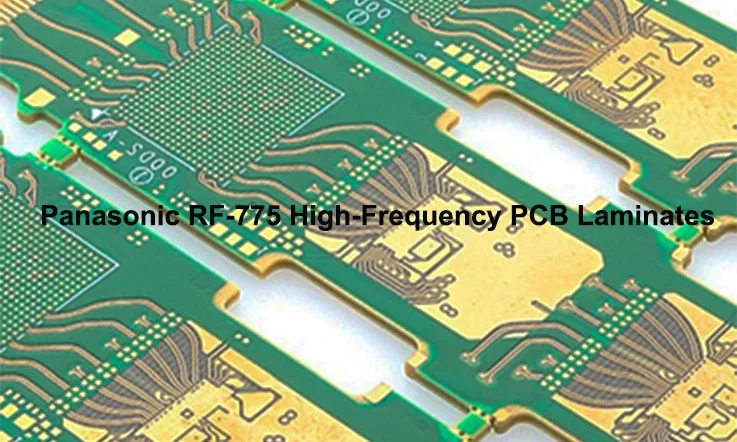

Panasonic RF-775 PCB laminates offer a cutting-edge solution for high-frequency applications, empowering PCB manufacturers to achieve exceptional performance and signal integrity. With its unique characteristics and advanced properties, RF-775 has become a go-to choice for demanding RF and microwave designs. This article explores the key features and advantages of Panasonic RF-775 laminates, highlighting their significance for PCB manufacturers in meeting the demands of modern high-frequency electronic systems.

What Is Panasonic RF-775?

Panasonic RF-775 PCB laminates, developed by Panasonic Corporation, are specialized materials used in the manufacturing of printed circuit boards (PCBs). These laminates possess specific electrical properties that make them suitable for applications requiring high-frequency signal transmission.

With a dielectric constant (Dk) of 3.2, Panasonic RF-775 laminates offer excellent signal stability and low signal loss, enabling efficient transmission of high-frequency signals within the frequency range of 0 to 1 GHz. The low dissipation factor (Df) of 0.003 ensures minimal energy loss and maintains signal integrity.

These laminates are designed to meet the demanding requirements of high-frequency applications, such as telecommunications, wireless communication systems, radar systems, and other electronic devices operating within the specified frequency range. The precise electrical characteristics of the Panasonic RF-775 laminates contribute to reliable signal performance and minimize signal distortion.

Performance Characteristics of Panasonic RF-775 PCB Laminates

1. High Signal Integrity: Panasonic RF-775 PCB laminates offer high signal integrity, ensuring minimal signal loss and distortion, and maintaining the integrity of high-frequency signals.

2. Low Dielectric Loss: These laminates have low dielectric loss, which helps in minimizing signal attenuation and maintaining signal strength over long distances.

3. Low Moisture Absorption: The laminates have low moisture absorption properties, which helps in maintaining their electrical and mechanical properties over a wide range of environmental conditions.

4. Thermal Stability: Panasonic RF-775 PCB laminates exhibit excellent thermal stability, ensuring reliable performance under varying temperature conditions.

5. Dimensional Stability: The laminates offer excellent dimensional stability, preventing warping or distortion of the PCB during manufacturing and operation.

6. RoHS Compliance: These laminates are compliant with RoHS (Restriction of Hazardous Substances) regulations, ensuring the use of environmentally friendly materials in their construction.

7. Process Compatibility: The laminates are compatible with standard PCB fabrication processes, making them suitable for use in various manufacturing environments.

8. Good Mechanical Strength: These laminates offer good mechanical strength, ensuring the durability and reliability of the PCBs in which they are used.

9. Chemical Resistance: Panasonic RF-775 PCB laminates exhibit resistance to various chemicals, ensuring their long-term stability in harsh operating environments.

10.Excellent Electrical Performance: The laminates offer excellent electrical performance in terms of impedance control, signal integrity, and high-frequency operation, making them suitable for use in high-speed and high-frequency applications.

RF-775 vs. Standard FR-4 Laminates

When comparing Panasonic RF-775 PCB laminates with standard FR-4 laminates, several key differences can be noted:

1. High-Frequency Performance: RF-775 laminates are specifically designed for high-frequency applications, offering superior signal integrity, low dielectric loss, and excellent impedance control. Standard FR-4 laminates, while suitable for general-purpose PCBs, may not offer the same level of performance in high-frequency applications.

2. Thermal Stability: RF-775 laminates exhibit better thermal stability compared to standard FR-4 laminates, making them more suitable for applications where temperature variations are a concern.

3. Moisture Absorption: RF-775 laminates have lower moisture absorption, which is beneficial for maintaining electrical and mechanical properties in high-humidity environments. Standard FR-4 laminates may be more susceptible to moisture absorption.

4. Process Compatibility: While both types of laminates are compatible with standard PCB fabrication processes, RF-775 laminates may require specific handling and processing techniques to fully harness their high-frequency performance characteristics.

5. Cost: RF-775 laminates are often more expensive than standard FR-4 laminates due to their specialized high-frequency performance and advanced material properties.

All in all, RF-775 laminates are specifically engineered for high-frequency and high-performance applications, offering superior signal integrity, thermal stability, and low dielectric loss compared to standard FR-4 laminates. However, for general-purpose PCBs and applications that do not require high-frequency performance, standard FR-4 laminates may be a more cost-effective and suitable option.

RF-775 vs. Other High-Frequency Laminates

When comparing RF-775 to other high-frequency laminates, it’s important to consider factors such as dielectric constant (Dk), dissipation factor (Df), thermal stability, cost, and processing capabilities. Different laminates may have variations in these properties, which can affect their suitability for specific applications.

FR-4:

FR-4 is a widely used and cost-effective laminate material. It has a moderate dielectric constant (around 4), which makes it suitable for many applications. However, FR-4 tends to have higher loss tangent (Df) at high frequencies, limiting its performance in high-frequency designs.

PTFE-Based Laminates:

Polytetrafluoroethylene (PTFE) is a popular material for high-frequency laminates due to its low loss and excellent electrical properties. Laminates like Rogers RT/duroid and Taconic TLY series are examples of PTFE-based laminates. They offer low dielectric constant and loss tangent, making them ideal for high-frequency applications. However, PTFE laminates can be more expensive and challenging to process compared to other materials.

Isola I-Tera:

I-Tera is a laminate material developed by Isola Group. It offers improved electrical performance compared to traditional FR-4 laminates, with lower dielectric loss and higher thermal stability. I-Tera laminates are designed for high-speed digital applications and offer good signal integrity at high frequencies.

Arlon AD Series:

Arlon AD series laminates are engineered for high-frequency and high-speed applications. They provide low dielectric loss and excellent thermal stability, making them suitable for demanding environments. Arlon laminates are commonly used in aerospace, defense, and telecommunications industries.

It’s important to note that the selection of a high-frequency laminate depends on the specific requirements of your application. Factors such as frequency range, signal integrity, power handling, cost, and manufacturing processes should be considered when choosing the appropriate laminate material.

Consideration Factor of Choose Panasonic RF-775 In PCB Design

When considering the Panasonic RF-775 for PCB design, there are several factors to take into account:

Specifications:

Review the specifications of the Panasonic RF-775 to ensure it meets your project requirements. Look for details such as frequency range, voltage rating, current rating, and power handling capabilities.

Size and Form Factor:

Consider the physical dimensions of the Panasonic RF-775 and ensure it fits within the available space on your PCB. Additionally, check if it is available in the desired package type (e.g., surface mount or through-hole) for easy integration into your design.

Performance:

Evaluate the performance characteristics of the Panasonic RF-775, such as its sensitivity, selectivity, and signal-to-noise ratio. These factors are crucial for optimal reception and transmission in your PCB application.

Environmental Considerations:

Determine if the Panasonic RF-775 is suitable for the environmental conditions in which your PCB will operate. Consider factors such as operating temperature range, humidity resistance, and any specific certifications or standards the component needs to meet.

Availability and Cost:

Check the availability and pricing of the Panasonic RF-775. Ensure that the component is readily available for purchase in the required quantities and consider its cost in relation to your project budget.

Support and Documentation:

Look for comprehensive documentation, including datasheets, application notes, and technical support resources provided by Panasonic. Availability of these resources can greatly assist in the design and troubleshooting processes.

How to Find a Reliable Panasonic RF-775 PCB Manufacturer?

When selecting a PCB manufacturer for the Panasonic RF-775 laminates, it is crucial to find a reliable partner with expertise in working with these specific materials. The manufacturer should possess in-depth knowledge of the properties and specifications of the laminates, as well as the necessary manufacturing capabilities to ensure the desired electrical performance is achieved.

Additionally, the manufacturer should have stringent quality control measures in place to verify that the PCBs manufactured using Panasonic RF-775 laminates meet the specified Dk, Df, and frequency range requirements. Testing and validation procedures should be implemented to ensure the integrity and reliability of the final PCBs.

By partnering with a reputable PCB manufacturer experienced in working with Panasonic RF-775 laminates, you can ensure the production of high-quality PCBs that meet the stringent demands of high-frequency applications.

By following these steps and conducting due diligence, you can find a reliable Panasonic RF-775 PCB manufacturer that meets your specific requirements and ensures the production of high-quality PCBs.

Why Choose Us?

JarnisTech, a leading PCB manufacturer based in China, is pleased to introduce the R-F775 PCB to the market. This cutting-edge PCB incorporates innovative advancements in Multilayer PCB fabrication, offering numerous advantages for your company’s needs.

With our state-of-the-art facilities and efficient production processes, we are capable of fulfilling both regular and urgent orders for the R-F775 PCB. Our extensive manufacturing capacity enables us to handle large-scale production, ensuring timely delivery of your goods. Rest assured, we prioritize customer satisfaction and strive to meet your specific requirements.

At JarnisTech, we understand the importance of technical support in the PCB industry. That’s why we have a team of highly skilled PCB professionals available to assist you with any engineering questions or concerns you may have. Our dedicated experts are committed to providing prompt and comprehensive responses, typically within one to two hours of inquiry.

Don’t hesitate to place your order now and embark on a successful partnership with JarnisTech for your R-F775 PCB needs. We are eager to collaborate with you and deliver exceptional PCB solutions tailored to your unique specifications. Contact us today to get started!

Conclusion

Panasonic RF-775 PCB laminates provide a game-changing solution for PCB manufacturers seeking high-frequency performance and reliability. With its optimized dielectric properties, low loss tangent, and robust thermal stability, RF-775 empowers designers to create PCBs that deliver exceptional signal integrity and reduced loss. By leveraging the capabilities of Panasonic RF-775, PCB manufacturers can stay at the forefront of technological advancements and meet the evolving needs of high-frequency electronic systems. Embrace the power of Panasonic RF-775 laminates and unlock unparalleled performance in your PCB designs.