In the field of electrical engineering, the Printed Circuit Board (PCB) holds significant prominence as a crucial component in electronics. Among the various types of PCBs, Bluetooth or Wireless PCBs play a pivotal role, particularly within smartphones and other wireless devices. In this comprehensive FAQ guide, we aim to delve into the intricacies of wireless devices and provide enlightening answers to common queries regarding wireless technology and wireless PCBs. Stay engaged as we embark on a journey to explore the wonders of this technology.

What is a Wireless PCB ?

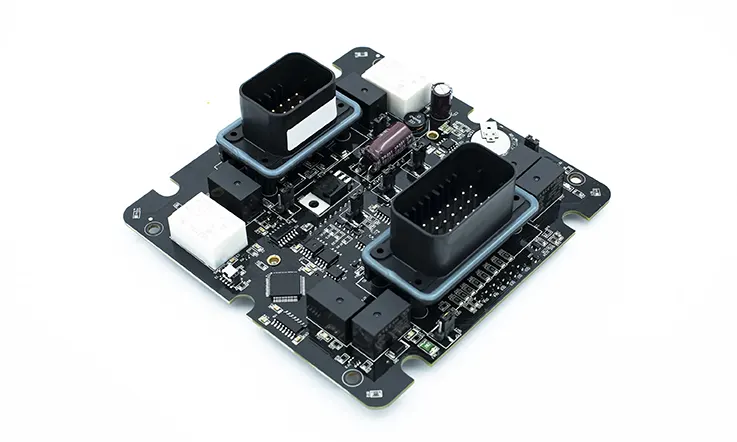

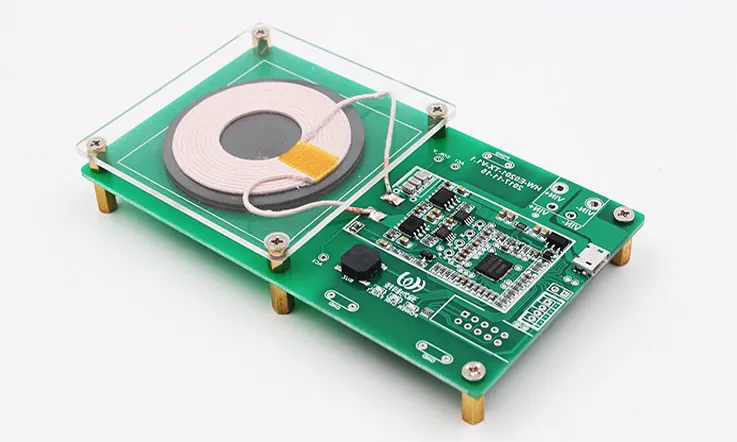

A wireless PCB is a thin circuit board consisting of composite epoxy, copper, fiberglass, and laminated materials. It incorporates conductive pads and tracks to establish both electrical connections and mechanical support for electronic devices. Bluetooth, a wireless communication technology, is integrated into this type of PCB to facilitate the wireless transmission of data between electronic devices. It is important to note that Bluetooth has a limited range and can only cover short distances.

A wireless circuit board is specifically designed to incorporate wireless technology and provide connectivity between devices. Bluetooth technology is integrated into the circuit to enable wireless connections without the need for physical wires. Devices such as wireless speakers, computers, and mobile phones, among others, incorporate wireless PCBs.

Wireless circuit boards are equipped with an antenna that receives signals transmitted by other Bluetooth devices. These signals are then processed within the circuit and transmitted to the output devices. The design of a wireless circuit involves the integration of various vital components. Additionally, a wireless PCB assembly typically includes at least two inductors, which fine-tune the power of the antenna for signal transmission and reception.

Types of Wireless PCBs

There are several types of wireless PCBs that are commonly used in electronic devices. Some of the most popular types include:

Bluetooth PCBs: Bluetooth is a wireless technology that allows devices to communicate with each other over short distances. Bluetooth PCBs are commonly used in mobile phones, wireless headphones, and other consumer electronics.

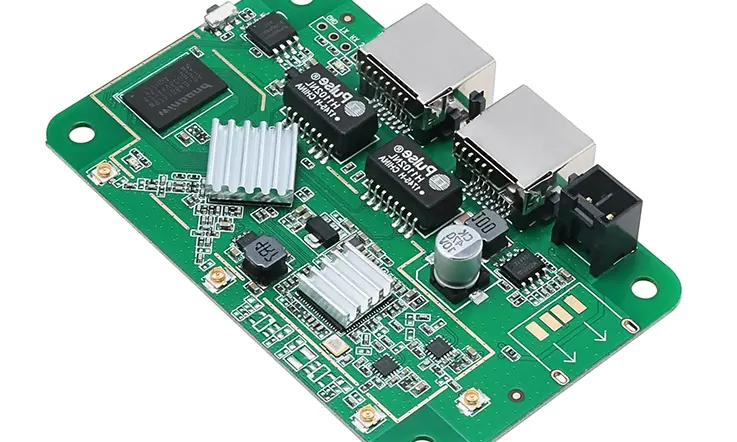

Wi-Fi PCBs: Wi-Fi is a wireless networking technology that allows devices to connect to the internet or other networked devices. Wi-Fi PCBs are commonly used in laptops, tablets, smart home devices, and other electronics that require high-speed internet connectivity.

Zigbee PCBs: Zigbee is a low-power wireless communication protocol that is often used in wireless sensor networks and other industrial applications. Zigbee PCBs are commonly used in smart home devices, industrial automation systems, and other applications that require low-power wireless connectivity.

RFID PCBs: RFID (Radio Frequency Identification) is a wireless technology that allows devices to read and transmit data to RFID tags. RFID PCBs are commonly used in inventory tracking, access control systems, and other applications where the ability to quickly and accurately read data from a distance is important.

NFC PCBs: NFC (Near Field Communication) is a wireless technology that allows devices to communicate with each other over short distances. NFC PCBs are commonly used in mobile payments, access control systems, and other applications where secure and convenient wireless communication is important.

Overall, the choice of wireless PCB technology will depend on the specific requirements of the device or application, including range, power consumption, data transfer speed, and other factors.

How to Design A Wireless PCB ?

Designing a wireless PCB (Printed Circuit Board) involves several steps. Here is a general overview of the process:

1. Determine the wireless protocol: The first step is to determine which wireless protocol you will be using. This will impact the hardware, software, and layout of the PCB. Some common wireless protocols include Wi-Fi, Bluetooth, Zigbee, and LoRa.

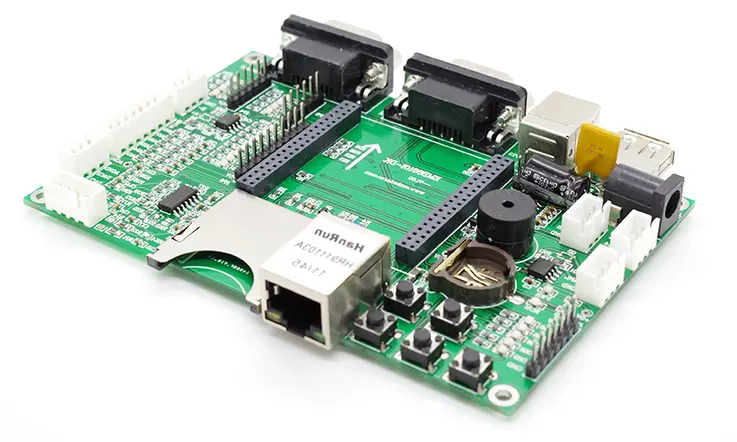

2. Select the appropriate components: Once you have determined the wireless protocol, you will need to select the appropriate components for your PCB. This will include a microcontroller, a wireless module, and any additional components required for your specific application.

3. Plan the layout: Plan the layout of the PCB, including the placement of components, power and ground planes, and signal traces. Pay close attention to the placement of the wireless module and antenna to ensure optimal performance.

4. Create the schematic: Once the layout is planned, create a schematic of the PCB. This will allow you to verify the connections between components and ensure that the design meets your specifications.

5. Design the PCB: Using the schematic as a guide, design the PCB layout using a PCB design software. This includes placing the components, routing the traces, and adding power and ground planes.

6. Verify the design: Use a design rule check (DRC) to verify that the design meets the requirements of your PCB manufacturer. This will help you catch any errors or issues before sending the design for manufacturing.

7. Fabricate the PCB: Once the design is complete and verified, send the design files to a PCB manufacturer for fabrication. Be sure to select a manufacturer that meets your specific requirements for quality, turnaround time, and cost.

8. Assemble the PCB: Once the PCB is fabricated, assemble the components onto the board. This can be done manually or using automated assembly equipment.

9. Test the PCB: Finally, test the functionality of the PCB to ensure that it meets your requirements. This may involve testing the wireless connectivity, power consumption, and other performance metrics.

All in all, designing a wireless PCB requires careful planning, attention to detail, and a good understanding of the specific wireless protocol and components being used.

Design Considerations for wireless PCBs

Designing a wireless PCB requires careful consideration of several factors to ensure optimal performance and reliability. Here are some of the key design considerations for wireless PCBs:

Antenna design: The antenna is a critical component of any wireless PCB, as it is responsible for transmitting and receiving signals. The antenna design should be carefully optimized for the desired frequency range and signal strength, and should take into account the size and shape of the device.

RF signal integrity: Radio frequency (RF) signal integrity is critical for ensuring reliable wireless communication between devices. The PCB layout should be carefully optimized to minimize interference and noise, and to maintain appropriate impedance matching between components.

Power management: Wireless PCBs typically require power to operate, and designing an efficient power management system is critical for optimizing battery life and minimizing power consumption. This may include the use of low-power components, power-saving modes, and other techniques to reduce power consumption.

EMI/EMC considerations: Electromagnetic interference (EMI) and electromagnetic compatibility (EMC) can be major challenges for wireless PCB design. The PCB layout should be carefully optimized to minimize EMI, and appropriate shielding and filtering may be necessary to ensure EMC compliance.

Thermal management: Wireless PCBs can generate significant heat, particularly if they are operating at high power levels. Effective thermal management is critical for maintaining optimal performance and preventing damage to components.

Testing and validation: Wireless PCBs should be thoroughly tested and validated to ensure optimal performance and reliability. This may include testing for signal strength, range, power consumption, and other factors.

Overall, designing a successful wireless PCB requires careful consideration of several factors, and may require specialized expertise in antenna design, RF engineering, and other areas.

Wireless PCB Protocols

The wireless solution technology encompasses four key protocols, namely:

Bluetooth radio and baseband: The Bluetooth radio is responsible for integrating the radio signal specifications, ensuring compatibility with the 2.4 GHz ISM band. It forms the foundation of the wireless communication system.

Antenna/RF component: The RF and Antenna components require special attention as they play a crucial role in the functionality of a wireless PCB. The antenna design within the circuit board is complex, and careful consideration is given to ensure optimal performance. The PCB design incorporates a built-in antenna that necessitates a specialized design approach.

Bluetooth application protocol: This protocol encompasses application profiles that facilitate wireless PCB users in establishing connections between devices using radio signals. These profiles define the communication parameters and protocols required for specific applications.

Wireless software protocol stack: This refers to the driver code that enables Bluetooth-enabled devices to transmit and receive signals from the Bluetooth module. The software protocol stack acts as an intermediary layer, facilitating communication between the hardware and higher-level applications.

Each of these protocols plays a vital role in ensuring the seamless functioning of wireless PCBs, enabling efficient and reliable wireless communication.

Components Used In Wireless PCB

There are several components used in wireless PCBs, depending on the specific wireless protocol and application. Here are some of the common components used in wireless PCBs:

Microcontroller: A microcontroller is the brain of the PCB and is responsible for controlling the wireless module and other peripheral components.

Wireless module: A wireless module is a small device that enables wireless communication between the PCB and other devices. Common wireless modules include Wi-Fi modules, Bluetooth modules, Zigbee modules, and LoRa modules.

Antenna: An antenna is used to transmit and receive wireless signals. The type of antenna used will depend on the wireless protocol and frequency band being used.

Power supply: A power supply is required to provide power to the PCB and its components. This may include a battery, power regulator, or power adapter.

Sensors: Depending on the application, sensors may be used to measure temperature, humidity, pressure, or other environmental variables.

Memory: Memory is used to store data and program code on the PCB. This may include flash memory, EEPROM, or other types of non-volatile memory.

Peripheral components: Various peripheral components may be used in a wireless PCB, such as resistors, capacitors, inductors, and diodes. These components are used to filter, regulate, and protect the circuit.

As a result, the specific components used in a wireless PCB will depend on the requirements of the application and the wireless protocol being used. It is important to select high-quality components that are compatible with the other components in the circuit and meet the specific requirements of the application.

Advantages of using wireless PCBs

Wireless PCBs offer several advantages over traditional wired PCBs, including:

Enhanced mobility: With wireless PCBs, devices can communicate with each other without the need for physical wired connections, which allows for greater mobility and flexibility in device placement and usage.

Reduced size and weight: Wireless PCBs eliminate the need for bulky wires and connectors, allowing for smaller and lighter devices.

Lower cost: In some cases, wireless PCBs can be less expensive than wired PCBs because they require fewer components and less assembly time.

Increased reliability: Wireless PCBs can reduce the risk of wire breakage or connector failure, which can improve overall system reliability.

Improved design flexibility: Wireless PCBs can allow for more creative and flexible device designs since they don’t require wires or connectors to be physically routed through the device.

Better energy efficiency: Wireless PCBs can be designed to conserve power, which can extend battery life and reduce energy consumption.

Therefore, the advantages of using wireless PCBs make them a popular choice for many applications, including IoT devices, wearables, and wireless sensor networks. However, it’s important to carefully consider the design and implementation of wireless PCBs to ensure proper performance and reliability.

Disadvantages of Using wireless PCBs

While wireless PCBs offer several advantages over traditional wired PCBs, they also have some disadvantages that should be considered. Here are some of the potential disadvantages of using wireless PCBs:

Limited range: Wireless PCBs typically have a limited range of operation, which can be a disadvantage in some applications. For example, Bluetooth and Wi-Fi signals may be limited to a few meters, which may not be sufficient for certain types of devices or applications.

Susceptible to interference: Wireless PCBs can be susceptible to interference from other wireless devices or sources of electromagnetic noise. This can result in degraded signal strength or unreliable communication.

Power consumption: Wireless PCBs typically require power to operate, which can be a disadvantage in some applications where power consumption is a concern. The use of wireless communication can also add additional power demands to the device.

Security concerns: Wireless communication can be more vulnerable to security risks, such as unauthorized access or interception of data. This can be a concern in applications where sensitive data or information is being transmitted.

Cost: Wireless PCBs can be more expensive than traditional wired PCBs, particularly if they require specialized components or materials. This can be a disadvantage in applications where cost is a primary concern.

Compatibility issues: Different types of wireless communication protocols may not be compatible with each other, which can be a disadvantage in some applications where interoperability is important.

So, the disadvantages of using wireless PCBs need to be carefully considered in the context of the specific application and requirements of the device. While wireless communication can offer significant benefits in terms of mobility and flexibility, it may not be the best choice for all applications.

Future developments in wireless PCB technology

Wireless PCB technology continues to evolve and improve, with new developments that are likely to shape the future of wireless communication. Here are some of the key areas of development in wireless PCB technology:

5G technology

The rollout of 5G technology promises to revolutionize wireless communication, offering faster speeds, lower latency, and greater capacity. This will enable new applications and use cases for wireless PCBs, particularly in the areas of IoT and smart cities.

Edge computing

The trend towards edge computing, which involves processing data at the network edge rather than in the cloud, is likely to drive demand for wireless PCBs that can handle more complex and compute-intensive tasks.

Low-power wireless communication

The development of low-power wireless communication protocols, such as LoRaWAN and Sigfox, is likely to drive the growth of wireless sensor networks and other low-power applications.

Improved antenna technology

Antenna technology continues to improve, with new developments in materials, designs, and manufacturing techniques that are likely to improve the range and reliability of wireless communication.

Integration with AI and machine learning

The integration of wireless PCBs with AI and machine learning technologies is likely to enable new applications and use cases, particularly in the areas of industrial automation and autonomous vehicles.

Development of new wireless communication protocols

The development of new wireless communication protocols, such as Wi-Fi 6E and Bluetooth 5.2, is likely to drive the growth of wireless PCBs in new applications and markets.

In a word, the future of wireless PCB technology is likely to be shaped by a combination of advances in wireless communication, computing, and materials science, as well as new applications and use cases that are yet to be imagined.

Conclusion

We trust that this FAQ guide has provided you with the comprehensive information you require regarding wireless PCBs. We have covered a range of basic and technical questions to enhance your understanding of this technology.

Bluetooth technology offers specific solutions where any existing disadvantages are often overshadowed by its advantages. Ultimately, Bluetooth-enabled wireless PCBs hold great significance in the electronic industry.

At JarnisTech, we take pride in being a trusted and reliable wireless PCB manufacturer. We are dedicated to producing high-quality PCBs while ensuring cost-effectiveness. If you are considering manufacturing wireless PCBs, we invite you to reach out to us. Our team is committed to meeting your requirements and exceeding your expectations.

Related Posts:

1. Exceptional Manufacturer of Antenna PCBs

2. JarnisTech – High Quality Bluetooth PCB Manufacturer

4. Why Carrier PCB in Telecommunication Is So Useful?

5. What Is GPS PCB and How to Use GPS Integration into PCB?

6.The Evolution of 5G PCB Technology: Transforming the Telecommunication Industry