Printed circuit board (PCB) material selection directly affects electrical performance, thermal management, and long-term reliability. Shengyi S1141 PCB is designed for high-speed digital, RF, and thermally demanding applications, making it a strong choice for industries requiring consistent signal integrity and durability. This guide explores its material composition, electrical and mechanical properties, manufacturing processes, and comparisons with industry alternatives like Isola, Panasonic, and Rogers.

For OEMs, PCB engineers, and manufacturers, understanding lamination, drilling, soldering, and thermal characteristics helps refine designs and streamline production. Whether for 5G infrastructure, industrial computing, or automotive electronics, Shengyi S1141 PCB offers the stability and reliability modern electronics require.

What Is Shengyi S1141 PCB?

Understanding Its Role in High-Performance Electronics

In modern electronics, selecting the right PCB laminate determines how well a circuit performs under demanding conditions. So, it’s used in 5G infrastructure, industrial automation, or advanced computing, the material must support high-frequency signals, withstand thermal fluctuations, and ensure mechanical stability.

Shengyi S1141 PCB is engineered to meet these expectations, offering low dielectric loss, reliable thermal properties, and strong mechanical durability. Human looking for consistent electrical performance across various operating conditions are increasingly turning to this laminate.

Overview of Shengyi S1141 PCB – Features and Industry Adoption

Shengyi S1141 PCB is designed for high-frequency, high-speed, and thermally demanding applications. Standard FR-4 laminates often fall short in signal transmission, heat resistance, and mechanical reliability, whereas S1141 is manufactured to address these factors.

Core Features of Shengyi S1141 PCB-

| Feature | Description | Benefit |

| Low Dielectric Constant (Dk) | Minimizes signal distortion | Supports stable high-frequency performance |

| Low Loss Tangent (Df) | Enhances signal efficiency | Reduces power dissipation |

| High Glass Transition Temperature (Tg) | Withstands extended exposure to heat | Limits thermal expansion issues |

| Moisture Resistance | Reduces water absorption | Enhances reliability in humid environments |

| Mechanical Strength | Improves structural integrity | Lowers the risk of PCB warping |

Industry Adoption-

●Telecommunications: Used in network infrastructure, antennas, and RF modules.

●Medical Equipment: Supports diagnostic imaging and monitoring devices.

●Automotive Electronics: Applied in ADAS (Advanced Driver Assistance Systems) and electric vehicle power control units.

Why Choose Shengyi S1141 PCB Over Traditional PCB Laminates?

Selecting PCB materials requires an understanding of electrical, thermal, and mechanical characteristics. Many engineers continue using FR-4 or mid-tier laminates, but as circuit complexity increases, those materials may not meet performance expectations.

Signal Transmission Properties-

Shengyi S1141 PCB features a low dielectric constant (Dk) and loss tangent (Df), enabling signals to travel with minimal interference in high-frequency applications. This makes it a suitable choice for RF circuits, radar systems, and data communication devices where stable electrical performance is needed.

Thermal Stability Under High-Load Conditions-

Electronic components generate heat during operation. Laminates with higher glass transition temperatures (Tg) and lower thermal expansion coefficients (CTE) help prevent structural deformation. Shengyi S1141 PCB provides enhanced thermal endurance, making it a suitable choice for industrial control systems and aerospace electronics.

Manufacturing Process Compatibility-

Many fabricators prefer laminates that integrate smoothly into existing production workflows. Shengyi S1141 PCB accommodates:

●Standard drilling and plating techniques

●Multilayer PCB stack-ups

●Copper adhesion properties that minimize delamination risks

Applications of Shengyi S1141 PCB in Telecommunications, Medical Devices, and High-Speed Computing

Advancements in data transmission, automation, and signal processing have led to increased demand for PCB materials that provide consistent electrical and mechanical properties. Shengyi S1141 PCB is used in multiple industries that require stable performance across a range of conditions.

5G & High-Frequency Communication Systems-

High-frequency signals used in 5G networks, satellite communications, and radar technology require PCB laminates that minimize energy loss. Shengyi S1141 PCB is manufactured with low dissipation factors to support signal clarity and high-speed data transmission.

Medical Devices-

Medical electronics rely on precise signal integrity to ensure consistent functionality. Shengyi S1141 PCB’s moisture resistance, dielectric stability, and mechanical durability make it a strong choice for diagnostic and monitoring systems.

High-Speed Computing & Data Centers-

As data processing demands increase, circuit boards must handle high power loads and continuous operation without performance degradation. Shengyi S1141 PCB enables high-layer PCB configurations for advanced computing and network infrastructure.

Shengyi S1141 PCB Material Composition and High-Performance Characteristics

Choosing the right PCB laminate goes beyond just meeting design requirements—it’s about making sure the board can manage real-world challenges, like high-frequency signals, heat, and mechanical stress. The Shengyi S1141 PCB is crafted with a specialized epoxy resin system and fiberglass reinforcement, making it a reliable option for those aiming to take their designs to the next level.

But what makes this material different from standard laminates? Let’s break down the composition, electrical performance, and mechanical properties that set it apart.

Epoxy Resin and Fiberglass Reinforcement – The Core of Shengyi S1141 PCB

At the heart of Shengyi S1141 PCB lies a robust epoxy resin matrix reinforced with high-quality fiberglass. This combination is engineered to provide stability, heat resistance, and durability, ensuring that circuits perform consistently across various operating conditions.

Epoxy Resin System – Why It Matters-

Shengyi S1141 PCB utilizes an advanced epoxy formulation designed for enhanced thermal stability and low dielectric loss. Unlike standard FR-4 materials, this resin system allows for improved signal transmission and reduced power dissipation, making it well-suited for RF applications, high-speed computing, and telecommunications infrastructure.

Glass Fiber Reinforcement – Strength Where It Counts-

The fiberglass reinforcement in the S1141 enhances its structural integrity and mechanical strength. Unlike traditional laminates, this material resists warping, delamination, and thermal expansion, making it a strong choice for multi-layer PCBs and high-density interconnect (HDI) designs.

Thermal Endurance and Moisture Resistance-

Shengyi S1141 PCB maintains low moisture absorption, which is a big plus for applications in high-humidity environments or industrial settings. Consistent performance under thermal cycling ensures that boards remain reliable over time, even in demanding applications like aerospace and automotive electronics.

Electrical Performance of Shengyi S1141 PCB – Low Dielectric Constant and Signal Integrity

When it comes to high-frequency applications, signal integrity is everything. A poorly optimized PCB material can lead to signal loss, impedance mismatches, and transmission delays—all of which are bad news for 5G networks, high-speed computing, and radar systems. Shengyi S1141 PCB is designed to tackle these issues head-on.

Low Dielectric Constant (Dk) for High-Frequency Stability-

One of the standout features of Shengyi S1141 PCB is its low and consistent dielectric constant (Dk). This ensures that electromagnetic waves travel with minimal distortion, helping to maintain precise signal timing in high-speed circuits.

| Frequency (GHz) | Dielectric Constant (Dk) |

| 1 GHz | 4.5 |

| 10 GHz | 4.3 |

| 20 GHz | 4.2 |

Loss Tangent (Df) – Keeping Power Dissipation in Check-

The low loss tangent (Df) of Shengyi S1141 PCB helps minimize energy dissipation, ensuring signals remain strong and clear over extended distances. This makes it a solid choice for RF circuits, 5G antennas, and satellite communication systems, where maintaining signal clarity is a must.

Impedance Control and Consistency in High-Speed Circuits-

For PCBs designed for data transmission, telecommunications, or medical imaging, maintaining precise impedance values is non-negotiable. Shengyi S1141 PCB is manufactured to tight tolerances, ensuring that we can achieve predictable circuit performance without last-minute design modifications.

Mechanical Strength and Durability – How Shengyi S1141 PCB Ensures Long-Term Stability

A PCB isn’t just about electrical performance—it also has to withstand mechanical stress, temperature fluctuations, and long-term wear and tear. Shengyi S1141 PCB is designed with reinforced mechanical properties, making it a smart pick for core applications that demand reliability over the long haul.

High Glass Transition Temperature (Tg) – Stability Under Heat Stress-

One of the biggest concerns in power electronics and high-speed circuits is thermal expansion. When PCB materials expand and contract unevenly, it can lead to delamination, warping, or solder joint failures. Shengyi S1141 PCB’s high Tg rating helps mitigate these risks by maintaining its structural integrity even under extreme temperature fluctuations.

| Material | Glass Transition Temperature (Tg) |

| FR-4 | 130-150°C |

| Shengyi S1141 PCB | 170-180°C |

Dimensional Stability and Warpage Resistance-

For multi-layer PCBs and fine-pitch components, even the slightest material shift can cause alignment issues. Shengyi S1141 PCB is engineered to minimize expansion and contraction, ensuring that boards retain their shape and layer alignment even in high-temperature environments.

Impact Resistance and Long-Term Reliability-

Beyond thermal factors, PCB materials must also resist mechanical stress from handling, assembly, and operation. Shengyi S1141 PCB’s fiber-reinforced construction provides extra durability, reducing the risk of cracks, fractures, or delamination over time.

Thermal Management and Heat Dissipation Strategies for Shengyi S1141 PCB

Managing temperature in PCB design is a big deal—neglecting it can lead to signal interference, reduced lifespan, and performance drops. When working with high-frequency circuits, compact layouts, or power-hungry applications, handling heat the right way becomes part of the design challenge.

Shengyi S1141 PCB is built with a high glass transition temperature (Tg) and efficient thermal conductivity, making it a solid choice for electronics that run under varying temperature conditions. Therefore, if you’re designing for telecom networks, industrial automation, or high-speed computing, knowing how this material deals with heat can help in building a more reliable and well-balanced PCB.

High Tg and Thermal Conductivity – How Shengyi S1141 PCB Handles Heat

When a PCB operates under high temperatures, everything from electrical signals to mechanical stability is affected. Shengyi S1141 PCB is designed to withstand extended heat exposure, keeping both structural integrity and electrical properties stable.

Glass Transition Temperature (Tg) – Stability in High-Heat Conditions-

Tg is the temperature where the PCB material shifts from rigid to a softer state. Shengyi S1141 PCB has a high Tg rating, meaning it can handle higher soldering temperatures and continuous thermal cycling without losing shape or function.

This makes it an excellent match for applications that go through frequent heating and cooling cycles, such as 5G infrastructure, high-speed routers, and industrial control systems.

Thermal Conductivity – Spreading Heat Efficiently-

One of the most common causes of PCB failure is uneven heat buildup. Shengyi S1141 PCB is designed with optimized thermal conductivity, allowing heat to spread rather than getting trapped in one place.

This is especially useful in power amplifiers, RF devices, and automotive electronics, where excess heat can cause signal disruptions or reduce the effectiveness of surrounding components.

Layered PCB Designs and Heat Management-

For multi-layer boards, heat distribution can get tricky. Shengyi S1141 PCB’s material composition helps maintain consistent thermal behavior across layers, reducing the risk of delamination, warping, or material expansion mismatches.

Best Practices for Heat Dissipation in Shengyi S1141 PCB Manufacturing

Thermal performance isn’t just about material selection—proper manufacturing techniques can improve heat control and enhance overall PCB efficiency.

Copper Plane Design for Better Heat Distribution-

The way copper is laid out in a PCB directly affects its thermal performance. Shengyi S1141 PCB benefits from well-placed copper traces and thermal planes, helping high-power sections dissipate excess heat effectively.

Using Thermal Vias to Improve Heat Flow-

Thermal vias act as heat escape routes, pulling excess heat away from components and distributing it across different layers. With Shengyi S1141 PCB, integrating stacked or filled thermal vias can help maintain a balanced thermal profile across the board.

Selecting the Right Surface Finish for Heat Resistance-

Surface finish choices affect thermal handling and oxidation resistance. Shengyi S1141 PCB pairs well with ENIG (Electroless Nickel Immersion Gold) and OSP (Organic Solderability Preservative), providing consistent thermal properties over time.

Comparing Shengyi S1141 PCB with Other High-Tg Laminates in Thermal Performance

Understanding how different PCB laminates react to heat can guide us in choosing the right material for their specific application. Shengyi S1141 PCB is designed to handle a broad range of thermal conditions while maintaining electrical consistency.

Handling Temperature Stress – A Look at Tg Ratings-

High-Tg laminates perform differently under temperature stress. Shengyi S1141 PCB is designed to maintain structural stability under prolonged heat exposure, making it suitable for high-reliability applications like aerospace, medical, and telecommunications.

Electrical Performance Under High Temperatures-

Dielectric properties can shift when a PCB is exposed to heat, which can affect signal transmission and impedance matching. Shengyi S1141 PCB is built to keep its dielectric constant stable, ensuring consistent electrical performance even in thermally demanding environments.

Mechanical Stability and Expansion Control-

Thermal expansion can lead to misalignment, solder joint failures, and stress fractures in multi-layer PCBs. Shengyi S1141 PCB is engineered for low thermal expansion, helping prevent these issues in dense, fine-pitch circuit designs.

Shengyi S1141 PCB Design Guidelines for OEMs and PCB Engineers

Designing Shengyi S1141 PCB requires precise engineering to balance electrical performance, mechanical strength, and manufacturability. Engineers working on high-speed circuits, RF applications, and multi-layer PCBs must carefully consider layer stack-up, routing strategies, and material selection to ensure consistent results.

Below, we’ll explore optimal PCB design practices, with data-driven insights to help us make fact-based decisions when working with Shengyi S1141 PCB.

Layer Stack-Up Recommendations for Shengyi S1141 PCB

Choosing the right layer configuration is one of the first steps in getting a functional and efficient PCB layout. Shengyi S1141 PCB offers flexibility in multi-layer designs, allowing us to optimize for signal integrity, thermal management, and mechanical strength.

Balanced Stack-Up to Minimize Mechanical Stress-

A well-balanced stack-up helps prevent twisting, bending, and reliability issues during manufacturing and operation. Since Shengyi S1141 PCB is commonly used in multilayer boards, using symmetrical layer arrangements with evenly distributed dielectric and copper thicknesses minimizes internal stress.

| Layer Type | Thickness (mm) | Dielectric Constant (Dk) | Loss Tangent (Df) |

| Copper Layer | 0.035 – 0.105 | N/A | N/A |

| Prepreg | 0.06 – 0.12 | 4.4 – 4.6 | 0.015 |

| Core Material | 0.1 – 0.5 | 4.5 | 0.018 |

Maintaining equal dielectric thickness on both sides of the PCB core ensures mechanical stability, preventing issues like twisting and delamination.

Power and Ground Plane Placement for Signal Stability-

For high-frequency PCBs, power and ground layers should be closely coupled to maintain a stable impedance environment. Placing ground planes directly beneath signal layers reduces noise and enhances return path efficiency.

| Layer Number | Function | Purpose |

| 1 (Top) | Signal | High-speed routing |

| 2 | Ground | Noise suppression |

| 3 | Power | Stable voltage delivery |

| 4 (Bottom) | Signal | Low-speed control lines |

By keeping high-speed traces sandwiched between power and ground planes, Shengyi S1141 PCB maintains low EMI emissions and consistent signal quality.

PCB Layout and Routing Best Practices for Shengyi S1141 PCB

Effective PCB routing ensures signal transmission with minimal loss, which is critical in telecom, medical electronics, and computing systems. Shengyi S1141 PCB provides low dielectric loss, making it suitable for GHz-range applications.

Trace Width and Spacing Guidelines-

To maintain consistent impedance, trace width should be calculated based on dielectric thickness and copper weight. The following table provides recommended trace dimensions for controlled impedance routing.

| Impedance (Ω) | Trace Width (mm) | Spacing (mm) | Copper Thickness (oz) |

| 50 | 0.25 | 0.3 | 1 |

| 75 | 0.18 | 0.25 | 1 |

| 100 | 0.12 | 0.2 | 1 |

For RF and high-speed designs, maintaining a consistent trace impedance is necessary to prevent signal reflections.

Thermal Via Placement for Heat Dissipation-

Shengyi S1141 PCB supports high-power components, requiring an optimized thermal management strategy. Integrating thermal vias beneath heat-generating ICs helps in distributing excess heat efficiently.

| Component Power (W) | Recommended Thermal Via Count | Via Diameter (mm) | Thermal Resistance (°C/W) |

| <1 | 4-6 | 0.3 | 10-15 |

| 1-5 | 8-12 | 0.4 | 5-10 |

| >5 | 16+ | 0.5 | <5 |

Placing thermal vias under power MOSFETs, BGAs, and voltage regulators prevents localized overheating.

Component Placement for Manufacturability-

Well-planned component placement improves both assembly efficiency and long-term reliability. Keeping high-speed components close to their drivers, avoiding 90-degree trace bends, and maintaining short return paths help in optimizing the PCB layout.

Choosing the Right Thickness and Copper Weight for Shengyi S1141 PCB

Material selection plays a big role in mechanical strength, heat dissipation, and signal stability. Shengyi S1141 PCB is available in various thicknesses and copper weights, allowing us to tailor designs for different applications and operating conditions. Therefore, selecting the correct board thickness and copper weight ensures mechanical stability and electrical efficiency.

Board Thickness Considerations-

For RF and high-speed digital circuits, thinner boards reduce signal loss and dielectric absorption. Shengyi S1141 PCB offers optimized dielectric properties, ensuring stable transmission characteristics even in compact layouts.

| Application | Recommended Board Thickness (mm) |

| High-Frequency RF | 0.8 – 1.2 |

| Standard Digital PCB | 1.6 – 2.0 |

| Power Electronics | 2.4 – 3.2 |

Shengyi S1141 PCB’s low Df supports low-loss transmission, even in thin board configurations.

Copper Weight and Current-Carrying Capacity-

The copper thickness in a PCB determines how much current it can handle without excessive heating. Shengyi S1141 PCB supports standard 1oz to 3oz copper weights, balancing electrical performance with thermal management.

| Copper Thickness (oz) | Max Current (A, per mm trace width) | Resistance (mΩ/cm) |

| 1 | 1.2 | 1.5 |

| 2 | 2.3 | 0.8 |

| 3 | 3.5 | 0.5 |

Thicker copper layers support higher currents, making them suitable for power electronics and automotive applications.

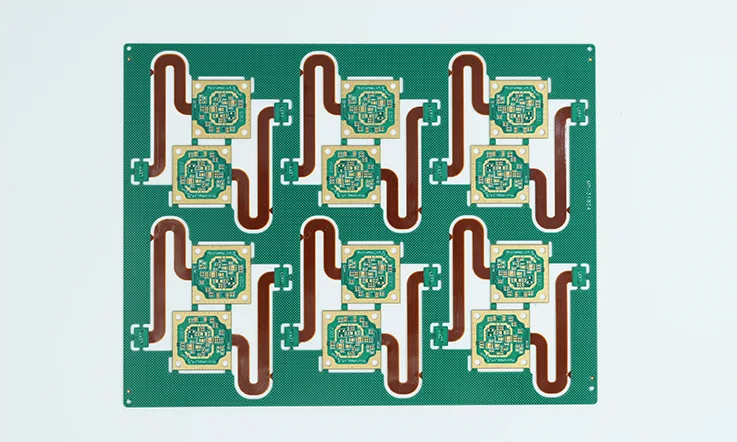

Flexibility vs. Rigidity – Selecting the Right Build-

Shengyi S1141 PCB is engineered for both rigid and semi-flex applications, making it a strong choice for wearable electronics, medical equipment, and automotive control systems. Picking the right thickness ensures mechanical stability without adding unnecessary weight or complexity.

Manufacturing and Processing Guidelines for Shengyi S1141 PCB

Fabricating Shengyi S1141 PCB requires a precise approach to layer bonding, hole drilling, etching, and soldering. The properties of S1141 material, particularly its high glass transition temperature (Tg) and low dielectric loss, demand carefully controlled thermal, mechanical, and chemical processes to maintain structural integrity and electrical performance.

This section covers specific lamination techniques, drilling methods for clean via formation, and optimized etching parameters, ensuring fabrication consistency.

Best Practices for Laminating and Bonding Shengyi S1141 PCB Layers

Laminating Shengyi S1141 PCB is a multi-step process that involves precise pressure, temperature, and resin flow control. This ensures that the fiberglass-reinforced epoxy layers create a dense, uniform structure without voids, resin starvation, or misalignment.

Lamination Process Control-

Lamination parameters directly influence dielectric consistency, interlayer adhesion, and long-term mechanical stability. Below are the recommended settings for Shengyi S1141 PCB lamination:

| Parameter | Recommended Value | Impact on PCB Structure |

| Preheat Temperature | 80 – 120°C | Facilitates uniform resin distribution |

| Press Temperature | 170 – 190°C | Activates resin and bonds layers |

| Pressure | 250 – 350 psi | Prevents internal void formation |

| Curing Time | 60 – 90 minutes | Ensures full polymer crosslinking |

Controlling Resin Flow to Maintain Dielectric Uniformity-

●Excessive resin flow can lead to thickness variation, affecting impedance control in high-frequency designs.

●Low resin flow results in delamination risks, which degrade mechanical stability.

●Selecting prepreg layers with appropriate resin content ensures uniform thickness across the PCB stack-up.

For high-layer-count PCBs, a gradual temperature ramp-up prevents resin voids and ensures even distribution.

Drilling, Etching, and Soldering Considerations for Shengyi S1141 PCB

Precision in hole drilling, copper etching, and soldering is necessary to avoid defects such as resin smear, over-etching, and poor solder joint adhesion.

Drilling Techniques to Prevent Hole Wall Defects-

Drilling must be precisely controlled to prevent delamination, cracking, and debris accumulation inside vias. Proper spindle speeds, feed rates, and entry materials improve hole quality and plating adhesion.

| Drill Diameter (mm) | Spindle Speed (RPM) | Feed Rate (mm/sec) | Chip Load (mm/rev) |

| 0.2 – 0.4 | 100,000 – 120,000 | 0.5 – 1.5 | 0.012 – 0.015 |

| 0.5 – 0.8 | 80,000 – 100,000 | 1.5 – 2.5 | 0.015 – 0.018 |

| 1.0+ | 60,000 – 80,000 | 2.0 – 3.5 | 0.018 – 0.025 |

To prevent drill bit wear and resin smearing, replacing bits every 800–1000 hits is recommended.

Optimizing Copper Etching for Clean Trace Formation-

Etching removes unwanted copper, defining circuit paths with sharp, well-defined edges. Inconsistent etching causes under-etched traces (short circuits) or over-etched traces (weakened connections).

| Etchant Type | Concentration (%) | Etching Rate (µm/min) |

| Ammoniacal CuCl₂ | 10 – 12 | 1.5 – 2.5 |

| Cupric Chloride | 15 – 18 | 2.0 – 3.0 |

Maintaining the etching temperature between 45 – 55°C prevents uneven trace widths.

Soldering Process Control to Minimize Thermal Stress-

Shengyi S1141 PCB can handle elevated soldering temperatures due to its high Tg. However, excessive heat exposure can still cause interlaminar separation.

| Soldering Process | Peak Temperature (°C) | Dwell Time (seconds) |

| Wave Soldering | 245 – 260 | 3 – 5 |

| Reflow Soldering | 230 – 250 | 30 – 60 |

Using temperature profiles matched to board thickness reduces internal stresses and material expansion mismatches.

How to Overcome Processing Challenges in Shengyi S1141 PCB Fabrication?

Producing Shengyi S1141 PCB comes with specific fabrication challenges, especially in high-layer-count designs and microvia structures.

Managing Warpage in Large PCBs-

Boards with asymmetrical copper distribution tend to warp due to differential thermal expansion. Strategies to minimize warpage include:

●Using balanced layer stack-ups with even copper weight distribution.

●Limiting reflow cycles, which introduce thermal stresses.

●Storing prepreg materials in a dry, controlled environment to prevent moisture absorption.

Reducing Plating Voids in High-Aspect-Ratio Vias

As vias become narrower and deeper, plating uniformity becomes more challenging. Poor copper deposition can lead to voids, increasing electrical resistance and reducing via reliability.

Best practices for via plating:

●Maintaining bath agitation during electroless copper deposition for even coating.

●Using pulsed reverse plating to promote uniform copper growth inside microvias.

●Controlling sulfuric acid concentration to prevent over-etching during desmear.

Avoiding Delamination Due to Moisture Absorption-

High-Tg materials like Shengyi S1141 PCB can absorb moisture if not stored properly. Before assembly and soldering:

●Pre-bake PCBs at 120°C for 2-4 hours to remove moisture.

●Use vacuum-sealed packaging for prepreg and copper foils.

This reduces the chance of blistering or delamination during high-temperature soldering cycles.

Shengyi S1141 PCB vs. The Competition

Selecting a PCB laminate is not just about following the crowd—it’s about understanding material behavior under different electrical and thermal conditions. Shengyi S1141 PCB competes with Isola, Panasonic, and Rogers, aiming to meet the demands of high-speed digital circuits, RF systems, and thermally challenging applications.

The following sections break down how Shengyi S1141 PCB measures up against these competitors, covering dielectric properties, thermal response, and cost considerations to help PCB designers and manufacturer choose the right material for their projects.

How Does Shengyi S1141 PCB Compare to Isola and Panasonic Laminates?

In the world of high-performance laminates, we consider signal integrity, thermal durability, and mechanical reliability when choosing materials. Isola and Panasonic have established reputations, but Shengyi S1141 PCB provides a compelling alternative.

With a dielectric constant suited for controlled impedance applications, this laminate ensures consistent signal transmission. Compared to Isola 370HR and Panasonic R-1755V, Shengyi S1141 PCB offers lower signal loss, making it a strong contender for high-speed data transmission applications.

Additionally, its thermal expansion properties allow for better reliability in multi-layer designs, ensuring reduced stress on vias and solder joints over time. Moisture absorption is also lower, contributing to better performance in humid environments.

Material Comparison – Electrical & Mechanical Properties-

| Property | Shengyi S1141 PCB | Isola 370HR | Panasonic R-1755V |

| Dielectric Constant (Dk) @1GHz | 4.2 | 4.3 | 4.4 |

| Dissipation Factor (Df) @1GHz | 0.018 | 0.019 | 0.020 |

| Glass Transition Temperature (Tg) (°C) | 140-150 | 180 | 170 |

| Thermal Expansion (Z-axis, ppm/°C) | 3.0 | 2.8 | 3.2 |

| Moisture Absorption (%) | 0.10 | 0.12 | 0.14 |

For projects where cost efficiency needs to be balanced with performance, Shengyi S1141 PCB stands as a viable option, particularly in industrial computing, telecommunications, and automotive electronics.

Shengyi S1141 PCB vs. Rogers – Which One Wins in 5G & RF Applications?

The RF and high-frequency circuit industry has long relied on Rogers laminates for their low-loss characteristics, but Shengyi S1141 PCB offers a competitive approach where ultra-low dissipation factors are not mandatory.

While Rogers materials exhibit superior dielectric stability at microwave frequencies, Shengyi S1141 PCB maintains steady performance in mid-range RF applications, ensuring efficient signal transmission without excessive loss. The thermal conductivity of Rogers laminates surpasses that of Shengyi S1141 PCB, making it the preferred choice for power-intensive RF applications.

RF Performance Comparison – Shengyi S1141 PCB vs. Rogers-

| Property | Shengyi S1141 PCB | Rogers 4350B | Rogers 4003C |

| Dielectric Constant (Dk) @10GHz | 4.2 | 3.48 | 3.38 |

| Dissipation Factor (Df) @10GHz | 0.018 | 0.0037 | 0.0027 |

| Thermal Conductivity (W/mK) | 0.4 | 0.6 | 0.8 |

| Moisture Absorption (%) | 0.10 | 0.06 | 0.04 |

For 5G infrastructure, wireless networking, and automotive radar systems, the choice depends on frequency requirements. Shengyi S1141 PCB works well in environments where moderate RF performance is needed without investing in high-end RF substrates.

Cost-Benefit Analysis – When Should You Invest in Shengyi S1141 PCB?

Balancing cost and technical performance is a main decision in PCB material selection. While some applications justify premium laminates like Rogers, others require a more budget-conscious yet capable solution.

For general high-speed digital circuits, Shengyi S1141 PCB delivers strong electrical characteristics without the premium cost of ultra-low-loss materials. Industrial electronics and automotive systems benefit from its thermal stability, ensuring reliability in environments subject to fluctuating temperatures.

Cost vs. Performance Comparison-

| Material | Cost Level | Recommended Applications |

| Shengyi S1141 PCB | Medium | High-speed digital, mixed-signal |

| Isola 370HR | High | Advanced multilayer PCBs |

| Rogers 4350B | Very High | RF, Microwave, 5G |

| Panasonic R-1755V | Medium | Automotive, Industrial |

For manufacturers and engineers looking for a well-balanced alternative to higher-cost laminates, Shengyi S1141 PCB presents itself as a capable solution, adaptable to a wide range of industry needs.

FAQs & Shengyi S1141 PCB

1.Can Shengyi S1141 PCB handle higher signal frequencies in high-speed circuits?

Yes, Shengyi S1141 is designed to support high-frequency signals and is well-suited for applications that require precise signal integrity and low signal loss.

2.What are the surface roughness and microstructure properties of Shengyi S1141 PCB?

Shengyi S1141 features a smooth surface finish with fine microstructure, optimizing it for high-speed circuits and precision electronic applications.

3.What types of testing are recommended for Shengyi S1141 PCBs after production?

Recommended testing includes visual inspection, electrical testing, thermal cycling, and high-frequency signal testing to ensure quality and performance.

4.What are the typical thickness ranges for Shengyi S1141 PCBs?

Shengyi S1141 PCBs typically range in thickness from 0.2mm to 3.0mm, depending on the application requirements and manufacturing process.

5.How does Shengyi S1141 PCB perform in terms of impedance control?

Shengyi S1141 provides excellent impedance control, making it suitable for high-speed and high-frequency signal applications, ensuring signal integrity.

6.What are the best manufacturing processes for achieving optimal results with Shengyi S1141 PCB?

The best processes include precise lamination, high-quality drilling, and controlled etching. Special attention should be paid to heat dissipation and maintaining high thermal stability throughout manufacturing.