In the ever-evolving world of electronics manufacturing, finding the right Gold Finger PCB manufacturer can feel a little like searching for a needle in a haystack. With so many options available, it’s not just about price—it’s about finding someone who understands the intricate details, delivers quality products, and stands by their work long-term. As a PCB design engineer, electronics manufacturer, or circuit board purchaser, making the wrong choice could lead to a pile of defective boards and missed deadlines. But hey, we’ve all been there, right?

This guide will walk you through the key steps to finding a reliable Gold Finger PCB manufacturer—someone you can trust to help your project not only get off the ground but soar.

What is a Gold Finger PCB and Why is it a Game-Changer?

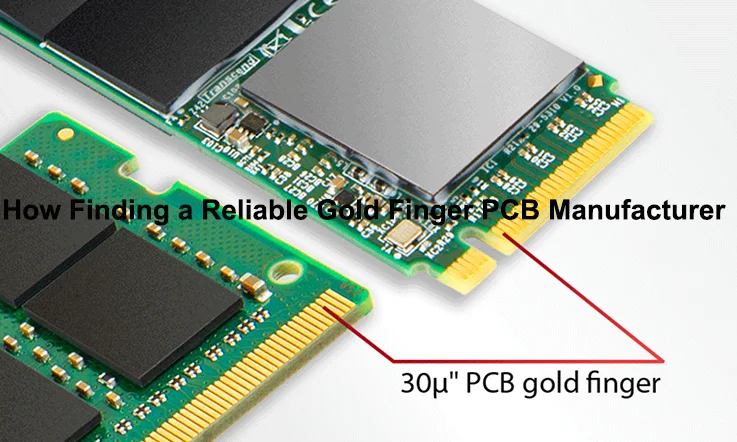

Before diving headfirst into finding a manufacturer, it’s helpful to understand what makes Gold Finger PCBs stand out. These “fingers” refer to the gold-plated connectors found on the edge of a PCB, which act as an electrical bridge between the board and external components. They ensure seamless conductivity and durability—meaning that, over time, your PCB will still deliver excellent performance even with repetitive plugging and unplugging.

Gold, as we all know, is more than just a shiny metal; it’s a powerhouse in the world of conductivity. In PCB manufacturing, gold-plated edge connectors provide that extra durability and reliability that standard materials simply can’t match.

Why Choose Gold-Plated Edge Connectors for Your PCB?

Now, why gold? Sure, it looks fancy, but this choice isn’t about style—it’s about function. Gold plating offers superior resistance to oxidation and corrosion, and its conductivity is off the charts. These edge connectors serve as critical points of contact, especially in applications that require frequent connection cycles, such as motherboards, graphic cards, and memory modules.

If your PCB is involved in any sort of high-frequency or high-speed signal transmission, gold-plated connectors are the way to go. Trust me, the performance boost is worth it.

Key Qualities of a Reliable Gold Finger PCB Manufacturer

So, what should you be looking for when narrowing down a Gold Finger PCB manufacturer? It’s not just about who can get you the lowest price per board or the fastest turnaround time (although those are nice bonuses). It’s about who can offer consistent quality, personalized service, and technical support when you need it most. Let’s break it down.

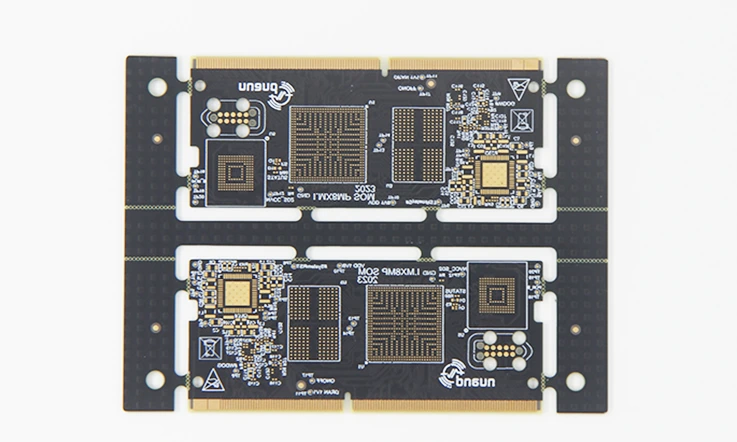

Proven Experience in PCB Fabrication

There’s no shortcut for experience in PCB fabrication, especially when it comes to Gold Finger PCBs. You want a manufacturer that knows the ins and outs of gold-plated connectors and has a track record of successful projects in your industry. A solid manufacturer will have experience across various sectors, including telecommunications, automotive, consumer electronics, and more.

Expand on the experience aspect by looking for manufacturers with a minimum of 5-10 years of experience specifically in gold plating. A manufacturer’s reputation is often built over decades, so ask for examples of past projects and specific case studies.

High-Quality Gold Plating Process

Not all gold plating is created equal. A reliable manufacturer should offer details about their gold plating process, including the thickness of the gold layer, the types of gold used, and the quality assurance steps they take. Gold Finger PCB reliability depends on the precision of this process. Ask questions about how the manufacturer ensures uniform plating and avoids issues like uneven contact surfaces.

Gold Plating Thickness and Quality

The gold plating on Gold Finger PCBs is one of the most important elements in determining the board’s durability and longevity. There are two primary methods used for gold plating in Gold Finger PCBs: Electroless Nickel Immersion Gold (ENIG) and Hard Gold Plating. Each method has its advantages and is used in different applications.

ENIG typically provides thinner gold layers (2-5 microinches) and is suited for low-wear applications. On the other hand, Hard Gold Plating involves a thicker layer (up to 50 microinches) and is more suitable for high-wear applications, like connectors that will see frequent insertion and removal.

| Gold Plating Method | Thickness Range | Durability | Cost | Applications |

| ENIG (Electroless Nickel Immersion Gold) | 2-5 microinches | Medium | Lower | High-reliability, low-wear applications |

| Hard Gold Plating | 30-50 microinches | High | Higher | High-wear applications like connectors with frequent insertion/removal |

Customization Capabilities

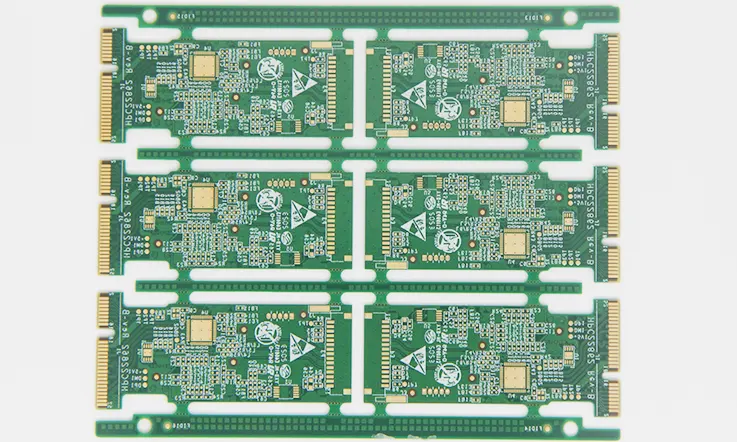

Every project is unique, and one-size-fits-all solutions rarely work in PCB manufacturing. The best Gold Finger PCB manufacturers offer extensive customization options, including different board thicknesses, gold plating specifications, and circuit layouts.

Before choosing a manufacturer, ask whether they can tailor the Gold Finger PCB design to suit your needs. Can they provide specialized plating thicknesses? What about custom edge connector configurations? Flexibility is key when working on projects that have specific design or performance requirements.

Advanced Circuit Board Manufacturing Technology

In today’s competitive world, sticking to the old ways of PCB manufacturing won’t cut it. You need a manufacturer that’s using cutting-edge technologies like precision laser cutting, advanced CNC machines, and state-of-the-art testing equipment. These tools not only ensure the accuracy of your Gold Finger PCBs, but also allow the manufacturer to handle both small batches and large-scale production runs.

How to Evaluate a Gold Finger PCB Manufacturer’s Reliability?

You’ve narrowed down your options, but how do you make sure you’re choosing the right PCB supplier? It’s like dating—there are red flags to avoid and green flags that signal you’ve found a keeper. Let’s look at how to separate the wheat from the chaff.

Certifications and Quality Standards Compliance

A reliable PCB manufacturer will be upfront about their certifications. Make sure they adhere to international standards like ISO 9001, ISO 14001 (environmental standards), and IPC-A-610 for PCB assembly. These certifications ensure the company is following best practices for quality management, environmental responsibility, and manufacturing processes. If they’re cagey about certifications, it’s probably a red flag.

Customer Reviews, Case Studies, and Real-World Applications

One of the easiest ways to vet a PCB manufacturer is to check what their previous clients have to say. Whether it’s customer reviews, case studies, or testimonials, you’ll get a real-world glimpse into how they operate. Look for manufacturers with a proven track record in Gold Finger PCB fabrication. If you see a pattern of late deliveries, inconsistent quality, or poor customer service, run—don’t walk.

Case Studies and Real-World Examples: a high-quality manufacturer might provide a case study where they successfully developed a custom multi-layer Gold Finger PCB for an automotive company. This could include overcoming challenges such as managing tight tolerances or ensuring durability for harsh environmental conditions.

Manufacturing Capacity and Scalability

Let’s say you start with a small order but suddenly need to scale up. Can your manufacturer handle it? A reliable PCB manufacturer should be able to ramp up production without sacrificing quality or missing deadlines. The last thing you want is to outgrow your supplier and be stuck looking for a new one halfway through a major project.

Technical Support and After-Sales Service

Even the best-laid plans can hit snags, and that’s where a good PCB manufacturer proves their worth. A company that offers robust technical support, both during production and after delivery, is worth its weight in gold (pun intended). Whether you need help troubleshooting a design or adjusting specs, they should be responsive and knowledgeable.

Expanded Support and After-Sales Service: Look for manufacturers that offer comprehensive after-sales support. This could include free consultations on future projects, replacement or repair services, and even ongoing training or support to ensure the smooth integration of the PCBs into your larger system.

Common Mistakes When Choosing a Gold Finger PCB Manufacturer

Even the savviest engineers and procurement officers can make mistakes when choosing a Gold Finger PCB supplier. These missteps can cost time, money, and a whole lot of headaches. Let’s go over some common blunders and how to avoid them.

Ignoring Manufacturer’s Expertise in Gold-Plated Edge Connectors

Sure, a manufacturer might excel in general PCB production, but gold-plated connectors are a different beast. Don’t assume that every PCB manufacturer has the necessary experience with gold-plating. Always ask for specifics about their Gold Finger PCB projects and how they manage the gold plating process.

Overlooking Customization Capabilities

Not every project fits neatly into a one-size-fits-all mold. If you need custom specifications for your Gold Finger PCB, make sure your manufacturer has the skills and equipment to accommodate your needs. Overlooking customization capabilities can lead to subpar products that don’t quite meet your technical requirements.

Not Verifying Certifications or Industry Compliance

We touched on this earlier, but it’s worth repeating: certifications matter. Make sure your chosen PCB manufacturer complies with industry standards and possesses the right certifications to guarantee quality and consistency.

Emerging Trends in Gold Finger PCB Manufacturing

The electronics industry is fast-paced, and keeping up with the latest PCB manufacturing trends can give you a leg up on the competition. Here are a few trends shaping the future of Gold Finger PCB production:

AI-Driven Design Optimization

For Gold Finger PCBs, AI can help fine-tune the design of gold-plated edge connectors, ensuring that they meet the highest standards for conductivity and durability. AI can even predict potential manufacturing defects before production begins, saving both time and money. If your chosen manufacturer is investing in AI and machine learning technologies, that’s a good sign they’re keeping up with industry advancements and are future-proofing their capabilities.

Automated Quality Control Systems

Another trend in Gold Finger PCB manufacturing is the increasing use of automated quality control systems. These systems use high-resolution cameras and AI to inspect each PCB in real time, identifying even the smallest defects or inconsistencies. This automation ensures a higher degree of precision and consistency compared to manual inspections, making it a must-have for any manufacturer that prioritizes quality.

Automated systems also help manufacturers scale more effectively, handling large production runs while maintaining the same high standards across every batch. By choosing a supplier that integrates this level of automation, you’ll reduce the likelihood of receiving faulty or inconsistent products.

Eco-Friendly Manufacturing Practices

Sustainability is an increasingly important concern in PCB manufacturing. Forward-thinking manufacturers are adopting eco-friendly practices, such as using recyclable materials, reducing waste during production, and implementing energy-efficient processes. Look for manufacturers who are committed to minimizing their environmental footprint without sacrificing quality or performance.

Cost-Effectiveness and ROI in Gold Finger PCB Manufacturing

As much as we love talking about high-tech features and cutting-edge trends, let’s get real for a minute: cost matters. But choosing a Gold Finger PCB manufacturer shouldn’t just be about the initial price tag. You’ve got to think about the long-term return on investment (ROI). A cheap option might save you money upfront, but it could end up costing you more in the long run due to poor quality, increased maintenance, or higher rates of failure.

Long-Term Savings from Quality Manufacturing

When you invest in a reliable manufacturer who delivers high-quality Gold Finger PCBs, you’re reducing the likelihood of defects, breakdowns, or performance issues over time. This can significantly cut down on repair and replacement costs—not to mention avoiding potential delays in your product’s launch or production schedule.

In other words, the right manufacturer might not be the cheapest, but they can help you save big down the line by minimizing product failures and maximizing performance. Choosing a quality manufacturer is like buying a dependable car: you might pay more upfront, but you’ll avoid costly repairs and headaches later on.

Scalability and Volume-Based Cost Benefits

Another factor to consider is scalability. A reliable PCB manufacturer should be able to scale production without sacrificing quality, and they should offer volume-based pricing to make larger orders more cost-effective. If you anticipate your production needs growing in the future, it’s essential to partner with a manufacturer who can grow with you and offer competitive pricing for larger batches.

Some manufacturers may offer discounts or incentives for long-term partnerships, so be sure to ask about cost-saving opportunities as you scale up.

Enhanced Focus on After-Sales Support and Customer Service

Even the best manufacturers can’t prevent every possible issue, which is why after-sales support is so important. A strong PCB manufacturer won’t disappear the moment the product ships. They’ll be there to help you troubleshoot, offer technical advice, and even handle repairs or replacements if necessary.

What Makes Excellent After-Sales Support?

Excellent after-sales support goes beyond just offering a warranty. It includes things like real-time technical support, personalized follow-up on orders, and even proactive communication about product upgrades or new technologies. If a manufacturer is dedicated to helping you get the most out of your Gold Finger PCBs, they’re more likely to offer long-term value.

Look for manufacturers who provide:

●Real-time troubleshooting for any issues that arise during integration or testing.

●Extended warranties that reflect their confidence in their product’s durability.

●Future project consultations where they can offer insight into how you might improve or scale future orders.

Building Long-Term Partnerships with Manufacturers

When you find a reliable PCB manufacturer that delivers on both product quality and customer service, consider them a long-term partner. Over time, a strong relationship with your manufacturer can lead to better pricing, quicker lead times, and tailored services that suit your specific needs.

Remember, it’s not just about getting the job done once—it’s about creating a partnership that ensures ongoing success for your business.

Final Thoughts

Making the Right Choice for Your Gold Finger PCB Needs

At the end of the day, choosing a Gold Finger PCB manufacturer is about more than just the specs or the price tag. It’s about finding a reliable partner who understands your needs, offers technical expertise, and provides the support you need to bring your projects to life.

By focusing on factors like gold plating quality, customization capabilities, certifications, after-sales support, and long-term scalability, you can ensure that you’re choosing a manufacturer who not only delivers great products but also supports your success.

Sure, it’s a process—one that involves research, tough questions, and maybe a little gut instinct. But when you find the right manufacturer, it’s like hitting the jackpot. You’ll have a partner you can rely on for quality, consistency, and innovation, making sure your PCBs perform perfectly for years to come.

So do your homework, ask the tough questions, and remember: finding a reliable Gold Finger PCB manufacturer is like finding a good partner—it’s worth taking the time to get it right.

Good luck on your search, and may you strike gold with your next PCB manufacturer!

Frequently Asked Questions (FAQs) about Gold Finger PCB Manufacturers

Q1: What is the typical thickness of gold plating on Gold Finger PCBs?

A1: The typical thickness of gold plating on Gold Finger PCBs ranges from 2 to 50 microinches, depending on the application and manufacturer standards. Hard gold plating is preferred for applications requiring frequent insertions and removals, while ENIG (Electroless Nickel Immersion Gold) is often used for high-reliability connectors with less wear.

Q2: How do I verify the reliability of a Gold Finger PCB manufacturer?

A2: You can verify a manufacturer’s reliability by checking their certifications (such as ISO 9001 and IPC-A-610), reviewing customer testimonials and case studies, and inquiring about their quality control processes. Additionally, ensure the manufacturer has experience with gold-plated edge connectors and uses advanced technologies like automated quality control systems.

Q3: Are custom Gold Finger PCB designs more expensive?

A3: Custom designs can be more expensive upfront due to the additional engineering and design work. However, customization allows for optimization of your specific application, which can lead to improved performance and long-term savings by reducing maintenance costs and product failures.

Q4: What is the best way to ensure the durability of Gold Finger PCBs?

A4: The durability of Gold Finger PCBs is ensured by using high-quality gold plating, typically hard gold, and making sure the plating is applied with precision. Regular quality checks such as plating thickness measurement and automated visual inspection are critical in maintaining durability over time.

Q5: How do I scale production with my Gold Finger PCB manufacturer?

A5: To scale production effectively, work with a manufacturer that has flexible manufacturing capacity and offers volume-based pricing. Ensure they have experience handling large-scale orders without compromising on quality. A manufacturer with automated processes and advanced technologies will be better equipped to handle your growing needs.