Ventec’s VT-4B7SP PCB material is at the forefront of technological innovation in the field of printed circuit boards. This comprehensive article delves into the unique properties and advantages of VT-4B7SP, providing valuable insights for professionals in the electronics and PCB manufacturing industries. From its thermal performance to electrical characteristics, this piece aims to showcase the exceptional features of VT-4B7SP and its potential impact on PCB design and fabrication.

Overview of Ventec VT-4B7SP PCB Materials

Ventec VT-4B7SP is a type of PCB material offered by Ventec International Group. It is a high-performance, thermally conductive laminate designed for applications that require efficient heat dissipation. The VT-4B7SP material is composed of a ceramic-filled woven glass fabric and a high-temperature epoxy resin system.

The material is known for its low dielectric constant and low loss tangent, which makes it ideal for use in high-frequency circuits. It also offers excellent thermal conductivity, allowing for efficient heat dissipation in high-power applications. The material is also highly resistant to moisture and chemical exposure, making it suitable for use in harsh environments.

The VT-4B7SP is available in various thicknesses and copper foil options, making it suitable for a wide range of PCB designs. It can be used in both rigid and flexible PCB applications, offering designers flexibility in their designs.

Overall, the Ventec VT-4B7SP is a high-performance PCB material that offers excellent electrical, mechanical, and thermal properties, making it suitable for use in demanding applications where high reliability and performance are required.

What Factor Consider when Choose Ventec VT-4B7SP In PCB Fabrication?

When choosing Ventec VT-4B7SP for PCB fabrication, several factors should be considered to ensure the material meets the specific requirements of the intended application. Some key factors to consider include:

1. Thermal Performance: Consider the thermal conductivity and dissipation properties of VT-4B7SP to ensure it can effectively manage heat in the PCB, especially in applications that require high power or operate in elevated temperature environments.

2. Electrical Properties: Evaluate the dielectric constant, dissipation factor, and impedance control capabilities of VT-4B7SP to ensure it meets the electrical performance requirements of the PCB design, especially for high-speed digital or RF applications.

3. Mechanical Strength: Consider the mechanical properties of VT-4B7SP, such as tensile strength, flexural modulus, and impact resistance, to ensure it can withstand the mechanical stresses encountered during PCB fabrication, assembly, and operation.

4. Dimensional Stability: Evaluate the dimensional stability and coefficient of thermal expansion (CTE) of VT-4B7SP to ensure minimal warpage or distortion during fabrication and under varying temperature conditions.

5. Chemical Resistance: Consider the resistance of VT-4B7SP to chemicals, solvents, and cleaning agents used during PCB fabrication and assembly processes.

6. Compatibility with Fabrication Processes: Ensure that VT-4B7SP is compatible with the chosen fabrication processes, such as drilling, plating, etching, lamination, solder mask application, and assembly techniques.

By carefully considering these factors, PCB designers and fabricators can make an informed decision when choosing Ventec VT-4B7SP for their specific PCB fabrication needs, ultimately leading to the successful production of high-quality and reliable printed circuit boards.

General Information of Ventec VT-4B7SP

The Ventec VT-4B7SP is a high-performance PCB material known for its excellent thermal conductivity, which is rated at 7.0 W/mK. It is a ceramic-filled material, which enhances its thermal management capabilities. Additionally, the material is halogen-free, making it environmentally friendly and compliant with industry regulations.

In terms of flammability, the VT-4B7SP is classified as UL94 V-0, indicating that it has excellent flame-retardant properties. This is crucial for applications where fire safety is a priority.

The material has a Maximum Operating Temperature (MOT) of 130°C, which means it can withstand relatively high operating temperatures without compromising its performance or integrity.

One of the key features of the VT-4B7SP is its selective preference as a dielectric for achieving ultra-low thermal resistance in PCB designs. This makes it a preferred choice for applications where efficient thermal management is critical.

Material Properties of VT-4B7SP

The Ventec VT-4B7SP PCB material offers a range of properties that make it suitable for high-performance applications. Some of the key material properties include:

1. Electrical properties:

Low dielectric constant: This property allows for efficient signal transmission in high-frequency circuits.

Low loss tangent: The low loss tangent minimizes signal loss, making it suitable for high-frequency and high-speed applications.

Excellent electrical insulation: The material provides reliable electrical insulation for PCB designs.

2. Mechanical properties:

High tensile strength: The material offers good mechanical strength, which is important for maintaining the structural integrity of PCBs.

Dimensional stability: It exhibits low thermal expansion, ensuring stable PCB dimensions even under varying temperature conditions.

3. Thermal properties:

High thermal conductivity: The material allows for efficient heat dissipation, making it suitable for high-power applications and thermal management.

Thermal resistance: It offers good resistance to temperature fluctuations and thermal stress.

4. Chemical and environmental resistance:

Moisture resistance: The material is highly resistant to moisture, making it suitable for use in humid environments.

Chemical resistance: It provides good resistance to various chemicals, ensuring the reliability of PCBs in challenging environments.

5. Availability:

The material is available in various thicknesses and copper foil options, providing flexibility for different PCB design requirements.

Ventec VT-4B7SP Vs Other FR4 PCB Materials

When comparing Ventec VT-4B7SP with other FR-4 PCB materials, several key differences and considerations should be taken into account, such as thermal performance, electrical properties, mechanical strength, and cost. Here’s a comparison of Ventec VT-4B7SP with other standard FR-4 materials:

1. Thermal Performance:

VT-4B7SP: Ventec VT-4B7SP offers enhanced thermal conductivity and heat dissipation properties compared to standard FR-4 materials. This makes it suitable for applications requiring improved thermal management.

Standard FR-4: Conventional FR-4 materials have lower thermal conductivity and may not be as effective in managing heat in high-power or high-temperature environments.

2. Electrical Properties:

VT-4B7SP: Ventec VT-4B7SP may offer superior electrical properties, including lower dielectric constant and dissipation factor, making it suitable for high-speed digital and RF applications that require controlled impedance and signal integrity.

Standard FR-4: Conventional FR-4 materials have moderate electrical properties, which may not be as ideal for high-frequency or high-speed applications.

3. Mechanical Strength:

VT-4B7SP: Ventec VT-4B7SP may offer enhanced mechanical strength, including higher tensile strength and flexural modulus, providing improved resistance to mechanical stresses during fabrication and operation.

Standard FR-4: Conventional FR-4 materials offer good mechanical strength, but may not match the specific properties of VT-4B7SP.

4. Dimensional Stability:

VT-4B7SP: Ventec VT-4B7SP may offer better dimensional stability and lower coefficient of thermal expansion (CTE), reducing the risk of warpage or distortion, especially in applications with varying temperature conditions.

Standard FR-4: Conventional FR-4 materials have acceptable dimensional stability but may not provide the same level of performance as VT-4B7SP in this regard.

5. Cost:

VT-4B7SP: Ventec VT-4B7SP may be higher in cost compared to standard FR-4 materials due to its enhanced properties and performance characteristics.

Standard FR-4: Conventional FR-4 materials are generally more cost-effective and widely used in many standard PCB applications.

Ultimately, the choice between Ventec VT-4B7SP and standard FR-4 materials depends on the specific requirements of the PCB application, including thermal, electrical, and mechanical performance needs, as well as budget considerations. Ventec VT-4B7SP may be a preferred choice for high-performance or specialty applications that require superior thermal management, electrical properties, and mechanical strength.

Application of Ventec VT-4B7SP PCB Materials

The Ventec VT-4B7SP PCB material is well-suited for a range of high-performance applications, including:

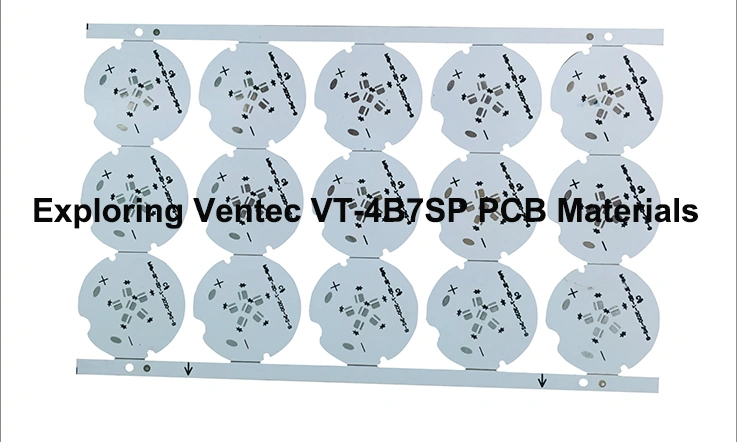

1.Matrix LED for Auto Bulb:

The material’s high thermal conductivity and excellent thermal management properties make it ideal for use in matrix LED applications for auto bulbs. Efficient heat dissipation is crucial for maintaining the performance and longevity of LED lighting systems, and the VT-4B7SP’s thermal properties can help ensure reliable operation in automotive lighting applications.

2.High Power LED for Projector:

High-power LED applications, such as those used in projectors, demand effective thermal management to dissipate the heat generated by the LEDs. The VT-4B7SP’s ceramic-filled composition, high thermal conductivity, and low thermal resistance make it a suitable choice for PCBs used in high-power LED projector applications, helping to maintain optimal LED performance and reliability.

3.Electric Power Steering:

Electric power steering systems require PCB materials that can withstand high temperatures and provide reliable electrical insulation. The VT-4B7SP’s high thermal conductivity, halogen-free composition, and excellent electrical properties make it a suitable material for PCBs used in electric power steering systems, ensuring efficient heat dissipation and electrical performance in demanding automotive applications.

Storage Condition and Shelf Life of Ventec VT-4B7SP

The storage conditions and shelf life of Ventec VT-4B7SP PCB laminates are important factors to consider in order to maintain the material’s quality and performance. While specific guidelines may vary, the general storage conditions and shelf life recommendations for PCB laminates typically include the following:

Storage Conditions:

1. Temperature: The laminates should be stored in a controlled environment with stable temperature conditions. Typically, the recommended storage temperature ranges from 10°C to 30°C (50°F to 86°F).

2. Humidity: The storage area should have controlled humidity levels to prevent moisture absorption. The recommended relative humidity for storage is typically less than 60%.

Shelf Life:

1. Shelf life refers to the period during which the PCB laminates can be stored under specified conditions without significantly degrading their performance or properties.

2. The shelf life of Ventec VT-4B7SP PCB laminates is typically indicated by the manufacturer. It is important to follow the specific shelf life recommendations provided by Ventec or the laminate supplier.

3. Shelf life can vary depending on factors such as storage conditions, exposure to light, and packaging. It is essential to adhere to the manufacturer’s recommendations to ensure the material’s integrity.

Handling and Packaging:

1. Proper handling and packaging of the PCB laminates are essential to prevent damage or contamination. Laminates should be stored in their original packaging and handled with care to avoid physical damage.

2. Exposure to direct sunlight, extreme temperatures, or moisture should be avoided during storage.

Effects of Improper Storage on VT-4B7SP PCB Laminates

Improper storage of VT-4B7SP PCB laminates can have several negative effects on the material, potentially impacting its performance and quality. Some of the effects of improper storage may include:

1. Moisture Absorption: If the laminates are stored in a high-humidity environment or exposed to moisture, they may absorb water, leading to delamination, dimensional changes, and reduced electrical performance.

2. Material Degradation: Exposure to extreme temperatures, especially high temperatures, can lead to material degradation, loss of mechanical strength, and changes in electrical properties.

3. Contamination: Improper storage can result in contamination from dust, dirt, or other particles, which can affect the surface quality and electrical properties of the laminates.

4. Dimensional Stability: Fluctuations in temperature and humidity can cause dimensional instability in the laminates, leading to warping or changes in shape, which can impact their usability in PCB manufacturing processes.

5. Electrical Performance: Improper storage conditions can alter the electrical properties of the laminates, leading to changes in impedance, dielectric constant, and signal integrity.

6. Shelf Life Reduction: Improper storage can shorten the shelf life of the laminates, making them less reliable for use in PCB manufacturing.

To mitigate these effects, it is important to adhere to the recommended storage conditions for VT-4B7SP PCB laminates, as provided by the manufacturer. This typically includes maintaining controlled temperature and humidity levels, protecting the laminates from light exposure, and ensuring proper packaging and handling to prevent contamination and physical damage. Adhering to these guidelines will help preserve the quality and performance of the laminates over their intended shelf life.

Ventec VT-4B7SP Has a Significant Impact on PCB Design

The Ventec VT-4B7SP has a significant impact on PCB design due to its unique properties and characteristics:

1. Thermal Management: The material’s high thermal conductivity and low thermal impedance allow for better heat dissipation, enabling the design of PCBs with improved thermal management, crucial for high-power applications.

2. Signal Integrity: The VT-4B7SP’s low dielectric constant and low loss tangent contribute to enhanced signal integrity, making it suitable for high-frequency and high-speed designs by minimizing signal loss and distortion.

3. Reliability: With excellent mechanical properties and dimensional stability, the material enhances the overall reliability of the PCB, reducing the risk of warping, delamination, and other mechanical failures.

4. Manufacturing Efficiency: The material’s compatibility with standard PCB fabrication processes facilitates efficient manufacturing, reducing production time and costs while maintaining high-quality standards.

5. Environmental Resistance: VT-4B7SP’s resistance to moisture, chemicals, and environmental stressors ensures the longevity and performance of the PCB in harsh operating conditions.

All in all, the Ventec VT-4B7SP positively impacts PCB design by offering improved thermal management, signal integrity, reliability, manufacturing efficiency, and environmental resistance, making it a compelling choice for a wide range of electronic applications.

In Conclusion

Ventec’s VT-4B7SP PCB material presents an enticing option for circuit board design engineers seeking to optimize thermal management, signal integrity, and mechanical durability in their designs. The unique attributes of VT-4B7SP position it as a valuable asset in addressing the evolving challenges of modern electronic applications.

As continue to push the boundaries of PCB material technology, Ventec remains dedicated to providing our customers with innovative solutions that drive performance and reliability in their electronic designs. Contact us today to discover how VT-4B7SP can elevate your next PCB project to new heights.