When designing high-performance printed circuit boards (PCBs), choosing the right material directly affects the overall quality, reliability, and longevity of the final product. One material that has gained significant traction in recent years is Isola IS680 AG-348. This advanced PCB substrate is specifically engineered to meet the demanding needs of industries that require precision in high-frequency and high-performance circuit designs.

The demand for superior materials like Isola IS680 AG-348 is growing rapidly, driven by advancements in fields such as telecommunications, medical equipment, and automotive electronics. As these industries demand more from their electronic systems, materials like IS680 AG-348 offer core properties to ensure that circuit designs are efficient and resilient.

Why Isola IS680 AG-348 PCB Substrates Are Shaping the Future of PCB Design?

As electronic devices become more advanced, the need for materials capable of supporting complex, high-performance circuits continues to rise. Isola IS680 AG-348 is quickly becoming the go-to choice for developers working on high-frequency and high-performance PCBs. This material is engineered to meet the demands of modern electronics, providing a reliable solution for designing the intricate circuits required in today’s cutting-edge applications.

In today’s competitive electronics industry, Isola IS680 AG-348 has quickly become a favored choice for PCB designers working with demanding projects. Therefore, whether in consumer electronics or specialized medical devices, this material allows us to develop high-quality PCBs capable of handling increasing complexity without compromising on performance.

Exploring Isola IS680 AG-348: Key Attributes That Set It Apart

Isola IS680 AG-348 stands out for its solid electrical performance and mechanical reliability. With a low dielectric constant (Dk) and low loss tangent (Df), this material reduces signal degradation, supporting effective signal transmission. It’s a solid choice for high-speed digital and RF circuits, where clear signal transmission is necessary for achieving reliable performance.

We can using Isola IS680 AG-348 can achieve stable signal transmission across a variety of applications. With its ability to reduce interference and signal loss, this material proves to be a strong choice for projects that require precise and clear communication between circuit components, including telecommunications and medical device manufacturing.

The Growing Demand for Advanced PCB Materials in Modern Electronics

The evolution of modern electronics means that the materials used in PCB design need to adapt to higher speeds and frequencies. Isola IS680 AG-348 is crafted to meet these growing demands, offering the performance needed for complex systems without compromising reliability.

Isola IS680 AG-348 is recognized for its stable electrical performance, making it well-suited for applications demanding high-speed data transmission. This is particularly evident in sectors like telecommunications and precision medical devices, where clear and uninterrupted signal transmission is necessary for consistent operation. As technology continues to evolve, IS680 AG-348 helps ensure that electronic devices stay efficient and reliable, meeting the demands of today’s fast-moving industry.

How Isola IS680 AG-348 Will Support Future PCB Designs?

As Isola IS680 AG-348 is poised to remain an essential material in PCB design as new technologies and applications emerge. From autonomous systems to next-generation communication networks, IS680 AG-348 will continue to support the creation of electronic devices that can meet the growing demands of modern industries.

As new challenges emerge in electronics, IS680 AG-348 delivers the reliability and performance needed for our many engineers to design advanced devices. Its continued use will support high-frequency, high-performance systems across various industries in the future.

Overview of Isola IS680 AG-348 PCB Substrates

Isola IS680 AG-348 is a high-performance PCB substrate designed to offer exceptional electrical properties, particularly in applications that require low signal loss and precise impedance control. The material boasts a low dielectric constant (Dk) and low dissipation factor (Df), making it ideal for maintaining signal integrity in high-speed, high-frequency circuits. These characteristics significantly reduce the signal degradation that can occur in conventional substrates, allowing circuits to perform at their best.

In addition to its excellent electrical properties, the IS680 AG-348 offers good thermal stability, ensuring that the PCB remains functional and reliable even under conditions of high thermal stress. The substrate’s resistance to thermal expansion and contraction ensures durability over long periods, reducing the risk of failure caused by temperature fluctuations.

Therefore, whether used for RF (radio frequency) circuits, microwave communication systems, or other high-speed designs, Isola IS680 AG-348 provides a reliable and efficient solution for engineers and designers who demand high-quality performance in their PCB substrates

Availability of Isola IS680 AG-348 PCB Substrates: A Versatile Material Offering

The versatility of Isola IS680 AG-348 PCB substrates lies in its adaptability to different designs, thicknesses, copper foil types, and copper weights. These variations make it a better choice for a wide range of applications, from consumer electronics to high-performance telecommunications, automotive, and IoT systems. When selecting the optimal IS680 AG-348 configuration for a project, we must consider factors such as performance requirements, signal integrity, thermal conductivity, and mechanical strength. The following breakdown provides insight into the material’s availability in different forms and copper foil options, helping you choose the right fit for your designs.

Standard Material Offering and Thickness Options for IS680 AG-348 PCB Substrates

The standard offering of IS680 AG-348 comes in a laminate form, with an ideal thickness of 60 mil (1.5 mm). This thickness is commonly used for medium-to-high-frequency applications, providing a balanced performance for signal integrity and thermal dissipation. The substrate is available in both full-size sheet and panel form, offering flexibility for different production processes, from prototyping to large-scale manufacturing.

Thickness Options-

●60 mil (1.5 mm): The standard thickness provides an excellent compromise between mechanical strength and signal transmission stability, making it suitable for a wide range of applications in telecom, automotive, and IoT.

●Custom Thickness: For specific design needs, custom thicknesses can be available, offering versatility in applications that demand tighter space constraints or unique physical properties.

This wide range of thicknesses ensures that IS680 AG-348 can meet various PCB design requirements while maintaining high signal fidelity and mechanical robustness, whether it’s for dense, high-frequency circuits or designs requiring greater structural integrity.

Copper Foil Options for IS680 AG-348 PCB Substrates

Copper foil plays an integral part in the performance of a PCB, especially in high-frequency applications where conductivity and heat dissipation need to be managed efficiently. IS680 AG-348 provides a selection of copper foil options, each designed to meet specific performance requirements and design goals.

Available Copper Foil Types-

VLP-2 (2 micron) Copper Foil: The VLP-2 copper foil option provides outstanding performance in high-frequency designs. With its ultra-thin structure, it minimizes signal loss and ensures high-quality transmission. This is especially beneficial for RF and high-speed digital applications where low loss and minimal attenuation are a priority.

Copper Foil Types-

●1 oz (35 µm): Standard copper foil thickness for a variety of PCB designs. This option balances performance and cost, providing good conductivity without significant loss.

●Thinner Copper Foils: Thinner copper options are available for designs that require smaller trace widths or reduced space requirements. These are often selected for compact and high-density circuits that don’t require heavy current capacity but still need reliable signal integrity.

With multiple copper foil options, IS680 AG-348 offers flexibility in matching copper weight with the specific needs of each design, optimizing the PCB’s performance.

Copper Weight and Its Impact on IS680 AG-348 PCB Performance

The copper weight in a PCB determines how much current the circuit can carry and impacts the thermal management of the design. IS680 AG-348 provides a range of copper weights to suit varying electrical and thermal requirements, ensuring that the material is suitable for both low- and high-power applications.

Copper Weight Options-

●½ oz (18 µm): This option is perfect for low-power applications, such as signal lines or interconnects where high current is not a concern. It is an excellent choice for designs in industries like telecommunications and consumer electronics, where the focus is on signal integrity rather than high current handling.

●1 oz (35 µm): Offering a standard option for a broad range of applications, this copper weight is ideal for most general-purpose PCB designs. It strikes a good balance between cost and performance, ensuring adequate current capacity and thermal management for most consumer and industrial applications.

●Heavier Copper Options (≥ 2 oz): For applications that require handling higher electrical currents, such as power electronics, heavy copper options are available. These materials are well-suited for use in power amplifiers, automotive systems, and certain industrial or military electronics where efficient heat dissipation and the ability to handle electrical loads are necessary for stable performance.

Copper Weight Comparison for IS680 AG-348 PCB Substrates-

| Copper Weight (oz) | Copper Thickness (µm) | Common Applications |

| ½ oz | 18 µm | Signal routing, low-power circuits, RF systems |

| 1 oz | 35 µm | General-purpose, consumer electronics, IoT |

| ≥ 2 oz | ≥ 70 µm | High-power applications, automotive, power electronics |

Flexible Form Factors for IS680 AG-348 PCB Substrates

IS680 AG-348 is available in both full-size sheets and panel form, giving customers the flexibility to choose the most suitable option based on production scale and design needs. Full-size sheets are ideal for larger, more complex PCB designs, while panel form is perfect for high-volume production where efficiency and cost savings are prioritized. Both options integrate smoothly into the PCB fabrication process, reducing the need for additional adjustments or cutting during manufacturing.

Why IS680 AG-348’s Availability Is an Advantage for PCB Manufacturers-

The flexibility in material availability, from different thicknesses to varied copper foil options, makes Isola IS680 AG-348 an adaptable solution for a wide range of applications. Whether you’re working on a compact consumer electronic device or a complex, high-frequency system, IS680 AG-348 can be tailored to meet your performance needs, while offering cost efficiency and reducing waste in manufacturing.

Key Features and Specifications of Isola IS680 AG-348 PCB Substrates

As the need for high-performance electronics continues to rise across industries like telecommunications, medical devices, and automotive, some of manufacturers are looking for materials that can support the next generation of circuit designs. Isola IS680 AG-348 offers a solution to this growing demand by providing a substrate with superior electrical performance, thermal stability, and mechanical durability. This section delves into the specific features and technical specifications that make IS680 AG-348 an optimal choice for demanding applications.

Dielectric Constant and Low-Loss Performance of Isola IS680 AG-348 PCB Substrates

One of the standout features of Isola IS680 AG-348 is its dielectric constant (Dk) and low-loss performance. These characteristics are fundamental when designing PCBs for high-frequency applications where signal degradation can be a concern.

The dielectric constant (Dk) is a material property that influences its interaction with electromagnetic fields.For IS680 AG-348, the material is engineered to have a stable dielectric constant across a wide frequency range, ensuring that signal integrity is maintained, even at high speeds.

The low-loss performance of IS680 AG-348 is a result of its low loss tangent (Df), which directly affects how much signal is lost during transmission. A lower loss tangent ensures a more efficient signal path, improving the speed and reliability of data transfer. This characteristic is particularly helpful in high-speed digital circuits and RF designs, where fast and accurate transmission is needed.

Dielectric Constant and Loss Tangent of Isola IS680 AG-348-

| Property | Value |

| Dielectric Constant (Dk) | 3.48 @ 10 GHz |

| Loss Tangent (Df) | 0.0029 @ 10 GHz |

| Frequency Range | 1 GHz to 40 GHz |

These values illustrate how Isola IS680 AG-348 reduces signal loss and maintains consistent dielectric properties, making it suitable for designs that require high precision, such as those in telecommunications and high-frequency applications, where signal clarity is necessary for optimal performance.

Thermal Stability and High-Thermal Conductivity of Isola IS680 AG-348 PCB Substrates

Thermal management is one of the most main aspects of PCB design, especially when dealing with power-dense electronics or applications that operate in extreme environments. Isola IS680 AG-348 provides excellent thermal stability and high-thermal conductivity, ensuring that heat generated by active components is effectively managed, preventing overheating and damage to the PCB.

Thermal stability refers to the ability of the material to maintain its mechanical and electrical properties when exposed to high temperatures. In contrast, high-thermal conductivity allows the PCB to quickly dissipate heat, ensuring uniform temperature distribution across the board.

Thermal Properties of Isola IS680 AG-348-

| Property | Value |

| Thermal Stability (Tg) | 288°C |

| Thermal Conductivity (W/m·K) | 0.38 -0.53W/m·K (in-plane) |

| Coefficient of Thermal Expansion (X/Y-Axis CTE) | 12 ppm/°C (below Tg) |

These values highlight the material’s excellent thermal characteristics, making it suitable for high-power applications such as automotive electronics and power amplifiers, where heat must be dissipated efficiently to maintain performance.

Impedance Control and Signal Integrity in Isola IS680 AG-348 PCB Substrates

In PCB design, maintaining consistent impedance helps ensure that signals are transmitted without distortion. . Impedance mismatches can result in signal reflection or loss of data integrity, which can be particularly problematic in high-speed digital circuits and RF designs.

Isola IS680 AG-348 offers precise impedance control, allowing us to create PCBs that have predictable and consistent impedance values, which is necessary for ensuring that the signals traveling through the PCB maintain their integrity.

By using IS680 AG-348, we can minimize the risk of signal degradation, ensuring that high-frequency signals are transmitted clearly. This is especially useful in applications such as 5G networks, automotive radar systems, and high-speed data processing, where maintaining signal integrity is necessary.

Impedance Control Properties of Isola IS680 AG-348-

| Property | Value |

| Impedance Control (Z0) | 50 ± 1 Ω |

| Insertion Loss (dB/inch) | < 0.3 dB @ 10 GHz |

| Return Loss (dB) | > 15 dB @ 10 GHz |

These specifications show how Isola IS680 AG-348 ensures reliable signal transmission with minimal loss or reflection, which is needed in high-speed and high-frequency applications, maintaining overall system performance.

Why Isola IS680 AG-348 PCB Substrates Excel in High-Frequency and Microwave Applications?

With the constant evolution of modern electronics, materials capable of supporting high-speed and high-frequency circuits are in high demand. Isola IS680 AG-348 PCB substrates are specifically designed to deliver low-loss and stable electrical performance, making them good for high-frequency and microwave applications. These substrates address the growing need for materials that can handle complex RF (radio frequency) circuits and microwave systems, ensuring consistent signal performance even under challenging operating conditions.

In areas such as microwave communications, radar systems, and satellite technology, materials must provide dependable performance under high-frequency conditions. Isola IS680 AG-348 ensures minimal signal degradation and interference, making it a top choice for advanced circuit designs. Let’s take a deeper look at why this material excels in such demanding applications.

Enhanced Performance in RF and Microwave Circuit Designs with Isola IS680 AG-348 PCB Substrates

Designing RF and microwave circuits requires careful attention to signal stability. The performance of RF circuits, particularly those used in satellite communications or military-grade radar systems, can suffer from even small amounts of signal loss. Isola IS680 AG-348 helps address this issue by offering low loss and reducing signal degradation even at high frequencies.

The low dielectric constant (Dk) and loss tangent (Df) properties of IS680 AG-348 help ensure that signals pass through the PCB with minimal attenuation, preserving signal strength along the entire transmission path. In RF circuits, where maintaining signal integrity is a must, IS680 AG-348 provides a stable medium for signal transmission, reducing data errors and meeting the high-speed demands of these circuits. Therefore, whether it’s used in satellite communications, radar systems, or other similar applications, this material helps keep signals consistent, clear, and uninterrupted.

Low Loss and High-Speed Signal Transmission in Isola IS680 AG-348 PCB Substrates

In high-speed circuit applications, such as RF systems, maintaining signal integrity is a top concern. Loss of signal integrity can cause severe operational issues, affecting performance across the entire system. Isola IS680 AG-348 addresses this challenge with its superior low-loss characteristics. This material significantly reduces energy dissipation, ensuring that signals remain strong and clear as they travel through the PCB.

The low-loss properties of IS680 AG-348 enhance data transmission speeds and optimize signal propagation, especially in high-frequency applications. These features support advanced systems like 5G and IoT, where high data throughput and low latency are necessary for smooth operation. By minimizing signal loss, IS680 AG-348 contributes to more reliable circuits, reduces maintenance, and extends device lifespan.

Why Isola IS680 AG-348 PCB Substrates Are Well-Suited for 5G and IoT Applications?

The expansion of technologies like 5G and IoT has created a higher demand for PCBs that can support high-speed, reliable communication. Isola IS680 AG-348 is tailored for these exact needs, offering stable signal transmission, low energy consumption, and excellent electrical performance.

For 5G networks, where high-speed communication and high data throughput are foundational, IS680 AG-348 ensures that signals are effectively transmitted without degradation, even over long distances. Similarly, for IoT applications, which often involve low power consumption and extended range, IS680 AG-348 serves as an ideal substrate. This material helps preserve signal integrity over long distances while enabling faster data rates, even in remote environments. Whether in IoT devices or 5G infrastructure, IS680 AG-348 ensures reliable and efficient performance, helping the next generation of connected technologies thrive.

Best Practices for Designing with Isola IS680 AG-348 PCB Substrates

When designing high-performance PCBs, selecting the right materials and understanding their properties is half the battle. Isola IS680 AG-348 is an excellent choice for high-frequency and high-speed applications, but to maximize its potential, we need to follow specific best practices throughout the design process. These practices not only ensure efficient performance but also help prevent issues that could arise later in the manufacturing process.

By implementing proven techniques in PCB layout, impedance control, and thermal management, designers can fully exploit the capabilities of Isola IS680 AG-348. This section highlights the steps and strategies that will make the design process smoother, more reliable, and more efficient.

PCB Layout Tips for Optimal Signal Integrity with Isola IS680 AG-348 PCB Substrates

Signal integrity is often one of the most challenging aspects of PCB design, especially when working with high-speed circuits. Achieving optimal signal integrity requires attention to detail in the PCB layout phase. With Isola IS680 AG-348, designers can make the most of its low loss and high-performance electrical properties by carefully planning their layouts.

Here are a few tips for improving signal integrity:

1.Minimize Trace Lengths: Shorter trace lengths help reduce resistance and inductance, ensuring that high-speed signals travel with minimal loss. In designs where fast signal transmission is a must, like RF and microwave circuits, this is a must.

2.Use Ground Planes Effectively: To reduce noise and maintain a stable reference point for signals, ground planes should be placed near signal traces. This helps maintain consistent impedance and improves overall signal quality.

3.Optimize Trace Widths and Spacing: Adjusting trace widths to meet impedance requirements helps avoid reflections and ensures clear signal transmission. Proper spacing between traces also minimizes crosstalk, which can affect signal quality.

Impedance Control Techniques for High-Speed PCBs Using Isola IS680 AG-348 PCB Substrates

Impedance control is a fundamental part of high-speed PCB design, especially when working with materials like Isola IS680 AG-348, which offer low-loss and stable electrical properties. Proper impedance management ensures that signals pass through without interference or distortion, maintaining accuracy in transmission.

Here are a few impedance control techniques to consider when using IS680 AG-348:

1.Microstrip and Stripline Configurations: Depending on the PCB stackup, we can choose microstrip (surface traces) or stripline (internal traces) configurations to control impedance. IS680 AG-348’s properties allow us to achieve precise impedance matching with minimal loss, making it suitable for high-speed RF circuits.

2.Match Trace Width and Substrate Properties: For consistent impedance, it’s essential to match trace width with the substrate’s thickness and Dk (dielectric constant). IS680 AG-348 offers a stable Dk, which helps us maintain consistent impedance throughout the PCB.

3.Controlled Return Path: Ensuring signals have a smooth return path to ground helps maintain clear transmission. By fine-tuning routing and layout, we can reduce the chances of noise or interference disrupting the signal flow.

By incorporating these techniques,we can ensure that our circuits perform with high precision, even under demanding high-speed conditions.

Thermal Management Considerations When Using Isola IS680 AG-348 PCB Substrates

In high-performance PCB designs, particularly with power-hungry components or in demanding environments, managing heat effectively is a must. Isola IS680 AG-348 substrates are engineered to handle heat effectively, but we need to take additional steps to ensure the PCB can handle the thermal loads expected in certain applications.

Consider these thermal management tips:

1.Use of Heat Sinks and Thermal Vias: When designing PCBs with IS680 AG-348 for high-power applications, integrating thermal vias and heat sinks into the layout can help dissipate heat effectively. Thermal vias create pathways for heat to travel away from hot components, preventing temperature build-up.

2.Material Selection for Heat Transfer: Although IS680 AG-348 has good thermal conductivity, combining it with materials that enhance heat dissipation, like copper, can further improve heat management. The careful selection of these materials allows the board to operate without thermal stress, which could otherwise cause signal degradation or component failure.

3.Component Placement: Proper placement of components with respect to their heat dissipation requirements can make a significant difference. High-heat components should be placed in areas that have sufficient airflow and thermal conductivity to prevent heat accumulation, ensuring long-term stability.

Implementing effective thermal management practices helps prevent overheating and ensures stable performance throughout the lifecycle. This is particularly true in high-power and high-speed systems, such as telecom and automotive applications, where heat can accumulate swiftly and impact system stability.

Isola IS680 AG-348 PCB Substrates vs. Other High-Performance PCB Materials

The high-performance PCB materials market includes a variety of solutions designed to meet the needs of industries requiring precise, stable electrical performance, especially in high-frequency environments. While Isola IS680 AG-348 is favored for its consistent results in such applications, comparing it with other high-performance materials such as Rogers, Taconic, Shengyi, and Ventec allows designers to better understand the strengths and trade-offs between materials. This comparison will focus on the electrical properties, cost efficiency, and environmental impact of these materials, helping you make an informed decision when selecting a substrate for your specific application.

Comparing Isola IS680 AG-348 PCB Substrates to Other High-Performance Materials

When selecting a PCB substrate, it’s crucial to understand the unique characteristics of different materials and how they perform across a range of applications. Isola IS680 AG-348 stands out due to its balanced performance at a reasonable cost, but how does it compare with other materials like Rogers RT/duroid, Taconic TLY-5, Shengyi S1000-2, and Ventec VT-901? The following table and discussion will highlight the differences in dielectric properties, thermal conductivity, and maximum operating frequencies, providing insights into where each material excels and where compromises might need to be made.

Performance Comparison-

| Property | Isola IS680 AG-348 | Rogers RT/duroid 6002 | Taconic TLY-5 | Shengyi S1000-2 | Ventec VT-901 |

| Dielectric Constant (Dk) | 3.48 | 2.94 | 2.20 | 3.25 | 3.50 |

| Loss Tangent (Df) | 0.0029 | 0.0015 | 0.0009 | 0.003 | 0.003 |

| Thermal Conductivity (W/mK) | 0.38-0.53 | 0.68 | 0.22 | 0.50 | 0.45 |

| Max Operating Frequency | 20 GHz | 40 GHz | 30 GHz | 20 GHz | 25 GHz |

| Cost | Low | High | Moderate | Low | Moderate |

| Applications | Telecom, Automotive, 5G | Aerospace, Military, RF | Military, High-frequency | Consumer Electronics, RF | Automotive, Consumer Goods |

Discussion:

●Rogers RT/duroid 6002: Rogers materials, like RT/duroid 6002, are recognized for their low loss and stable dielectric properties, particularly at very high frequencies (up to 40 GHz). These materials are suited for demanding applications, such as aerospace and military communications. While Rogers offers excellent thermal stability, the high cost of these materials often limits their use to high-end applications where performance is non-negotiable.

●Taconic TLY-5: Taconic’s TLY-5 series offers outstanding performance in microwave and high-frequency RF applications. Its high heat tolerance makes it best for aerospace and military-grade systems. However, like Rogers, it is priced higher, which may make it less desirable for commercial or mid-range applications.

●Shengyi S1000-2: A more cost-effective option, Shengyi S1000-2 offers solid electrical properties for consumer electronics and general RF applications. While it does not match the high-frequency performance of Rogers or Taconic, it is a good choice for designs that do not require extreme frequencies but still demand reliability.

●Ventec VT-901: Ventec’s VT-901 is a well-suited solution for automotive and consumer goods applications. Its thermal and electrical performance makes it suitable for these industries, but it does not perform at the ultra-high frequencies that some other materials, such as Rogers or Taconic, handle better.

Cost-Effectiveness of Isola IS680 AG-348 PCB Substrates

When choosing PCB materials, cost-effectiveness becomes a need consideration, especially in applications where high performance is needed but budget constraints exist. Isola IS680 AG-348 offers a strong balance between performance and price, making it an attractive option for designs in telecom, automotive, 5G, and IoT sectors. The following comparison outlines the cost per square meter for several high-performance PCB materials, alongside their performance-to-cost ratios, to provide insight into which materials deliver the best value for money.

Cost Comparison-

| Material | Average Price per Square Meter | Performance-to-Cost Ratio | Common Applications |

| Isola IS680 AG-348 | $90 – $120 | High | Telecom, Automotive, 5G, IoT |

| Rogers RT/duroid 6002 | $220 – $300 | Moderate | Aerospace, Military, RF Systems |

| Taconic TLY-5 | $150 – $210 | Moderate | Military, High-frequency |

| Shengyi S1000-2 | $50 – $75 | High | Consumer Electronics, RF Systems |

| Ventec VT-901 | $80 – $110 | High | Automotive, Consumer Goods |

Discussion:

Isola IS680 AG-348 is widely regarded for providing excellent value without sacrificing essential performance characteristics. For example, a telecom manufacturer designing a 5G PCB can achieve the required signal integrity and low loss with IS680 AG-348, all at a fraction of the cost of Rogers’ high-end materials. Similarly, automotive and IoT sectors, which require reliable communication but at a reasonable price, find IS680 AG-348 a solid choice over pricier options like Taconic and Rogers.

Environmental Impact of Isola IS680 AG-348 PCB Substrates

In today’s market, the environmental impact of materials is becoming an increasingly core factor in the selection of PCB substrates. As regulations around sustainability tighten, the demand for eco-friendly and halogen-free materials grows. Isola IS680 AG-348 meets this need by offering a halogen-free solution that aligns with global environmental standards. Below, we compare the environmental characteristics of IS680 AG-348 with other high-performance materials to assess their environmental impact.

Environmental Impact Comparison-

| Material | Halogen-Free | RoHS Compliant | Recyclability | Eco-Friendly Certifications |

| Isola IS680 AG-348 | Yes | Yes | High | Yes |

| Rogers RT/duroid 6002 | No | Yes | Low | No |

| Taconic TLY-5 | Yes | Yes | Moderate | Yes |

| Shengyi S1000-2 | Yes | Yes | High | Yes |

| Ventec VT-901 | Yes | Yes | High | Yes |

Discussion:

Isola IS680 AG-348’s halogen-free composition and compliance with RoHS regulations give it an advantage in eco-conscious industries. While Rogers RT/duroid materials are less eco-friendly due to the use of halogenated resins, Taconic, Shengyi, and Ventec all provide environmentally sustainable options, with varying levels of recyclability and eco-certifications. IS680 AG-348’s minimal environmental footprint makes it a preferred choice for companies seeking to meet stringent environmental standards.

Why Choose Us for Fabricating Your Isola IS680 AG-348 PCB Projects?

When it comes to fabricating high-performance Isola IS680 AG-348 PCBs, selecting the right partner can significantly impact the results. . Our factory offers cutting-edge PCB Fabrication capabilities, advanced equipment, and a dedicated engineering team with years of expertise in PCB manufacturing. From the moment you entrust us with your Isola IS680 AG-348 project, we focus on delivering exceptional performance, precision, and quality that exceeds your expectations.

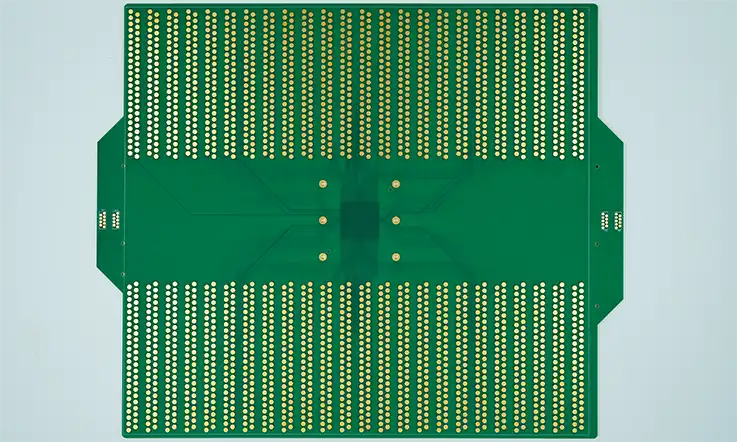

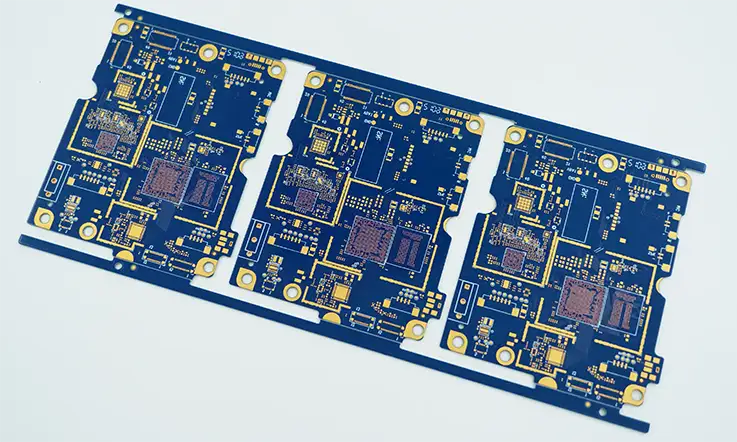

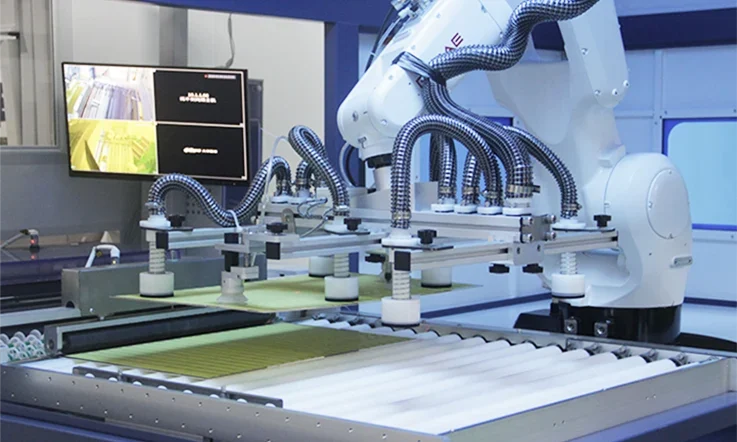

1.Advanced PCB Fabrication Facility

At our state-of-the-art facility, we understand the intricacies involved in creating high-performance PCBs, especially when using advanced materials like Isola IS680 AG-348. Our comprehensive approach to PCB fabrication is designed to meet the unique needs of demanding industries such as telecommunications, automotive, aerospace, 5G, and IoT. With cutting-edge equipment, an experienced engineering team, and strict quality control processes, we provide exceptional precision, performance, and reliability in every project we handle.

2.One-Stop PCB Fabrication Services

We specialize in offering a one-stop service that covers every aspect of your PCB fabrication needs. From the initial design consultation through to production, we ensure that every stage of your project is executed seamlessly. Our ability to work with a wide range of high-performance PCB materials, including Isola IS680 AG-348, Rogers, Taconic, Nelco, and Teflon-based options, allows us to offer customized solutions for your specific circuit board requirements. Whether you’re looking for low-loss materials for high-speed signal transmission or advanced thermal management solutions, our team is equipped to support your project with the right materials and expertise.

3.Expert Material Selection for High-Performance PCBs

By choosing us, you benefit from our deep understanding of various substrates, which allows us to recommend and use the best-suited material for your application. Our engineering team is skilled in optimizing designs to meet your needs for low-loss characteristics, impedance control, and high-frequency performance, ensuring that your PCBs meet both electrical and mechanical requirements. With our flexible manufacturing capabilities, we also offer rapid prototyping and efficient production times, helping to keep your project on track and within budget.

4.Efficient and High-Quality PCB Production

We pride ourselves on being a one-stop solution for all your PCB needs, handling everything under one roof. This streamlined approach reduces the complexity of sourcing different vendors and ensures that every part of your project meets our high standards of quality. So, whether you’re working on a new IoT device or a complex telecom infrastructure project, our team is ready to deliver top-tier results with high-performance materials and flawless execution. Let us be your trusted partner in bringing your PCB projects to life with efficiency, quality, and expertise.

Isola IS680 AG-348 PCB Substrates &FAQ

1. What is the typical thickness range for IS680 AG-348?

Thickness ranges from 30 mils (0.75mm) to 60 mils (1.5mm).

2. Can IS680 AG-348 be used for multilayer PCBs?

Yes, it is suitable for both single-layer and multilayer PCBs.

3. What is the maximum operating temperature of IS680 AG-348?

It can handle up to 180°C (356°F).

4. Is IS680 AG-348 halogen-free?

Yes, it is halogen-free and meets RoHS and WEEE regulations.

5. Can IS680 AG-348 be used in automotive PCBs?

Yes, it is commonly used in automotive communication systems.