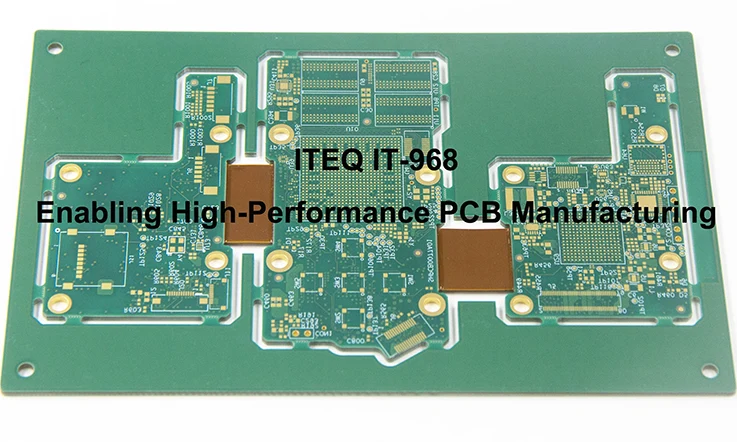

In the world of PCB manufacturing, choosing the right substrate material is crucial for achieving optimal performance, reliability, and manufacturability. One such material that has gained prominence in the industry is ITEQ IT-968 PCB substrate. With its exceptional characteristics and technical specifications, ITEQ IT-968 offers a range of benefits for PCB manufacturers. This article provides a comprehensive overview of ITEQ IT-968 as a high-performance substrate material, highlighting its key features, advantages, and applications

What Is ITEQ IT-968 PCB Materials?

ITEQ IT-968 is a type of PCB (Printed Circuit Board) material offered by ITEQ Corporation, a global manufacturer of high-quality PCB materials. PCB materials are used in the construction of electronic circuits and provide the foundation for mounting and connecting various electronic components.

ITEQ IT-968 is a high-performance, high-Tg (glass transition temperature) material that is commonly used in applications where reliability and durability are critical. It is classified as a high-speed, low-loss material, designed to meet the demanding requirements of modern electronic devices, including telecommunications, computing, automotive, and aerospace industries.

Feature of ITEQ IT-968

Some key features and characteristics of ITEQ IT-968 PCB material may include:

1. High Tg: The glass transition temperature of ITEQ IT-968 is typically above 170°C, indicating excellent thermal stability and resistance to high temperatures.

2. Low Loss: It offers low dielectric loss, which helps maintain signal integrity and reduce signal attenuation in high-frequency applications.

3. High-Frequency Performance: ITEQ IT-968 is engineered to provide excellent electrical performance at high frequencies, making it suitable for high-speed digital and RF (Radio Frequency) applications.

4. Thermal Reliability: The material exhibits good thermal reliability, ensuring the PCB can withstand thermal stress during manufacturing processes and in operation.

5. Mechanical Strength: ITEQ IT-968 possesses good mechanical strength and can withstand the rigors of PCB assembly, handling, and environmental conditions.

6.Compatibility: It is compatible with various fabrication processes, including multilayer constructions, through-hole plating, and surface finishes.

Application Areas and Industries where It is Commonly Used

ITEQ IT-968 PCB material is commonly used in a range of application areas and industries that require high-performance and reliable circuit boards. Some of the typical application areas where ITEQ IT-968 is utilized include:

1. Telecommunications: ITEQ IT-968 is suitable for applications in the telecommunications industry, including networking equipment, base stations, routers, switches, and communication infrastructure.

2. Computing and Servers: ITEQ IT-968 is used in the manufacturing of high-speed computing devices, servers, data centers, and storage systems that require reliable and high-performance PCBs.

3. Automotive Electronics: The automotive industry relies on ITEQ IT-968 for various electronic components, such as engine control units (ECUs), advanced driver-assistance systems (ADAS), infotainment systems, and automotive sensors.

4. Aerospace and Defense: ITEQ IT-968 is chosen for aerospace and defense applications due to its high reliability, thermal stability, and resistance to harsh environmental conditions. It is used in avionics, satellites, military communication systems, radar systems, and other electronic components.

5. Industrial Electronics: ITEQ IT-968 can be found in industrial automation, control systems, power electronics, robotics, and other industrial electronic devices that demand high-performance PCBs capable of withstanding challenging operating conditions.

6. Consumer Electronics: ITEQ IT-968 is used in consumer electronics products such as smartphones, tablets, laptops, gaming consoles, and wearable devices where high-speed and reliable circuit boards are crucial for optimal performance.

7. Medical Devices: ITEQ IT-968 is employed in medical devices and equipment, including diagnostic instruments, patient monitoring systems, imaging devices, and other electronic medical devices that require precision and reliability.

It’s important to note that ITEQ IT-968’s application extends beyond these areas, and it can be used in other industries and applications where high-performance PCB materials are required. The specific application depends on the technical requirements and performance characteristics of the PCB design.

PCB Stack-up Design Considerations when Choose ITEQ IT-968

When considering the PCB stack-up design with ITEQ IT-968 PCB material, several factors need to be taken into account. These considerations ensure optimal performance, reliability, and manufacturability. While the exact stack-up design may vary depending on the specific application and requirements, here are some general considerations:

1.Layer Count:

Determine the required number of layers for the PCB based on the complexity of the design, signal integrity requirements, and space constraints.

2.Signal Integrity:

Place high-speed signal traces and critical signal paths on inner layers to minimize signal degradation and interference. Consider controlled impedance routing for high-frequency signals.

3.Power and Ground Planes:

Incorporate power and ground planes in the stack-up for efficient distribution of power and to reduce noise and electromagnetic interference (EMI).

4.Signal Layer Arrangement:

Determine the arrangement of signal layers and adjacent planes to minimize crosstalk and ensure good signal integrity. Alternating signal and ground plane layers is a common practice.

5.Thickness and Copper Weight:

Determine the appropriate thickness of the ITEQ IT-968 material based on the mechanical requirements and impedance control. Consider the required copper weight for power and ground planes.

6.Dielectric Layer Selection:

ITEQ IT-968 typically has specific dielectric constants and loss tangents. Take these values into account when selecting the thickness and arrangement of dielectric layers for impedance control and signal integrity.

7.Via Construction:

Consider the via construction, such as through-hole vias or microvias, depending on the density and complexity of the design. Use blind or buried vias for layer transitions when necessary.

8.Thermal Management:

Evaluate the thermal characteristics of ITEQ IT-968 and incorporate proper thermal management techniques, such as thermal vias or heat sinks, to dissipate heat effectively.

9.Manufacturability:

Ensure that the stack-up design is compatible with the manufacturing processes, such as lamination, drilling, and plating, and meets the capabilities of PCB fabrication facilities.

Drilling with ITEQ IT-968 in PCB Manufacturing

The drilling process plays a crucial role in PCB manufacturing when using ITEQ IT-968 as the PCB material. Here’s an overview of the drilling process specific to ITEQ IT-968:

1. Tool Selection: Select the appropriate drilling tools based on the size and type of holes required for your PCB design. Common drilling tools include twist drills and carbide drills. The selection of the tool should consider the material’s properties and thickness.

2. Tool Speed and Feed Rate: Set the drilling machine’s speed and feed rate parameters based on the recommendations provided by ITEQ or the tool manufacturer. These parameters depend on the specific properties of ITEQ IT-968, such as its hardness and machinability.

3. Drill Start and Alignment: Properly position the PCB panel or individual board on the drilling machine, ensuring it is securely held in place. Align the drill with the pre-determined drill locations, taking into account the PCB design and hole coordinates.

4. Drilling Process: Initiate the drilling process by activating the drilling machine. The drill bit will penetrate the ITEQ IT-968 material, creating holes for component mounting and interconnection. The drilling process can be performed using computer-controlled drilling machines or automated drilling equipment.

5. Cooling and Chip Removal: During the drilling process, it is important to ensure effective cooling and chip removal to prevent heat buildup and clogging of the drill bit. Use a coolant or lubricant to cool the drill bit and facilitate chip evacuation. Common coolants include water-soluble oils or coolants specifically designed for PCB drilling.

6. Hole Quality and Cleanliness: Inspect the drilled holes to ensure they meet the required specifications in terms of diameter, position, and cleanliness. Use visual inspection or automated optical inspection (AOI) systems to verify the quality of the drilled holes.

7. Deburring: After drilling, remove any burrs or sharp edges around the drilled holes. This can be done using a deburring tool or by employing mechanical or chemical deburring techniques to ensure smooth hole surfaces.

It’s important to note that the drilling process must be performed with precision to avoid any damage to the ITEQ IT-968 material or the PCB itself. Consult the drilling guidelines provided by ITEQ or the PCB manufacturer, and work with experienced drilling operators who are familiar with the specific characteristics and requirements of ITEQ IT-968.

ITEQ IT-968 Comparison with Other PCB Substrates

When comparing ITEQ IT-968 PCB material with other PCB materials, several factors come into consideration, including electrical performance, thermal properties, mechanical strength, cost, and availability. While the specific comparison may vary based on the materials being compared, here are some general aspects to consider:

Electrical Performance:

ITEQ IT-968 is known for its high-frequency performance, low dielectric loss, and good signal integrity. When comparing with other materials, consider factors such as dielectric constant, loss tangent, and impedance control for high-speed and RF applications.

Thermal Properties:

ITEQ IT-968 typically offers a high glass transition temperature (Tg), indicating good thermal stability and reliability. Compare the Tg values and coefficient of thermal expansion (CTE) with other materials to assess their suitability for applications with high-temperature environments.

Mechanical Strength:

Evaluate the mechanical strength and rigidity of ITEQ IT-968 compared to other materials. Consider factors such as flexural strength, tensile strength, and impact resistance to ensure the PCB can withstand mechanical stress during handling, assembly, and operation.

Cost and Availability:

Compare the cost and availability of ITEQ IT-968 with other PCB materials. The cost may vary depending on factors such as material composition, manufacturing process, and market demand. Assess the availability and lead times to ensure a reliable supply chain.

Manufacturing Compatibility:

Consider the compatibility of ITEQ IT-968 with different manufacturing processes, such as multilayer construction, plating, and surface finishes. Evaluate how well it integrates into the fabrication processes compared to other materials.

Application-Specific Considerations:

Assess the specific requirements of your application and compare how ITEQ IT-968 performs in those specific areas. For example, if your application requires high-frequency performance, compare the material’s characteristics related to impedance control and signal integrity.

Summary

ITEQ IT-968 PCB substrate material has emerged as a preferred choice for advanced PCB manufacturing due to its outstanding properties and performance capabilities. With its high-frequency performance, low dielectric loss, thermal stability, and mechanical strength, ITEQ IT-968 provides an excellent foundation for a wide range of applications, including telecommunications, automotive electronics, aerospace systems, and high-speed computing. Its compatibility with various manufacturing processes and ease of use make it a reliable and efficient substrate material for PCB fabrication.

As PCB engineers strive to meet the increasing demands for complex designs, signal integrity, and reliability, ITEQ IT-968 PCB substrate stands out as a viable solution. By leveraging the exceptional characteristics of ITEQ IT-968, manufacturers can achieve high-quality PCBs that meet the stringent requirements of modern electronic systems. With its proven track record and industry recognition, ITEQ IT-968 continues to empower PCB manufacturers to push the boundaries of innovation and deliver cutting-edge solutions to their customers.