JarnisTech boasts decades of specialized expertise in delivering Box Build Assembly services, ranging from straightforward enclosures to comprehensive sub-assemblies. Our extensive PCB Box Build offerings encompass product assembly, sub-level product assembly, system-level assembly, complete system integration, product testing, packaging and labeling, and more. Additionally, we excel at providing a high mix for low volume PCB box builds or a low mix for high-volume box build assemblies.

We also provide box build turnkey assembly and bespoke assembly services, including cable and harness assembly and electro-mechanical assembly. Our exceptional team of engineers and skilled technicians meticulously constructs your PCB box builds in accordance with custom design specifications while ensuring all safety measures are in place. Our PCB box build services seamlessly integrate all components, PCBs, and any interconnecting wire harness assembly with the utmost precision. Possessing expertise in all three areas, JarnisTech occupies a distinctive position, offering superior box build assembly services.

Essential Components for a Successful Box Build Assembly Project

In order to ensure the success of your box build assembly project, it’s important to have a clear understanding of the electromechanical assembly process involved in creating a functional electronic device. Once you have a grasp of this process, you can provide the necessary components to your chosen electronic contract manufacturing company. This includes all the relevant specifications, drawings, and bill of materials needed to complete the project. Effective communication throughout the assembly process is also crucial for ensuring that the end result meets your expectations.

Bill of Materials (BOM)

The bill of materials (BOM) is a critical document that serves as the formula for building the electronic device. It contains a comprehensive list of all the components required for the assembly of the final electronic product. Each item on the BOM includes essential details, such as part numbers, manufacturer name, quantity, reference numbers, item description, sourcing information, and more. The BOM is the most crucial element of a successful box build assembly project, as it provides the necessary information to ensure that all components are correctly sourced and assembled. By having an accurate and detailed BOM, the electronic contract manufacturing company can ensure that the finished product meets the customer’s specifications and expectations.

Assembly Design Files

The assembly design information for an electronic device can be provided to the electronic contract manufacturing company in the form of printed or electronic files. A 3-D CAD model is the preferred method for conveying this information, as it provides a comprehensive view of the assembly design. A reliable electronic contract manufacturing company can use this information to adapt the design into a functional, manufacturable product. By utilizing a 3-D CAD model, the electronic contract manufacturer can identify any potential issues in the design and provide suggestions for improving manufacturability and efficiency. Therefore, providing accurate and detailed design information is key to ensuring a successful box build assembly project.

Working Prototype

Presenting a working prototype to the electronic contract manufacturing company is an effective way to communicate the product design for manufacturing and production. By analyzing the working prototype, the electronic contract manufacturing company can suggest improvements to make the design more efficient and cost-effective to produce. The ability to identify potential design issues during the prototype stage allows for adjustments to be made before production, reducing the risk of costly errors and delays. Therefore, a working prototype is a valuable tool for both the customer and the electronic contract manufacturing company to ensure a successful product launch.

Test Plan

As part of the box build assembly process, it’s essential to test the functionality and performance of the product’s components. To ensure customer satisfaction, it’s important to provide detailed test cases outlining how the product should be tested before acceptance. These test cases may include a range of tests, such as on-board and off-board programming, functional testing of client and manufacturer-designed features, visual inspections, 3D automated optical inspections, factory acceptance testing, and more. A comprehensive and detailed test plan will ensure optimal results from the electronic contract manufacturer, leading to a successful box build assembly project.

What Is A Box Build Assembly ?

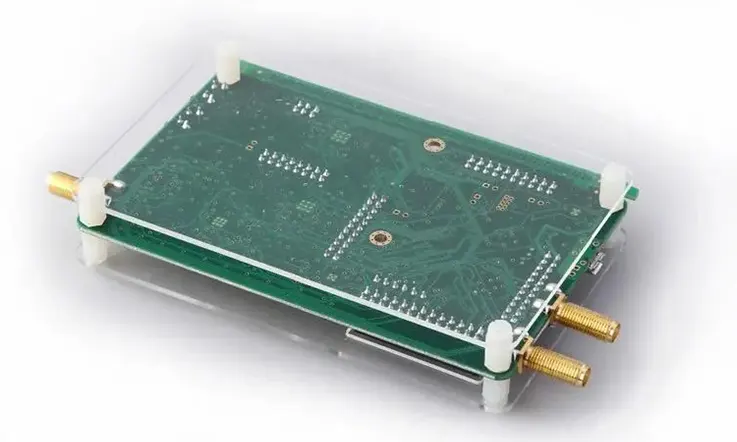

Before proceeding with a box build assembly project, it’s crucial to have a clear understanding of its purpose and function. Box builds involve the integration of printed circuit boards (PCBs) and custom cable components to create a complete system, ranging from simple single-PCB enclosures to complex electromechanical systems that undergo multiple subassembly steps.

Box builds typically include components such as modular connectors, custom cable assemblies, batteries, enclosures (either custom or off-the-shelf), heat sink attachments with thermal interface materials, brackets, standoffs, and fans. The capabilities and service levels offered by different manufacturers vary, and some of these components may need to be procured from vendors or partners while others can be purchased off-the-shelf.

To ensure a successful box build assembly project, it’s essential for the designer to work closely with the electronic contract manufacturing company to determine which components should be procured and which can be custom-built. This collaboration is critical for ensuring that the finished product meets the customer’s specifications and performs reliably.

Types of Box Builds

The materials and components utilized in various box build assemblies can exhibit significant variations depending on the specific project requirements. While some box builds may necessitate minimal assembly, others may require a high degree of technical proficiency to accomplish. Regardless of the complexity level, box build assemblies can be broadly categorized into two types: simple and complex box builds.

Simple Box Build Assembly

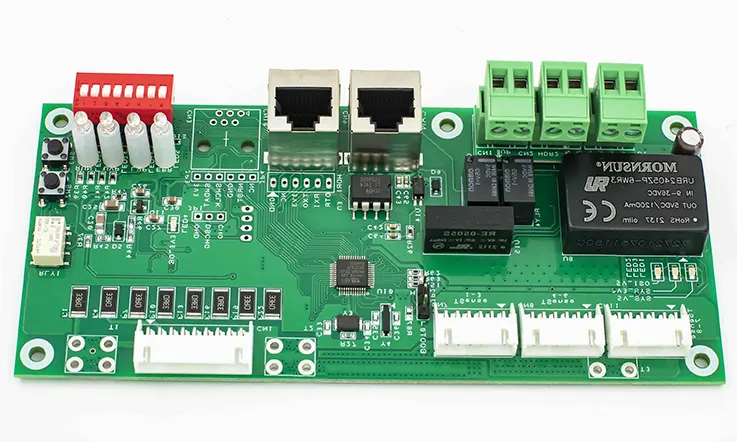

Box build assemblies that fall under the category of simple box builds typically entail the installation of a terminal block or a printed circuit board (PCB) into an enclosure or box with minimal or no involvement of intricate procedures.

Simple Box Build Assembly

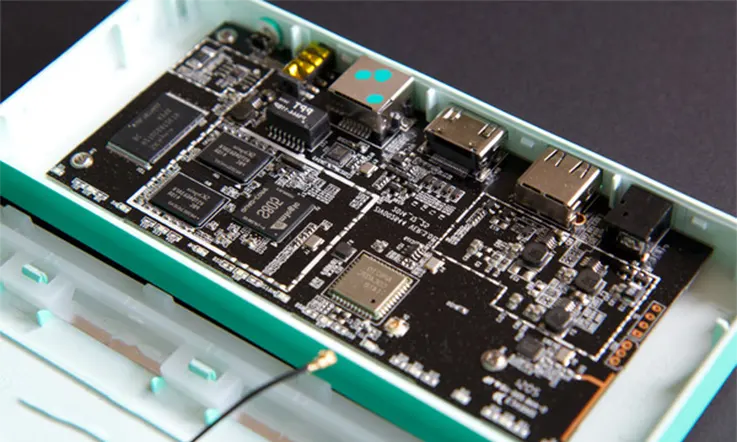

A box build assembly categorized as complex typically involves the incorporation of additional components and procedures, such as the integration of a printed circuit board (PCB) with a user interface display, building fully integrated systems, or other intricate subassemblies.

At JarnisTech, we provide comprehensive solutions for both simple and complex box build assemblies. Our expertise enables us to cater to the specific requirements of your interconnective cable project, ensuring optimal outcomes. Regardless of the complexity level, you can rely on JarnisTech to deliver high-quality results.

To summarize, the success of both complex and simple box build assemblies hinges on the meticulous gathering of project requirements. Ensuring that the electronics manufacturer is equipped with all necessary information during the planning phase can lead to faster, higher quality, and safer product outcomes. At JarnisTech, we are committed to tailoring our box build processes to meet the unique objectives of each customer. Our operations and processes are underpinned by lean manufacturing techniques, enabling us to deliver the finest electronic box assemblies in China.

JarnisTech Box Build Assembly Process

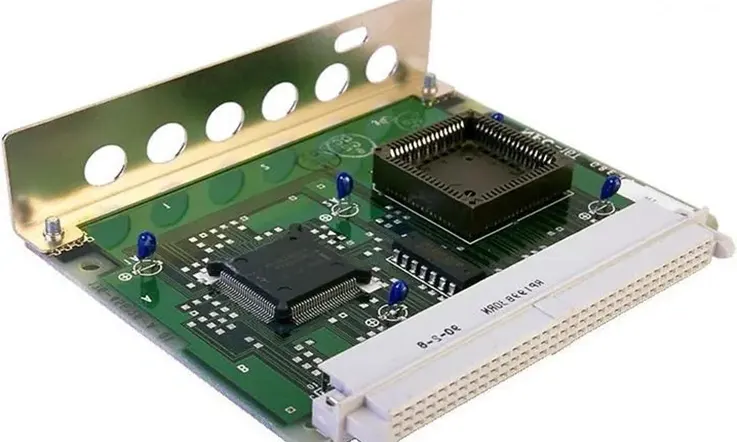

Box build assembly encompasses all aspects of electronic systems manufacturing, from ideation to execution. It involves designing the enclosure, installing circuit boards, cables, connectors, terminal blocks, controllers, and even entire electrical or pneumatic systems.

At JarnisTech, we have the expertise to deliver precise box build assembly solutions that meet the specific requirements of our clients. However, achieving this level of precision requires clear and effective communication from our clients regarding their end goals. This information is conveyed through a bill of materials that distinguishes the components that are truly necessary.

To ensure that your bill of materials is accurate for your order, we have published a recent blog post that covers JarnisTech Group’s entire box build and panel assembly process. This resource will help you prepare and provide us with the information we need to deliver the best possible results for your project.

JarnisTech Assembly’s Box Build Assembly Services

Our company offers a comprehensive range of box build assembly services, including:

1. Product assembly: We can assemble individual components into finished products according to your specifications.

2. Sub-level product assembly: Our sub-level product assembly services involve the integration of multiple subassemblies into a larger product.

3. System level assembly: We can assemble entire systems by integrating multiple subassemblies and components.

4. Complete product testing: Our testing services include functional testing, environmental testing, and burn-in testing to ensure that the finished product meets your requirements.

5. Software loading: We can load software onto your products as part of the assembly process.

6. Complete system integration: Our system integration services involve the integration of multiple subsystems into a larger system.

7. Packaging and labeling: We can package and label your products according to your specifications, including barcoding.

8. Direct shipment: We can ship your finished products directly to your customers, saving you time and money.

At JarnisTech, we are committed to delivering high-quality box build assembly services that meet your exact requirements. Our expertise and experience enable us to provide end-to-end solutions that streamline your product development process and ensure that your products are delivered on time and on budget.

JarnisTech: Competitive Advantages of Box Build Assembly

Our company places a strong emphasis on client collaboration to achieve high-quality results in box build assembly. We have a proven track record of delivering exceptional results, as demonstrated by the following points:

1. ISO 9001:2015 certification: Our facilities are certified to the internationally recognized quality management standard, which ensures that our processes and procedures meet the highest standards.

2. Vast resource pool of testing equipment and automated tools: We have a wide range of testing equipment and automated tools at our disposal, enabling us to deliver accurate and reliable results.

3. Strict adherence to quality procedures: We follow strict quality procedures to ensure that our products meet or exceed the required standards.

4. Experienced IPC trained production assembly staff: Our production assembly staff are experienced and trained to the highest standards set by the IPC.

5. Well-developed global and domestic supplier networks for sourcing custom manufactured components: We have established relationships with global and domestic suppliers to source custom manufactured components that meet our clients’ specifications.

6. Cost-effective assembly services: We provide cost-effective box build assembly services without compromising on quality.

7. Competence in assembling box builds for a variety of complex applications and equipment protection levels: Our expertise enables us to assemble box builds for a range of complex applications and equipment protection levels.

8. Technical support services: We provide technical support services to our clients to ensure that their products meet all necessary requirements.

With our company’s box build assembly services, you can expect high-quality results at cost-effective prices. Contact us today via phone at 0086-0755-23034656 or email us at [email protected] to learn more.

Benefits of Box Build PCB

Box build PCB services can provide significant advantages for businesses seeking to streamline their operations. In-house assembly requires a dedicated staff, specialized tools, and additional production space. Outsourcing PCB box build assembly from JarnisTech, on the other hand, offers a range of benefits, including cost-effective assembly and higher quality control standards.

Here are some additional benefits of box build PCB services for organizations:

Expertise and experience: JarnisTech has the expertise and experience to deliver high-quality box build PCB assemblies that meet the specific requirements of our clients. Our team of professionals is trained to the highest industry standards and can provide end-to-end solutions that streamline the product development process.

Cost savings: Outsourcing box build PCB assembly can result in significant cost savings for businesses. By eliminating the need for specialized tools, additional production space, and a dedicated staff, businesses can save money on overhead costs and focus on their core competencies.

Quality control: JarnisTech follows strict quality control procedures to ensure that every box build PCB assembly meets or exceeds industry standards. Our advanced testing equipment and automated tools ensure that every product is thoroughly tested before it is delivered to our clients.

Faster turnaround times: Outsourcing box build PCB assembly can result in faster turnaround times for businesses. JarnisTech has the resources and expertise to complete projects quickly and efficiently, delivering finished products on time and on budget.

Scalability: Outsourcing box build PCB assembly allows businesses to scale their operations up or down as needed. JarnisTech can accommodate large-scale projects or small-scale runs, depending on our clients’ needs.

In summary, outsourcing box build PCB assembly from JarnisTech can provide businesses with a range of benefits, including expertise and experience, cost savings, quality control, faster turnaround times, and scalability.

JarnisTech: Box Build Assembly Capabilities

JarnisTech offers tailored PCB box build assembly services for clients seeking high-quality, efficient, and cost-effective solutions. Our team works diligently to provide immediate solutions related to PCB box build assembly services, using only the highest quality components.

Comprehensive designs for box build PCBs provide flexibility in PCB manufacturing, and we ensure that our services are flexible enough to meet our clients’ unique needs. With years of experience in PCB manufacturing, we have a complete understanding of creating effective box build PCB services that meet our clients’ expectations. At JarnisTech, we never compromise on the quality of the box build PCB.

Our advanced testing mechanisms ensure that every Printed Circuit Board box build meets the highest quality standards. During testing, we perform all necessary repairs to ensure the highest quality PCB box build.

JarnisTech compiles all crucial components for the PCB box build with proper system integration and completes all necessary tests for higher PCB box build manufacturing. Our team is committed to ensuring that every aspect of the box build assembly process is carefully managed and executed to deliver the best possible result.

Therefore JarnisTech provides tailored PCB box build assembly services that are efficient, cost-effective, and of the highest quality. With our advanced testing mechanisms, flexible manufacturing processes, and experienced team, we are committed to delivering exceptional results for our clients.

Final Thought

JarnisTech is a leading provider of high-quality box build integrated assemblies. Our team of highly skilled and experienced manufacturing specialists is dedicated to delivering custom box build assemblies that go beyond the limits of standard Printed Circuit Board Assemblies (PCBA).

We specialize in offering flexible and responsible production of custom box build assemblies that meet the unique needs of our clients. Our team is committed to delivering the highest quality products that exceed our clients’ expectations.

If you are looking to partner with a reliable and experienced provider of box build integrated assemblies, JarnisTech is the ideal choice. Please feel free to contact us to learn more about our services and how we can help you achieve your production goals.

Related Posts:

- Mixed PCB Assembly Technology Services For Your Next New Project

- Why Electronic Potting is So Important in PCB Assembly?

- A Full Guide to Electro mechanical Assemblies

- Cable and Wire Harness Assembly

- Electronics Components PCB Assembly

- China:The Best PCB Consignment Assembly Services At JarnisTech

- What Is Printed Circuit Boards Assembly?

- Nine Method of Save Cost PCB Assembly Production

- How Many Types of Turnkey PCB Assembly?