Rogers Ro3006 PCB materials are commonly used in applications where performance and consistency are highly valued, such as in telecommunications, aerospace, and medical device designs. With a focus on low-loss, high-frequency capabilities, these materials support complex and precise circuit board designs.

This guide covers the key properties of Rogers Ro3006, comparisons with other PCB materials, and tips on selecting the best manufacturer for your needs. By understanding the strengths of Rogers Ro3006, we can optimize our designs for efficiency and reliability, ensuring projects meet our requirements without unnecessary compromises.

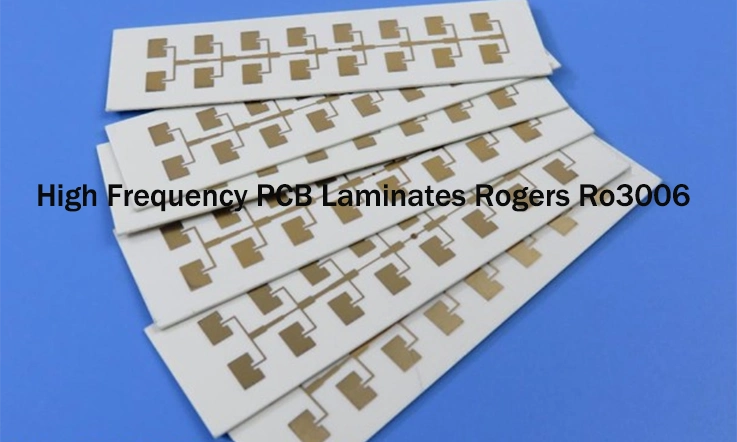

Introduction to Rogers Ro3006 PCB Materials

When working with high-frequency PCB designs, choosing the right material is core to ensuring stable performance and long-term reliability. Rogers Ro3006 is a material that stands out in applications that demand low signal loss and consistent performance over a broad frequency range. It is widely used across industries such as aerospace, telecommunications, and military for its exceptional ability to maintain signal integrity and operate efficiently in high-frequency environments.

In this section, we will examine the main attributes of Rogers Ro3006, its application in various industries, and why this material continues to gain traction in high-performance settings.

What Are Rogers Ro3006 PCB Materials and Their Importance?

Rogers Ro3006 is a high-frequency laminate material that stands out due to its low-loss performance and stable dielectric properties. The material was specifically designed to meet the needs of applications requiring high-frequency operation and signal clarity, such as RF (Radio Frequency) and microwave circuits.

Compared to traditional PCB materials like FR4, which are often unsuitable for high-frequency work due to their unpredictable dielectric constants and high loss tangents, Rogers Ro3006 offers exceptional consistency, allowing signals to transmit effectively over longer distances and with less degradation. It is particularly favored in designs where signal loss is minimized, and maintaining signal integrity is a priority, especially for 5G networks and aerospace systems where reliability is a concern.

This material features a dielectric constant (Dk) of 6.15, making it a top choice for high-frequency applications like radar systems, satellite communication, and advanced wireless technologies.

Key Features of Rogers Ro3006 PCB Materials

The Rogers Ro3006 PCB material is known for its distinct set of properties that make it suitable for demanding environments. The following are some of the primary features that set Rogers Ro3006 apart:

Dielectric Constant (Dk) and Loss Tangent (Df)-

One of the standout characteristics of Rogers Ro3006 is its reliable dielectric constant (Dk), which stays stable across a wide frequency spectrum. At 10 GHz, the Dk value is around 6.15 ± 0.15, allowing for consistent impedance control even at higher frequencies. This stability makes it a solid choice for applications requiring high accuracy in signal transmission, like RF circuits and fast data transfer systems.

Rogers Ro3006 features an impressively low loss tangent (Df) of 0.0022 at 10 GHz, meaning signal loss remains minimal. This characteristic makes it an excellent choice for systems that rely on efficient transmission of high-frequency signals. Whether you’re working on microwave communications, automated systems, or medical devices, Rogers Ro3006 ensures that signals stay strong and intact, even over longer distances.

Thermal Stability and High-Temperature Performance-

When operating in extreme environments, maintaining thermal stability is a must. Rogers Ro3006 is engineered to handle severe temperature fluctuations, making it a go-to material for high-performance applications in aerospace, automotive systems, and military electronics. With its robust design, this laminate ensures that performance stays steady, even when subjected to thermal stress.

This material also features low thermal expansion, meaning the physical dimensions of the PCB remain stable even under temperature extremes, ensuring that impedance does not change, and signal integrity remains intact.

Signal Integrity and Impedance Control-

One of the primary reasons to go with Rogers Ro3006 is its ability to keep signal integrity intact. The material provides excellent impedance control, even at high frequencies. This helps cut down on signal reflections, ensuring that the transmitted signals stay clean and reliable. This feature is especially useful in communication systems, RF circuits, and other high-frequency applications where any loss in signal quality could impact overall performance.

Applications of Rogers Ro3006 in High-Performance Industries

With its exceptional properties, Rogers Ro3006 is used across various industries where performance, reliability, and minimal signal degradation are required. Let’s take a closer look at the primary sectors where Rogers Ro3006 PCB materials are being utilized:

Medical Devices: Precision in Signal Transmission-

In the medical field, where precision is core for diagnostics and device operation, Rogers Ro3006 is becoming a popular choice for high-end medical devices such as MRI machines, implantable devices, and medical sensors. Its low-loss characteristics ensure that signals are transmitted with minimal degradation, making it a reliable material for applications where even the smallest signal loss could affect the accuracy and effectiveness of the device.

For example, In MRI systems, Rogers Ro3006 contributes to maintaining clear signals with minimal loss, helping to achieve high-quality imaging. As high-frequency signals travel through different tissues and materials, they must remain intact without interference or distortion. Rogers Ro3006 plays a key part in this process, ensuring that signals stay consistent across the system, delivering precise and clear images.

Military and Aerospace: Reliability Under Extreme Conditions-

In military and aerospace applications, Rogers Ro3006 offers reliable performance even under the most demanding conditions. Systems in these sectors are often exposed to extreme temperatures, radiation, and mechanical stress. Therefore, whether it’s radar systems, satellite communications, or guided missile systems, Rogers Ro3006 ensures that signal quality is maintained in these high-stakes applications.

For example, In radar systems, Rogers Ro3006 reduces signal loss during the transmission and reception of electromagnetic waves. This is especially useful in military operations, where radar efficiency influences the outcome of missions. The material’s low loss and stable Dk help radar systems detect objects clearly, even at longer ranges, without any loss of signal quality.

5G Networks: High-Speed Communication-

The rapid development of 5G networks worldwide has fueled the need for high-performance PCB materials that can support the massive increase in data traffic and high-frequency signals. Rogers Ro3006 provides the low-loss and high-frequency stability required for 5G base stations, antennas, and other essential infrastructure components.

Rogers Ro3006 offers the perfect combination of low-loss performance and stable dielectric properties, making it a go-to choice for us designing 5G equipment. For example, 5G base stations rely on PCBs capable of handling high-frequency signals with minimal attenuation. Rogers Ro3006 delivers consistent performance, ensuring that signals are transmitted with efficiency, helping to keep up the high-speed data transfers required in 5G systems.

Technical Properties of Rogers Ro3006 PCB Materials

When designing PCBs for high-frequency applications, it’s essential to select materials that deliver excellent performance under challenging conditions. Rogers Ro3006 is designed to meet the demanding needs of industries such as aerospace, military, telecommunications, and medical devices, where low signal loss, high-frequency performance, and thermal stability are required.

This section explores the technical characteristics of Rogers Ro3006, including its dielectric constant, loss tangent, thermal stability, and impedance control.

Dielectric Constant and Loss Tangent: The Key to High-Frequency Design

The dielectric constant (Dk) and loss tangent (Df) of a material directly impact its ability to maintain signal quality at high frequencies over time. Rogers Ro3006 is specifically designed to offer a stable dielectric constant and low loss tangent, ensuring minimal signal degradation, especially for RF and microwave circuits.

Here’s how Rogers Ro3006 performs in terms of these properties:

| Property | Rogers Ro3006 |

| Dielectric Constant (Dk) | 6.15 @ 10 GHz |

| Loss Tangent (Df) | 0.0022 @ 10 GHz |

| Frequency Range | Up to 10 GHz |

These figures demonstrate that Rogers Ro3006 experiences minimal signal loss even at higher frequencies, making it a strong choice for applications like satellite communications, radar systems, and 5G networks, where clear and accurate signal transmission is needed.

The material’s stable Dk and Df ensure that signals maintain their strength and integrity over long distances, minimizing attenuation, and improving the overall performance of high-speed communication systems.

Thermal Stability and Durability in Harsh Environments

When selecting materials for aerospace or military systems, ensuring reliable performance under temperature fluctuations is a must. Rogers Ro3006 stands out for its ability to maintain electrical performance even in extreme conditions, thanks to its strong thermal stability.

Here’s a breakdown of the thermal properties of Rogers Ro3006:

| Property | Rogers Ro3006 |

| Coefficient of Thermal Expansion (CTE) | 15 ppm/°C |

| Glass Transition Temperature (Tg) | 330°C |

| Thermal Conductivity | 0.53 W/m·K |

These properties make Rogers Ro3006 suitable for high-performance applications where temperatures can vary significantly, such as satellite electronics or military radar systems. The material’s low CTE ensures that it can withstand thermal expansion without cracking or losing electrical performance, even under extreme conditions.

In aerospace or military PCB designs, where reliability in harsh environments is required, Rogers Ro3006 offers enhanced durability and consistent performance, ensuring that the thermal fluctuations do not affect the PCB’s ability to transmit signals effectively.

Impedance Control and Signal Integrity with Rogers Ro3006

Impedance control is a reliable factor in PCB design, particularly in high-speed circuits where maintaining signal clarity is a top concern. Rogers Ro3006 offers stable impedance characteristics, which help reduce signal reflections that can cause signal degradation and data loss. This ensures smoother transmission of signals across high-frequency systems.

| Property | Rogers Ro3006 |

| Impedance Stability (Z) | ±10% |

| Dielectric Constant (Dk) | 6.15 |

| Recommended Line Width Tolerance | ±0.05 mm |

By maintaining precise impedance matching, Rogers Ro3006 minimizes signal reflections in RF designs, providing clear and uninterrupted data transmission. The stable Dk ensures that impedance control remains consistent, even in complex circuits like 5G infrastructure, medical devices, and military communication systems.

The ability to maintain impedance stability within the specified range of ±10% makes Rogers Ro3006 better for telecommunications and high-speed data systems, where clear signal transmission and minimal interference are necessary for the proper functioning of the system.

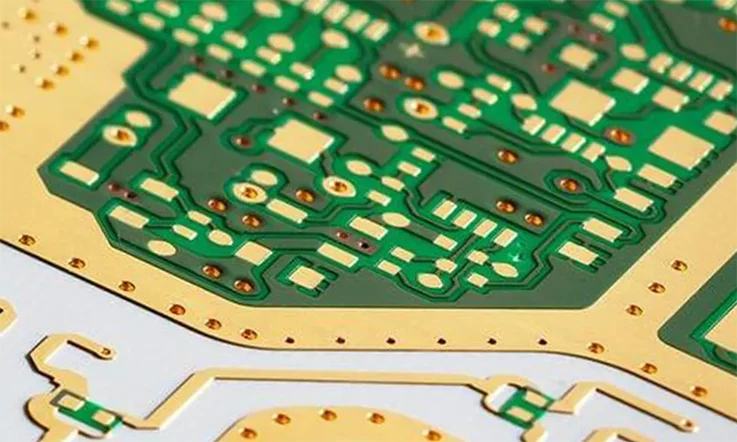

Design and Manufacturing with Rogers Ro3006 PCB Materials

Designing and manufacturing PCBs using Rogers Ro3006 materials presents several unique challenges and opportunities, particularly when it comes to high-frequency performance, signal integrity, and thermal management.

This section dives deep into the best practices for Rogers Ro3006 PCB fabrication. We will cover multilayer PCB fabrication, soldering techniques, and electrical testing that ensure the end product can handle high-frequency signals while maintaining high reliability. The proper design and manufacturing processes will help you get the most out of Rogers Ro3006 in applications that require precision and durability.

Multilayer PCB Fabrication with Rogers Ro3006

Fabricating multilayer PCBs with Rogers Ro3006 material involves several main steps to ensure precise signal alignment, thermal dissipation, and overall performance. The unique properties of Ro3006—such as its low-loss characteristics and thermal stability—make it an excellent choice for high-frequency, high-performance applications.

Here’s how the fabrication process works:

| Step | Process Details |

| Layer Alignment | Precision tools are used to align layers to ensure uniform signal routing and minimize loss. |

| Signal Isolation | Careful planning of signal paths and isolation between layers ensures that high-frequency signals do not interfere with each other. |

| Thermal Management | Ro3006’s low coefficient of thermal expansion (CTE) ensures minimal warping and distortion during high-temperature processes, providing thermal reliability for military and aerospace applications. |

In multilayer PCB fabrication, the alignment of layers and the placement of copper traces need to be done with precision. Rogers Ro3006’s high thermal conductivity makes it especially beneficial for high-power designs where heat dissipation is a priority. When designing for military and aerospace applications, where components need to perform consistently under stress, Rogers Ro3006 ensures durability without compromising signal integrity.

One challenge that PCB manufacturers often encounter when working with high-performance materials like Ro3006 is managing signal interference between layers. The solution lies in carefully planning signal paths and incorporating effective shielding techniques. This approach helps minimize interference and ensures reliable signal transmission across the PCB.

Soldering and Assembly Techniques for Rogers Ro3006

When it comes to soldering and assembling Rogers Ro3006 PCBs, we need to ensure that the soldering process maintains the integrity of the high-frequency signals. This step can be tricky, as improper soldering can lead to signal degradation and thermal issues, particularly in 5G communications or military-grade devices that operate under high stress.

Here’s how to approach soldering and assembly for Ro3006:

| Process | Key Considerations |

| Pre-soldering Preparation | Ensure the PCB surface is clean, free from oxidation or contamination to achieve a strong, reliable solder joint. |

| Soldering Process | Ro3006’s high thermal conductivity helps with heat distribution during the soldering process, making it easier to ensure that each joint remains stable under stress. |

| Component Placement | Use precision equipment to place components precisely to avoid issues with alignment, ensuring that high-frequency signals are preserved. |

Soldering on Rogers Ro3006 can be more challenging than with traditional FR4 PCBs due to its higher thermal conductivity. It’s important to carefully control the soldering temperature to avoid excessive heat, which can cause delamination or compromise the thermal performance of the PCB.

One solution to this challenge is controlled soldering—using temperature-controlled soldering irons and reflow soldering techniques. These methods allow you to avoid overheating the material and preserve the signal integrity.

Moreover, precise component placement is necessary to prevent thermal damage and ensure that the components function correctly, especially when dealing with high-speed signals. Medical devices and radar systems benefit from this level of detail in assembly because even a small misalignment can cause data errors or performance drops.

Electrical Testing and Verification of Rogers Ro3006 PCBs

After fabrication and assembly, it’s time to test the Rogers Ro3006 PCBs to ensure they meet the high-performance standards expected of them. Electrical testing verifies the signal integrity, thermal stability, and overall electrical performance of the PCB under real-world operating conditions.

Here are the common testing procedures for Ro3006 PCBs:

| Test Type | Purpose |

| Signal Integrity Testing | Measures signal loss, reflection, and interference during high-frequency operation. |

| Thermal Cycling Test | Simulates temperature fluctuations to ensure the PCB can handle extreme conditions. |

| Impedance Control Test | Ensures the impedance levels of signal traces are within the required range. |

Signal integrity testing helps identify signal loss and ensures that the PCB can handle high-speed signals without introducing noise. This is particularly useful in 5G networks or military systems where stable data transmission is needed for consistent performance.

Thermal cycling tests are particularly beneficial for ensuring that the Ro3006 PCB can operate within strict temperature ranges, a requirement for aerospace and military applications. These tests simulate extreme environmental conditions and monitor how the PCB holds up under thermal stress.

Finally, impedance control testing ensures that Ro3006 maintains steady impedance across the design. This is relevant for applications like satellite communications or radar systems, where impedance mismatches can cause reflections, signal loss, or disrupt system performance.

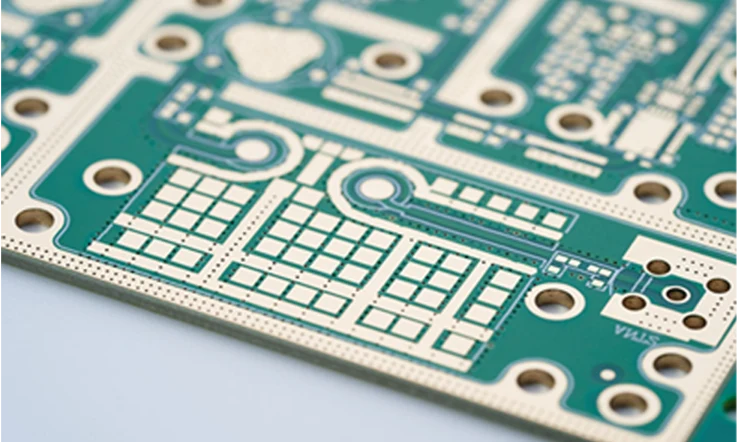

Comparing Rogers Ro3006 PCB Materials to Other PCB Materials

When selecting a PCB material for high-frequency applications, understanding the distinctions between materials is essential. As industries like aerospace, telecommunications, and medical devices demand high-speed, low-loss signal transmission, materials that meet specific performance standards are required. Rogers Ro3006 stands out in this area, but how does it stack up against other high-performance PCB materials such as Shengyi PCB, Taconic PCB, Isola PCB, and others? Let’s explore the differences.

Rogers Ro3006 vs FR4: Which Is Better for High-Frequency Applications?

FR4, a standard PCB material, has been widely used in many applications due to its low cost and reasonable electrical properties. However, in high-frequency designs such as 5G, telecommunications, and aerospace, Rogers Ro3006 far surpasses FR4. The key differences between Rogers Ro3006 and FR4 include:

| Property | Rogers Ro3006 | FR4 |

| Dielectric Constant (Dk) | 6.15 ± 0.15 | 4.5 ± 0.5 |

| Loss Tangent (Df) | 0.0022 | 0.02 – 0.03 |

| Thermal Stability | Excellent high-temperature stability | Limited stability at high temperatures |

| Frequency Range | Up to 40 GHz | Up to 3 GHz |

Rogers Ro3006’s low dielectric constant and low loss tangent make it a suitable choice for high-frequency circuits, enabling better signal integrity and reduced signal loss over longer distances, making it much more suitable for 5G networks, radar, and satellite systems compared to FR4.

Rogers Ro3006 vs Rogers 4003 and 4350: Understanding the Differences

Rogers 4003 and 4350 are also popular choices for high-performance PCB applications. They are often compared to Rogers Ro3006 due to their similar characteristics in terms of high-frequency operation. However, the difference lies in their dielectric constants and loss tangent values, which directly influence signal transmission and thermal performance.

| Property | Rogers Ro3006 | Rogers 4003 | Rogers 4350 |

| Dielectric Constant (Dk) | 6.15 ± 0.15 | 3.38 ± 0.05 | 3.48 ± 0.05 |

| Loss Tangent (Df) | 0.0022 | 0.003 | 0.003 |

| Thermal Stability | Excellent stability | Good | Excellent stability |

For example, Rogers 4003 is often used in applications where lower loss at lower frequencies is required, such as RF circuits below 3 GHz, while Rogers Ro3006 excels in applications that demand more precise control over signal integrity at higher frequencies. Rogers 4350, on the other hand, is commonly used in high-power microwave applications, but it offers lower thermal stability than Ro3006.

Rogers Ro3006 vs Shengyi PCB and Taconic PCB

Shengyi and Taconic PCBs are widely used in industries requiring high-frequency and high-reliability materials. While Rogers Ro3006 is a top choice for many high-performance applications, it’s helpful to compare it to other PCB materials such as those from Shengyi and Taconic.

●Shengyi PCB: Known for offering a wide range of PCB materials, Shengyi focuses on offering cost-effective solutions for standard and high-frequency applications. Their high-frequency PCB materials have reasonable dielectric constants, but they don’t typically match the stability and performance of Rogers Ro3006 at higher frequencies.

●Taconic PCB: Taconic’s RF PCB materials, like Taconic TLY, provide an alternative to Rogers Ro3006 for applications requiring low loss and excellent thermal stability. Taconic is highly regarded in industries such as aerospace and telecom, but Rogers Ro3006 tends to have a more consistent performance across the full range of high-frequency and low-loss requirements.

Here’s a comparison of key properties across these three materials:

| Property | Rogers Ro3006 | Shengyi PCB | Taconic TLY |

| Dielectric Constant (Dk) | 6.15 ± 0.15 | 3.2 to 6.0 | 6.15 ± 0.05 |

| Loss Tangent (Df) | 0.0022 | 0.003 to 0.008 | 0.002 |

| Thermal Stability | Excellent | Good | Very Good |

| Frequency Range | Up to 40 GHz | Up to 10 GHz | Up to 30 GHz |

The comparison above shows that Rogers Ro3006, with its excellent low loss and stable dielectric constant, stands out against Shengyi and Taconic materials, particularly for applications requiring precise high-frequency behavior and long-term stability under harsh environmental conditions.

Why Choose Rogers Ro3006 Over Other PCB Materials for Military and Aerospace Designs?

Military and aerospace applications have some of the most demanding performance requirements for PCBs, particularly in terms of reliability, high-frequency signal transmission, and thermal performance. Rogers Ro3006 offers a distinct edge in these applications, especially when compared to materials like FR4, Taconic, and others.

Here’s why Rogers Ro3006 is often the preferred material:

●High-Frequency Performance: With a low dielectric constant and low loss tangent, Rogers Ro3006 minimizes signal loss and maintains clarity even at high frequencies.

●Thermal Stability: Military and aerospace designs often operate in extreme conditions. Rogers Ro3006 maintains its electrical performance even under high temperatures and varying environmental conditions, something that is less consistent with other materials like FR4.

●Impedance Matching: With its high precision in impedance control, Rogers Ro3006 ensures that signal integrity is maintained over long distances, reducing the risk of signal interference or degradation.

Here’s a quick breakdown of how Rogers Ro3006 compares in military and aerospace applications:

| Property | Rogers Ro3006 | Taconic TLY | Shengyi PCB |

| Impedance Control | Excellent | Good | Moderate |

| Signal Integrity | Excellent | Good | Fair |

| Thermal Stability | Excellent | Good | Fair |

In military and aerospace systems where high-reliability and durability are non-negotiable, Rogers Ro3006 provides an edge, ensuring minimal risk of failure even in the most challenging environments.

How to Select the Best Rogers Ro3006 PCB Manufacturer?

When selecting the right Rogers Ro3006 PCB manufacturer, there are several factors to keep in mind. The choices made during this process can impact the functionality and durability of your final product. Here’s a breakdown of the core considerations:

1.Reputation and Experience in High-Frequency PCB Manufacturing

Selecting a manufacturer with a strong reputation and extensive experience in producing high-frequency PCB materials can make a significant difference. Manufacturers with a solid track record typically have refined processes and a history of delivering consistent, reliable products. You can assess their reputation by reviewing customer feedback, case studies, and their experience in sectors such as telecom, aerospace, and defense.

Look for companies with specific expertise in Rogers Ro3006 and similar materials. Experience in high-frequency applications is a good indicator that the manufacturer understands the challenges posed by materials like Rogers Ro3006 and knows how to overcome them.

| Manufacturer | Years of Experience | Industry Focus | Case Studies |

| Manufacturer A | 20+ years | Aerospace, Medical, Telecom | High-performance military PCB |

| Manufacturer B | 15 years | Telecom, IoT, Automotive | 5G PCB for telecom infrastructure |

| Manufacturer C | 10 years | Aerospace, Medical Devices | Satellite communication boards |

2.Quality Control: Meeting Industry Standards

Top-tier manufacturers will have rigorous quality control measures in place. This ensures that the final product adheres to all required specifications and performance standards, from dielectric constant consistency to thermal stability. The manufacturer should also hold relevant certifications such as ISO 9001 or IPC standards, which demonstrate a commitment to quality management.

You’ll want to inquire about their quality assurance processes—are their inspection protocols up to industry standards? For Rogers Ro3006, even minor discrepancies in material thickness or signal integrity can affect the performance of the finished PCB. A reliable manufacturer should perform thorough testing at every stage of production, from raw material procurement to final assembly.

3.Technical Expertise and Customer Support

The complexity of working with Rogers Ro3006 demands manufacturers who can offer more than just standard production. Look for manufacturers who can provide expert technical support and guidance throughout the entire development cycle, from design to testing. A deep understanding of materials science and RF engineering is a must, particularly for applications in the high-frequency space.

Here are a few points to assess:

●Does the manufacturer provide assistance with impedance matching, signal integrity, and thermal considerations?

●Are they open to consultations and providing custom solutions based on your specific project requirements?

Additionally, consider their customer support service. Clear, timely communication is essential, especially if any issues arise during the production process.

4.Manufacturing Capabilities and Scalability

Make sure that the manufacturer has the capacity to handle both your current project needs and any future scalability requirements. This includes having the necessary equipment, facilities, and production lines to handle both small-scale prototype runs and large-volume manufacturing.

Some questions to consider:

●Does the manufacturer have automated systems for precise layer alignment and copper deposition?

●Are they capable of manufacturing multilayer PCBs with Rogers Ro3006 without compromising performance?

●How well can they handle unique customer demands, such as custom copper weights or specialized laminate thickness?

If your project requires high-volume production, it’s must to ask about their lead times and their ability to meet deadlines without sacrificing quality.

5.Customization Options: Tailoring to Specific Project Needs

Every PCB design is unique, and so are its material requirements. If you need specific customization, such as unique copper weights, material thickness, or tailored thermal management solutions, ensure that the manufacturer can accommodate these requests.

Rogers Ro3006, for example, may require adjustments to material thickness or special copper bonding techniques for enhanced signal transmission in high-frequency circuits. A manufacturer who can offer flexibility in these areas will be better equipped to meet your unique requirements.

6.Supply Chain Management: Reliability and Transparency

A manufacturer’s ability to manage their supply chain can have a direct impact on project timelines. At first, we need to confirm that the company maintains solid relationships with suppliers of top-tier raw materials and has a dependable sourcing process in place. This is especially true for Rogers Ro3006, where consistent material quality is needed to maintain reliable high-frequency performance.

Ask about:

●The manufacturer’s lead time for procuring materials.

●Their process for dealing with potential supply chain disruptions.

●Transparency in their sourcing process and their ability to keep you informed about any delays or changes.

7.Cost and Pricing: Focusing on Value

While cost is a factor, it’s essential to look at the bigger picture. A low-cost manufacturer may not always provide the best value, particularly for high-frequency applications like those using Rogers Ro3006. Price should be evaluated in terms of overall quality, technical expertise, production speed, and customer support.

Ensure you understand what is included in the quoted price. For example:

●Does the quote include testing and certification of the final product?

●Are there additional costs for rush orders or expedited delivery?

●Are there price breaks available for larger orders?

By evaluating the total value of a manufacturer’s offerings, you’ll make a more informed decision on which one best fits your needs.

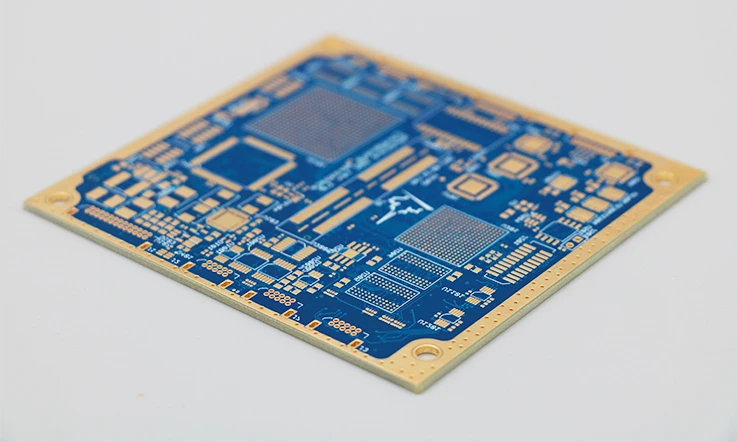

Why Choose JarnisTech for Manufacturing Your Rogers Ro3006 PCB Project?

When it comes to manufacturing high-performance printed circuit boards (PCBs) using materials like Rogers Ro3006, JarnisTech stands out as a reliable partner. Our years of expertise in the field allow us to deliver products that meet the rigorous demands of advanced technologies, including telecommunications, aerospace, and RF applications.

With over 20 years of PCB manufacturing experience, JarnisTech brings precision and proficiency to every project, making us a trusted choice for your Rogers Ro3006 PCB needs. Our engineering team works closely with clients to ensure that each design is optimized for both performance and reliability.

1.Our Manufacturing Process

At JarnisTech, we utilize state-of-the-art equipment and advanced techniques to manufacture Rogers Ro3006 PCBs that meet the most stringent requirements. Our commitment to quality is backed by strict quality control procedures and certifications, including ISO 9001, ISO 14001, UL, and RoHS. Each PCB undergoes thorough testing to ensure that it meets specifications for signal integrity, thermal stability, and electrical performance.

2.Quick Turnaround and Flexibility

In addition to providing dependable products, we recognize the need for quick turnaround times. Our efficient manufacturing process allows us to handle urgent orders while maintaining high standards. So, whether you need a small batch for prototyping or large-scale production, we can meet your needs with flexibility and precision.

3.Tailored Solutions for Your Project

We know that each project has unique requirements, which is why we offer a range of customization options. From varying material thicknesses to copper weights, we work with you to ensure that your Rogers Ro3006 PCBs are tailored to your exact needs. Our technical team provides guidance and support throughout the design and manufacturing phases, ensuring your project stays on track.

4.Why Choose Us?

At JarnisTech, we aim to foster long-term relationships by providing high-quality products and exceptional customer service. Our approach goes beyond simply manufacturing PCBs—we are dedicated to your project’s success. With our commitment to providing timely communication, support, and technical expertise, we ensure that you have everything you need to meet your project deadlines and objectives.

Rogers Ro3006 PCB Material &FAQ

1. What is the maximum operating temperature for Rogers Ro3006?

Rogers Ro3006 can typically operate in temperatures ranging from -55°C to +288°C, with short-term exposure to higher temperatures.

2. Can Rogers Ro3006 be used for flexible PCB applications?

Rogers Ro3006 is primarily designed for rigid PCBs and may not be suitable for flexible PCB applications due to its material properties.

3. What is the typical thickness of Rogers Ro3006 laminates?

Rogers Ro3006 laminates are available in various thicknesses, typically ranging from 0.003″ to 0.060″, depending on the specific requirements.

4. Can Rogers Ro3006 be used in high-speed digital circuits?

While Rogers Ro3006 is well-suited for RF and microwave applications, it may not perform as well as specialized materials for high-speed digital circuits, which often require different properties.

5. Can Rogers Ro3006 be used for high-power applications?

Rogers Ro3006 is more suited for high-frequency applications rather than high-power applications, as it is designed for signal integrity rather than power handling.

6. What type of copper is typically used with Rogers Ro3006?

The most common copper used with Rogers Ro3006 is oxygen-free copper, which helps maintain signal quality and reduce loss.

Our services

Rogers PCB Laminates & Series