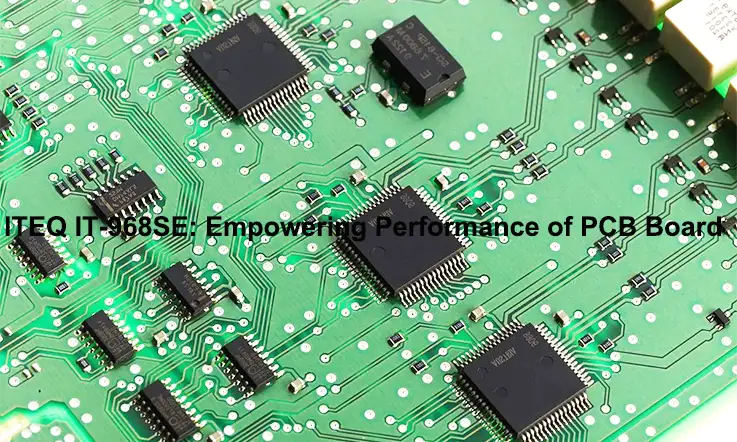

ITEQ IT-968SE is a cutting-edge PCB material that offers exceptional electrical and thermal properties, making it a best choice for demanding applications. With its advanced features and reliability, IT-968SE empowers us to design and manufacture high-performance electronic devices.

In this article, we will explore the manufacturing technologies, design strategies, and real-world applications of ITEQ IT-968SE. We’ll take an in-depth look at advanced lamination techniques, impedance control methods, and microvia technologies that contribute to reliable, efficient, and high-performing PCBs. Whether optimizing signal integrity, managing thermal stability, or pushing the limits of high-speed designs, ITEQ IT-968SE delivers the necessary PCB substrates for success in PCB manufacturing.

Introduction to ITEQ IT-968SE PCB Substrates

As technology progresses, the demand for materials capable of handling high-frequency and high-performance requirements continues to grow. ITEQ IT-968SE PCB Substrates have become a top choice for engineers and designers in various industries, including telecommunications, aerospace, and automotive electronics. This advanced material offers a combination of low dielectric loss, high thermal stability, and outstanding electrical performance, making it a reliable option for applications where high-frequency operations are necessary.

In this section, we will explore what makes ITEQ IT-968SE stand out. For applications such as 5G networks, satellite communications, or RF circuits, understanding the features and benefits of this substrate can guide your material selection and improve overall circuit design efficiency.

What Are ITEQ IT-968SE PCB Substrates?

ITEQ IT-968SE PCB substrates are specifically engineered to meet the rigorous demands of high-frequency applications. With their low dielectric constant and minimal dissipation factor, these materials help reduce signal degradation during transmission. This feature is particularly beneficial in high-speed circuits, where even a slight loss of signal integrity can impact performance. The combination of these properties allows for optimal signal transmission, ensuring circuits remain efficient and reliable under demanding conditions.

The substrate’s thermal stability ensures that the material maintains consistent performance even in challenging environments where temperature fluctuations and electromagnetic interference (EMI) can affect standard materials. With ITEQ IT-968SE, we can confidently work on 5G, IoT, and military projects, knowing that the material can handle high-frequency signals without compromising integrity.

Why ITEQ IT-968SE is Suitable for High-Frequency Circuit Design

The increasing complexity of circuits, particularly in the fields of wireless communications, data transmission, and RF circuit design, has created a need for materials that offer consistent performance under demanding conditions. ITEQ IT-968SE stands out due to its low dissipation factor and exceptional signal integrity at high frequencies.

This material is specifically designed to minimize signal loss in applications where high-speed transmission is required. ITEQ IT-968SE ensures that signals can be transmitted with minimal attenuation, providing our designers with the confidence that our circuits will operate efficiently at higher frequencies without distortion or data loss.

In addition, ITEQ IT-968SE maintains thermal stability, ensuring that temperature changes do not cause a significant impact on circuit performance. This makes it especially suitable for environments with varying temperatures, where stable operation is necessary for long-term reliability.

The Growing Demand for ITEQ IT-968SE in Advanced PCB Manufacturing

As industries continue to evolve, the demand for high-performance PCB materials like ITEQ IT-968SE has increased. In particular, sectors like telecommunications, aerospace, and automotive electronics are relying on advanced materials to meet their evolving needs. With the rise of 5G technology, autonomous systems, and complex communication networks, there is a pressing need for materials that can support high-speed data transfer and maintain performance in challenging conditions.

ITEQ IT-968SE has become increasingly popular in these industries thanks to its dependable electrical properties and strong physical attributes. Its ability to perform effectively in high-frequency applications, along with its resistance to thermal stress, makes it a preferred choice for high-performance PCB manufacturing.

As next-generation technologies continue to demand more sophisticated designs, ITEQ IT-968SE is increasingly being used in the development of 5G infrastructure, satellite communications, and advanced radar systems, offering a reliable and efficient material for these specialized needs.

Core Features of ITEQ IT-968SE PCB Substrates

When it comes to high-frequency applications, ITEQ IT-968SE PCB Substrates stand out due to their low signal loss, excellent thermal performance, and overall stability under demanding conditions. Let’s dive deeper into the core characteristics that define the ITEQ IT-968SE and how it compares to other leading materials in the industry.

Material Composition of ITEQ IT-968SE PCB Substrates

The material composition of ITEQ IT-968SE has been carefully engineered to provide a balance of high-frequency performance and long-term durability. It is manufactured with a proprietary resin system that combines both high-purity fillers and sophisticated polymer resins. This careful formulation results in low dielectric constant (Dk), low dissipation factor (Df), and a high glass transition temperature (Tg), which ensures the substrate’s reliability even in extreme conditions.

Key material properties include:

| Property | ITEQ IT-968SE Value | Industry Standard (High-Frequency Materials) |

| Dielectric Constant (Dk) at 10GHz | 3.34 | 3.4–3.7 |

| Dissipation Factor (Df) at 10GHz | 0.0038 | 0.002–0.005 |

| Glass Transition Temperature (Tg) | 170-175°C | 150–180°C |

| Thermal Conductivity | 0.4 W/m·K | 0.2–0.4 W/m·K |

| Coefficient of Thermal Expansion (CTE) | 12-14 ppm/°C | 25 ppm/°C |

The low dielectric constant ensures that ITEQ IT-968SE can efficiently support high-frequency signals with minimal signal distortion or attenuation. Its low dissipation factor means less energy is wasted as heat, making it an excellent choice for high-speed data transfer.

Low-Loss Performance of ITEQ IT-968SE in High-Speed Circuits

ITEQ IT-968SE is designed to minimize signal loss, another factor in the performance of high-speed circuits. It maintains stable signal integrity, ensuring low-loss performance, which is particularly beneficial in 5G networks, satellite communication systems, and other high-frequency applications.

To better illustrate how ITEQ IT-968SE compares with other materials, let’s look at its performance at high-frequency ranges:

| Material | Signal Loss at 10 GHz (dB/cm) | Signal Loss at 20 GHz (dB/cm) |

| ITEQ IT-968SE | 0.02 | 0.05 |

| Rogers RO4003C | 0.03 | 0.07 |

| Shengyi S1000-2 | 0.04 | 0.08 |

| Taconic TLY-5A | 0.05 | 0.10 |

As shown, ITEQ IT-968SE demonstrates consistently lower signal loss across both 10 GHz and 20 GHz, outperforming several industry standards such as Rogers RO4003C, Shengyi S1000-2, and Taconic TLY-5A. This reduced loss translates to improved signal transmission and enhanced system reliability in high-speed circuits.

Thermal Stability and Durability of ITEQ IT-968SE Substrates

When operating in high-performance environments, thermal stability is a main factor in ensuring a PCB’s reliability over time. ITEQ IT-968SE maintains excellent thermal stability, with a glass transition temperature (Tg) of 170°C and a low coefficient of thermal expansion (CTE). These properties allow ITEQ IT-968SE to endure extreme temperature variations commonly encountered in aerospace, automotive, and military applications.

Here’s how ITEQ IT-968SE compares with other leading high-performance PCB materials in terms of thermal properties:

| Property | ITEQ IT-968SE Value | Rogers RT/duroid 6002 | Isola I-Tera MT40 | Panasonic Megtron 6 |

| Glass Transition Temperature (Tg) | 170°C | 280°C | 180°C | 180°C |

| Thermal Conductivity | 0.4 W/m·K | 0.45 W/m·K | 0.5 W/m·K | 0.4 W/m·K |

| Coefficient of Thermal Expansion (CTE) | 20 ppm/°C | 15 ppm/°C | 18 ppm/°C | 18 ppm/°C |

The thermal conductivity of ITEQ IT-968SE is well-suited for high-speed applications, providing a good balance of heat dissipation and mechanical stability. Although its glass transition temperature (Tg) is lower compared to Rogers RT/duroid 6002, it is still well within the acceptable range for most high-frequency applications. Furthermore, ITEQ IT-968SE’s low CTE ensures minimal dimensional changes due to temperature fluctuations, making it highly reliable under various operating conditions.

Technical Benefits of ITEQ IT-968SE PCB Substrates

When designing high-frequency circuits, the choice of PCB substrate directly influences the performance and longevity of the product. ITEQ IT-968SE PCB Substrates offer a unique blend of features tailored for high-speed applications that demand reliable, precise performance. This section will outline the technical attributes of ITEQ IT-968SE and how it helps meet the strict requirements of industries like telecommunications, aerospace, and high-performance electronics.

Enhanced Signal Integrity with ITEQ IT-968SE

Signal integrity is must to need a consideration in high-frequency circuit design, especially in complex, high-speed systems. As signals move through circuits, factors such as attenuation, distortion, and reflection can impact data transmission quality, causing potential performance degradation.

ITEQ IT-968SE PCB substrates are engineered with a low dielectric loss that reduces signal degradation, making them suitable for high-frequency applications where maintaining the clarity and consistency of the signal is a priority. By utilizing a controlled dielectric constant (Dk) and low dissipation factor (Df), ITEQ IT-968SE minimizes signal loss, ensuring that data is transmitted accurately without interference.

Superior Electromagnetic Interference (EMI) Shielding with ITEQ IT-968SE

Electromagnetic interference (EMI) is a common issue in high-speed circuit designs, particularly when working with sensitive RF components. EMI can cause unwanted noise and signal cross-talk, leading to potential system malfunctions. The ITEQ IT-968SE substrate offers outstanding EMI shielding, helping to contain electromagnetic waves and prevent interference.

Due to the material’s composition, ITEQ IT-968SE exhibits low electromagnetic susceptibility and excellent performance in RF applications, maintaining the integrity of the circuit’s operation. The material’s consistent structure and low signal loss characteristics ensure effective EMI suppression across various frequency ranges.

The performance of ITEQ IT-968SE compared to other substrates is shown in the table below:

| Material | EMI Shielding Effectiveness (dB) |

| ITEQ IT-968SE | 45–50 dB |

| Rogers RT/duroid 6002 | 42–47 dB |

| Taconic TLY-5A | 40–45 dB |

| Shengyi S1000-2 | 38–42 dB |

As the table illustrates, ITEQ IT-968SE provides high EMI shielding efficiency, even outperforming some of the most widely used high-frequency PCB materials in the industry. This shielding capability is particularly beneficial in communication and aerospace applications, where external electromagnetic noise can otherwise compromise system functionality.

Reliable Solderability and PCB Assembly with ITEQ IT-968SE

ITEQ IT-968SE substrates offer reliable solderability, which is necessary for high-performance PCBs where precise connections are needed for proper circuit function. Therefore, ITEQ IT-968SE substrates offer consistent soldering characteristics, even during the high temperatures required for lead-free soldering processes. This ensures a high-quality PCB assembly process with minimal defects.

Because ITEQ IT-968SE maintains a smooth surface finish and stable chemical composition, it supports clean solder joints without the risk of delamination or cracking. These attributes are particularly beneficial when designing complex circuit boards with fine-pitch components or when working with advanced automated assembly techniques.

For manufacturers, ITEQ IT-968SE provides:

| Property | ITEQ IT-968SE Value | Industry Standard (High-Performance PCB Materials) |

| Surface Finish | Smooth, homogeneous | Smooth, homogeneous |

| Solder Wetting Test | Passes 100% of tests | Passes 85–95% of tests |

| Thermal Cycling Test | Passes 1000 cycles | Passes 800–1000 cycles |

The data shows that ITEQ IT-968SE not only meets the industry standard for solderability, but it also excels in tests like thermal cycling, proving its resilience even after exposure to extreme temperature shifts. This makes ITEQ IT-968SE a reliable choice for manufacturers looking to maintain high-quality standards during large-scale production.

Manufacturing Excellence with ITEQ IT-968SE PCB Substrates

When it comes to producing high-performance PCBs, precision in manufacturing is indispensable. ITEQ IT-968SE PCB substrates are engineered to meet the demands of advanced high-frequency and high-speed applications. This section will explore how ITEQ IT-968SE is enabling manufacturers to achieve consistent results and meet the rigorous requirements of complex circuit designs.

The ITEQ IT-968SE substrate brings reliability and precision to PCB production, enabling us to execute advanced designs with greater ease.

Precision Manufacturing with ITEQ IT-968SE

In high-frequency PCB manufacturing, accuracy is must. The ITEQ IT-968SE substrate provides the precision necessary for multi-layer designs, ensuring each layer is accurately aligned and bonded. The material’s uniformity in terms of dielectric constant and low dissipation factor makes it particularly effective in ensuring minimal signal loss across multiple layers, which is a significant advantage for high-speed circuits.

The tight tolerances offered by ITEQ IT-968SE also minimize the risk of performance degradation due to misalignments or manufacturing defects. For example, even in demanding applications like RF circuits and 5G network components, the consistent material properties help maintain the integrity of the circuit.

| Property | ITEQ IT-968SE Value | Industry Standard |

| Layer-to-Layer Tolerance | ≤ 0.1mm | ≤ 0.15mm |

| Flatness of Substrate | ± 0.05mm | ± 0.1mm |

The ability to meet tight tolerances makes ITEQ IT-968SE a dependable choice for precision manufacturing of high-performance PCBs.

Quality Control and Testing of ITEQ IT-968SE Substrates

Quality control is an integral part of PCB production. ITEQ IT-968SE substrates undergo rigorous testing to verify their performance in high-frequency applications. This includes evaluating properties such as signal retention, thermal stability, and mechanical durability to ensure the substrates perform optimally throughout their lifecycle.

The rigorous testing processes involve the following steps:

●Electrical Testing: Ensuring that the substrate can handle high-speed signals without degradation.

●Thermal Cycling: Verifying the material’s resilience under extreme temperature changes.

●Dimensional Testing: Checking for consistency in the dimensions and thicknesses of the substrates to ensure smooth manufacturing.

| Test Type | ITEQ IT-968SE Performance | Industry Benchmark |

| Dielectric Strength | 65 kV/mm | 60–70 kV/mm |

| Thermal Cycling (1000 cycles) | Passes >1000 cycles | Passes 800–1000 cycles |

| Solderability Test | Passes 100% | Passes 90–95% |

| Dimensional Stability | ± 0.05mm | ± 0.1mm |

The robust quality control measures make ITEQ IT-968SE a reliable substrate that consistently meets manufacturing standards.

Cost-Effective Solutions for High-Performance PCBs Using ITEQ IT-968SE

For PCB manufacturers, cost is always a consideration in choosing the right materials. ITEQ IT-968SE presents a balanced solution that allows manufacturers to produce high-performance PCBs without significantly impacting production budgets. Its combination of affordable pricing and reliable performance makes it an attractive choice for large-scale production.

We can leverage ITEQ IT-968SE to reduce operational costs associated with material defects or production delays. The substrate’s solderability and thermal stability also contribute to reducing rework, further improving the overall efficiency of the manufacturing process.

With ITEQ IT-968SE, we can enjoy cost-effective production without sacrificing the performance required for high-frequency designs.

What Technologies Are Needed in PCB Manufacturing Using ITEQ IT-968SE Substrate?

When manufacturing PCBs using ITEQ IT-968SE, certain advanced technologies must be utilized to make the most of the substrate’s features. The material’s properties, such as stable dielectric constants and low loss, require careful attention throughout the production process to ensure that the resulting boards perform as expected.

Technologies employed during this process include:

●Lamination Techniques: Proper lamination ensures precise bonding between layers of the PCB and maintains the stability of electrical performance. The consistency of the lamination process helps to prevent defects such as warping, delamination, or inconsistent layer adhesion, which can impact the reliability of the finished product.

●Impedance Control Technology: Maintaining consistent impedance across the PCB is necessary for high-speed applications. Specialized equipment is used to measure and regulate impedance during the manufacturing process.

●Microvia Processing: Microvias are often used in high-density designs, and their creation must be precise to ensure reliable electrical performance. Laser drilling technology is employed to create these small vias, followed by electroplating to ensure connectivity between layers.

Advanced Lamination Technologies in PCB Manufacturing with IT-968SE Substrate

The lamination process ensures that the IT-968SE substrate maintains its thermal and electrical properties. This process involves carefully layering and bonding the substrate with materials like copper using heat and pressure, helping to achieve a strong, reliable structure for the PCB.

Some of the specific challenges addressed during lamination include:

●Precise Time and Temperature Control: The curing process must be carefully monitored to avoid warping or degradation of the substrate.

●Layer Alignment: Ensuring perfect alignment of layers during lamination prevents misalignments that could result in signal loss.

By utilizing advanced lamination equipment, the material’s integrity and high-frequency performance can be preserved throughout the process.

Impedance Control During PCB Manufacturing with IT-968SE Substrate

Impedance control is a core component in the manufacture of high-speed PCBs. In the case of IT-968SE substrates, maintaining precise impedance measurements throughout the fabrication process is necessary to ensure reliable signal transmission in high-speed applications.

We use high-precision etching, drilling, and measurement technologies to maintain impedance consistency:

●Etching and Drilling: Advanced machinery ensures the accurate formation of traces and vias, which are necessary for controlling impedance across different layers of the PCB.

●Impedance Testing: Through time-domain reflectometry (TDR), we can identify impedance mismatches and adjust the design accordingly before assembly.

These technologies help create reliable high-speed PCBs that perform well under a wide range of conditions.

Microvia Technology for High-Density Designs with IT-968SE Substrate

Microvias allow for higher-density designs by enabling the routing of signals in smaller spaces. IT-968SE substrates are well-suited for these applications due to their high thermal stability and precise dielectric properties.

Technologies used to create microvias include:

●Laser Drilling: High-precision lasers are used to create vias in the substrate. This process requires careful control to prevent substrate damage or irregularities in via size.

●Electroplating: After drilling, copper plating is applied to establish reliable electrical connections between layers, helping maintain signal integrity throughout the PCB.

The use of microvia technology enables us to create smaller, more complex designs while maintaining the reliability of the end product.

Quality Control Measures in PCB Manufacturing with IT-968SE

Strict quality control processes are necessary to ensure that each PCB meets the required performance standards. In the case of IT-968SE substrates, this involves testing and inspecting every step of the production process.

We can employ various equipment, such as:

●Automated Optical Inspection (AOI): This technology scans the board for defects such as misalignment, broken traces, or unwanted copper etching, ensuring the PCB meets the design specifications.

●Thermal Cycling Tests: These tests simulate extreme temperature fluctuations that the finished product may experience, confirming that the IT-968SE substrate can withstand these conditions without degrading.

Design Considerations with ITEQ IT-968SE PCB Substrates

When it comes to high-frequency PCB designs, there’s a lot more than just picking a material—there’s a blend of performance, stability, and precision that needs to be in sync. ITEQ IT-968SE PCB substrates are engineered to meet these demands, offering features that cater to the specific needs of high-speed and high-frequency designs. This section dives deep into how ITEQ IT-968SE can optimize various aspects of PCB design, from signal integrity to thermal management and impedance control.

So, if you’re working in telecommunications, automotive electronics, or aerospace, every step in the design process requires a material that can keep up with complex and demanding applications. Here’s how ITEQ IT-968SE fits the bill.

Signal Integrity Design with ITEQ IT-968SE

In high-frequency PCB design, signal integrity is non-negotiable. With ITEQ IT-968SE, you’re working with a substrate that ensures minimal signal loss and maintains consistent dielectric constant (Dk) throughout its layers. This results in a much more stable transmission of signals, even at high speeds.

For high-speed circuits, maintaining signal integrity is necessary—any fluctuation in Dk can result in timing mismatches, distortion, or degradation of the signal. ITEQ IT-968SE substrates feature low dissipation factor (Df) and stable Dk, which significantly reduce the chance of signal loss. Whether you’re designing RF (Radio Frequency) or microwave circuits, ITEQ IT-968SE enables the design of circuits that operate at their peak efficiency without the common problems that arise from signal degradation.

By using ITEQ IT-968SE, we can meet the exacting standards of 5G and advanced communications systems, where signal integrity can make or break the performance of a design.

Thermal Management in PCB Designs Using ITEQ IT-968SE

High-performance designs often come with their own set of challenges, one of which is managing heat. With ITEQ IT-968SE, the thermal properties of the material provide excellent thermal stability. This ensures that the PCB continues to function optimally, even when subjected to extreme temperature variations.

Why is this so crucial? When temperature fluctuates, materials can expand or contract, potentially causing stress on the PCB and affecting component alignment. In high-frequency applications, this is even more pronounced because heat buildup can degrade signal integrity and disrupt performance.

With ITEQ IT-968SE, the thermal expansion coefficient (CTE) is tightly controlled. This allows the PCB to maintain structural integrity under a wide range of conditions, from automotive designs where heat is a constant factor, to space applications, where temperature extremes are the norm. Thermal stability ensures that the design will stay intact without compromising the operational stability of the high-speed circuits.

Impedance Control with ITEQ IT-968SE

In high-speed circuit designs, maintaining proper impedance control is a basic requirement for ensuring consistent and reliable signal transmission. ITEQ IT-968SE is specifically designed to keep impedance within tight tolerances, reducing reflections and helping signals travel seamlessly from one point to another without interference.

Impedance mismatches can cause signal reflections, leading to interference or complete data loss. ITEQ IT-968SE helps achieve an accurate match between the PCB’s electrical design and the material’s impedance properties. This is especially useful in RF designs, where precise impedance matching directly impacts system performance.

In high-speed digital circuits, impedance mismatches can cause data corruption and errors in signal transmission. By utilizing ITEQ IT-968SE for impedance control, you’re better equipped to prevent these types of issues, allowing for reliable signal transmission, even in the most demanding environments.

Applications of ITEQ IT-968SE PCB Substrates

ITEQ IT-968SE is designed to meet the demands of various high-performance applications across industries. In the next sections, we will break down its performance across different sectors, explaining how its specifications align with the requirements of each application.

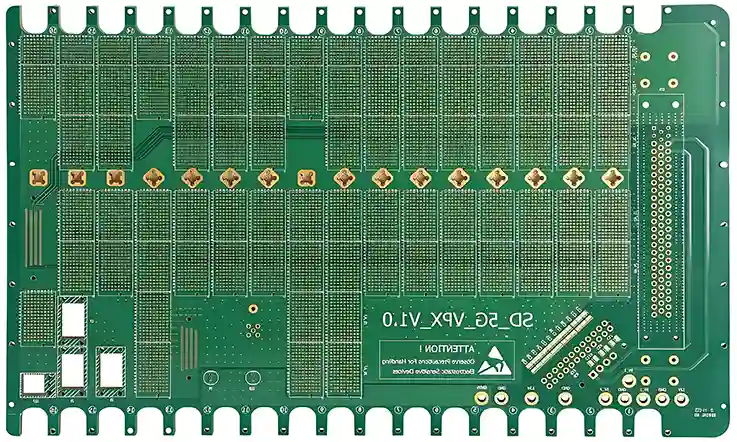

High-Speed Communications and 5G Applications with ITEQ IT-968SE

As 5G technologies advance, the performance of the supporting PCBs becomes even more demanding. IT-968SE is a strong candidate for these applications due to its low-loss and stable dielectric properties, making it suitable for high-speed signals in 5G infrastructures. Its minimal signal attenuation ensures reliable data transmission over longer distances and at higher frequencies.

Data Points for High-Speed Applications:

| Property | IT-968SE Specifications |

| Dielectric Constant (Dk) | 3.2 |

| Loss Tangent (Df) | <0.003 |

| Operating Frequency | Up to 40 GHz |

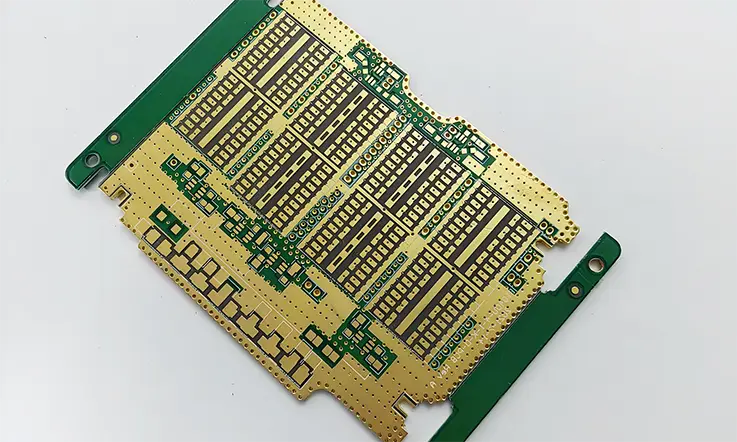

Aerospace and Satellite Systems Utilizing ITEQ IT-968SE

The aerospace and satellite industries require materials that can operate reliably under extreme conditions, including high thermal variations and harsh environmental factors. ITEQ IT-968SE’s excellent thermal stability, along with its low signal loss, ensures consistent performance even in these challenging environments. This makes it an optimal choice for satellite communication systems and aerospace radar applications.

Performance Metrics in Aerospace Systems:

| Property | IT-968SE Specifications |

| Thermal Expansion Coefficient | 15 ppm/°C |

| Glass Transition Temperature (Tg) | 175°C |

| Thermal Conductivity (W/m·K) | 0.2 |

Automotive and Consumer Electronics Using ITEQ IT-968SE

In the automotive and consumer electronics sectors, thermal management and high-frequency performance are central to product longevity and efficiency. IT-968SE’s properties make it good for automotive radar systems, where signal integrity must be maintained in real-time, as well as for consumer electronics requiring heat dissipation. The material’s consistent electrical and thermal performance contributes to the durability and reliability of end products.

Performance Metrics for Automotive Applications:

| Property | IT-968SE Specifications |

| Dielectric Constant (Dk) | 3.1 |

| Loss Tangent (Df) | <0.004 |

| Operating Temperature | -40°C to 125°C |

FAQ for ITEQ IT-968SE PCB Substrates

1.Does ITEQ IT-968SE require special handling during PCB fabrication?

While ITEQ IT-968SE can be processed using standard PCB fabrication techniques, its high-performance characteristics demand precise lamination and etching parameters for optimal results

2.Can ITEQ IT-968SE be used for high-density interconnect (HDI) designs?

Yes, ITEQ IT-968SE’s excellent impedance control and fine-line capabilities make it well-suited for high-density interconnect designs.

3.What type of soldering process is suitable for ITEQ IT-968SE?

ITEQ IT-968SE substrates are compatible with standard soldering processes, including wave soldering and selective soldering, offering strong bond formation and durability.

4.Is ITEQ IT-968SE compatible with existing PCB manufacturing processes?

Yes, ITEQ IT-968SE can be processed using standard PCB manufacturing techniques, including laminating and drilling.