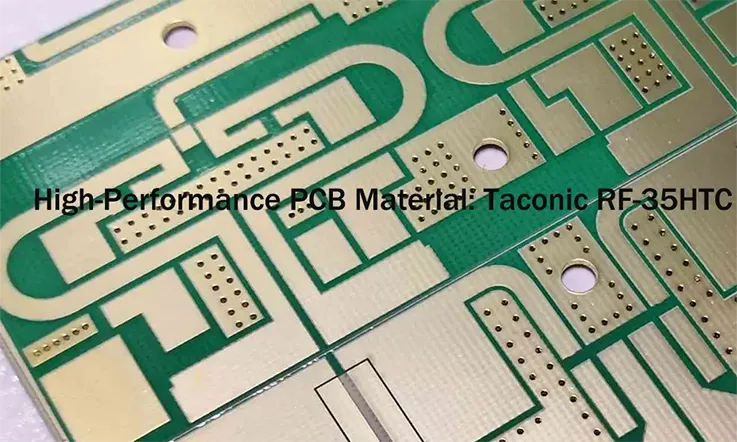

In today’s competitive, tech-driven environment, choosing the right materials for PCB (Printed Circuit Board) production is more necessary than ever. Taconic’s RF-35HTC is a leading choice for high-frequency applications, offering superior signal integrity, thermal stability, and cost-performance balance.

This guide delves into the technical details, real-world applications, and key benefits of RF-35HTC, comparing it with other high-performance PCB materials on the market. Therefore, when you’re designing for telecommunications, automotive, or aerospace, understanding how to leverage RF-35HTC’s unique features can lead to more reliable, efficient, and cost-effective products. Join us as we explore why Taconic RF-35HTC might be the right fit for your next project.

Key Properties of Taconic RF-35HTC PCB Materials for High-Frequency Applications

When developing products for high-frequency and high-power systems, the choice of PCB material can make or break the design’s success. Taconic RF-35HTC PCB Materials stand out by addressing the challenges of signal integrity, loss management, and consistent performance over wide frequency ranges. These materials are engineered to deliver reliable operation in some of the most demanding environments, whether it’s a 5G antenna, an automotive radar, or a satellite communication system. Below, we’ll dig into the core attributes that make Taconic RF-35HTC a trusted choice among engineers.

Low Dielectric Constant for Superior Signal Integrity

One of the standout features of Taconic RF-35HTC is its low dielectric constant (Dk), which is precisely calibrated to approximately 3.5 (±0.05). A lower Dk value directly reduces the delay of signal propagation, ensuring that data travels through the PCB at near-optimal speeds with minimal interference. This property is particularly advantageous for systems operating in the GHz range, where even slight signal distortions can lead to degraded performance.

For instance, in a 5G antenna transmitting signals at 28 GHz, maintaining a low and stable Dk minimizes phase delay. The result? A cleaner, sharper signal output that can support higher data rates and lower latency—a must for modern wireless infrastructure.

| Property | Value | Impact |

| Dielectric Constant (Dk) | ~3.5 (±0.05) | Faster signal propagation |

| Frequency Stability | Consistent at GHz | Minimal phase distortion |

| Application Example | 5G Antenna Systems | Enhanced data transmission quality |

This precision in Dk also helps simplify the simulation and design process for us, as the predictable behavior of the material reduces uncertainties during prototyping.

Exceptional Low Loss Tangent for Minimal Signal Loss

Signal loss is the bane of high-frequency design. Taconic RF-35HTC addresses this with an impressively low dissipation factor (Df) of 0.0007 at 10 GHz. This characteristic ensures that energy transmitted through the PCB is preserved, rather than being lost as heat or interference.

For applications like automotive radar, where millimeter-wave frequencies (24 GHz and beyond) are employed, this low Df ensures that radar signals remain clear and undistorted even over longer distances. Imagine a scenario where a vehicle’s radar system must detect an obstacle at high speed; any signal loss could mean the difference between smooth operation and a safety failure. Taconic RF-35HTC reduces this risk by delivering reliable, low-loss performance in these core applications.

Additionally, low loss tangent reduces the power required for signal amplification, which can lead to energy savings and reduced thermal management challenges in high-power devices.

| Frequency | Loss Tangent (Df) | Application |

| 10 GHz | 0.0018 | High-speed routers |

| 24 GHz | 0.002 | Automotive radar systems |

| 77 GHz | 0.0025 | Advanced driver assistance systems |

By preserving signal integrity and reducing energy waste, Taconic RF-35HTC ensures optimal performance across a wide range of demanding use cases.

Stability Across High-Frequency Ranges

Frequency stability is another hallmark of Taconic RF-35HTC PCB Materials. As operating frequencies increase, many materials struggle to maintain consistent performance. However, RF-35HTC is designed to excel under these conditions, providing reliable results from MHz all the way up to millimeter-wave GHz frequencies.

For engineers working on systems that span multiple frequency bands—like satellite communication modules—the stability offered by RF-35HTC makes a big difference. With its consistent performance, this material helps minimize the need for constant recalibration or design tweaks, allowing engineers to put their focus on creating new solutions instead of dealing with ongoing adjustments.

Moreover, RF-35HTC’s impressive temperature stability helps keep performance steady, even in the face of fluctuating environmental conditions. This makes it a solid choice for aerospace applications, where temperature changes are common. The material’s ability to maintain reliable data transmission ensures that essential communication is uninterrupted, no matter how extreme the temperature shifts.

Advanced Thermal Management with Taconic RF-35HTC PCB Materials

Effective thermal management is a cornerstone of high-performance PCB design, particularly in applications where power density and environmental conditions push materials to their limits. Taconic RF-35HTC PCB Materials are engineered to address these challenges head-on, offering solutions that enhance heat dissipation, maintain structural integrity, and optimize thermal pathways in advanced designs. So, managing heat effectively is a non-negotiable part of ensuring operational success.

Let’s break down how Taconic RF-35HTC PCB Materials excel in thermal management.

High Thermal Conductivity for Heat Dissipation

Taconic RF-35HTC boasts a thermal conductivity of approximately 1.84 W/mK, a specification designed to meet the rigorous demands of high-power electronic applications. This high thermal conductivity ensures that excess heat generated during operation is efficiently dissipated, preventing hotspots and enhancing device reliability.

Take, for instance, a power amplifier in a 5G base station operating at 28 GHz. Such components generate significant heat, and without proper dissipation, performance can degrade rapidly. By integrating Taconic RF-35HTC into the design, heat spreads uniformly across the PCB substrate, minimizing temperature gradients and enabling the use of higher power densities without compromising efficiency.

| Property | Value | Impact |

| Thermal Conductivity | ~0.67 W/mK | Reduced heat buildup |

| Heat Dissipation Pathways | Optimized for uniformity | Improved long-term reliability |

| Use Case Example | 5G power amplifiers | Stable operation at high power levels |

By providing consistent thermal conductivity, Taconic RF-35HTC empowers us to push the limits of power density without worrying about thermal bottlenecks.

Thermal Cycling Resistance for Durability

Durability under fluctuating temperatures is another area where Taconic RF-35HTC excels. This material has been rigorously tested to endure thermal cycling—repeated exposure to high and low temperatures—without compromising its structural or electrical properties. For applications like aerospace systems, where PCBs face drastic temperature swings during launch and re-entry, this resilience ensures that performance remains rock-solid.

For example, in a satellite communication system, materials need to withstand cycles ranging from -40°C to 125°C. Taconic RF-35HTC retains its mechanical integrity and adhesion properties, ensuring that the PCB remains operational over extended periods and under demanding conditions.

| Thermal Cycling Range | Performance |

| -40°C to 125°C | Minimal dimensional and material degradation |

| Cycle Durability | Excellent structural stability |

This resistance to thermal cycling not only extends product lifespans but also reduces maintenance and replacement costs for end users, making it a dependable choice for high-stakes applications.

Thermal Via Optimization in PCB Layouts

Heat dissipation doesn’t rely solely on the substrate—it also depends on intelligent PCB layout design. Taconic RF-35HTC works seamlessly with thermal vias, a technique commonly used to transfer heat away from high-power components. By combining the material’s inherent thermal conductivity with strategically placed vias, we can create PCBs that efficiently manage heat in even the most demanding scenarios.

For example, in a high-power RF module, copper-filled thermal vias can be designed to connect heat-generating components to heat sinks or ground planes. Taconic RF-35HTC enhances the effectiveness of these vias by ensuring that heat transfer occurs uniformly across the substrate.

| Design Parameter | Optimization Strategy |

| Via Placement | Align with high-heat regions |

| Via Fill Material | Copper for enhanced thermal performance |

| Substrate Compatibility | Taconic RF-35HTC for seamless integration |

To maximize results, we should carefully analyze thermal simulation data, ensuring that via placement aligns with heat-generating hotspots.

Mechanical Advantages of Taconic RF-35HTC PCB Materials

Designing PCBs for advanced applications requires materials that meet stringent mechanical demands. Taconic RF-35HTC PCB Materials excel in providing the precision, resilience, and reliability us seek. From intricate multilayer designs to operation in extreme environments, this material consistently delivers measurable advantages.

Let’s break down the specific properties that make this material stand out in demanding mechanical applications.

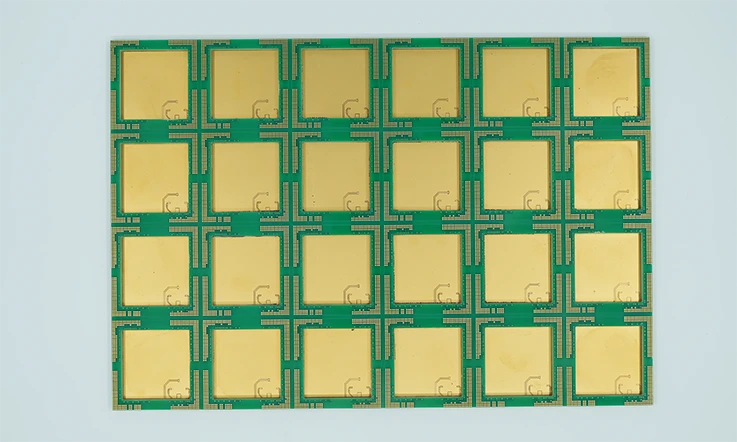

Dimensional Stability for Multilayer PCB Manufacturing

When manufacturing multilayer PCBs, precise alignment is non-negotiable. Even a minor deviation during lamination or drilling can result in flawed electrical performance. Taconic RF-35HTC is engineered with dimensional stability in mind, ensuring its structure remains consistent under varying thermal and mechanical stresses.

For example, in a telecommunications application requiring a 16-layer PCB, thermal expansion mismatches could compromise the entire design. Taconic RF-35HTC mitigates this risk with its low thermal expansion coefficient, which closely matches that of copper. This alignment minimizes warping and ensures clean registration of all layers during manufacturing.

| Property | Performance | Practical Impact |

| Coefficient of Thermal Expansion | Low (matches copper) | Enhanced layer alignment |

| Stability During Processing | Maintains uniformity | Avoids layer misregistration |

| Example Use Case | 16-layer telecom PCBs | Delivers consistent high-frequency performance |

By using Taconic RF-35HTC, we can tackle complex multilayer designs without concerns about structural inconsistencies.

High Peel Strength for Enhanced Reliability

Peel strength directly impacts the ability of copper traces to remain bonded to the substrate. Taconic RF-35HTC provides strong adhesion, even under physical stress or in high-temperature conditions, making it an excellent choice for designs that demand durability.

Take aerospace PCBs, for instance. Vibrations and thermal cycling during flight put significant strain on materials. A weaker substrate could cause delamination, leading to signal integrity issues or even system failure. Taconic RF-35HTC’s robust peel strength ensures copper remains securely bonded, even in these challenging environments.

| Metric | Value | Engineering Benefit |

| Peel Strength | High | Ensures copper adhesion under stress |

| Durability in Harsh Conditions | Outstanding | Suitable for aerospace and automotive use |

| Example Use Case | High-frequency radar systems | Ensures performance consistency |

By integrating Taconic RF-35HTC, we can confidently create PCBs that withstand mechanical challenges.

Moisture Resistance for Harsh Environments

Humidity can wreak havoc on conventional PCB materials by altering their electrical properties and weakening structural integrity. Taconic RF-35HTC addresses this issue with excellent resistance to moisture absorption, maintaining stable performance even in high-humidity settings.

For instance, PCBs used in offshore oil exploration systems face constant exposure to saline water vapor and fluctuating temperatures. Without sufficient moisture resistance, the substrate could degrade, leading to unreliable signal transmission. Taconic RF-35HTC avoids these pitfalls, ensuring reliable operation and extended service life.

| Feature | Performance | Application Example |

| Moisture Absorption Rate | Extremely low | Offshore oil exploration systems |

| Dielectric Consistency | Stable under humidity | Enhances signal reliability |

| Durability | Long-lasting in wet conditions | Reduces maintenance requirements |

Taconic RF-35HTC stands up to harsh environments, allowing us to design PCBs for challenging applications without compromise.

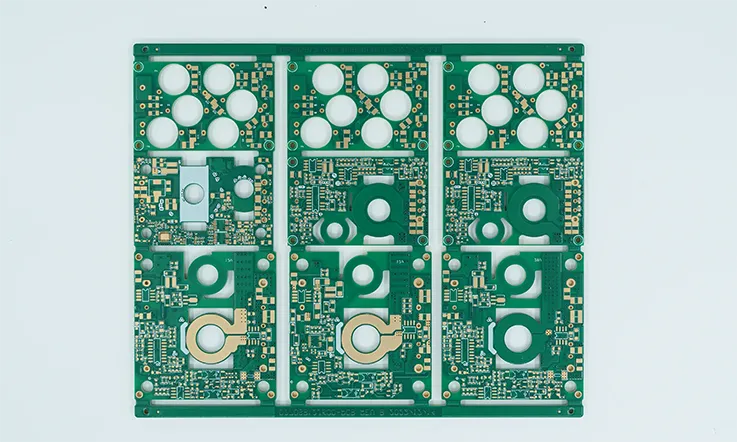

Industry Applications of Taconic RF-35HTC PCB Materials

Taconic RF-35HTC PCB Materials have carved a reputation for being reliable and effective in high-performance applications across diverse industries. Their unique composition and advanced properties meet the demanding requirements of systems operating in high-frequency environments. From communication infrastructure to automotive technologies, this material provides unmatched advantages tailored to specific industry needs.

Let’s dive into some main application areas and how this material supports groundbreaking innovation in these fields.

High-Frequency Communication Systems

In high-frequency communication systems, signal integrity is everything. Antennas, microwave links, and base stations need materials that maintain signal accuracy while handling substantial thermal and environmental stresses. Taconic RF-35HTC stands out as a preferred material for these applications due to its low dielectric constant and exceptional thermal conductivity.

Consider a microwave link used in a 5G network, where transmission efficiency and consistent performance are non-negotiable. Taconic RF-35HTC ensures minimal signal loss and stable operation, even in fluctuating temperature conditions. Additionally, its compatibility with advanced manufacturing processes simplifies the production of intricate designs, such as phased array antennas.

| Application | Performance Requirements | Taconic RF-35HTC Benefits |

| Base Stations | Low signal distortion | Superior dielectric stability |

| Microwave Transmission | Consistent performance under heat | Low loss tangent reduces signal attenuation |

| Antenna Arrays | Lightweight and durable materials | Optimized for high-frequency signal handling |

If you’re looking to enhance your communication system’s performance, Taconic RF-35HTC offers a dependable solution that’s engineered to exceed expectations.

Aerospace and Defense Electronics

In the aerospace and defense sectors, reliability isn’t just a preference—it’s mandatory. Systems like radar, avionics, and missile guidance require materials that can handle extreme conditions without compromising performance. Taconic RF-35HTC PCB Materials meet these rigorous standards with their high thermal resistance, mechanical durability, and moisture-repelling properties.

For example, military radar systems operating in high-frequency ranges face significant thermal loads during operation. Using Taconic RF-35HTC ensures that thermal buildup is managed effectively, reducing the risk of system failures. Additionally, its low moisture absorption makes it good for airborne and marine applications where environmental exposure is a concern.

| Aerospace/Defense Application | Challenges | Taconic RF-35HTC Solution |

| Radar Systems | High thermal load | Outstanding heat dissipation |

| Avionics | Mechanical stress | Durable, dimensionally stable material |

| Marine Electronics | Humidity and salinity exposure | Low moisture absorption and stable Dk values |

From avionics to defense-grade electronics, Taconic RF-35HTC offers unmatched performance tailored to the demands of aerospace and defense industries.

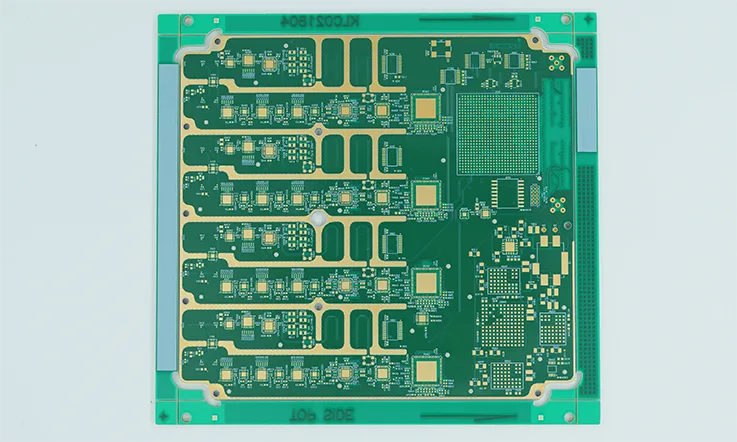

Automotive Radar and Advanced Driver Assistance Systems (ADAS)

The rise of autonomous driving and advanced safety systems has put high-frequency PCBs in the spotlight as a driving force behind automotive innovation. Taconic RF-35HTC PCB materials are a natural fit for these technologies, where high-frequency radar and millimeter-wave communication systems are integral to ensuring safe, smooth operations.

For example, a 77 GHz radar module used for lane-keeping or collision avoidance in modern vehicles. Such systems require materials that deliver consistent dielectric performance, even under rapid temperature shifts during vehicle operation. Taconic RF-35HTC not only supports these requirements but also ensures long-term reliability by resisting thermal cycling and mechanical stress.

| Application | Performance Needs | Taconic RF-35HTC Advantages |

| Millimeter-Wave Radar | Stable Dk over wide temperature ranges | Reduces signal distortion |

| ADAS Sensors | Reliable signal processing | Maintains consistent dielectric performance |

| Autonomous Vehicle Systems | Long-term durability | Resistant to wear, tear, and environmental changes |

The integration of Taconic RF-35HTC into automotive systems is a major leap toward boosting safety, precision, and long-lasting performance. For engineers advancing ADAS (Advanced Driver Assistance Systems) and autonomous driving technologies, this material becomes an indispensable tool. By offering reliable, high-frequency signal transmission with low loss, RF-35HTC helps ensure that radar and sensor systems in vehicles are not only accurate but also stable across varying conditions.

Design Considerations for Taconic RF-35HTC PCB Materials

When designing high-frequency PCBs, every detail counts. From achieving precise impedance control to optimizing laminate stack-ups, careful planning ensures that Taconic RF-35HTC delivers its full potential. We using this material benefit from its superior thermal and electrical properties, but extracting maximum performance requires deliberate attention to design parameters. This section breaks down some of the most core considerations when working with Taconic RF-35HTC PCB materials.

Impedance Control in RF Circuit Design

Achieving consistent impedance is fundamental to the reliable transmission of high-frequency signals. With Taconic RF-35HTC, the low and consistent dielectric constant (Dk) simplifies the process of impedance matching across a wide range of frequencies. We can leverage this material’s properties to fine-tune transmission line geometries, ensuring that signal reflection and distortion are minimized.

For instance, in a 50-ohm microstrip line design, the stable Dk of RF-35HTC ensures predictable impedance, even in multi-layer configurations. Pairing this with advanced simulation tools can help refine trace dimensions and spacing, allowing for precise control over signal behavior.

| Parameter | Challenge | Taconic RF-35HTC Solution |

| Impedance Matching | Maintaining signal integrity | Consistent Dk across temperature ranges |

| High-Frequency Signals | Signal reflection and losses | Low loss tangent minimizes distortion |

| Multi-Layer Designs | Variability in Dk and thickness | Reliable dielectric properties |

Incorporating this material into your RF designs reduces guesswork and opens the door to more efficient, high-performance circuits.

Laminate Stack-Up Optimization

For high-frequency multi-layer PCBs, laminate stack-up configuration directly impacts performance. Taconic RF-35HTC offers a unique advantage with its consistent dielectric performance, making it easier to achieve the desired electrical and mechanical properties across the entire stack.

When designing with RF-35HTC, we can choose from a range of prepreg and laminate thicknesses to balance electrical performance and manufacturability. For example, a multi-layer RF front-end board might include alternating layers of RF-35HTC and FR4 to reduce costs without compromising performance in critical signal paths. This hybrid approach, when properly optimized, maintains signal integrity while supporting cost efficiency.

| Layer Configuration | Application | Benefits with RF-35HTC |

| All-RF-35HTC Design | High-frequency circuits | Maximized signal fidelity |

| Hybrid with FR4 | Cost-sensitive designs | Reduced cost with maintained performance |

| Thick Dielectric Layers | Power applications | Improved heat dissipation and stability |

A well-planned stack-up that leverages RF-35HTC’s features ensures that even the most demanding applications perform as intended.

Minimizing Crosstalk in High-Density Layouts

As device complexity grows, the risk of crosstalk between adjacent traces increases, particularly in densely packed layouts. Crosstalk, or unintended coupling of signals, can degrade performance in high-frequency designs. Using Taconic RF-35HTC PCB materials, we can minimize this interference through smart material selection and layout practices.

The low loss tangent and precise dielectric control of RF-35HTC help contain signal energy, reducing its spread into neighboring traces. For high-density designs, the material’s inherent ability to support fine-pitch features allows tighter control over trace widths, spacing, and ground plane configuration. Additionally, the inclusion of properly designed ground vias and separation between differential pairs can further isolate signals.

| Design Element | Potential Issue | Taconic RF-35HTC Advantage |

| Trace-to-Trace Spacing | Increased crosstalk in small gaps | Consistent Dk supports precise layouts |

| Ground Plane Placement | Signal coupling | Improved isolation with stable materials |

| High-Density Routing | Crosstalk from packed signals | Low loss tangent for minimal interference |

Whether you’re designing compact RF modules or extensive multi-layer systems, RF-35HTC provides a solid foundation for reducing crosstalk and achieving clean signal paths.

Key Considerations for Choosing Taconic RF-35HTC for PCB Board Production

Selecting the right material for PCB production can be a complex task, especially when dealing with high-frequency applications like RF circuits. Taconic RF-35HTC is a solid choice for such needs, but several factors must be taken into account to ensure that this material matches your design requirements. Below, we’ll dive deeper into what to look for when choosing RF-35HTC for your PCB production.

1.Material Specifications

Before moving forward with Taconic RF-35HTC, it’s essential to take a deep dive into the material specifications. You’ll want to ensure the material aligns with the specific demands of your project to unlock its full potential. Here are the main properties to consider:

●Dielectric Constant (Dk): RF-35HTC features a dielectric constant of 3.5± 0.05 at 10 GHz, offering consistent signal transmission and minimal signal loss, even at high frequencies. This is key when working with high-speed data transmissions.

●Loss Tangent (Df): With a low loss tangent of just 0.0007, RF-35HTC significantly reduces signal loss, making it a reliable choice for applications where keeping the signal intact is a top concern.

●Thermal Conductivity: RF-35HTC offers 1.84 W/m·K thermal conductivity, allowing it to dissipate heat effectively. For high-frequency designs where heat buildup could cause reliability issues, this is a must-have feature.

2.Frequency Range and Signal Integrity

The performance of RF circuits is highly dependent on the frequency range at which they operate. Taconic RF-35HTC is engineered to perform well in high-frequency applications, but it’s essential to check that the material is suitable for the specific frequencies your PCB needs to handle.

●High-Frequency Range: Taconic RF-35HTC is built for high-frequency circuits, from 3 GHz to over 30 GHz. This wide range makes it versatile for use in telecommunications, radar systems, and other wireless communication technologies.

●Signal Integrity: Signal integrity is a must in high-frequency PCB designs. RF-35HTC maintains excellent signal quality by providing low dispersion and stable impedance over a wide range of frequencies. This helps to reduce signal distortion and ensures consistent performance, especially in complex circuits where signal degradation can result in errors or failures.

3.Thermal Management Considerations

High-power and high-frequency PCBs often generate a lot of heat, which can impact the board’s performance and longevity. To tackle this, managing heat efficiently becomes a major factor in keeping everything in check.

●Heat Dissipation: RF-35HTC’s thermal conductivity of 1.84 W/m·K makes it an excellent material for applications requiring effective heat dissipation. This ensures that your PCB doesn’t overheat during operation, protecting the components and extending their lifespan.

●Thermal Stability: In addition to heat dissipation, RF-35HTC maintains thermal stability across a range of temperatures, allowing it to endure in harsh environments or fluctuating conditions without compromising performance.

4.Manufacturing Process Compatibility

Not all PCB materials are compatible with every manufacturing process. When selecting RF-35HTC, it’s essential to verify that the material aligns with your manufacturer’s capabilities. Some factors to consider include:

●Processing Temperature: Taconic RF-35HTC has a higher glass transition temperature (Tg) compared to some other materials, making it more suitable for processes that involve high temperatures, like soldering or reflow.

●Etching and Drilling: RF-35HTC can be processed with standard etching and drilling techniques used for high-frequency PCB manufacturing. However, it’s important to ensure that your chosen PCB manufacturer has experience working with this specific material.

5.Cost-Efficiency and Budget Planning

While the performance of RF-35HTC is outstanding, cost is always a consideration in PCB production. When comparing costs, consider the following:

●Material Cost: RF-35HTC typically comes with a higher price tag compared to standard FR4 materials, but its performance in high-frequency applications makes the extra cost worth considering. The challenge is to find a balance between the material’s price and the specific performance needs of your project.

●Long-Term Savings: Thanks to its robust thermal management and superior signal integrity, RF-35HTC can extend the lifespan of your PCB, potentially reducing the need for repairs or replacements in the long term.

Taconic RF-35HTC PCB Materials vs. Competitor Materials

In the world of high-frequency applications, human are constantly looking for materials that can provide both reliable performance and cost-efficiency. Taconic RF-35HTC, with its unique blend of thermal conductivity, low dissipation factor, and mechanical properties, is becoming a strong contender in high-frequency PCB design. However, as the market for RF PCB materials grows, several other well-established brands like Rogers, Isola, and Shengyi also offer competitive options. Let’s explore how RF-35HTC compares to these materials in main areas such as thermal performance, electrical characteristics, and overall value.

Comparing Thermal Conductivity Performance

Thermal conductivity is a big deal when it comes to high-frequency PCBs, especially in environments where managing heat is a top concern. Taconic RF-35HTC stands out here with a thermal conductivity rating of 1.84 W/m·K, which gives it an edge over many other materials in the high-frequency PCB market. This enhanced thermal performance helps maintain consistent operation and extends the lifespan of the board, even under heavy loads.

●Rogers RO4000 Series, for example, has a lower thermal conductivity of approximately 0.6 W/m·K. This makes RF-35HTC a better choice for applications where heat buildup is a concern, such as 5G base stations, satellite communications, and automotive radar systems. The ability of RF-35HTC to effectively manage heat ensures that components operate within optimal temperature ranges, thus prolonging the life of the entire system and reducing the risk of thermal damage.

●Isola I-Tera is another well-known player, with a thermal conductivity of around 0.5 W/m·K. While Isola offers solid performance, Taconic’s higher thermal conductivity provides a distinct edge when dealing with high-power applications, where heat generation is more intense.

| Material | Thermal Conductivity (W/m·K) |

| Taconic RF-35HTC | 1.84 |

| Rogers RO4000 | 0.71 |

| Isola I-Tera | 0.61 |

As shown, Taconic RF-35HTC stands out for its superior heat management capabilities, making it an attractive option for us designing high-power RF systems that need effective thermal dissipation.

Electrical Performance Comparison

When it comes to electrical performance, the dielectric constant (Dk) and dissipation factor (Df) are two of the most main parameters. Taconic RF-35HTC boasts a dielectric constant of 3.5, along with a low dissipation factor of 0.0007. These properties help minimize signal loss and distortion, contributing to maintaining signal stability and clarity in high-frequency circuits.

●Rogers RO4350B is a well-known material in the RF industry, with a dielectric constant of 3.66 and a dissipation factor of approximately 0.0031. While these properties are similar to Taconic RF-35HTC, Taconic stands out due to its lower dissipation factor, which can provide a noticeable advantage in high-frequency applications where maintaining signal clarity is a priority.

●Shengyi’s S1000-2 offers a higher Dk of around 3.5 but with a slightly higher dissipation factor of 0.004. This makes it less ideal for precision applications, where minimizing signal loss is paramount. For instance, in satellite communication or radar systems, even a small signal degradation could lead to performance issues.

| Material | Dielectric Constant (Dk) | Dissipation Factor (Df) |

| Taconic RF-35HTC | 3.5 | 0.0007 |

| Rogers RO4350B | 3.66 | 0.0031 |

| Shengyi S1000-2 | 3.5 | 0.004 |

As this table illustrates, Taconic RF-35HTC offers a slightly lower dissipation factor than both Rogers and Shengyi, giving it an edge in maintaining signal fidelity over long distances, especially in complex communication systems like 5G networks and aerospace systems.

Cost-Efficiency and Long-Term Reliability

Cost-efficiency remains a top priority for us, especially when working on large-scale projects. Taconic RF-35HTC provides a solid balance of performance and cost, offering reliable long-term service at a competitive price point. Compared to some of its high-end competitors, such as Rogers’ RO3000 series, Taconic RF-35HTC offers similar performance but at a more budget-friendly cost.

●Rogers’ RO3000 materials, while providing excellent electrical performance and thermal properties, come at a higher cost due to their advanced formulations and manufacturing processes. In contrast, Taconic RF-35HTC offers comparable performance in many areas at a more accessible price, making it a solid choice for high-volume applications where cost efficiency is necessary without compromising reliability.

●Shengyi’s S1000-2 also competes well on price but falls short of Taconic in terms of thermal conductivity and low loss, which can lead to higher operational costs in the long run, especially in systems that generate a lot of heat or operate at high frequencies.

| Material | Price Range (USD/m²) | Long-Term Reliability |

| Taconic RF-35HTC | Mid-Range | High |

| Rogers RO3000 | High | Very High |

| Shengyi S1000-2 | Low-Mid Range | Medium |

Taconic RF-35HTC offers a strong performance-to-cost ratio, making it the right choice for us seeking a reliable, high-performing material without breaking the bank. This cost-effectiveness, paired with its long-term durability, makes it better for large-scale production runs, such as those in telecommunications, industrial electronics, and automotive radar systems.

Technical Data and Specifications for Taconic RF-35HTC PCB Materials

When choosing the right PCB material for high-frequency applications, it’s crucial to look beyond just basic properties like thermal and electrical performance. A material’s thickness, copper cladding options, and compliance with environmental standards are also main aspects to consider. Taconic RF-35HTC delivers strong performance in all these areas, making it a standout choice for a variety of industries. Let’s break down the technical details that set RF-35HTC apart from other materials.

Detailed Thermal and Electrical Properties

The thermal conductivity and electrical properties of a material are two major factors determining its performance in high-speed and high-frequency circuits. Taconic RF-35HTC excels in both of these areas.

●Thermal Conductivity: At 1.84 W/m·K, Taconic RF-35HTC is well-suited for applications where heat dissipation is a priority.

●Dielectric Constant (Dk): RF-35HTC offers a stable dielectric constant of 3.5±0.05 at 10 GHz, which ensures minimal signal loss at high frequencies.

●Loss Tangent (Df): RF-35HTC’s low loss tangent of 0.0007 makes it an excellent material for minimizing signal attenuation and reducing power loss.

| Property | Taconic RF-35HTC | Rogers RO4000 | Isola I-Tera |

| Thermal Conductivity | 1.84 W/m·K | 0.60 W/m·K | 0.61 W/m·K |

| Dielectric Constant (Dk) | 3.5 @ 10 GHz | 3.66 @ 10 GHz | 3.75 @ 10 GHz |

| Loss Tangent (Df) | 0.0007 | 0.0031 | 0.0032 |

These values show how RF-35HTC compares favorably with similar materials like Rogers RO4000 and Isola I-Tera, especially when it comes to thermal performance and low-loss signal transmission.

Material Thickness and Copper Cladding Options

Taconic RF-35HTC also offers flexibility in terms of thickness and copper cladding options. Whether you’re working on multi-layer designs or tackling high-frequency challenges, having the ability to fine-tune these factors can help achieve the best possible results for your specific needs.

●Material Thickness: Taconic RF-35HTC is available in a wide range of thicknesses, from 0.004″ to 0.125″. This makes it suitable for both standard and high-performance applications, depending on your needs.

●Copper Cladding: Taconic offers various copper cladding options, including 1/2 oz, 1 oz, and 2 oz. These cladding options provide flexibility for a variety of circuit board designs, allowing us to choose the right copper weight for their thermal and electrical requirements.

The availability of these customizable options helps us optimize their PCB design for both functionality and manufacturability. By selecting the right combination of thickness and copper cladding, users can achieve more efficient heat dissipation and signal propagation.

RoHS and REACH Compliance for Sustainable Manufacturing

With increasing emphasis on sustainability in manufacturing, Taconic RF-35HTC stands out by meeting the latest environmental standards. The material is RoHS and REACH compliant, ensuring that it is free from harmful substances and environmentally safe.

●RoHS Compliance: Taconic RF-35HTC meets the Restriction of Hazardous Substances (RoHS) directive, ensuring that it is free from dangerous chemicals such as lead, mercury, and cadmium. This makes it a safe choice for manufacturers looking to meet global environmental standards.

●REACH Compliance: The material also complies with the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulations. This ensures that the materials used in RF-35HTC do not pose a risk to human health or the environment.

Both RoHS and REACH certifications not only align with legal requirements but also support the ongoing trend toward green manufacturing. By using Taconic RF-35HTC, manufacturers contribute to a more sustainable and eco-friendly production process.

Why Choose JarnisTech for Manufacturing High-Performance PCB Boards?

When it comes to high-performance printed circuit boards (PCBs), choosing the right manufacturing partner is just as critical as selecting the right materials. At JarnisTech, we specialize in delivering PCBs that perform consistently in demanding environments, combining advanced materials like Taconic’s RF-35HTC with top-tier fabrication expertise. Whether you’re working in telecommunications, automotive, or aerospace, we’ve got you covered from design to delivery.

Proven Success in High-Tech Applications

At JarnisTech, our experience with high-tech applications speaks for itself. From aerospace systems to high-speed communication infrastructure, we’ve partnered with a diverse range of industries to provide reliable PCB manufacturing and assembly solutions. Take the example of a telecommunications company that required ultra-low-loss PCBs for their next-gen 5G infrastructure. By using Taconic RF-35HTC, we helped them achieve the superior signal quality they needed without the typical performance drop-offs seen with other materials.

●Example Case Study: One automotive manufacturer partnered with us to integrate Taconic RF-35HTC boards into their radar systems for advanced driver assistance. The precision in signal integrity and high-frequency performance delivered by the boards allowed the system to meet safety standards and improve overall vehicle performance. This is just one of the many instances where JarnisTech’s focus on high-performance PCB manufacturing and processes led to success in complex, tech-heavy industries.

End-to-End Support for Design and Fabrication

Our commitment to high-performance PCB manufacturing goes beyond just delivering the right materials. JarnisTech provides complete support throughout the design and fabrication process to ensure a smooth, efficient production journey. We collaborate closely with clients, from the initial design phase to final fabrication, offering insights and technical support that help eliminate common pitfalls and streamline the process.

●Support at Every Step: With our deep understanding of Taconic RF-35HTC, we ensure that the design is optimized for thermal management, signal integrity, and mechanical durability before fabrication even begins. Our team helps identify the best copper cladding options, material thickness, and stack-up configuration, minimizing the need for revisions. Whether you’re tweaking your design for a new product release or tackling a complex engineering challenge, JarnisTech is here to help you make it happen.

●Real-World Example: One of our long-time clients in the aerospace sector relied on our expertise to create custom PCBs for a high-speed data transmission project. By working closely with our engineers, they were able to perfect their design with minimal iterations, which drastically reduced the time-to-market for their product.

Get In touch with Us Today!

At JarnisTech, we understand that successful PCB manufacturing is about more than just choosing the right materials—it’s about bringing together the best practices in design, fabrication, and customer support. If you’re looking for a manufacturing partner that delivers consistent performance, cost-effective solutions, and expert guidance every step of the way, you’ve found the right place. Let’s build something great together.

FAQ & Taconic RF-35HTC PCB Materials

1. Can RF-35HTC be used for high-speed digital circuits?

While RF-35HTC is optimized for high-frequency analog and RF applications, it may not be the best option for high-speed digital circuits requiring ultra-low signal propagation delays.

2. What thickness options are available for RF-35HTC?

RF-35HTC is available in various thicknesses, typically ranging from 0.2mm to 3.0mm, offering flexibility for different circuit designs.

3. How does Taconic RF-35HTC perform in moisture resistance?

RF-35HTC is highly resistant to moisture absorption, maintaining stable electrical properties even in high-humidity environments.

4. What types of copper cladding are compatible with RF-35HTC?

RF-35HTC is compatible with a variety of copper cladding options, including rolled and electrodeposited copper, which can be selected based on the specific requirements of the PCB design.