Printed circuit board (PCB) materials have come a long way, but when it comes to 5G networks, AI-driven computing, and next-gen IoT devices, not all laminates make the cut. MEGTRON M R-5735 Laminate is designed for those who push technology to its limits—offering low transmission loss, outstanding thermal stability, and precise impedance control.

Let’s dive into what sets this material apart, how it stacks up in real-world applications, and why engineers across telecom, medical, defense, and high-frequency computing industries are turning to it for their most demanding projects.

What is MEGTRON M R-5735 Laminate?

Key Features and Benefits

As modern electronics push the limits of speed, reliability, and thermal stability, human are constantly hunting for materials that can handle the heat—literally and figuratively. MEGTRON M R-5735 Laminate from Panasonic is tailored for high-frequency, low-loss applications, making it a prime choice for 5G infrastructure, AI-driven computing, IoT devices, and advanced medical electronics.

Unlike conventional laminates that buckle under extreme frequencies, this material is engineered to minimize signal loss, improve power efficiency, and maintain structural integrity over time. So, if you’re crafting multi-layer PCB stacks for data centers or designing compact circuits for aerospace applications, this laminate delivers the consistency and precision that today’s high-performance electronics demand.

MEGTRON M R-5735 Laminate vs. Traditional PCB Materials

Not all PCB laminates are cut from the same cloth. Many older materials struggle with high-speed transmission, dielectric loss, and thermal expansion, leading to signal degradation, heat accumulation, and design limitations. Let’s stack MEGTRON M R-5735 Laminate against traditional options and see where it stands:

| Feature | MEGTRON M R-5735 Laminate | Traditional High-Frequency PCB Laminates |

| Dielectric Constant (Dk) | Stable over a wide frequency range | Can fluctuate, affecting signal integrity |

| Dissipation Factor (Df) | Ultra-low, minimizing energy loss | Higher, leading to increased attenuation |

| Thermal Stability | Withstands extreme temperatures | Prone to expansion and material stress |

| Copper Adhesion | Optimized for high-frequency use | Standard bonding, may cause signal issues |

| Manufacturing Precision | Tight tolerances for impedance control | Less predictable, requiring adjustments |

Looking at the numbers, it’s clear that MEGTRON M R-5735 Laminate isn’t just another option—it’s an upgrade.

Electrical and Mechanical Properties of MEGTRON M R-5735 Laminate

When designing high-speed PCBs, knowing the numbers is half the battle. This laminate delivers a combination of low dielectric loss, stable impedance, and superior thermal performance, making it a strong contender for applications where signal fidelity and heat dissipation are non-negotiable.

Key Electrical Properties-

●Dielectric Constant (Dk): Maintains consistency across a broad frequency spectrum, ensuring predictable circuit performance.

●Dissipation Factor (Df): Keeps energy losses to a minimum, reducing unwanted attenuation in high-speed signal paths.

●Low Insertion Loss: Helps maximize transmission efficiency, suitable for 5G antennas, base stations, and data centers.

Mechanical & Thermal Characteristics-

●Thermal Conductivity: Enhances heat dissipation, preventing material degradation in high-power applications.

●Dimensional Stability: Minimizes warping and expansion, allowing precise layer stacking for multi-layer PCB designs.

●High Copper Peel Strength: Ensures reliable bonding between layers, reducing the risk of delamination over time.

When paired with high-performance copper foils, these properties create a robust foundation for cutting-edge PCB layouts, allowing designers to push the envelope without second-guessing material limitations.

Why MEGTRON M R-5735 Laminate is Ideal for Next-Gen PCB Applications?

Electronics aren’t getting simpler—if anything, they’re becoming denser, faster, and more demanding. As we push for higher frequencies and tighter designs, PCB materials must keep up with the game plan.

MEGTRON M R-5735 Laminate is particularly well-suited for:

5G & High-Speed Data Transmission-

●Designed for millimeter-wave (mmWave) signals, reducing unwanted transmission losses.

●Supports massive MIMO, phased arrays, and beamforming technologies without distortion.

●Suitable for base stations, satellite communications, and high-frequency networking equipment.

AI & High-Performance Computing-

●Handles data-heavy processing with stable impedance and heat control.

●Reduces latency in AI accelerators, quantum computing boards, and advanced GPU systems.

●Compatible with multi-layer PCB configurations, enhancing power efficiency and thermal management.

Medical & Aerospace Electronics-

●MEGTRON M R-5735 Laminate provides strong EMI/EMC shielding, making it a solid choice for MRI, CT, and diagnostic imaging systems where signal interference isn’t an option.

●Resistant to moisture absorption, ensuring long-term stability in aerospace environments.

●Maintains high-frequency accuracy, ensuring reliable performance in radar systems, avionics, and deep-space communications.

From telecom leaders to AI innovators, industries need PCB materials built for precision and reliability. If your project demands precision, reliability, and future-ready performance, this laminate is worth a serious look.

The Role of MEGTRON M R-5735 Laminate in High-Speed, Low-Loss PCB Design

High-frequency PCB design is anything but simple. Once you cross into multi-gigabit signal transmission, even minor material inconsistencies can throw off impedance matching, cause signal degradation, or introduce thermal instability. That’s where material selection becomes a real engineering challenge—every layer in the PCB stack influences performance, and there’s no room for guesswork.

MEGTRON M R-5735 Laminate is designed specifically to handle ultra-high-speed digital and RF applications, where low-loss signal transmission and consistent dielectric properties are absolute requirements. Unlike conventional PCB substrates, this material allows for precise impedance control, reduced dielectric variation, and superior high-frequency signal integrity.

Signal Integrity Optimization with MEGTRON M R-5735 Laminate

One of the biggest headaches in high-speed circuit design is maintaining signal integrity across long traces and multi-layer interconnections. As signal speeds increase, propagation delays, reflections, and crosstalk become more pronounced, leading to data corruption and performance instability.

Material Uniformity and Dielectric Stability-

Traditional PCB materials exhibit inconsistent dielectric properties at different frequencies, which can distort signals, especially in differential pairs and high-speed buses. MEGTRON M R-5735 Laminate offers tightly controlled dielectric constants across a broad frequency range, preventing impedance fluctuations and phase mismatches. This is particularly useful in:

●5G mmWave circuits, where phase accuracy is crucial for beamforming.

●AI processor interconnects, where high-speed parallel bus synchronization is necessary.

●Data center network backplanes, which require multi-meter transmission distances with minimal loss.

Surface Roughness and Conductor Loss-

Copper surface roughness is another silent killer in high-speed PCB designs. A rough copper-to-dielectric interface increases skin effect losses, causing unintended resistance and reducing signal amplitude. MEGTRON M R-5735 Laminate is optimized for use with low-profile copper foils, ensuring minimal conductor loss and improved high-frequency performance.

If you’re pushing 28 GHz+ signals, even a slight variation in copper roughness can degrade performance. This laminate sidesteps that issue by maintaining a highly uniform copper-to-substrate interface, reducing skin depth impact and preserving clean signal transmission.

Dielectric Constant & Dissipation Factor – Why It Matters?

Every engineer designing RF, microwave, or high-speed digital circuits knows that dielectric properties dictate PCB performance. If your substrate material can’t maintain a stable dielectric constant (Dk) and low dissipation factor (Df) over the operating frequency, you’ll be dealing with:

●Phase distortion, causing signal delays and timing mismatches.

●Unpredictable impedance variations, leading to increased insertion loss.

●Energy absorption, resulting in excess heat and power loss.

Tightly Controlled Dielectric Properties-

MEGTRON M R-5735 Laminate maintains a consistent Dk across a broad frequency spectrum, ensuring predictable signal propagation and minimal phase distortion. Unlike standard FR-4, which experiences fluctuations in dielectric performance as frequency increases, this material is engineered to provide:

●Lower loss tangents, minimizing signal degradation over longer distances.

●Stable impedance values, reducing the need for excessive design compensation.

●Enhanced heat dissipation, preventing material stress failures in high-power applications.

In RF amplifier circuits, unstable Dk values lead to signal dispersion, which affects modulation accuracy and power efficiency. Similarly, in PCIe 5.0 and 6.0 interconnects, variations in Dk directly impact data eye openings, potentially increasing bit error rates. With MEGTRON M R-5735 Laminate, these concerns are dramatically reduced.

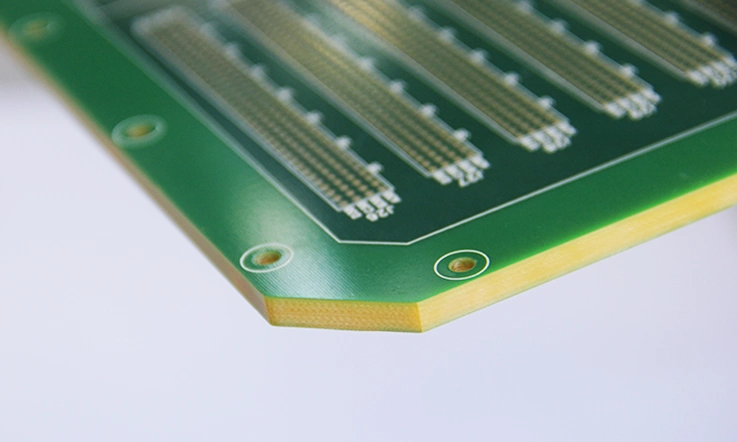

Impedance Control and Layer Stack-Up for High-Frequency Circuits

Why Impedance Consistency is Non-Negotiable-

Once signal speeds exceed 10 GHz, even minor impedance mismatches result in unwanted reflections and standing waves that can cripple circuit performance. The problem gets worse when designing for multi-layer PCBs, where each dielectric layer must maintain exact thickness tolerances to prevent deviations in characteristic impedance.

MEGTRON M R-5735 Laminate allows for precise impedance matching due to its:

●Ultra-low dielectric variation, preventing impedance shifts across different board sections.

●Superior thickness control, ensuring layer stack-up consistency.

●Optimized resin content, allowing for precise etching and via reliability.

This makes it particularly effective for:

●High-speed differential pair routing (PCIe, USB4, 112G SerDes).

●Microwave filters and antennas, where precise impedance matching is required.

●Multilayer RF modules, where signal stacking must be tightly controlled.

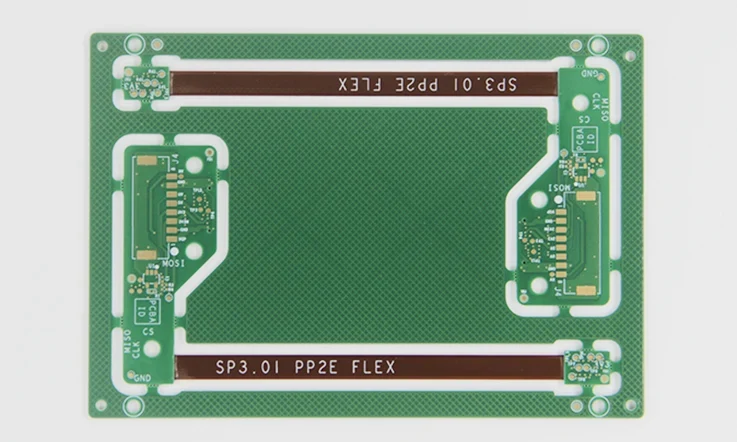

Optimizing Layer Stack-Ups for RF and High-Speed Applications-

Getting the stack-up right is half the battle in high-frequency PCB design. A poorly planned dielectric arrangement can result in excessive losses, EMI issues, and poor power distribution. MEGTRON M R-5735 Laminate’s low-loss dielectric properties enable advanced stack-up configurations, such as:

●Alternating signal and ground planes, reducing crosstalk and return path discontinuities.

●Embedded capacitance layers, lowering impedance for power integrity improvements.

●Dielectric smoothing techniques, enhancing high-frequency wave propagation.

For designers working on RF front-end modules, automotive radar systems, and next-gen wireless base stations, these advantages translate to better efficiency, improved thermal management, and more robust signal transmission.

Optimizing PCB Design with MEGTRON M R-5735 Laminate – Best Practices

High-performance electronics demand precision engineering, especially when working with high-speed signals, thermal management challenges, and extreme environmental conditions. MEGTRON M R-5735 Laminate is built to support the most demanding PCB designs, offering low signal loss, stable dielectric properties, and excellent thermal resistance. However, simply choosing the right laminate isn’t enough—proper design strategies ensure that the full potential of MEGTRON M R-5735 is realized.

From stack-up configurations to heat dissipation techniques and long-term durability considerations, let’s explore best practices that will elevate your PCB performance.

Layer Stack-Up Design Strategies for High-Speed Digital Circuits

PCB stack-up design isn’t just about arranging layers—it’s about optimizing impedance control, minimizing crosstalk, and ensuring signal integrity at high frequencies. MEGTRON M R-5735 provides a stable dielectric constant, making it well-suited for high-speed applications.

Balancing Signal and Power Layers-

A well-structured stack-up ensures low EMI, consistent impedance, and minimal signal degradation. Here’s an example of an optimized 8-layer stack-up using MEGTRON M R-5735 for a high-speed digital circuit:

| Layer | Function | Description |

| L1 | Signal Layer (Top) | High-speed differential pairs with impedance control |

| L2 | Ground Plane | Solid reference plane for signal integrity |

| L3 | Inner Signal Layer | Controlled impedance traces for data transmission |

| L4 | Power Plane | Isolated power distribution to reduce noise |

| L5 | Power Plane | Additional power reference for multi-voltage designs |

| L6 | Inner Signal Layer | High-speed bus routing with minimal stubs |

| L7 | Ground Plane | Solid return path for low-noise operation |

| L8 | Signal Layer (Bottom) | Low-speed and control signals |

This configuration ensures a strong return path, minimizes impedance discontinuities, and keeps signal losses under control—main factors when dealing with 10Gbps+ data rates.

Avoiding Signal Integrity Pitfalls-

●Keep differential pairs tightly coupled to maintain consistent impedance.

●Route high-speed signals on inner layers when possible to reduce radiation and external noise coupling.

●Use wide ground planes to ensure a stable return path and prevent unwanted reflections.

By leveraging these techniques, we can take full advantage of MEGTRON M R-5735’s electrical properties for high-speed PCB designs.

Thermal Management and Heat Dissipation Solutions

With increased power densities in modern PCBs, heat dissipation is a major concern. MEGTRON M R-5735’s high thermal decomposition temperature (Td) and low dielectric loss help manage thermal performance, but proper design strategies further enhance heat regulation.

Spreading Heat Efficiently-

Efficient heat dissipation begins with material selection and layout optimization. Consider the following heat management techniques:

| Technique | Implementation | Impact |

| Thermal Vias | Placing vias under hot components | Transfers heat to inner layers and ground planes |

| Copper Heat Spreaders | Using thick copper layers (2oz or more) | Improves conduction across PCB |

| Embedded Heat Pipes | Integrating vapor chambers or heat pipes | Moves heat away from localized hotspots |

| Thermal Interface Materials (TIMs) | Applying TIMs under IC packages | Enhances heat transfer to PCB |

For power-intensive applications like 5G base stations or AI accelerators, a combination of these techniques ensures thermal stability, preventing performance degradation over time.

Ensuring Long-Term Reliability in Harsh Operating Environments

PCB materials don’t just need to perform well under lab conditions—they need to maintain reliability in real-world scenarios involving temperature fluctuations, humidity, and mechanical stress. MEGTRON M R-5735 offers excellent long-term stability, but implementing the right design practices further extends operational lifespan.

Protecting Against Thermal Cycling and Expansion-

Repeated thermal cycling can lead to mechanical stress, causing microcracks or delamination. Consider these design strategies to improve resilience:

●Match the coefficient of thermal expansion (CTE) between PCB materials and components to prevent warping.

●Use reinforced via structures such as stacked vias instead of single vias for critical connections.

●Apply conformal coatings or underfill materials for added protection in high-humidity environments.

Moisture and Chemical Resistance-

In industrial, aerospace, and automotive applications, PCBs are often exposed to moisture and contaminants. MEGTRON M R-5735 has a low moisture absorption rate of 0.05%, significantly reducing the risk of electrical failures due to humidity ingress. However, additional safeguards like plasma surface treatments and hydrophobic coatings can provide extra protection.

Mechanical Durability for High-Vibration Environments-

For applications in aerospace, automotive, and heavy machinery, PCBs must withstand constant vibration and mechanical stress. Reinforcing solder joints with corner bonding or underfill materials prevents component detachment over time.

| Environmental Factor | Impact on PCB | Design Solution |

| High Temperature | Material degradation | Use MEGTRON M R-5735 for stability above 400°C Td |

| Vibration/Shock | Solder joint failure | Reinforce components with underfill |

| Humidity | Corrosion, short circuits | Apply hydrophobic conformal coatings |

By implementing these best practices, MEGTRON M R-5735-based PCBs remain robust and reliable, even in the most demanding environments.

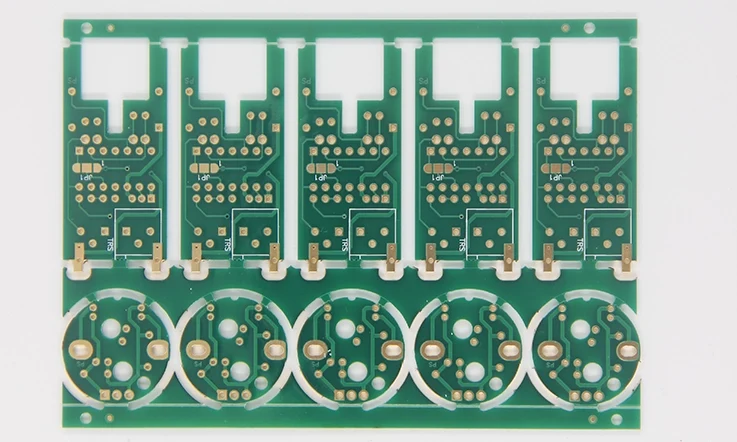

PCB Fabrication and Processing Considerations for MEGTRON M R-5735 Laminate

When it comes to high-frequency PCB manufacturing, material selection is just the starting point. The real performance comes down to precision in fabrication techniques, from copper adhesion to high-density interconnect (HDI) structures.

MEGTRON M R-5735 Laminate offers low dielectric loss, high thermal stability, and excellent adaptability for advanced PCB designs. However, to truly maximize its potential, process optimization is a must. This section covers copper foil adhesion, lamination techniques, and HDI via design challenges, with data-driven insights to support decision-making in PCB fabrication.

Copper Foil Adhesion and Surface Roughness Optimization

How Does Copper Roughness Affect High-Frequency Signal Transmission?

In high-frequency PCB applications, copper surface roughness directly impacts signal integrity. Too much roughness boosts conductor loss, hindering high-speed performance.

For MEGTRON M R-5735 Laminate, low-profile (LP) or hyper-low-profile (HVLP) copper foil is recommended. Below is a comparison of different copper foil types and their impact on signal transmission:

| Copper Foil Type | Surface Roughness (Ra, µm) | Frequency Suitability | Characteristics |

| Rolled Annealed (RA) | 0.4 – 0.6 | <5 GHz | Strong adhesion but higher loss |

| Low-Profile (LP) | 0.2 – 0.4 | 5-40 GHz | Reduced loss, good for high-speed PCBs |

| Hyper-Low-Profile (HVLP) | <0.2 | 40 GHz+ | Best for 5G, AI accelerators, and low-loss applications |

Optimization Tips:

●Use HVLP copper to minimize conductor loss at high frequencies.

●Apply oxide alternative treatments to enhance adhesion between copper and MEGTRON M R-5735 Laminate.

●Maintain strict chemical cleaning processes to prevent contaminants from reducing bond strength.

Lamination Techniques for High-Performance PCB Manufacturing

How Does the Lamination Process Impact PCB Reliability?

MEGTRON M R-5735 Laminate uses an advanced resin system, making temperature, pressure, and heating rate main factors in lamination to ensure uniform bonding and minimal defects.

The table below highlights main lamination parameters and their effects on PCB quality:

| Lamination Parameter | Recommended Range | Impact on PCB Quality |

| Lamination Temperature | 180 – 220°C | Too low reduces flow, too high may over-cure resin |

| Heating Rate | 1.5 – 3.0°C/min | Too fast induces stress, too slow may cause incomplete curing |

| Pressure | 2 – 4 MPa | Too low causes voids, too high leads to resin squeeze-out |

| Vacuum Processing Time | 20 – 30 min | Removes trapped air, improves layer adhesion |

Optimization Tips:

●Implement multi-stage heating profiles to ensure uniform resin distribution.

●Use vacuum-assisted lamination to eliminate voids and enhance bonding strength.

●For HDI layout, sequential lamination improves alignment precision.

High-Density Interconnect (HDI) and Via Design Challenges

How Does Via Design Impact High-Speed Signal Integrity?

For advanced HDI PCB structures, MEGTRON M R-5735 Laminate’s low thermal expansion coefficient (CTE) makes it an excellent fit for stacked microvias and buried/blind vias.

The table below compares different via fabrication methods and their suitability for high-frequency applications:

| Via Type | Diameter Range | Frequency Suitability | Characteristics |

| Mechanical Drilling | ≥100 µm | <5 GHz | Cost-effective, but limited for HDI designs |

| CO₂ Laser Drilling | 50 – 100 µm | 5-40 GHz | Suitable for HDI, requires high resin absorption |

| UV Laser Drilling | 30 – 50 µm | 40 GHz+ | High precision, best for 5G, AI, and IoT PCBs |

Optimization Tips:

●Use UV laser drilling for improved via quality and reduced signal distortion.

●Implement staggered microvia stacking to minimize stress and improve electrical reliability.

●Optimize electroplating processes to ensure uniform copper deposition and prevent open circuits.

Comparing MEGTRON M R-5735 Laminate with Other High-Performance PCB Laminates

High-frequency and high-speed digital applications demand PCB laminates that minimize signal loss, maintain thermal stability, and support advanced circuit designs. Choosing the right material isn’t just about electrical properties—it’s also about manufacturability, cost-effectiveness, and long-term reliability. MEGTRON M R-5735 Laminate is often stacked against industry-leading materials like Rogers, Isola, and other RF laminates. Let’s break down the differences and see where MEGTRON M R-5735 stands in the competition.

MEGTRON M R-5735 Laminate vs. Rogers, Isola, and Other RF Laminates

Not all PCB laminates are created equal, and each material comes with its own advantages in terms of dielectric properties, thermal performance, and processing characteristics. Here’s a head-to-head comparison of MEGTRON M R-5735 with other popular laminates.

Electrical Performance-

When designing for high-speed communication, RF circuits, or 5G infrastructure, dielectric constant (Dk) and dissipation factor (Df) dictate how efficiently signals propagate. Lower values for both mean reduced signal attenuation, which is a big deal for advanced electronics.

| Laminate | Dielectric Constant (Dk) @ 10 GHz | Dissipation Factor (Df) @ 10 GHz | Moisture Absorption (%) | Thermal Decomposition (Td, °C) |

| MEGTRON M R-5735 | 3.3 | 0.002 | 0.05 | 410 |

| Rogers RO4350B | 3.48 | 0.0037 | 0.06 | 390 |

| Isola Astra MT77 | 3.0 | 0.0017 | 0.02 | 400 |

| Taconic RF-35 | 3.5 | 0.0025 | 0.06 | 360 |

From the numbers, MEGTRON M R-5735 delivers strong performance in dielectric properties, staying competitive with Rogers and Isola while offering better thermal resistance than most alternatives.

Thermal and Mechanical Properties-

For PCB manufacturers, maintaining stability under thermal stress is just as necessary as achieving strong electrical performance. MEGTRON M R-5735 features a higher decomposition temperature (Td) than many competitors, ensuring durability in multilayer PCBs exposed to repeated thermal cycling.

Another overlooked factor is moisture absorption. A lower percentage means the laminate is less susceptible to environmental humidity, which directly impacts long-term dielectric stability. MEGTRON M R-5735’s ultra-low absorption rate gives it an edge in applications where performance degradation over time is a concern.

Price-to-Performance Ratio for Different Industry Applications

Choosing a PCB laminate isn’t just about raw specs—it’s also about getting the best return on investment based on your industry’s needs. Let’s break it down for different applications:

| Industry | Performance Needs | Preferred Laminates | Cost Considerations |

| 5G Infrastructure | Low loss, high-frequency support, thermal stability | MEGTRON M R-5735, Rogers RO4350B | MEGTRON M R-5735 offers a balance of performance and affordability |

| Aerospace & Defense | Extreme thermal cycling, mechanical durability | Isola Astra MT77, Taconic RF-35 | Astra MT77 excels in ultra-low loss but comes at a premium price |

| Automotive Radar | High-reliability, low moisture absorption | MEGTRON M R-5735, Rogers RO4835 | MEGTRON M R-5735 offers better thermal stability than RO4835 |

| High-Speed Computing | Signal integrity, low Df | MEGTRON M R-5735, Isola I-Speed | MEGTRON M R-5735 competes well while being easier to manufacture |

For companies looking to maximize performance while keeping costs under control, MEGTRON M R-5735 provides an excellent balance—delivering the electrical and thermal properties needed for high-frequency applications without the premium price tag of some competitors.

Future Trends in High-Speed, Low-Loss PCB Materials

The world of PCB materials is constantly evolving to keep pace with emerging technologies like AI, IoT, and next-gen telecommunications. Here’s where the industry is headed:

1. Lower Loss, Higher Frequency Capability

As data rates push beyond 100Gbps, loss characteristics at millimeter-wave frequencies are becoming the defining factor in PCB material selection. Expect future laminates to feature even lower dissipation factors while maintaining robust thermal stability. MEGTRON M R-5735 is already optimized for these conditions, but continuous refinements in resin formulations will further improve signal integrity.

2. Improved Processability for HDI & Advanced Packaging

As high-performance computing and mobile devices push for smaller designs, PCB materials must accommodate finer lines and smaller vias while maintaining reliability. Upcoming advancements will refine adhesion, via plating compatibility, and manufacturability—areas where MEGTRON M R-5735 is already well-suited.

3. Eco-Friendly PCB Materials

Regulatory pressures and sustainability initiatives are pushing human to reduce the environmental footprint of PCB production. This means lower VOC emissions, halogen-free formulations, and improved recyclability. While MEGTRON M R-5735 meets current industry standards, next-generation laminates will likely introduce new resin technologies to minimize ecological impact.

MEGTRON M R-5735 Laminate for 5G, AI, and IoT Applications

The push for higher data rates, lower latency, and greater device connectivity is reshaping the way PCBs are designed. 5G networks, AI accelerators, and IoT hardware demand materials that can handle multi-gigabit signal speeds, thermal fluctuations, and electromagnetic noise without compromise.

For us working on next-gen telecommunications, edge computing, or ultra-low-power IoT devices, choosing the right laminate isn’t just about mechanical durability—it directly impacts signal performance, power efficiency, and long-term reliability.

MEGTRON M R-5735 Laminate is engineered to address the challenges of high-frequency, high-density PCB layouts, making it a top-tier choice for designers working on 5G base stations, AI hardware, and IoT edge computing modules. Let’s break down exactly how this material stacks up in real-world applications.

How MEGTRON M R-5735 Laminate Enhances 5G PCB Design?

5G isn’t just another step up from 4G—it’s an entirely different ball game. Millimeter-wave (mmWave) frequencies, massive MIMO antenna arrays, and ultra-low-latency networking demand a level of PCB precision that traditional materials struggle to provide.

High-Frequency Signal Stability-

5G signals operate at sub-6 GHz and mmWave bands (24 GHz – 100 GHz), where even the smallest dielectric variations or conductor losses can introduce serious signal degradation. MEGTRON M R-5735 Laminate provides:

●Consistent dielectric properties across wide frequency ranges, ensuring uniform propagation speeds.

●Low dissipation factor (Df) to minimize energy absorption, preserving signal strength.

●Optimized loss performance, reducing the impact of skin effect and dielectric attenuation.

For engineers designing 5G small cells, baseband processing units, and phased array antennas, this means fewer signal dropouts, better beamforming precision, and higher overall network efficiency.

Thermal Performance Under High Power Loads-

5G network hardware doesn’t just push the limits of speed—it generates substantial heat due to the high power amplification and dense component integration. MEGTRON M R-5735 Laminate offers:

●Stable thermal expansion coefficients, preventing mechanical stress in multi-layer PCBs.

●High glass transition temperature (Tg), reducing performance shifts at elevated temperatures.

●Exceptional moisture resistance, ensuring durability in outdoor 5G infrastructure facing extreme conditions.

This makes it particularly effective in massive MIMO base station PCBs, where power levels can exceed tens of watts per channel and traditional FR-4 laminates would fail over time.

AI & IoT Hardware Optimization with MEGTRON M R-5735 Laminate

The AI and IoT revolutions are fueled by edge computing, ultra-low-latency processing, and AI acceleration hardware that depend on high-speed interconnects, multi-layer PCBs, and dense routing configurations. MEGTRON M R-5735 Laminate is specifically suited for:

●High-bandwidth AI accelerators, such as GPUs, TPUs, and custom ASICs.

●Embedded IoT sensors, requiring reliable wireless communication in compact PCB layouts.

●Low-power, high-speed networking hardware, such as industrial IoT gateways and edge servers.

Signal Integrity for AI Accelerators and High-Speed Interconnects-

AI workloads demand extreme data throughput, meaning interconnects like PCIe Gen5, HBM (High Bandwidth Memory), and high-speed SerDes must function with near-zero loss and jitter. MEGTRON M R-5735 Laminate ensures:

●Stable impedance across high-speed differential pairs, reducing reflections and timing errors.

●Minimized insertion loss, extending signal reach without requiring excessive equalization.

●Controlled layer stack-ups, ensuring clean power and signal distribution.

For AI engineers developing deep-learning processors and edge inference chips, these factors translate to more efficient AI model execution and reduced power consumption per inference.

Wireless Performance in IoT Sensor Networks-

IoT devices often operate in wireless frequency bands such as 2.4 GHz, 5 GHz, and sub-GHz ISM bands. Signal degradation due to PCB material inconsistencies can limit range and increase power draw—both of which are deal-breakers in battery-operated IoT devices. MEGTRON M R-5735 Laminate helps by:

●Minimizing RF signal distortion, improving link reliability for long-range communication.

●Reducing EMI susceptibility, ensuring stable operation in crowded RF environments.

●Lowering dielectric losses, optimizing power efficiency in low-power IoT nodes.

This is particularly beneficial for smart city sensors, industrial automation modules, and medical wearables, where every milliwatt of power is considered.

Reducing Electromagnetic Interference (EMI) in High-Speed Applications

As circuit speeds increase, so do EMI-related headaches. High-speed switching generates unintended radiation, affecting nearby circuits and potentially violating FCC and CE compliance standards. MEGTRON M R-5735 Laminate is engineered to combat EMI at its root cause.

Material-Based EMI Suppression-

Unlike conventional laminates, which require extensive shielding techniques, MEGTRON M R-5735 Laminate offers:

●Uniform dielectric constant, reducing impedance mismatches that contribute to radiated emissions.

●Low-loss characteristics, preventing excessive harmonics and signal distortion.

●Enhanced interlayer bonding, ensuring solid ground plane connections for better shielding.

For high-speed Ethernet switches, aerospace radars, and automotive ADAS systems, these properties result in cleaner signal transmission, fewer EMI issues, and reduced compliance testing failures.

Reducing Crosstalk in High-Density PCB Layouts-

With the increasing complexity of multi-layer PCBs, designers must contend with crosstalk between adjacent traces, which can severely impact signal quality. MEGTRON M R-5735 Laminate minimizes this risk by:

●Supporting thinner dielectric layers, enabling better ground plane separation for signal isolation.

●Reducing propagation delay mismatches, ensuring synchronized signal transmission.

●Allowing precise etching control, improving trace geometry accuracy.

This is particularly beneficial in 112G PAM4 backplanes, automotive radar PCBs, and RF front-end modules, where even minimal crosstalk may impact signal fidelity.

MEGTRON M R-5735 Laminate for Medical Devices and Wearable Technology

Medical electronics have evolved significantly—from large room-sized imaging systems to compact, wearable sensors that monitor physiological data in real time. Whether it’s advanced MRI and CT scanner circuitry or flexible PCBs in modern health wearables, the selection of PCB laminate directly affects the design outcome.

Medical-grade printed circuit boards require reliable signal integrity, low dielectric loss, and high resistance to environmental stress. We working on diagnostic imaging, patient monitoring, and surgical robotics can’t afford to gamble on materials that degrade over time or fail under thermal and mechanical stress.

MEGTRON M R-5735 Laminate is engineered for these exact challenges. With its low-loss properties, high thermal stability, and long-term durability, this material supports high-frequency medical imaging systems and compact wearable health monitors alike. Let’s break down exactly how this laminate fits into the evolving world of medical electronics.

High-Reliability PCB Solutions for MRI, CT Scanners, and Medical Sensors

Modern medical imaging devices depend on precise, high-speed signal processing to deliver clear, accurate diagnostics. MRI, CT, and ultrasound systems utilize high-frequency radio signals to generate detailed images of internal structures, demanding low-loss PCB materials to prevent signal degradation.

Minimizing Signal Loss in High-Frequency Medical Imaging Systems-

MRI and CT scanners operate in the RF spectrum, often within 64 MHz to 400 MHz for MRI and several gigahertz for high-resolution CT. Any loss in signal integrity can introduce noise and artifacts, reducing diagnostic accuracy. MEGTRON M R-5735 Laminate ensures:

●Stable dielectric properties, preserving signal consistency across the PCB.

●Low dissipation factor (Df) to reduce energy absorption, maintaining strong RF signals.

●Controlled impedance, preventing distortion in high-density interconnects (HDI) and microstrip transmission lines.

For imaging systems that require high-speed analog-to-digital conversion, PCBs built with MEGTRON M R-5735 Laminate help reduce latency and jitter, ensuring sharper image resolution and faster scan times.

Withstanding Heat and Mechanical Stress in Medical Environments-

CT scanners and high-power MRI machines generate significant electromagnetic fields and heat. Standard PCB laminates can suffer from thermal expansion mismatch, leading to mechanical failure or signal drift over time. MEGTRON M R-5735 Laminate addresses this with:

●High glass transition temperature (Tg), ensuring structural integrity at elevated temperatures.

●Low coefficient of thermal expansion (CTE), reducing the risk of layer delamination.

●Excellent moisture resistance, preventing performance degradation in sterile and humidity-controlled environments.

For hospital-grade imaging systems, this means longer operational lifespans and reduced maintenance cycles, translating to greater reliability for healthcare providers and patients alike.

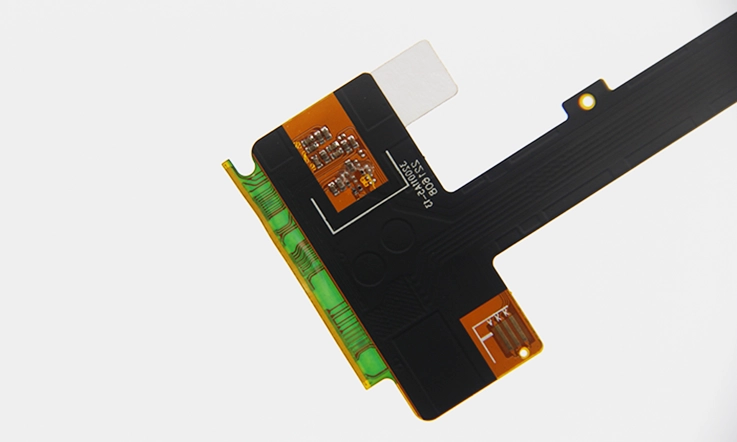

MEGTRON M R-5735 Laminate in Wearable and Portable Medical Electronics

The rise of wearable health monitors, remote patient tracking devices, and point-of-care diagnostic tools is transforming healthcare delivery. Unlike traditional medical equipment, these devices must balance high performance with ultra-compact, lightweight form factors—all while ensuring long battery life and consistent wireless connectivity.

Optimized Performance for Compact, Low-Power Wearable Devices-

From continuous glucose monitors (CGMs) to ECG patches and fitness trackers, today’s wearables require PCBs that can handle miniaturization and flexible layouts. MEGTRON M R-5735 Laminate supports:

●Ultra-thin dielectric layers, allowing higher circuit density for compact designs.

●Stable electrical properties across a wide frequency range are beneficial for Bluetooth Low Energy (BLE), NFC, and Wi-Fi modules.

●Minimal power loss, extending battery runtime in energy-sensitive medical wearables.

For many company of implantable and body-worn devices, these characteristics help deliver higher accuracy and longer operational life, making medical wearables more effective and user-friendly.

Enhancing Wireless Communication and Sensor Accuracy-

Wearable medical devices rely on low-power RF transmissions to send real-time health data to external receivers. Fluctuations in PCB material properties can disrupt wireless performance, leading to data loss or reduced transmission range. MEGTRON M R-5735 Laminate helps avoid these issues by:

●Providing consistent impedance matching, optimizing antenna efficiency.

●Reducing RF signal attenuation, maintaining clear connectivity in hospital and home-care environments.

●Offering superior EMI shielding, preventing signal interference from nearby medical equipment.

For AI-powered health monitors and wireless biosensors, these benefits translate to more reliable remote diagnostics and continuous patient tracking.

Biocompatibility and Long-Term Performance Considerations

Medical electronics don’t just need to function—they need to last. Devices used in critical care, surgical applications, and implantable technologies must meet strict biocompatibility and durability standards to ensure safety and effectiveness over time.

Material Stability for Long-Term Medical Use-

Medical devices are subject to repeated sterilization cycles, mechanical stress, and exposure to bodily fluids. MEGTRON M R-5735 Laminate is designed to withstand:

●Chemical exposure from sterilization processes, including autoclaving and gamma radiation.

●Long-term mechanical flexing, suitable for flexible hybrid electronics (FHE) used in skin-contact wearables.

●Low outgassing characteristics, preventing contamination in implantable and high-purity medical applications.

For manufacturers developing next-gen medical devices, these material properties help extend product lifespan and reduce device failures in clinical settings.

Meeting Regulatory and Compliance Standards-

Medical PCB materials must adhere to strict regulatory requirements, including:

●ISO 10993 biocompatibility testing, ensuring safe interaction with human tissue.

●FDA and CE compliance for medical electronics, verifying electrical safety and performance.

●RoHS and REACH certifications, preventing hazardous substance contamination.

By using a laminate that already meets high-reliability electronics standards, we can streamline the certification process and bring medical innovations to market faster.

MEGTRON M R-5735 Laminate – FAQ

1.How does MEGTRON M R-5735 compare to PTFE-based laminates in RF applications?

While PTFE laminates offer extremely low loss, MEGTRON M R-5735 provides better mechanical stability and easier processing, making it a strong alternative for mixed-signal and multilayer designs.

2.Is MEGTRON M R-5735 suitable for flexible or rigid-flex PCB designs?

No, MEGTRON M R-5735 is designed for rigid PCBs and is not intended for flexible circuit applications.

3.What is the maximum operating temperature for MEGTRON M R-5735?

It has a Tg (glass transition temperature) of approximately 185°C and can withstand high-temperature reflow soldering processes.

4.Does MEGTRON M R-5735 require special surface treatments for plating and soldering?

Standard oxide or oxide alternative treatments are recommended to ensure good copper adhesion, but it does not require exotic processing techniques.

5.What is the moisture absorption rate of MEGTRON M R-5735?

It has an exceptionally low moisture absorption of 0.05%, making it ideal for humid or high-moisture environments.

6.Is MEGTRON M R-5735 RoHS and REACH compliant?

Yes, it meets environmental compliance standards and does not contain hazardous substances restricted under RoHS or REACH regulations.