The advancement of mobile electronic components has been nothing short of revolutionary. While the fabrication of miniature, smart electronic instruments can prove intricate, the utilization of versatile printed circuit boards has streamlined the production of complex electronic elements.

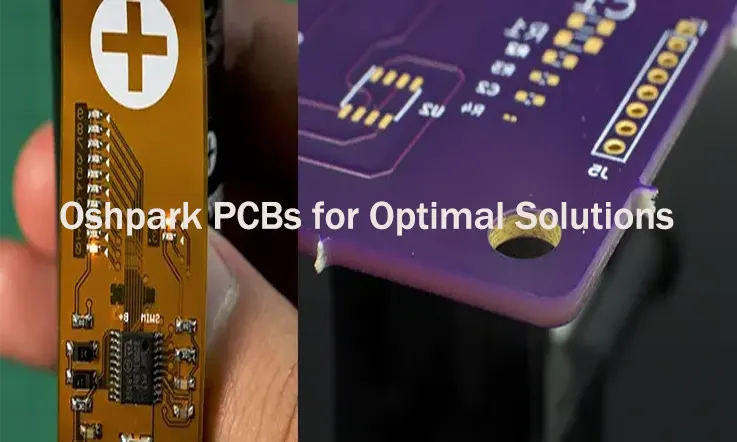

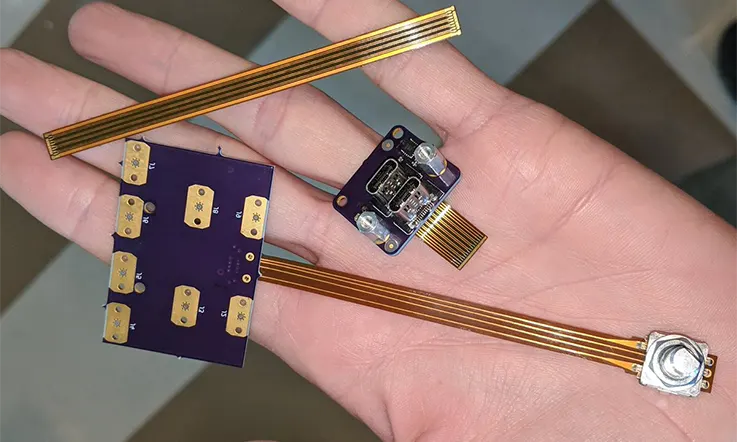

Flex PCB have proven to be particularly efficient in static and dynamic electronic devices, and as a result, many industries are incorporating them in the production of portable multi-functional devices. OSHPARK, a respected producer of flex PCBs, has solidified its standing for top-notch quality in the sector. In this piece, we’ll explore further into OSHPARK and their flex PCB.

What is OSHPARK?

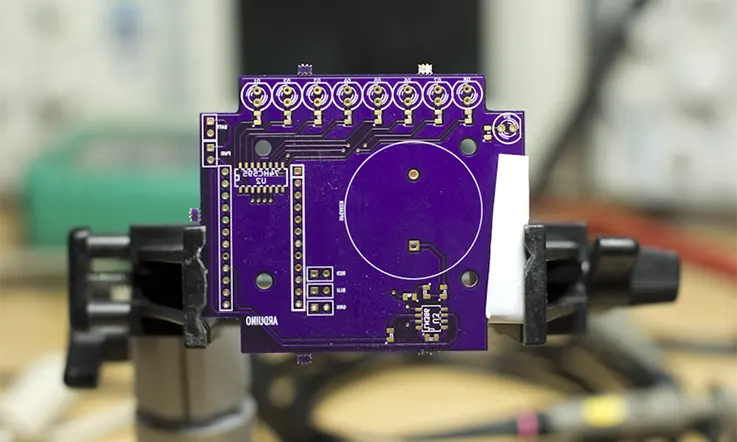

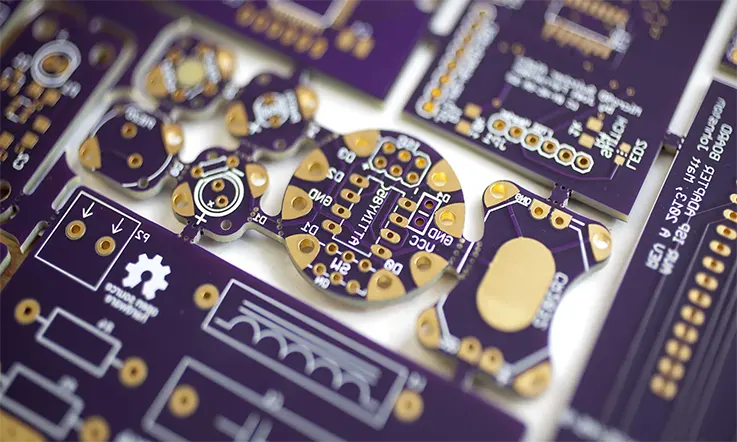

OSHPARK is a well-regarded online platform providing fabrication and assembly services for printed circuit boards. It is a community-driven platform that enables hobbyists, makers, and engineers to design and order custom PCBs in small quantities at an affordable cost. OSHPARK PCB, known for their distinctive purple-hued boards, have become a brand hallmark. The venture took off in 2011, and has since earned commendation for top-tier PCB provision with rapid delivery times. Broadly utilized within the electronics industry, OSHPARK PCB are first choice for prototype creation and limited-scale production of electronic apparatus.

History and Background of OSHPARK

OSHPARK was founded in 2011 by Drew Fustini, Laen O’Connor and Dave Young. The company was born out of frustration with the high costs and long lead times associated with low-volume PCB production. the founders hope to devise a service enabling enthusiasts, inventors, and engineers to avail high-quality PCBs in smaller volumes at economical pricing.

The company’s name, “OSHPARK,” is a combination of “OSH” (short for “Open Source Hardware”) and “park” ( signify a community space). The founders of company believed that open-source hardware was a crucial part of the maker movement and wanted to create a platform that would support and encourage its development.

OSHPARK quickly garnered popularity within the creator community, recognized for their notable purple-hued circuit boards. The firm’s dedication to superior quality and exceptional customer service secured its differentiating space amidst widespread competition. Consequently, it has emerged as one of the most sought-after PCB fabrication services on the digital platform.

In 2018, OSHPARK was acquired by Advanced Circuits, a leading PCB manufacturer, but it continues to operate as an independent brand with its own unique identity and community.

Oshpark’s Technologies and Integrations

OSHPARK PCB sets the industry standard as a premier fabricator of top-tier flex PCB. It is distinguished for its superior technologies and synergies that facilitate meeting the stringent industry benchmarks for PCB production. One of the technologies that OSHPARK utilizes in its PCB production is the advanced computer-aided design (CAD) software. This proprietary software empowers the firm to generate exact and intricate designs in accordance with specific client stipulations.

OSHPARK PCB also employs advanced printing technologies to produce PCB with high resolution and accuracy. The company’s printing equipment uses advanced techniques such as laser direct imaging and inkjet printing to achieve high-quality results. OSHPARK’s printing technologies are highly efficient, producing PCB with excellent resolution and reduced manufacturing times.

Moreover, OSHPARK PCB amalgamates cutting-edge technologies in PCB examination and analysis. The firm leverages automated optical inspection (AOI) along with X-ray scrutiny to assure that each PCB is congruent with the stipulated quality benchmarks. These contemporary technologies facilitate OSHPARK in detecting and rectifying any discrepancies or imperfections in the PCB prior to their dispatch to the clientele.

OSHPARK PCB’s technologies and integration are designed to ensure that their PCB meet the highest industry standards. The company’s commitment to quality has earned it a reputation as a leading manufacturer of high-quality flex PCB.

Oshpark Flex PCB Types

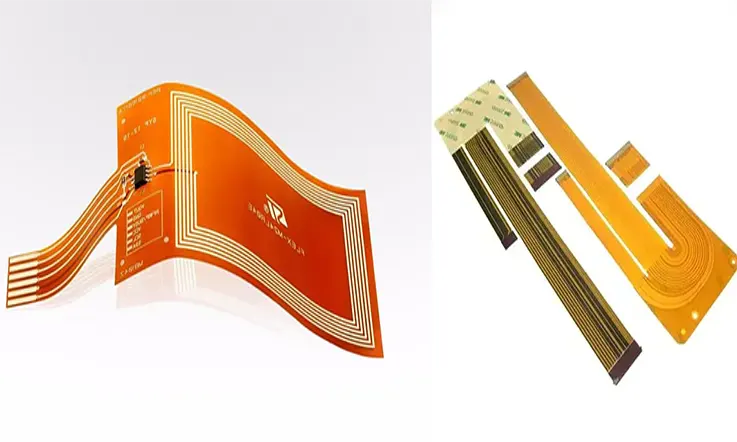

Providing a comprehensive array of flex PCB types, OSHPARK caters to the extensive gamut of its client’s requirements. The offerings encompass the following types of flex PCB:

Single layer flex PCB: Incorporating a solitary conductive layer, these flexible PCB are distinguished by their simplicity. Their rudimentary design lends itself seamlessly to applications requiring a flexible and uncomplicated circuit layout.

Double sided flex PCB: Furnishing two conductive layers, these flex PCB offer enhanced design adaptability. Their dual-layer structure suits applications that demand a higher level of complexity.

In addition, the following are the minimum design rules for two-layer flex PCB:

● 6mil (0.1524mm): specified as the trace width.

● 5mil (0.127mm): denoted as the annular ring dimension.

● 6mil (0.1524mm): signified as the trace clearance.

● 10mil (0.254mm): characterized as the drill size.

Multi-layer flex PCB: These flexible PCB are characterized by three or more layers of conductive matter. The high-density circuit requisites of certain applications make multi-layer flex PCB an optimal choice.

the following are the minimum design rules for 4-layer flex PCB:

● 5mil (0.127mm): The prescribed measure for the trace width.

● 4mil (0.1016mm): The exact specification for the annular ring.

● 5mil (0.127mm): Designated value for the trace clearance.

● 10mil (0.254mm): Officially recognized standard for the drill size.

the following are the minimum design rules for 6 layer flex PCB:

● 5mil (0.127mm): Trace width is designated as such.

● 4mil (0.1016mm): This marks the annular ring‘s standard dimension.

● 8mil (0.2032mm): The drill size is defined by this measure.

● 5mil (0.127mm): This signifies the trace clearance for the design.

Rigid-flex PCB: These PCB exhibit a hybrid nature with sections both rigid and flexible. By amalgamating the advantages of both types of circuitry, rigid-flex PCB cater perfectly to applications that demand a synthesis of the two.

Sculptured flex PCB: These are flexible PCB with a unique three-dimensional shape. Sculptured flex PCB are ideal for applications that require a customized shape or fit.

OSHPARK’s range of flex PCB types allows clients to choose the type of PCB that best suits their specific application requirements.

Bend Radius of OSHPARK Flex PCB

Determination of the bend radius for a flex PCB, either in a static or dynamic state, is dependent on the thickness of all the layers present in the board that are affected by bending. This assessment is done by multiplying the board’s thickness by the bend ratio. A static bend is a process where the flex PCB is manipulated into a specific shape and subsequently installed while maintaining this curvature.

Contrastingly, a dynamic bend signifies the bending and straightening progression which a flex PCB experiences. Determining the bend radius for a dynamic bend may pose certain challenges, yet maintaining larger dynamic bends is essential to reduce wear during functionality. Conversely, brisk, dynamic bends could precipitate rapid PCB degradation.

Quality Assurance of OSHPARK

OSHPARK has a strong commitment to quality assurance and takes several steps to ensure that its PCB meet the required specifications and perform reliably.

Design verification: Before manufacturing begins, OSHPARK verifies the design files to ensure that they are error-free and meet the required specifications.

Material selection: OSHPARK uses high-quality materials, including FR-4 fiberglass, copper foil, and solder mask, to ensure that its PCB meet industry standards and perform reliably.

Testing: Every PCB undergoes electrical connectivity and functionality tests prior to distribution. OSHPARK utilizes state-of-the-art automated testing machinery to verify that every board adheres to the necessary specifications.

Quality control: OSHPARK benefits from a cadre of seasoned technicians who carry out meticulous visual assessments and manual analysis, ensuring that each fabricated PCB satisfies the required specifications.

Client feedback: OSHPARK greatly appreciates customer suggestions and employs them for the enhancement of its product offerings and services. The firm boasts a robust assembly of product creators and engineers who contribute their designs and cooperate on endeavors, providing invaluable feedback and discernment.

Customer Support and Community

OSHPARK exhibits a profound commitment towards customer service and community engagement, which has been instrumental in establishing a steadfast clientele comprising hobbyists, makers, and engineers. The following are some of the features provided by OSHPARK related to customer support and community interaction:

Online support: OSHPARK offers online support through its website, including a knowledge base, FAQs, and detailed instructions for designing and ordering PCB.

Community Forum: OSHPARK boasts a vibrant community forum that provides a platform for clients to showcase their designs, solicit feedback, and team up on ventures. The forum, overseen by OSHPARK personnel, constitutes a stellar resource for knowledge acquisition and professional networking.

Social media: OSHPARK commands a robust presence on various social media platforms – Twitter, Facebook, and Instagram included. These platforms serve as effective channels to broadcast novel developments and news pertinent to its offerings and services.

Customer Service: OSHPARK employs a committed customer service unit, accessible to resolve queries and extend support through email. Additionally, the company also possesses a direct contact number for addressing urgent matters.

Blog: OSHPARK has a blog where it shares news and updates about the company, and providing instructive and resources beneficial to creators and engineers.

Conclusion

OSHPARK PCB has become a popular choice for hobbyists, electronics manufacturers, and engineers looking for high-quality PCB in small quantities. Through their commitment, to quality, affordability and customer care OSHPARK has built a following and established itself as one of the premier online PCB fabrication services.

OSHPARK PCB is likely to continue to innovate and expand its offerings to meet the evolving needs of its customers. The company may investigate fresh fabrication methodologies, materials, and design instruments to make PCB fabrication increasingly obtainable and economical for hobbyists and creators.

OSHPARK’s strong community and online presence are also likely to play an important role in its future growth. With the continuous development and evolution of the maker movement, OSHPARK is strategically poised to be a significant participant in this vibrant and stimulating community.

Related Posts:

1. Flex PCB

2. Battery FPC: Advantages, Limitations, Application and Future Developments

3. FPC Circuit Board Materials and Application

4. What Is the Main Differences Between FFC and FPC?

5. Understanding Kapton PCB: Advantages, Challenges, and Applications