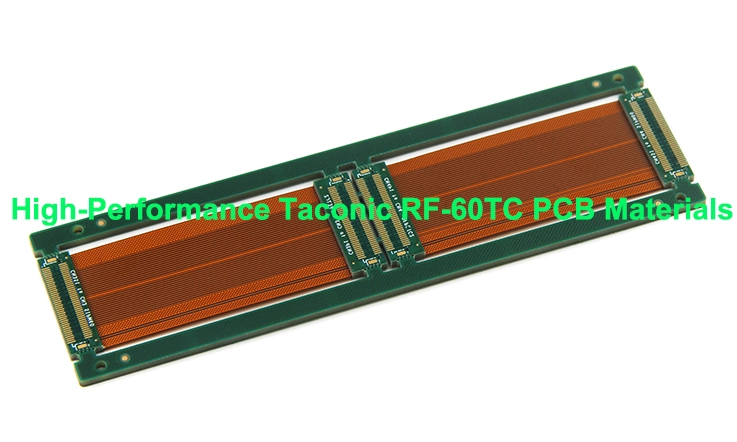

Taconic RF-60TC PCB materials are renowned for their exceptional performance and reliability in high-frequency applications. With its unique properties, RF-60TC offers a range of advantages for PCB designers and manufacturers. This article provides an in-depth exploration of the key features and benefits of Taconic RF-60TC, highlighting its suitability for demanding PCB applications.

Taconic RF-60TC

RF-60TC is a PTFE based, ceramic filled fiberglass substrate specifically developed for high power RF and microwave applications. This advanced material is engineered to deliver lower operating temperatures and improved gains and efficiencies in miniaturized antenna applications within the 6.15 DK market. It achieves this through enhanced dielectric heat dissipation and extremely low dielectric losses.

The enhanced heat transfer properties of RF-60TC provide greater design flexibility, prolonging the lifespan of active components and enhancing long term reliability. Furthermore, RF-60TC exhibits outstanding adhesion to low profile and reverse treated copper, resulting in reduced insertion loss. Additionally, heavy metal backed laminates are also available.

With its low coefficient of thermal expansion (CTE) and improved dimensional stability, RF-60TC enables the construction of high layer count multilayer printed wiring boards (PWBs) with enhanced plated through hole reliability.

Taconic RF-60TC: Performance characteristics

Taconic RF-60TC is a high-performance material specifically designed for PCB manufacturing, offering several notable performance characteristics.

•Improved loss tangent

One of its key advantages is an improved loss tangent, resulting in lower insertion loss and enhanced antenna gain and efficiency. This translates to improved signal performance and better overall system performance.

• High thermal conductivity

The material also exhibits high thermal conductivity, enabling exceptional thermal management. By efficiently dissipating heat, RF-60TC helps maintain lower operating temperatures and allows for higher power applications. Moreover, its thermal properties contribute to long-term reliability, ensuring the stability and durability of the PCBs.

• Enhanced dimensional stability

Another benefit of Taconic RF-60TC is its enhanced dimensional stability. This characteristic ensures that the material maintains its structural integrity and dimensional accuracy during the PCB manufacturing process, leading to better overall reliability and performance.

• Low Z-axis CTE

The material’s low Z-axis coefficient of thermal expansion (CTE) makes it suitable for multilayer applications and ensures reliable plated through holes. This attribute is crucial for maintaining signal integrity and preventing issues such as delamination or mechanical stress.

• Excellent adhesion to metal

Additionally, Taconic RF-60TC exhibits excellent adhesion to metal substrates. It offers options for lower profile copper, which is advantageous in certain design requirements, and heavy metal back, providing additional support and stability.

• Stable DK over frequency

The stability of the dielectric constant (DK) over frequency and temperature is a crucial aspect of Taconic RF-60TC. This ensures consistent electrical performance across a wide range of frequencies and temperatures, making it suitable for demanding applications.

• Low moisture absorption

Moreover, the material has low moisture absorption, reducing the risk of performance degradation or electrical breakdown due to moisture ingress. This feature enhances the reliability and longevity of the PCBs manufactured with Taconic RF-60TC.

Overall, Taconic RF-60TC is a professional-grade PCB material that offers improved loss tangent, high thermal conductivity, enhanced dimensional stability, low Z-axis CTE, excellent adhesion to metal, stable DK over frequency and temperature, and low moisture absorption. These characteristics make it a reliable and high-performance choice for a variety of PCB applications.

Limitations of Using Taconic RF-60TC PCB Materials

While Taconic RF-60TC PCB materials offer several advantages, it’s important to consider some limitations associated with their use:

1. Cost: Taconic RF-60TC is a high-performance material, and as such, it tends to be more expensive compared to standard PCB materials. The increased cost may be a limiting factor for projects with tight budget constraints or applications that do not require the material’s specific performance characteristics.

2. Availability: RF-60TC may not be as readily available as more common PCB materials. Availability can vary depending on the region and the specific supplier. This limited availability could potentially lead to longer lead times or challenges in sourcing the material for certain projects.

3. Processing Complexity: RF-60TC may require specialized processing techniques due to its unique properties. PCB manufacturers may need to adapt their manufacturing processes to accommodate this material, which could add complexity or require additional expertise. This could impact production timelines and costs.

4. Design Considerations: RF-60TC has specific electrical and mechanical properties that need to be considered during the design phase. For example, its lower profile copper option may have limitations in terms of current-carrying capacity compared to thicker copper options. Designers need to carefully evaluate and account for these factors to ensure optimal performance and reliability.

5. Material Thickness: RF-60TC may have limitations in terms of available thickness options. This can impact the design flexibility and may require additional considerations when designing PCBs with specific thickness requirements.

6. Environmental Considerations: While RF-60TC demonstrates good stability and reliability under normal operating conditions, it may have limitations in extreme environmental conditions. It is important to assess the material’s suitability for applications that involve exposure to high temperatures, humidity, or harsh chemicals.

It is crucial to thoroughly evaluate the specific requirements of the project and consider these limitations in order to make an informed decision regarding the use of Taconic RF-60TC PCB materials.

Storage and Shelf Life For Taconic RF-64TC PCB Laminates

Taconic RF-64TC PCB laminates, like most PCB materials, have specific storage and shelf life considerations to ensure their optimal performance. Here are some guidelines regarding the storage and shelf life of Taconic RF-64TC laminates:

1.Storage Conditions:

It is recommended to store Taconic RF-64TC laminates in a controlled environment that is dry, clean, and free from excessive heat, humidity, and direct sunlight. The storage area should be well-ventilated to prevent the accumulation of moisture.

2.Temperature and Humidity:

The ideal temperature for storing Taconic RF-64TC laminates is usually between 10°C and 30°C (50°F and 86°F). The relative humidity should be maintained below 50% to prevent moisture absorption, which could adversely affect the material’s electrical properties.

3.Packaging:

Taconic RF-64TC laminates are typically supplied in sealed packaging to protect them from moisture and contaminants. It is important to keep the original packaging intact until the laminates are ready for use. If the original packaging is compromised, it is recommended to transfer the laminates to a moisture-resistant and dust-free storage container.

4.Shelf Life:

The shelf life of Taconic RF-64TC laminates can vary depending on factors such as storage conditions and the specific requirements of the application. Generally, the shelf life is specified by the manufacturer and can range from 4 to 5 years from the date of manufacture. It is advisable to use the laminates within this specified shelf life to ensure their optimal performance.

5.Precautions:

When handling Taconic RF-64TC laminates, it is important to avoid exposing them to excessive bending, scratching, or impact, as these can damage the material and affect its performance. Additionally, it is recommended to follow any specific handling instructions provided by the manufacturer to prevent any potential issues.

How to Handling on Taconic RF-60TC PCB Laminates?

PTFE (polytetrafluoroethylene) is a thermoplastic material known for its reusability and slippery nature. When handling PTFE, care should be taken to avoid dropping or scratching the material. Over time, passive smoke particles may collect on the surface, darkening its appearance but not impacting its performance. PTFE is stable electrically and chemically, and it will not contaminate other materials or cause adverse effects. RF-60TC laminates are excellent for use with PTFE substrates as a substrate or top cover.

• When cleaning PTFE laminates, it is important to avoid mechanical scrubbing, brushing, or sanding. Instead, use a lint-free cloth to dust the surface, and refrain from using abrasive cleaners as the laminates are highly durable. Stainless steel wool should be avoided, as it may break at temperatures below 125°C (257°F), releasing silica dust that can cause allergic reactions.

• In the event of solvent contamination that cannot be removed mechanically, the laminate can be heated to 175°C (347°F) for a short period to evaporate the solvent and restore most of its strength.

• For removing solder mask from FR-4 PCBs, PTFE can be placed in water at 60 degrees Celsius (140 degrees Fahrenheit) for over two hours, after which the solder mask can be removed mechanically with tweezers.

• When handling PTFE laminates, avoid picking up panels horizontally by one end or edge. To inspect the laminate surface, a lint-free cloth moistened with water can be used to allow light to shine through, and a magnifying glass can provide the best results. Additionally, a glossy gold or silvery coating on the laminate surface is the result of an added metal layer.

• During fabrication and assembly, it is important to keep the laminates clean and prevent contaminant deposits on the material or copper. Avoid stacking panels directly on top of each other to maintain adhesion between the laminate surface and the PCB or PCB substrate, ensuring excellent performance of the printed circuit. Use a contact material between the PCB substrate and the laminate surface that maintains adhesion over a long period without causing damage.

Key Factor When Choose Taconic RF-60TC in PCB Designing and Manufacturing

When choosing Taconic RF-60TC for PCB designing and manufacturing, several key factors should be considered:

1. High Frequency Performance: Taconic RF-60TC is known for its excellent high-frequency performance, making it suitable for applications where low insertion loss and enhanced antenna gain are crucial.

2. Thermal Management: The high thermal conductivity of RF-60TC allows for efficient heat dissipation, leading to lower operating temperatures and enabling higher power applications. This is particularly important for PCBs that require reliable thermal management.

3. Dimensional Stability: RF-60TC offers enhanced dimensional stability, ensuring that the PCB maintains its shape and size under varying environmental conditions or during manufacturing processes.

4. Material Compatibility: The material is suitable for use as a substrate or top cover with PTFE substrates, offering versatility in PCB design and manufacturing.

5. Reliability: RF-60TC provides long-term reliability, making it a suitable choice for applications where durability and consistent performance are essential.

6. Chemical and Electrical Stability: The material’s stability in both chemical and electrical aspects ensures that it will not contaminate other materials or cause adverse effects in the PCB assembly.

7. Ease of Handling: While handling PTFE materials requires care, the characteristics of RF-60TC, such as low moisture absorption and resistance to passive smoke particle accumulation, contribute to its ease of use in PCB manufacturing.

Considering these factors, Taconic RF-60TC is a suitable choice for PCB designing and manufacturing in high-frequency applications that demand thermal management, dimensional stability, reliability, and material compatibility with PTFE substrates.

Taconic RF-60TC PCB Laminates Materials: Applications

Taconic RF-60TC PCB laminates are well-suited for a range of applications that require high performance and reliability. Some notable applications where RF-60TC excels include:

1.High Power Amplifiers:

RF-60TC’s high thermal conductivity and exceptional thermal management make it an excellent choice for high-power amplifier applications. Its ability to dissipate heat efficiently helps maintain lower operating temperatures, enabling higher power applications with improved long-term reliability.

2.Miniaturized Antennas:

RF-60TC is well-suited for miniaturized antenna designs such as GPS antennas, patch antennas, and RFID readers. Its improved loss tangent and enhanced antenna gain/efficiency contribute to improved signal performance, ensuring reliable and efficient wireless communication.

3.Filters, Couplers & Dividers:

The stability of the dielectric constant (DK) over frequency and temperature in RF-60TC makes it an ideal material for filters, couplers, and dividers. This stability ensures consistent electrical performance, enabling precise signal filtering and signal distribution in RF and microwave circuits.

4.Satellites:

RF-60TC’s exceptional thermal management, dimensional stability, and reliable plated through holes make it suitable for satellite applications. The material’s ability to withstand harsh environmental conditions and maintain signal integrity makes it a reliable choice for satellite communication systems.

Final Thoughts

Taconic RF-60TC PCB materials stand out as a top choice for high-frequency PCB designs, offering superior performance, thermal management, and reliability. The unique properties of RF-60TC make it a versatile and dependable option for diverse applications in the electronics industry. With its exceptional characteristics, RF-60TC continues to be a preferred material for PCB designers and manufacturers striving for high-quality and high-performance circuitry.