Mixed PCB assembly has become increasingly popular in the electronics industry due to its ability to provide a balance between functionality, reliability, and cost-effectiveness. The combination of SMT and THT components allows for the miniaturization of components while still maintaining the durability and reliability of through-hole components. This makes mixed PCB assembly ideal for a wide range of applications, including aerospace and defense, medical devices, automotive electronics, industrial equipment, and consumer electronics.

Mixed PCB Assembly Services

Printed Circuit Board (PCB) assemblies comprise various components and parts, mounted using either Surface Mount Technology (SMT) or Through Hole Technology (THT). The choice of the assembly method depends on factors such as component quantity and location. However, when time constraints or the need for rapid PCB assembly services arise, mixed model PCB assembly services are the optimal solution.

Mixed model assembly services integrate the advantages of both THT and SMT technologies. The primary advantage of mixed model PCB assembly services is the potential for reduced costs, shorter assembly time, and increased productivity. The mixed technology PCB assembly process is suitable for both small and large scale production. Our company, JarnisTech, boasts a long-standing reputation of delivering top-quality mixed model assembly services at competitive prices.

Benefits of Mixed Model PCB Assembly

Mixed model PCB assembly is a relatively new technique in the PCB manufacturing industry that combines the advantages of manual and automatic assembly methods. This hybrid approach uses automatic machinery for placing Surface Mount Technology (SMT) components on the PCB while employing manual machinery for larger parts, such as through-hole components or heat sinks, to achieve flexibility, precision, and good quality.

One of the primary benefits of mixed model PCB assembly is its cost-effectiveness in PCB manufacturing. By leveraging automation to expedite labor-intensive processes and using human labor to execute necessary tasks that machines cannot handle, businesses can meet their financial goals while delivering products manufactured efficiently and at affordable prices, keeping customers satisfied.

Moreover, mixed model assembly processes can yield higher quality PCBs and increase production speed. They can also reduce labor costs by eliminating hand-soldering in favor of automated soldering, which requires fewer workers for the same amount of work.

Mixed model PCB assembly is an excellent option for manufacturing PCBs with complex routing and interconnections. Many electronics OEMs are now embracing this method to enhance product performance while reducing overall manufacturing costs.

Differences Between Surface Mount Technology and Through Hole Technology in PCB Assembly

In the PCB assembly process, Surface Mount Technology (SMT) components are welded onto the board via a fully automated reflow machine, whereas Through Hole Technology (THT) assembly requires pre-drilled holes on the board and the use of leads to connect components and circuits. Wave-soldering and hand-soldering are the conventional methods of THT assembly.

PCBs with SMT components can be reflow or wave-soldered, whereas those with only THT components can only be wave-soldered. Thus, when both SMT and THT components are used on a board, there are more assembly steps involved, with SMT typically being performed first, followed by THT assembly.

Advanced and precision machines enable high-accuracy and fast-speed SMT assembly, with small-sized and thin components placed precisely, making it suitable for high-density and small-sized PCB applications. THT, on the other hand, is preferred for components with larger sizes and higher reliability requirements due to its stronger connections.

Overall, SMT assembly features high productivity, precision, lightweight, and lower cost, making it more economical and faster for mass production. THT assemblies, on the other hand, are typically highly reliable, have high-stress tolerance, are heavier, and more expensive, making them a preferred option for small quantity PCBs and prototyping fabrication.

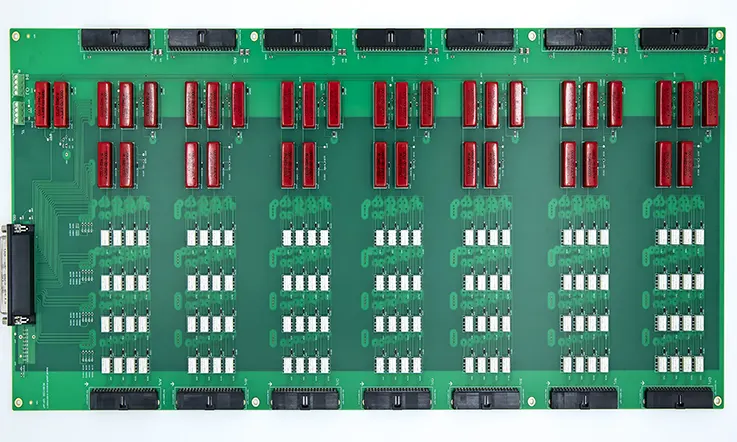

Mixed PCB Assembly Process

The mixed PCB assembly process involves the combination of surface mount technology (SMT) and through-hole technology (THT) components on a printed circuit board (PCB). Here are the basic steps of the mixed PCB assembly process:

PCB design: The first step is to design the PCB layout, including the placement of SMT and THT components, as well as the routing of electrical connections.

SMT component placement: Surface mount components such as resistors, capacitors, and integrated circuits are placed on the PCB using pick-and-place machines. The machines use a vacuum to pick up the components from reels or trays and place them accurately on the PCB.

SMT soldering: After the SMT components are placed on the PCB, the board is passed through a reflow oven that melts the solder paste and creates a permanent bond between the components and the PCB.

THT component insertion: Through-hole components such as connectors, switches, and transformers are inserted into pre-drilled holes on the PCB. The leads of the components are then bent and soldered to the opposite side of the board using a wave soldering machine.

Inspection and testing: After the mixed PCB assembly is complete, the board is inspected for defects and tested for functionality. This includes visual inspection, automated optical inspection (AOI), and functional testing.

Final assembly: Once the PCB passes inspection and testing, it is ready for final assembly into the end product. This may involve additional assembly steps such as enclosure assembly, cable harnessing, and testing.

The mixed PCB assembly process requires specialized equipment and expertise to ensure the proper placement and soldering of both SMT and THT components. It also requires careful consideration of the PCB design to ensure that the components are placed in a way that optimizes the functionality and reliability of the end product.

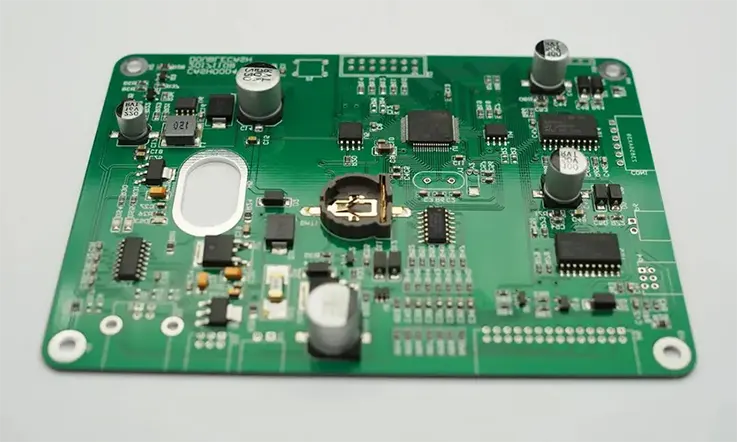

Choose the Reliable Mixed (hybrid) PCB Assembly Factory in China: JarnisTech

At JarnisTech, we are dedicated to providing our clients across diverse industries with highly intricate mixed PCB assemblies. Our mixed technology PCB assembly services are tailored to cater to applications that require both surface mount and through-hole components. We specialize in manufacturing double-layer SMT mixed technology PCBs, ensuring that our clients receive highly efficient and reliable products.

Our Mixed Technology Capabilities

We utilize independent automated mixed technology assembly lines for manufacturing PCBs. This enables us to offer our clients complete PCB assemblies and prototypes within short turnaround times. Our customers can take advantage of our broad range of capabilities, which include:

● Chassis wiring and assembly.

● Wave and soldering machines.

● Automated laser sighting and flux dispensing.

● State-of-the-art automated assembly equipment.

● Automated aqueous cleaning at multiple stages of production.

● Fast production of densely populated mixed technology assemblies.

● Fast placement machines for ultra-small and ultra-thin chip components.

Our advanced facilities and equipment enable us to deliver high-quality products and services to our clients, ensuring that we consistently meet and exceed their expectations.

Other Equipment Used

At JarnisTech, we utilize state-of-the-art equipment to deliver high-performance and top-quality PCBs. Our commitment to excellence is reflected in the use of the following best-in-class equipment, which has helped us establish our reputation as a leading provider of double-sided SMT and mixed technology services in China:

● Rheometers.

● Reflow ovens.

● Environment chambers.

● Stencil printing machines.

● Acoustic scanning microscopes.

● Automatic dispensing machines.

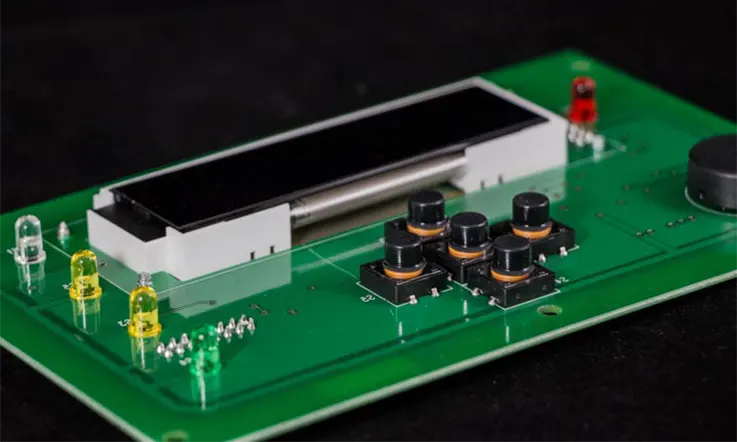

Testing and Inspection Procedures at JarnisTech

At JarnisTech, we adhere to stringent testing and inspection procedures to ensure the high accuracy of our circuit boards:

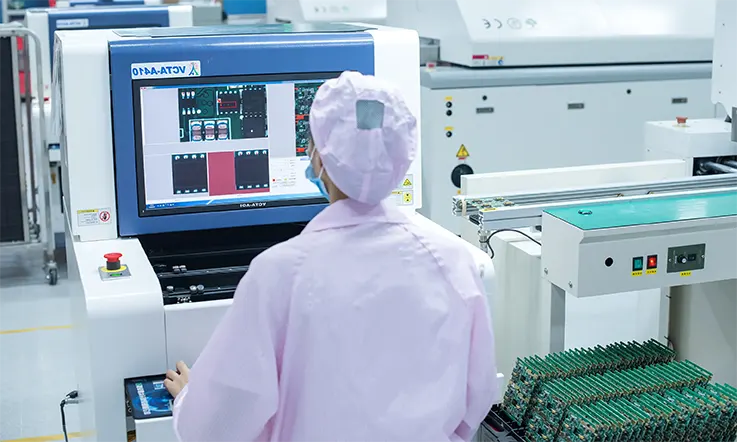

Automated Optical Inspection

Our advanced automated optical inspection (AOI) equipment is designed to provide comprehensive fault coverage, enabling us to thoroughly inspect various components of printed circuit boards (PCBs). This includes optical placement, orientation, value, color differences, short circuits, dry joints, and other potential defects. Our AOI system is highly effective in inspecting mixed technology PCBs, as well as surface-mount technology (SMT), through-hole, and ball grid array (BGA) assemblies. By utilizing this cutting-edge technology, we can ensure that our customers receive high-quality and reliable products.

X-Ray Testing

At our facility, we employ a cutting-edge automated X-ray system to conduct comprehensive inspections of printed circuit boards (PCBs). This advanced testing method is crucial in identifying any hidden faults or defects that may not be visible during traditional visual inspections. By utilizing this state-of-the-art technology, we can ensure the highest quality of PCB components and eliminate any manufacturing defects in the early stages of production. This proactive approach not only helps us avoid potential issues down the line but also saves our customers from costly performance problems. Our commitment to utilizing the latest technologies and techniques is a testament to our dedication to providing top-quality products and services.

Functional Testing

This process is conducted to verify the optimal operation of the printed circuit board (PCB) assembly.

Standards Conformance

At our organization, we prioritize compliance with UL safety standards for printed circuit boards (PCBs). To ensure that our PCBs meet these rigorous safety requirements, we adhere to all relevant industry standards and protocols.

● IPC-CC-830B.

● SBA certified.

● IPC-WHMA-A-610.

● All assemblies built to IPC-A-610-D & ANSI/J-STD-001.

JarnisTech is proud to offer comprehensive RoHS-compliant printed circuit board (PCB) assembly and design services. If you are interested in learning more about our mixed technology PCB assembly services or any of our other PCB assembly offerings, please do not hesitate to contact us. Our team can be reached by phone at 0086-0755-23034656 or by email at [email protected]. We strive to provide timely and informative responses, and you can expect to hear back from us within one business day.

The Applications of Mixed Assembly Technology

Mixed PCB assembly refers to the process of assembling printed circuit boards (PCBs) with a combination of surface mount technology (SMT) and through-hole technology (THT) components. Here are some of the applications of mixed PCB assembly:

Aerospace and defense: Mixed PCB assembly is commonly used in aerospace and defense systems, where the high reliability and durability of through-hole components are required along with the high density and miniaturization of surface mount components.

Medical devices: Medical devices require a combination of through-hole and surface mount components for their complex functionality and safety-critical nature. Mixed PCB assembly is used to ensure the reliability and accuracy of medical devices.

Automotive electronics: Mixed PCB assembly is used in automotive electronics for the combination of high-power through-hole components and miniaturized surface mount components, ensuring the reliability and performance of automotive systems.

Industrial equipment: Industrial equipment requires a combination of through-hole and surface mount components for their ruggedness and durability. Mixed PCB assembly is used in industrial equipment to ensure the reliability and stability of their operation.

Consumer electronics: Mixed PCB assembly is used in consumer electronics such as smartphones, tablets, and laptops, where the miniaturization of components is essential for their compact size and portability, while the durability of through-hole components ensures their long-term reliability.

Overall, mixed PCB assembly is a versatile and widely used technology that enables the combination of various types of electronic components, providing a balance between performance, reliability, and cost-effectiveness.

Future Directions for Mixed PCB Assembly Technology

Mixed PCB assembly technology has come a long way since its inception, and it is likely to continue evolving to meet the changing needs of the electronics industry. Here are some possible future directions for mixed PCB assembly technology:

1. Miniaturization: As the demand for smaller and more compact electronic devices continues to grow, mixed PCB assembly technology will need to keep up with the trend towards miniaturization. This may involve the development of even smaller and more precise pick-and-place machines, as well as the use of more advanced materials and processes to reduce the size of components.

2. Automation: The use of automation in mixed PCB assembly is likely to increase in the future, as manufacturers seek to improve productivity and reduce costs. This may involve the use of more advanced robotics and artificial intelligence to automate the assembly process and improve the accuracy and consistency of component placement and soldering.

3. Integration with other technologies: Mixed PCB assembly technology is likely to be integrated with other emerging technologies such as 3D printing and flexible electronics. This may enable the creation of more complex and innovative electronic devices that are not limited by the constraints of traditional PCB assembly methods.

4. Sustainability: The electronics industry is under increasing pressure to reduce its environmental impact, and mixed PCB assembly technology is no exception. In the future, manufacturers may need to adopt more sustainable practices in the assembly process, such as the use of eco-friendly materials and the implementation of more efficient and energy-saving processes.

5. Improved inspection and testing: The inspection and testing of mixed PCB assemblies are critical to ensuring the reliability and functionality of electronic devices. In the future, manufacturers may develop more advanced inspection and testing methods, such as the use of artificial intelligence and machine learning algorithms to detect defects and improve the quality of the final product.

In conclusion, mixed PCB assembly technology is likely to continue evolving to meet the changing needs of the electronics industry. Whether it involves miniaturization, automation, integration with other technologies, sustainability, or improved inspection and testing, the future of mixed PCB assembly looks promising and exciting.

In Summary

Mixed PCB assembly technology has become an essential part of modern electronics manufacturing, enabling the combination of surface mount technology (SMT) and through-hole technology (THT) components on a single printed circuit board (PCB). This versatile and widely used technology offers several advantages over traditional assembly methods, including improved reliability and durability, increased flexibility and functionality, and cost-effectiveness.

Mixed PCB assembly is used in a wide range of applications, including aerospace and defense, medical devices, automotive electronics, industrial equipment, and consumer electronics. The process involves several steps, including PCB design, SMT component placement, SMT soldering, THT component insertion, inspection and testing, and final assembly. Each step requires specialized equipment and expertise to ensure the proper placement and soldering of both SMT and THT components.

For the past two decades, JarnisTech has been providing exceptional services to our clients, consistently exceeding their expectations. We remain committed to offering affordable mixed model printed circuit board (PCB) assembly services while maintaining the highest standards of quality. Our team takes great care to ensure that all PCBs are assembled using only the finest materials and craftsmanship. We take great pride in providing reliable PCB assembly services and are dedicated to serving our customers in a timely and efficient manner. If you are searching for a trustworthy and cost-effective mixed model assembly service, do not hesitate to reach out to us today.

Related Posts:

- What Is Printed Circuit Boards Assembly?

- Why Electronic Potting is So Important in PCB Assembly?

- A Full Guide to Electro mechanical Assemblies

- Cable and Wire Harness Assembly

- Electronics Components PCB Assembly

- China:The Best PCB Consignment Assembly Services At JarnisTech

- PCB Box Build Assembly

- Nine Method of Save Cost PCB Assembly Production

- How Many Types of Turnkey PCB Assembly?