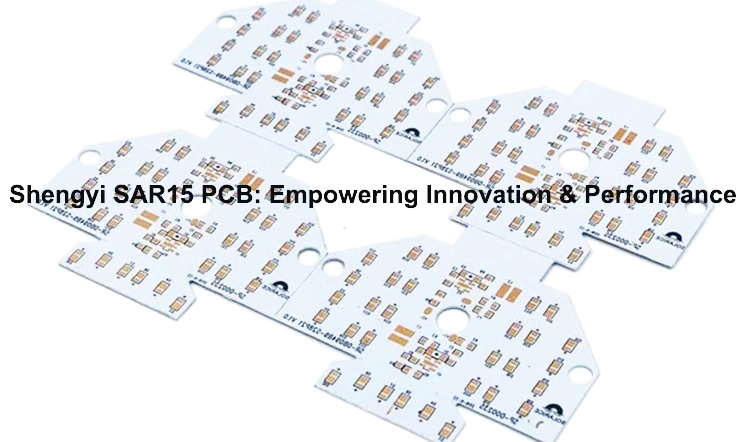

In the fast-paced world of electronic manufacturing, staying ahead of the competition requires cutting-edge materials that deliver exceptional performance and reliability. Shengyi Technology, a renowned leader in the PCB industry, presents SAR15 PCB boards, a game-changer in the realm of electronic substrates. With its advanced features and superior capabilities, SAR15 boards empower manufacturers to unlock new levels of innovation and drive their products to new heights.

What Is Shengyi SAR15 PCB Materials?

Shengyi SAR15 is a type of PCB (Printed Circuit Board) material manufactured by Shengyi Technology Co., Ltd. It is specifically designed to meet the requirements of high-performance applications, offering excellent electrical and mechanical properties.

SAR15 is a halogen-free material with a high comparative tracking index (CTI), ensuring a safer and more environmentally friendly solution. The material also exhibits superior heat dissipation capabilities, allowing for efficient thermal management. SAR15 is known for its exceptional thermal resistance and insulation reliability, providing reliable performance even in challenging conditions.

Furthermore, SAR15 offers excellent process ability, making it easy to manufacture and integrate into various production processes. Overall, Shengyi SAR15 is a high-quality PCB material that meets the demands of modern electronic applications.

Characteristic of Shengyi SAR15

Shengyi SAR15 possesses several notable characteristics that make it a desirable choice for electronic applications. These characteristics include:

Halogen free and high CTI:

Shengyi SAR15 is a PCB substrate material offered by Shengyi Technology Co., Ltd. It is characterized by its halogen-free composition and high Comparative Tracking Index (CTI), making it compliant with environmental regulations and ensuring enhanced safety in electronic applications.

Superior heat dissipation:

One of the notable features of SAR15 is its exceptional heat dissipation capabilities. With its high thermal conductivity, SAR15 efficiently transfers and dissipates heat generated by electronic components on the PCB. This property is crucial for preventing overheating issues and maintaining the reliability of the circuitry.

Excellent thermal resistance and insulation reliability:

Furthermore, SAR15 exhibits excellent thermal resistance and insulation reliability. It effectively withstands high temperatures and maintains its insulation properties over extended periods, ensuring the stable performance of the PCB even under demanding conditions.

Excellent process ability:

In terms of processability, SAR15 demonstrates outstanding characteristics. It can be easily processed and fabricated during PCB manufacturing processes, facilitating efficient and reliable production.

Overall, Shengyi SAR15 stands out as a high-quality PCB substrate material that combines halogen-free and high CTI properties with superior heat dissipation, excellent thermal resistance, insulation reliability, and exceptional processability. These features make it a preferred choice for electronic applications where stringent performance, safety, and environmental requirements are essential.

Challegan and Limitation of Shengyi SAR15

While Shengyi SAR15 offers many advantages for electronic applications, it also has some challenges and limitations to consider:

1. Cost: SAR15 may have a higher cost compared to other PCB substrate materials. The advanced properties and performance characteristics of SAR15 contribute to its higher price point. Therefore, it may not be the most cost-effective option for budget-sensitive projects.

2. Availability: SAR15 may not be as widely available as some other PCB substrate materials. Depending on the region and supplier, it may have limited availability, which could potentially impact production timelines and project schedules.

3. Thickness Limitations: SAR15 may have limitations in terms of available thickness options. The range of thicknesses offered for SAR15 may not cover all design requirements, which could restrict its suitability for certain applications.

4. Compatibility: While SAR15 is compatible with various manufacturing processes, it may not be compatible with every specific process or technology. It is essential to verify its compatibility with specific assembly methods, surface finishes, and soldering techniques to ensure successful integration into the manufacturing process.

5. Mechanical Strength: SAR15 may have lower mechanical strength compared to some other PCB substrate materials. It may not be the best choice for applications that require high rigidity or resistance to physical stress, such as heavy-duty industrial equipment.

6. Environmental Considerations: While SAR15 is halogen-free and compliant with environmental regulations, it is still important to consider the overall environmental impact of the material. This includes factors such as the energy consumption and emissions associated with its manufacturing process, as well as its recyclability at the end of its lifecycle.

It is crucial to evaluate these challenges and limitations against the specific requirements of the project to determine if Shengyi SAR15 is the most suitable choice for the intended application.

Applications Area of Shengyi SAR15

Shengyi SAR15 finds wide application in various electronic devices and systems, particularly in the following areas:

Mid-power LED Lighting: SAR15 is well-suited for use in mid-power LED lighting applications. Its superior heat dissipation properties ensure efficient thermal management, allowing for reliable operation of LED lighting systems. The material’s excellent thermal resistance and insulation reliability contribute to the longevity and performance stability of LED lighting products.

LED TV: SAR15 is an ideal choice for the manufacturing of LED TVs. With its high thermal conductivity, it effectively dissipates heat generated by the LED backlight and other components, preventing overheating and ensuring the longevity of the TV. The material’s excellent processability facilitates the fabrication of intricate PCB designs required for LED TVs.

Power Supply Boards: SAR15 is commonly used in power supply boards due to its exceptional thermal resistance and insulation reliability. Power supply boards often generate significant heat, and SAR15’s superior heat dissipation properties help maintain the stability and efficiency of the power supply system. The material’s excellent processability enables the production of reliable and high-performance power supply boards.

Therefore, Shengyi SAR15 is extensively applied in mid-power LED lighting, LED TVs, and power supply boards. Its exceptional heat dissipation, thermal resistance, insulation reliability, and processability make it a preferred choice for these applications, ensuring optimal performance, reliability, and longevity of electronic devices.

Factors to Consider When Selecting Shengyi SAR15

When choosing Shengyi SAR15 for PCB design and manufacturing, several factors should be considered to ensure its suitability for the intended application. Here are some key factors to consider:

1. Thermal Management: Evaluate the thermal conductivity and heat dissipation capabilities of SAR15 to ensure it can effectively manage the heat generated by electronic components. Consider the power dissipation requirements and the expected operating temperature range of the PCB.

2. Electrical Performance: Assess the electrical properties of SAR15, including its dielectric constant, loss tangent, and insulation resistance. These characteristics impact signal integrity, impedance control, and electrical isolation in the PCB design.

3. Flame Retardancy: Consider the flame retardancy properties of SAR15, especially if the PCB will be used in applications where fire safety is critical. Ensure that SAR15 meets the required flame retardancy standards and regulations.

4. Mechanical Strength: Evaluate the mechanical strength and durability of SAR15 to ensure it can withstand the mechanical stress and environmental conditions encountered during PCB assembly, handling, and operation. Consider factors such as flexural strength, tensile strength, and resistance to warping or delamination.

5. Chemical Resistance: Assess the resistance of SAR15 to chemicals and solvents that may be encountered during PCB manufacturing processes, such as cleaning agents or soldering fluxes. Ensure that SAR15 can withstand exposure to these substances without degradation or damage.

6. Compatibility with Manufacturing Processes: Consider the compatibility of SAR15 with the chosen PCB manufacturing processes, such as drilling, plating, solder mask application, and component assembly. Ensure that SAR15 can be easily processed and that it is compatible with the chosen fabrication techniques.

By considering these factors, you can make an informed decision when selecting Shengyi SAR15 for your PCB design and manufacturing, ensuring that it meets the specific requirements of your application and delivers reliable performance.

How to Test Quality for Shengyi SAR15 PCB Substrates Materials?

To test the quality of Shengyi SAR15 PCB substrate materials, several methods and tests can be performed. Here are some common quality tests for PCB substrates:

1.Visual Inspection:

Conduct a visual inspection to check for any visible defects such as cracks, delamination, warping, or surface abnormalities. This can be done manually or with the assistance of automated optical inspection (AOI) equipment.

2.Dimensional Measurement:

Measure the dimensions of the PCB substrate to ensure it meets the specified tolerances. This includes measuring the thickness, width, and length of the substrate.

3.Thermal Conductivity Testing:

Evaluate the thermal conductivity of SAR15 using methods such as the hot disk method or laser flash analysis. These tests measure the material’s ability to conduct heat efficiently.

4.Dielectric Constant and Loss Tangent Measurement:

Determine the dielectric constant and loss tangent of SAR15 using techniques like the resonant cavity method or impedance analyzer. These measurements assess the material’s electrical properties, including its ability to transmit electrical signals without significant energy loss.

5.Flame Retardancy Testing:

Verify the flame retardancy properties of SAR15 by subjecting it to flame tests, such as the UL 94 test. This evaluates the material’s resistance to combustion and its ability to self-extinguish.

6.Chemical Resistance Testing:

Assess the material’s resistance to various chemicals by exposing it to specific substances commonly encountered in the intended application. This helps determine if SAR15 can withstand exposure without significant degradation or damage.

7.Electrical Insulation Testing:

Perform electrical insulation tests, such as the insulation resistance test or dielectric strength test, to ensure SAR15 provides adequate electrical isolation and meets the required standards.

8.Mechanical Strength Testing:

Evaluate the mechanical strength of SAR15 by conducting tests like flexural strength, tensile strength, or peel strength tests. These tests assess the material’s ability to withstand mechanical stress and ensure its suitability for specific applications.

9.Environmental Testing:

Subject SAR15 to environmental tests, such as temperature cycling, humidity testing, or thermal shock testing, to assess its performance under different environmental conditions and ensure its reliability.

Final Thoughts

Embrace the Future with Shengyi SAR15

In the ever-evolving landscape of electronic manufacturing, the demand for high-performance PCB boards continues to soar. Shengyi SAR15 emerge as the ideal solution, offering a perfect blend of technological excellence, reliability, and versatility. With SAR15, manufacturers can embark on a journey of limitless possibilities, pushing the boundaries of what is achievable in the world of electronics. Trust in Shengyi Technology’s commitment to innovation and quality, and let SAR15 be your catalyst for success in the dynamic realm of electronic manufacturing.