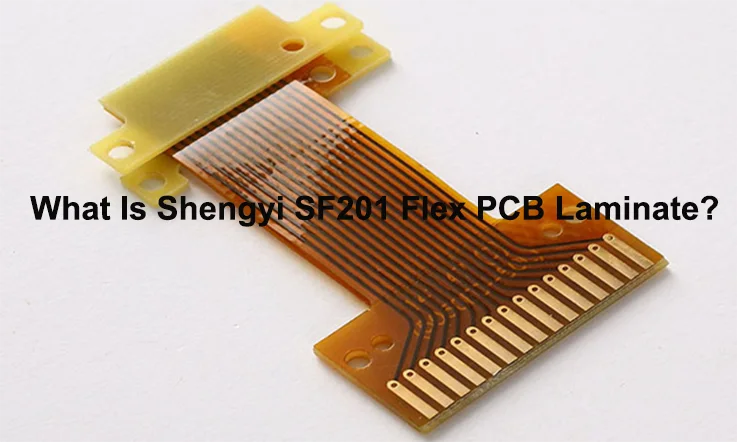

Flex PCBs have revolutionized the electronics industry with their ability to conform to complex shapes and provide reliable interconnectivity in space-constrained applications. Among the various laminate materials available, Shengyi SF201 stands out as a versatile and high-performance option. This article explores the exceptional characteristics of SF201 and highlights its advantages over other Flex PCB laminate materials.

Shengyi SF201 Flex PCB Laminate: Overview

Shengyi SF201 is a type of flexible printed circuit board (PCB) laminate designed for use in various electronic applications. This laminate material offers excellent flexibility and bendability, making it suitable for use in products that require a high degree of flexibility and reliability.

The SF201 laminate is made from a combination of polyimide and adhesive materials, which provide it with the necessary mechanical and electrical properties required for flexible PCB applications. This material is also known for its high thermal resistance, allowing it to withstand elevated temperatures during the PCB manufacturing process and in operation.

Shengyi SF201 is commonly used in applications such as flexible circuits, wearable electronics, medical devices, and automotive electronics. Its properties make it well-suited for use in products that require a combination of high performance and flexibility.

Overall, Shengyi SF201 is a reliable and versatile flexible PCB laminate material that can meet the demanding requirements of various electronic applications. Its excellent flexibility, thermal resistance, and electrical properties make it a popular choice for designers and manufacturers looking to create innovative and reliable flexible PCB solutions.

Features of Shengyi SF201 PCB Laminate

Shengyi SF201 PCB Laminate boasts an impressive range of features that make it a top choice for professional PCB engineers. This exceptional laminate offers outstanding soldering reliability, ensuring secure and durable connections. It exhibits remarkable dimensional stability, ensuring that the PCB maintains its intended shape and structure even under challenging conditions. Furthermore, SF201 demonstrates excellent chemical resistance, safeguarding against the detrimental effects of various substances.

In addition to its mechanical properties, SF201 excels in electrical performance. It exhibits exceptional flexibility, allowing for efficient routing and installation in various applications. The electrical properties of this laminate are of the highest quality, ensuring reliable signal transmission and minimizing signal loss.

SF201 is designed with safety in mind. It is halogen-free and meets the stringent flammability standard of UL .94 V-0. This ensures that the laminate exhibits excellent fire-resistant properties, providing an added layer of protection in PCB applications.

Moreover, Shengyi SF201 is fully compliant with the EU RoHS directive, which restricts the use of hazardous substances in electronic products. It is free from lead (Pb), mercury (Hg), cadmium (Cd), hexavalent chromium (CrP*), polybrominated biphenyls (PBB), polybrominated diphenyl ethers (PBDE), and other restricted substances. By adhering to these regulations, SF201 promotes environmental sustainability and ensures the safety of both end-users and the environment.

Overall, Shengyi SF201 PCB Laminate combines exceptional soldering reliability, dimensional stability, and chemical resistance with excellent flexibility and electrical properties. It meets the highest safety standards, including RoHS compliance, and is an ideal choice for demanding PCB applications in various industries.

Applications of Shengyi SF201 PCB Material

Shengyi SF201 PCB material finds wide-ranging applications in various industries due to its exceptional properties. Here are some specific applications where SF201 is commonly used:

1.Computer:

Shengyi SF201 PCB material can be used in various computer applications, including desktop computers, laptops, servers, and networking equipment. It provides excellent electrical performance, thermal stability, and reliability necessary for high-speed data transmission and processing in computer systems.

2.Mobile Phone:

Shengyi SF201 is suitable for mobile phone applications due to its flexibility, compactness, and lightweight properties. It enables the design and manufacturing of flexible PCBs that can be integrated into the slim and compact form factors of modern smartphones while maintaining reliable electrical connections.

3.Digital Camera:

SF201 PCB material is used in digital cameras to ensure high-quality image capture, efficient signal processing, and reliable operation. Its excellent thermal and mechanical properties help maintain the structural integrity of the camera module, ensuring stable performance in various environmental conditions.

4.VCR:

Shengyi SF201 can be utilized in video cassette recorders (VCRs) to enable reliable signal transmission and processing. The material’s low dielectric loss and good signal integrity characteristics are crucial for maintaining video and audio quality in VCRs.

5.Flat Panel Display:

SF201 is suitable for flat panel displays, including LCD (liquid crystal display) and OLED (organic light-emitting diode) screens. Its high thermal stability and dimensional stability ensure consistent performance and prevent warping or distortion of the display module.

6.Apparatus and Instrument:

Shengyi SF201 PCB material finds application in various apparatus and instruments requiring flexible circuitry, such as medical devices, test and measurement equipment, industrial control systems, and consumer electronics. Its flexibility, durability, and electrical performance make it suitable for these applications.

7.Automotive Electronics:

SF201 is used in automotive electronics due to its ability to withstand high temperatures, mechanical vibrations, and harsh environmental conditions. It is commonly employed in automotive control units, infotainment systems, navigation systems, and dashboard displays, ensuring reliable and long-lasting performance in demanding automotive environments.

These are just a few examples of the applications where Shengyi SF201 PCB material can be employed. Its versatility, reliability, and performance characteristics make it suitable for a wide range of electronic devices and industries.

Design Guidelines for Flex PCBs Using SF201

When designing Flex PCBs using Shengyi SF201, it is important to consider certain guidelines to ensure optimal performance and reliability. Here are some design guidelines to keep in mind:

1. Flexibility and Bending Radius: SF201 offers excellent flexibility, allowing the PCB to bend and conform to different shapes. When designing the Flex PCB, consider the minimum bending radius specified by the manufacturer to prevent excessive stress on the PCB traces and components. This will help avoid mechanical failure and ensure the longevity of the Flex PCB.

2. Trace Routing: When routing traces on the Flex PCB, ensure that they follow smooth, gradual curves rather than sharp angles. Sharp bends can lead to stress concentration, which may lead to trace damage or failure over time. Use curved traces and teardrop-shaped pads to minimize stress and enhance the overall flexibility of the PCB.

3. Keepout Zones: Identify and define keepout zones on the Flex PCB to prevent any interference between the flexible circuit and other components or mechanical elements in the system. These keepout zones will help ensure that the Flex PCB can bend and flex without any obstructions or collisions.

4. Component Placement: Carefully consider the placement of components on the Flex PCB to avoid placing them in areas that will experience excessive bending or stress. Components should be positioned in areas where the bending and flexing of the PCB are minimal. Additionally, consider the height of components to prevent interference with the bending and flexing of the PCB.

5. Stiffeners and Support Structures: In areas where extra support is needed, consider incorporating stiffeners or support structures. These can be added to specific sections of the Flex PCB to provide rigidity and prevent excessive bending or stress. Stiffeners can be made of materials like FR-4 or polyimide, and they should be designed to match the flexibility of the SF201 laminate.

6. Thermal Management: Consider the thermal characteristics of the Flex PCB design, especially if it will be exposed to high temperatures or heat-generating components. Ensure proper heat dissipation by incorporating thermal vias, heat sinks, or other cooling techniques to maintain the temperature within acceptable limits.

7. Signal Integrity: Pay attention to signal integrity considerations, such as impedance control and signal routing techniques, to maintain reliable electrical performance. Follow best practices for high-speed signal routing, such as minimizing trace lengths, avoiding crosstalk, and maintaining controlled impedance for critical signal paths.

8. Test and Inspection: During the design phase, consider accessibility for testing and inspection of the Flex PCB. Ensure that test points and inspection points are accessible and properly positioned to facilitate testing and quality control processes.

By following these design guidelines, you can maximize the performance and reliability of Flex PCBs using Shengyi SF201. It is also recommended to consult the manufacturer’s datasheets and design guidelines for specific recommendations and considerations related to SF201 laminate.

Comparison of SF201 with Other Flex PCB Laminate Materials

When comparing Shengyi SF201 with other Flex PCB laminate materials, several factors come into play, including mechanical properties, electrical performance, chemical resistance, and cost. Here’s a comparison of SF201 with some commonly used Flex PCB laminate materials:

1.Polyimide (PI):

Polyimide is a widely used Flex PCB laminate material known for its excellent flexibility, high-temperature resistance, and good electrical properties. Compared to SF201, polyimide generally offers better thermal stability and higher operating temperature range. However, SF201 may have better dimensional stability and chemical resistance.

2.Polyester (PET):

Polyester is another common Flex PCB laminate material that offers good flexibility and cost-effectiveness. It has lower thermal resistance compared to SF201 and may not perform as well in high-temperature applications. SF201, on the other hand, provides better thermal stability and chemical resistance.

3.Liquid Crystal Polymer (LCP):

LCP is a high-performance Flex PCB laminate material known for its outstanding electrical properties, low moisture absorption, and excellent dimensional stability. LCP typically offers better electrical performance than SF201, but SF201 may have better flexibility and cost-effectiveness.

4.FR-4:

FR-4 is a popular PCB laminate material used in rigid PCBs, but it can also be used in Flex PCBs. It offers good mechanical strength, electrical performance, and cost-effectiveness. However, compared to SF201, FR-4 is less flexible and may not be suitable for applications requiring high flexibility or bending.

In terms of cost, SF201 is generally considered to be a cost-effective option compared to some high-performance Flex PCB laminate materials like LCP. However, the actual cost can vary depending on factors such as the specific manufacturer, quantities, and other project-specific requirements.

Ultimately, the choice of Flex PCB laminate material depends on the specific application requirements, such as flexibility, temperature range, chemical resistance, electrical performance, and cost considerations. It is recommended to consult with the PCB manufacturer or material supplier to determine the most suitable laminate material for a particular project.

In Conclusion

Shengyi SF201 Flex PCB Laminate stands out as a top-tier material for flexible PCB applications. Its excellent flexibility, thermal resistance, and electrical properties make it a popular choice for designers and manufacturers seeking high-performance solutions. With its compliance with environmental regulations and industry standards, the SF201 laminate is poised to play a pivotal role in driving the advancement of flexible electronics. As the demand for flexible and reliable electronic products continues to grow, the Shengyi SF201 Flex PCB Laminate is well-positioned to meet the evolving needs of the industry.