS410, using advanced design software ensures that the layout is optimized for both performance and manufacturability. These tools assist in refining the design to leverage the material’s attributes. From managing signal integrity to considering thermal aspects, modern software streamlines the design stage, helping to avoid issues down the line by setting up everything properly from the beginning.

●ECAD Tools: Electronic Computer-Aided Design (ECAD) tools like Altium Designer, Eagle, or Mentor Graphics are used to create the PCB layouts. These tools allow for intricate designs with multiple layers, ensuring that the high-frequency and high-thermal demands of Isola IS410 are met.

●Signal Integrity Simulations: Advanced simulation software like Ansys HFSS or Keysight ADS is used to model the electrical properties of the PCB design. This ensures the PCB meets stringent requirements like low dissipation factor (Df) and stable dielectric constant (Dk), preventing signal loss and distortion at high speeds.

These tools ensure that every design aspect is meticulously planned and optimized to deliver top-tier performance using Isola IS410 materials.

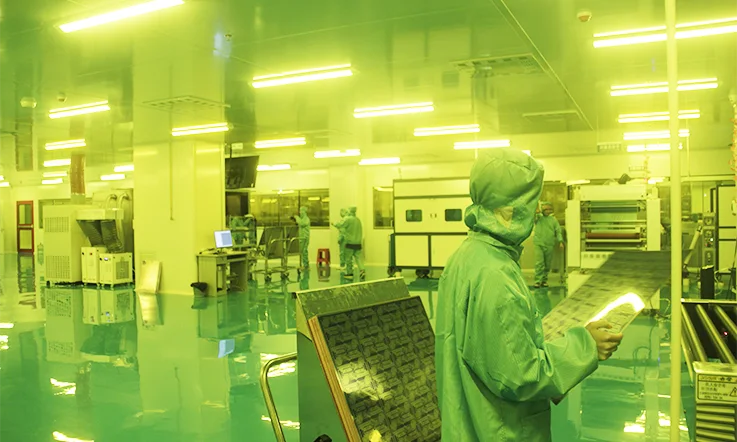

Specialized PCB Fabrication Equipment for Isola IS410

Once the design is finalized, the next step is to move forward with manufacturing the PCB using Isola IS410 materials. This process demands precision equipment that’s capable of handling the unique qualities of high-performance laminates. Technologies involved in this stage include advanced laser drilling, automated optical inspection (AOI), and precise lamination techniques, all of which ensure that the final product meets the required standards for thermal and electrical performance. These steps come together to produce a reliable and durable PCB, suitable for demanding applications in consumer electronics, aerospace, and more.

●Laser Drilling and Etching: For high-density designs, laser drilling is used to create precise vias and holes in the PCB layers. This technology allows for the creation of microvias, which are often used in high-frequency applications, ensuring minimal signal loss and a cleaner path for electrical transmission.

●Impedance Control: Isola IS410’s low dissipation factor and stable dielectric constant make it ideal for impedance-controlled designs. Using controlled impedance etching, we can precisely match the impedance of the PCB traces to avoid signal degradation in high-speed circuits, such as those found in RF and microwave applications.

●High-Precision Copper Plating: The copper plating process guarantees that the traces on the PCB meet high-quality standards, helping to reduce signal loss, especially in high-frequency applications. Techniques such as electroplating and electroless plating ensure an even copper distribution and solid bonding to the Isola IS410 laminate. This results in a dependable electrical connection that can perform consistently under various operational conditions.

These technologies ensure that the PCB meets all the performance criteria needed for advanced applications like 5G networks, automotive electronics, and aerospace systems.

Advanced Testing and Quality Control

Once the PCBs are fabricated, they undergo a series of rigorous tests to ensure that they meet the required performance standards. Isola IS410’s robust thermal and electrical properties need to be tested thoroughly to ensure the PCB can withstand demanding real-world conditions.

●Automated Optical Inspection (AOI): This technology is used to inspect the physical characteristics of the PCB, checking for defects in trace widths, via placements, and overall alignment. The AOI system can identify flaws that might otherwise go unnoticed, ensuring the integrity of the design.

●X-ray Inspection:X-ray inspection is a go-to method for examining the inner layers of a multi-layer PCB. This technique is especially useful when working with high-frequency designs and intricate stack-ups like those crafted from Isola IS410. It’s important to ensure that vias are properly formed and that there are no hidden issues that could cause problems later. By using X-ray inspection, we can verify that the PCB’s internal structure meets the required standards.

●Thermal Cycling Tests: Given Isola IS410’s superior thermal stability, it’s essential to perform thermal cycling tests to simulate the temperature fluctuations the PCB will experience during its lifecycle. These tests ensure that the material’s low CTE (Coefficient of Thermal Expansion) will prevent issues like delamination or cracking when subjected to heat.

In addition, electrical testing is performed to ensure that the PCB meets the required performance specifications, including signal integrity and high-frequency performance.

Factors to Consider for Isola IS410 in PCB Manufacturing

The selection and use of Isola IS410 as a material for printed circuit boards requires careful consideration of several factors. These factors range from material preparation and handling to detailed processing parameters. Each of these steps ensures that the high-performance properties of Isola IS410 are leveraged fully in the final product. This section dives deeper into the technical aspects of working with Isola IS410, focusing on elements such as material preparation, lamination techniques, process compatibility, and cost considerations. By understanding these factors thoroughly, we can optimize our production processes and achieve superior results.

Material Preparation and Handling

The quality of the PCB laminate material directly influences the final product’s mechanical, electrical, and thermal performance. In the case of Isola IS410, its high glass transition temperature (Tg) and low coefficient of thermal expansion (CTE) make it a premium choice, but these advantages can only be realized through proper material handling.

Moisture Control-

Isola IS410 laminates are sensitive to moisture absorption, which can lead to various defects such as delamination, voids, or blistering during the curing process. To maintain the material’s integrity, proper moisture control is imperative.

●Storage: Store Isola IS410 in vacuum-sealed bags or containers that maintain a relative humidity level of less than 50%. This minimizes moisture absorption before the material is used in production.

●Pre-baking: Laminates should be pre-baked at 125°C for 4 to 6 hours to remove any moisture absorbed during storage. This step ensures that any remaining moisture does not expand during high-temperature processes, which could cause defects in the laminate. Properly handling this stage helps the material maintain its intended performance during later heating steps.

| Parameter | Recommendation |

| Storage Temperature | 20°C–25°C |

| Humidity Level | < 50% RH |

| Pre-Baking Time | 4–6 hours at 125°C |

Cutting and Drilling-

Precision cutting and drilling are essential when working with Isola IS410. The material’s inherent rigidity requires high-quality tools and optimized parameters to ensure clean cuts and holes.

●Drill Bits: Use carbide drill bits with sharp edges to minimize mechanical stress on the material.

●Feed Rate: Ensure the correct feed rate for each operation to reduce the risk of stress and ensure smooth, clean edges.

Lamination Process Optimization

The lamination process is fundamental to creating reliable, defect-free multi-layer PCBs. Isola IS410’s high Tg provides excellent thermal stability, allowing it to endure multiple reflow cycles without degradation. However, fine-tuning various parameters is needed to achieve the best results during lamination. Managing these factors carefully will ensure the material behaves as expected during the heating stages.

Temperature and Pressure Settings-

Isola IS410 has specific requirements for temperature and pressure during the lamination process to achieve the desired bond strength between layers.

●Heat-Up Rate: Control the heat-up rate to about 3°C per minute to avoid thermal shock, which can lead to cracks or warping in the laminate.

●Laminate Pressure: A uniform pressure of 250–350 psi is recommended to ensure that each layer bonds properly and that no air pockets remain.

●Cure Cycle: The ideal cure cycle involves heating the laminate to 175°C for 60–90 minutes. This ensures complete cross-linking of the epoxy resin system, which is essential for long-term reliability.

| Parameter | Recommended Value |

| Heat-Up Rate | 3°C/min |

| Lamination Pressure | 250–350 psi |

| Cure Time | 60–90 minutes at 175°C |

Voids and Delamination Prevention-

Voids and delamination are common defects that can occur during the lamination process. To prevent these issues, consider using vacuum-assisted lamination techniques, which ensure that any air trapped between layers is evacuated. This guarantees a high-quality bond and prevents the formation of voids.

Compatibility with Manufacturing Processes

The performance of Isola IS410 is influenced by its compatibility with different manufacturing processes. This section covers how to integrate Isola IS410 into your PCB production line while optimizing its performance under various conditions, including lead-free soldering and high-frequency applications.

Lead-Free Soldering Compatibility-

Lead-free soldering has become the industry standard, but it comes with higher reflow temperatures that can place additional thermal stress on PCBs. Isola IS410’s high Tg (180°C) ensures excellent resistance to thermal cycling and stress, making it suitable for lead-free soldering processes that reach temperatures as high as 260°C.

●Soldering Process: Isola IS410 is capable of withstanding multiple lead-free reflow cycles without compromising the integrity of the PCB.

●Thermal Stability: The material’s low CTE minimizes the risk of PCB warping during the soldering process, ensuring long-term durability.

High-Frequency Applications-

Isola IS410 excels in high-frequency applications due to its low dielectric constant (Dk) and dissipation factor (Df). These properties minimize signal loss and distortion, making it an ideal material for RF, microwave, and high-speed digital designs.

●Signal Integrity: For high-frequency signals, the low Dk and Df of Isola IS410 ensure minimal signal degradation, enabling clean, reliable transmission over extended distances.

●Impedance Control: Isola IS410 provides excellent impedance control for high-speed PCB designs, helping to reduce reflections and keep signal integrity intact. This material ensures the signals travel smoothly across the board without interference, a must for high-performance designs. The ability to manage impedance consistently, even in demanding applications, contributes to the overall reliability of the system.

| Process | Performance with Isola IS410 |

| Lead-Free Soldering | Excellent thermal resistance |

| High-Frequency Signals | Low Dk and Df for minimal loss |

| Thermal Cycling | Low CTE for dimensional stability |

Cost Considerations and Alternatives

Although Isola IS410 offers significant performance benefits, it is also essential to consider cost when selecting a laminate material. In many cases, alternatives may provide similar performance at a lower cost, depending on the specific requirements of the application.

Cost-Performance Trade-Off-

While Isola IS410 offers excellent thermal and electrical performance, justifying its higher price in demanding applications, there are cases where more budget-friendly options, like Shengyi S1000-2 or Panasonic Megtron 4, could be up to the task without putting a dent in your wallet. These alternatives may provide a solid performance for less intense applications, offering a good balance between cost and functionality for designs that don’t require the top-tier specs of Isola IS410.

| Material | Cost Index | Tg (°C) | Df @ 10 GHz |

| Isola IS410 | 3.5 | 180 | 0.017 |

| Shengyi S1000-2 | 2.8 | 170 | 0.020 |

| Panasonic Megtron 4 | 3.2 | 175 | 0.018 |

These alternative materials can provide a cost-effective solution for designs that don’t require the high performance of Isola IS410. However, in applications that demand high-frequency operation or thermal stability, investing in Isola IS410 will ensure better long-term results.

Why Choose Us to Fabricate Isola IS410 PCBs for Your Project?

When it comes to high-performance PCBs, Isola IS410 stands out as an excellent choice due to its superior thermal stability, signal integrity, and mechanical strength. However, achieving a successful fabrication of these high-end boards requires more than just top-tier materials—it demands a combination of skilled expertise, advanced technology, and a commitment to delivering high-quality results on time. Let’s walk through why partnering with us will make all the difference for your Isola IS410 PCB project.

1.Expertise and Technical Know-How

We’ve spent years working with PCBs, gaining a deep understanding of the unique challenges that come with materials like Isola IS410. Our team is well-versed in the art of working with specialized laminate materials, and we know exactly how to fabricate multi-layer boards that meet the highest standards. Whether it’s perfecting the copper plating process, optimizing signal flow, or managing impedance control, our engineers are experts at tackling these intricate details. We’ve got the skills and experience to make sure every aspect of your board is dialed in and working as it should, right down to the finest specs.

Example: For a recent project requiring high-speed, high-frequency circuits, our team used Isola IS410 to achieve stable signal transmission over a complex multi-layer board. By leveraging our advanced design and production techniques, we ensured the PCB’s reliability and consistent performance—no hiccups along the way.

2.State-of-the-Art Technology

When it comes to manufacturing precision, we don’t cut corners. We utilize the latest PCB fabrication technologies, from sophisticated CAD software for design to cutting-edge automated machines for lamination, drilling, and plating. These technologies allow us to create boards with high density, fine trace widths, and smooth finishes that meet the demands of complex applications.

Example: One of our clients needed a multi-layer Isola IS410 PCB with ultra-fine traces and precise impedance control. Using our high-precision laser drilling and automated plating systems, we were able to meet the requirements for their high-frequency design—delivering it on time, and within budget.

3.Top-Notch Service and Support

Working with us means you’re not just getting a product; you’re gaining a dedicated partner for your PCB project. From design consultation to post-production support, we provide comprehensive services to ensure your project runs as smoothly as possible. Whether you need assistance with design modifications or last-minute adjustments, our support team is available to answer your questions and guide you through every step of the process.

4.Quick Turnaround Times

We know that meeting deadlines is just as important as the quality of the boards. Our streamlined manufacturing process ensures that your Isola IS410 PCBs are fabricated quickly and efficiently without compromising on quality. Whether you’re working on a prototype or full-scale production, we offer flexible turnaround times to fit your project’s needs.

Example: A client recently needed a batch of high-performance Isola IS410 PCBs for an urgent product launch. We were able to expedite the production and delivery process, getting their boards to them on schedule while maintaining high quality.

5.Competitive Pricing

While Isola IS410 is a premium material, we offer competitive pricing to ensure you get the best value for your investment. By optimizing our production processes, we’re able to keep costs down without sacrificing quality. We also provide a range of price options depending on the complexity of the project and volume, giving you flexibility in choosing the solution that fits your budget.

6.Specialized PCB Fabrication for Unique Applications

Isola IS410 is not just for generic applications. We specialize in creating custom PCBs for specialized applications, such as high-speed communications, automotive electronics, aerospace, and more. If you require unique design parameters or materials, our team can provide the expertise to meet your specific needs.

Example: One of our clients in the aerospace industry required a high-heat-resistant PCB for a critical component. We used Isola IS410 to meet their exact specifications, ensuring the board could withstand the high temperatures and maintain performance under extreme conditions.

7.Providing a Range of Specialized PCB Manufacturing and Assembly Services

In addition to meeting standard requirements, we also offer a wide range of specialized PCB manufacturing and assembly services. If your project requires unique materials, custom stacking structures, or specific thermal, humidity, and frequency specifications, our team can provide tailored solutions. We specialize in various types of PCBs, including but not limited to high-frequency materials, high-temperature resistance materials, flexible circuit boards, rigid-flex boards, and more. Additionally, we provide a variety of assembly services to ensure that your boards perform optimally during the assembly process.

Example: We recently worked with a client who needed a custom rigid-flex PCB for an application that required high-frequency signal handling in a compact space. By employing advanced assembly techniques, we ensured the design was both space-efficient and signal-stable, and the client was thrilled with the result.

Ready to Get Started?

If you’re looking to bring your high-performance PCB project to life with Isola IS410, we’re here to help! From design consultation to delivery, we offer the knowledge, technology, and support you need to get the job done right. Don’t settle for less—reach out to us today and let’s build your next PCB together!

FAQs & Isola IS410 PCB materials

What makes Isola IS410 a preferred material for high-speed PCB designs?

Isola IS410 offers excellent thermal stability and low signal loss, making it ideal for high-frequency applications. It is particularly suited for designs that require stable performance across multiple thermal cycles and high-speed signal integrity.

Can Isola IS410 be used for both single-layer and multi-layer PCBs?

Yes, Isola IS410 is highly versatile and can be used for both single-layer and multi-layer PCB designs. Its high glass transition temperature (Tg) allows it to handle complex multi-layer stack-ups without compromising performance.

What are the key advantages of using Isola IS410 for high-speed designs?

Isola IS410 offers reduced signal loss, consistent impedance control, and low dissipation factor, which are all crucial for maintaining high-speed signal integrity. These properties make it an excellent choice for RF and high-speed digital circuits.

Can Isola IS410 withstand the stress of multiple reflow cycles?

Yes, Isola IS410 is designed to withstand multiple reflow cycles, making it perfect for high-performance PCBs that require durability and stability even after repeated thermal exposure.