The demand for high-performance electronic devices has led to increased power densities and thermal challenges in printed circuit board (PCB) designs. As a leading circuit board supplier, we recognize the critical role of efficient thermal management in ensuring the reliability and longevity of electronic systems.

In this article, we explore the exceptional thermal properties of Bergquist MP-06503, a cutting-edge material for PCB applications. We delve into the design considerations and techniques that can be employed to optimize heat dissipation and enhance the overall thermal performance of PCBs using MP-06503

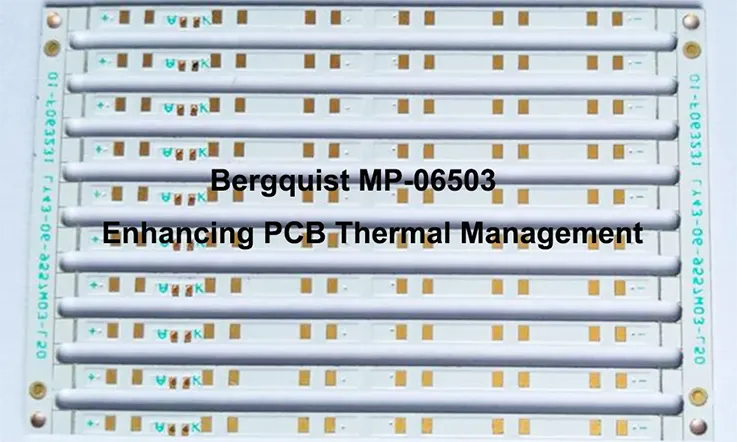

Introduction of Bergquist MP-06503

Bergquist MP-06503 is a specific type of dielectric material used in Thermal Clad Metal Core PCBs (MCPCBs). It is designed to provide excellent thermal management and electrical insulation properties in high-temperature applications. MP-06503 is a multi-purpose dielectric material that offers superior performance in terms of thermal conductivity, dielectric breakdown strength, and resistance to degradation caused by exposure to high temperatures. It is specifically engineered to meet the demanding requirements of electronic devices that generate significant heat, allowing for efficient heat dissipation and improved overall reliability.

Thermal Clad Metal Core PCBs (MCPCBs) offer superior thermal management compared to standard printed wiring boards (PWBs) by minimizing thermal impedance and enhancing heat conduction. These substrates provide enhanced mechanical robustness when compared to thick-film ceramic and direct bond copper constructions.

Thermal Clad technology presents a cost-effective solution that can streamline designs, reduce component count, enable smaller devices, and simplify the overall production process. In addition, Thermal Clad offers the advantage of lower operating temperatures, leading to extended component lifespan and improved durability.

The key to Thermal Clad technology lies in its dielectric material. Furthermore, it demonstrates even higher dielectric breakdown characteristics compared to BERGQUIST TCLAD TIC_TIP HT 04503.

Features and Benefits

Bergquist MP-06503 offers a range of exceptional features and benefits, making it an ideal choice for high-performance PCB applications. Here are the key attributes of this dielectric material:

Excellent Thermal Performance:

With a thermal resistance of 0.58°C-cm²/W, MP-06503 provides efficient heat dissipation, ensuring optimal thermal management for electronic devices. It enables effective transfer of heat away from critical components, reducing the risk of overheating and improving overall system reliability.

High Thermal Conductivity:

MP-06503 exhibits a thermal conductivity of 2.4 W/m-K, enabling efficient heat transfer across the PCB. This property allows for rapid dissipation of heat generated by power components, ensuring consistent and reliable operation even under demanding thermal conditions.

Versatile Applications:

MP-06503 is a versatile dielectric material suitable for a wide range of applications. Whether it’s power electronics, LED lighting, automotive electronics, or industrial control systems, this material delivers consistent performance and reliability across various industries.

Compatibility with Lead-Free Solder and Eutectic AuSn:

MP-06503 is designed to be compatible with lead-free soldering processes, ensuring compliance with environmental regulations and industry standards. Additionally, it is also compatible with eutectic AuSn (gold-tin) solder, providing flexibility in assembly techniques and facilitating reliable solder joint formation.

RoHS Compliance and Environmental Friendliness:

MP-06503 is fully compliant with the Restriction of Hazardous Substances (RoHS) directive, ensuring the absence of harmful substances such as lead, mercury, cadmium, and others. This compliance underscores its commitment to environmental sustainability and aligns with green manufacturing practices.

Availability on Aluminum and Copper Substrates:

MP-06503 is available on both aluminum and copper metal substrates, providing flexibility in design and manufacturing choices. Whether you require the lightweight properties of aluminum or the superior thermal conductivity of copper, this dielectric material can be seamlessly integrated into your desired substrate.

Typical Properties of Bergquist MP-06503

Physical Properties:

● Peel Strength@ 25°C, ASTM D2861, N/mm

● Glass Transition, ASTM E1356, ºC

● Coefficient of Thermal Expansion, ASTM D3386:

● XY/Z Axis Below Tg, µm/-mºC

● XY/Z Axis Above Tg, µm/-mºC

● Storage Modulus, ASTM D4065, GPa:

Thermal Properties:

● Product Thermal Conductivity, MET 5.4-01- 40000, W/(m-K)

● Dielectric Thermal Conductivity, ASTM D5470, W/(m-K)

● Thermal Resistance, ASTM D5470, ºC-cm²/W

● Thermal Impedance MET 5.4-01-40000, ºC/W

Electrical Properties:

● Dielectric Constant, ASTM D150

● Dissipation Factor, ASTM D150:

● Capacitance, ASTM D150, pF/cm²

● Volume Resistivity, ASTM D257, ohm-meter

● Surface Resistivity, ASTM D257, ohm/sq

● Breakdown voltage, ASTM D149, kVAC

Chemical Properties:

● Water Vapor Retention, ASTM E595, wt %

● Out-Gassing Total Mass Loss, ASTM E595, wt %

● Collect Volatile Condensable Material, ASTM E595, wt %

Typical Application of Bergquist MP-06503

Bergquist MP-06503 finds extensive application in various high-performance PCB designs where achieving low thermal resistance is crucial. Its exceptional thermal properties make it an ideal choice for the following applications:

1.High Watt-Density Applications:

MP-06503 is particularly well-suited for high watt-density applications where efficient heat dissipation is essential. Its low thermal resistance enables effective heat transfer, ensuring that electronic components operate within optimal temperature ranges and minimizing the risk of thermal damage.

2.Power Conversion:

In power conversion circuits, MP-06503 serves as a reliable dielectric material for maintaining proper insulation and facilitating efficient heat management. Its ability to dissipate heat efficiently enhances the overall performance and reliability of power conversion systems.

3.Heat-Rails:

MP-06503 is commonly used in heat-rail designs, where it helps in managing and distributing heat generated by power components. By providing effective thermal conductivity and insulation properties, it ensures the reliable operation of heat-rail systems, even under demanding thermal conditions.

4.Solid State Relays:

Solid state relays require reliable thermal management to ensure their proper functioning. MP-06503’s low thermal resistance and excellent thermal conductivity make it an ideal choice for these applications, enabling efficient heat dissipation and contributing to the overall reliability of solid state relay systems.

5.Motor Drives:

MP-06503 is well-suited for motor drive applications, where it helps in dissipating heat generated by high-power motors. Its thermal properties aid in maintaining optimal operating temperatures, thereby enhancing the performance and longevity of motor drive systems.

6.High Reliability LED Applications:

LED applications often demand efficient heat dissipation to ensure the longevity and reliability of the devices. MP-06503’s low thermal resistance and high thermal conductivity make it suitable for high-reliability LED applications, allowing for effective heat transfer and temperature management.

Design Considerations for Bergquist MP-06503

1. Heat Dissipation: Bergquist MP-06503 is chosen for its excellent thermal properties, so it’s crucial to design the PCB layout and heat management system to maximize heat dissipation. Consider incorporating thermal vias, copper pours, and heatsinks to efficiently transfer heat away from the components mounted on MP-06503.

2. Component Placement: Proper component placement plays a significant role in thermal management. Position high-power components and those generating more heat in areas with better airflow or closer to heat sinks. This helps to minimize the heat concentration and ensures efficient heat dissipation through MP-06503.

3. Thermal Vias: Utilize thermal vias strategically to enhance heat dissipation. Place thermal vias near heat-generating components and connect them to copper planes or heatsinks to facilitate the transfer of heat to the PCB’s inner layers or external heat dissipation mechanisms.

4. Copper Pours: Implement copper pours on PCB layers adjacent to Bergquist MP-06503 to improve thermal conductivity. These copper pours act as heat spreaders, distributing heat across a larger area and reducing temperature gradients.

5. Thermal Relief: When connecting components to MP-06503, use thermal relief pads for better heat transfer. Thermal relief pads have reduced copper coverage, allowing heat to flow more freely between the component and the PCB.

6. Material Selection: Consider the thermal compatibility of other PCB materials used in conjunction with MP-06503. Ensure that the materials have similar coefficients of thermal expansion (CTE) to minimize the risk of delamination or mechanical stress-induced failures.

7. Stackup Design: Optimize the PCB stackup to promote efficient heat dissipation. Place MP-06503 on an inner layer close to a ground plane or a layer with copper pours for effective heat spreading. Avoid sandwiching MP-06503 between layers with poor thermal conductivity.

8. Thermal Simulation and Analysis: Utilize thermal simulation software to analyze and optimize the thermal performance of the PCB design. Conduct thermal analysis to identify potential hotspots, temperature gradients, and areas that require additional heat dissipation measures.

9. Handling and Assembly: Follow proper handling and assembly guidelines provided by Bergquist for MP-06503. Ensure that the PCB assembly process does not subject the material to excessive heat or mechanical stress, which can affect its thermal properties and reliability.

10. Testing and Validation: Perform thorough testing and validation of the PCB design to ensure that the thermal management measures implemented for MP-06503 are effective. Conduct temperature measurements and thermal cycling tests to verify the thermal performance and reliability of the design.

By considering these design considerations, you can maximize the thermal performance and reliability of Bergquist MP-06503 in your PCB design.

How to Look for a Reliable Bergquist MP-06503 PCB Manufacturer?

To find a reliable Bergquist MP-06503 PCB manufacturer, you can follow these steps:

1. Research and Identify Potential Manufacturers: Start by conducting thorough research to identify potential PCB manufacturers that specialize in working with Bergquist MP-06503. Look for manufacturers with a proven track record in producing high-quality PCBs and a strong reputation in the industry.

2. Evaluate Experience and Expertise: Assess the manufacturer’s experience and expertise in working with Bergquist MP-06503. Look for manufacturers who have extensive knowledge of the material’s properties, its handling requirements, and the specific challenges associated with using it in PCB manufacturing.

3. Quality Certifications: Check if the manufacturer holds relevant quality certifications such as ISO 9001 or AS9100. These certifications indicate that the manufacturer follows stringent quality control processes and adheres to industry standards.

4. Manufacturing Capabilities: Evaluate the manufacturer’s manufacturing capabilities, including their equipment, production capacity, and ability to handle complex PCB designs. Ensure that they have the necessary resources and technology to meet your specific requirements.

5. Sample and Prototype Services: Inquire about the manufacturer’s sample and prototype services. A reliable manufacturer will offer the option to produce a small batch or prototype of your design using Bergquist MP-06503 to ensure its compatibility and performance before proceeding with full-scale production.

6. Customer Reviews and References: Look for customer reviews and testimonials to gauge the manufacturer’s reputation and customer satisfaction. Additionally, ask the manufacturer for references from their existing clients who have worked with them on similar projects involving MP-06503 PCBs.

7. Communication and Support: Evaluate the manufacturer’s communication channels and support services. A reliable manufacturer will have responsive customer support and clear channels of communication to address any concerns or queries during the manufacturing process.

8. Pricing and Lead Times: Obtain quotes from multiple manufacturers and compare their pricing and lead times. However, keep in mind that the cheapest option may not always be the most reliable. Consider the overall value, including quality, expertise, and customer support, when making your decision.

9. Visit the Facility: If possible, schedule a visit to the manufacturer’s facility. This will allow you to assess their production environment, quality control processes, and the overall professionalism of their operations.

10. Request Samples and Conduct Testing: Before committing to a large-scale production order, request samples from the manufacturer and conduct thorough testing to ensure that the PCBs meet your specifications and performance requirements.

Conclusion

Thermal management is a key aspect of modern PCB design, particularly in high-power applications. Bergquist MP-06503 offers remarkable thermal properties that enable effective heat dissipation and temperature control.

By strategically incorporating MP-06503 into PCB designs and implementing design considerations such as optimized component placement, thermal vias, copper pours, and proper material selection, circuit board suppliers can significantly enhance the thermal performance of their products. The use of MP-06503 empowers engineers to tackle thermal challenges, improve reliability, and extend the lifespan of electronic systems. As a trusted circuit board supplier, we are committed to providing innovative solutions like Bergquist MP-06503 to meet the evolving needs of the electronics industry and ensure the success of our customers’ thermal management strategies.