This guide presents an in-depth exploration of high power PCBs, beginning with an introductory section that provides essential definitions and highlights key features. Following this, we will identify various types of high power PCB designs and carefully examine their advantages and disadvantages. We will also delve into the crucial aspects of PCB layout and discuss safety requirements associated with this design. In addition, we will thoroughly analyze the prototyping, fabrication, and assembly processes involved in high power PCB development.

Finally, we will conclude by discussing considerations for selecting a suitable manufacturer. Let us commence this comprehensive discussion.

What is High Power PCB ?

High Power PCB (Printed Circuit Board) refers to a type of circuit board designed to handle high current and power levels. It is used in applications that require efficient heat dissipation and robust electrical performance. High-power PCBs typically have thicker copper traces and larger copper pads to handle higher current levels without excessive heating.

They may also incorporate additional features like heat sinks, thermal vias, and other cooling mechanisms to manage the generated heat. High-power PCBs are commonly used in power electronics, electric vehicles, renewable energy systems, industrial machinery, and other high-power applications.

Layout Guidelines for High Power PCBs

When designing PCB layouts for high-power applications, several layout guidelines should be followed to ensure proper functionality, reliable power delivery, efficient heat dissipation, and minimal interference. Here are some important layout considerations for high-power PCBs:

Component placement: Strategically place high-power components to minimize trace lengths and optimize power flow. Group components with similar thermal and electrical characteristics together. Consider the positioning of heat-generating components to facilitate heat dissipation.

Power plane design: Utilize dedicated power planes to distribute power and minimize voltage drops. Ensure low impedance by using a sufficient copper area and removing any unnecessary splits or cuts in the planes. Optimize the stackup to provide adequate power plane regions.

Traces and current carrying capacity: Use wide traces and appropriate copper thickness to handle high current flows without excessive voltage drops or thermal issues. Follow the guidelines provided by trace width calculators or standards to determine the trace dimensions required for the specific current levels.

Thermal management: Implement techniques like thermal vias, heat sinks, and copper pours to aid in heat dissipation. Connect thermal pads of heat-generating components to the respective copper planes or heat sinks to dissipate heat efficiently.

Grounding: Establish a solid and low-impedance ground plane to reduce noise and minimize ground loops. Place ground vias strategically to ensure a comprehensive grounding network. Separate the analog and digital ground planes, if applicable, to prevent interference.

Signal isolation: Maintain sufficient clearance and spacing between high-power and low-voltage signal traces to avoid crosstalk or interference. Utilize ground planes or shielding techniques to provide isolation and reduce electromagnetic interference (EMI).

EMI/EMC considerations: Implement proper grounding and shielding techniques to minimize EMI. Use EMI filters and decoupling capacitors near high-power components. Follow signal routing guidelines to reduce radiated emissions and susceptibility to interference.

Thermal relief for vias: Add thermal relief (copper spokes) to vias connected to high-power components or power planes. This aids in efficient heat transfer and prevents excessive heating of the surrounding copper during soldering.

PCB material selection: Choose PCB materials with high thermal conductivity and appropriate electrical properties to handle high-power demands. Metal-core PCBs or high-temperature laminates can provide better heat dissipation and reliability.

Keep traces short: Minimize the length of high-current traces to minimize voltage drop and resistive losses. Minimize the trace length between decoupling capacitors and their respective components for effective decoupling.

Component clearance and spacing: Provide appropriate clearance and spacing between components to avoid thermal interference, electrical arcing, and potential damage resulting from heat dissipation.

Test points and accessibility: Include test points or access points for voltage and current measurements to facilitate testing and debugging during the development and maintenance phases.

By following these layout guidelines, you can ensure efficient power distribution, effective heat dissipation, minimal interference, and reliable operation of high-power PCB designs.

High Power PCB manufacturing Process

The manufacturing process for high power PCBs involves several stages from design to final product assembly. Here is a generalized overview of the manufacturing process for high power PCBs:

Design and Prototyping:

● Design the high power PCB layout using specialized PCB design software.

● Consider power requirements, thermal management, component placement, and signal integrity.

● Create a prototype PCB to validate the design and make necessary adjustments.

Material Selection:

● Choose appropriate materials for the high power PCB based on power handling, thermal conductivity, and electrical performance requirements.

● High temperature laminates with good thermal properties are often preferred.

PCB Fabrication:

● Generate Gerber files or manufacturing data from the PCB design software.

● Select a PCB fabrication facility and provide them with the design files.

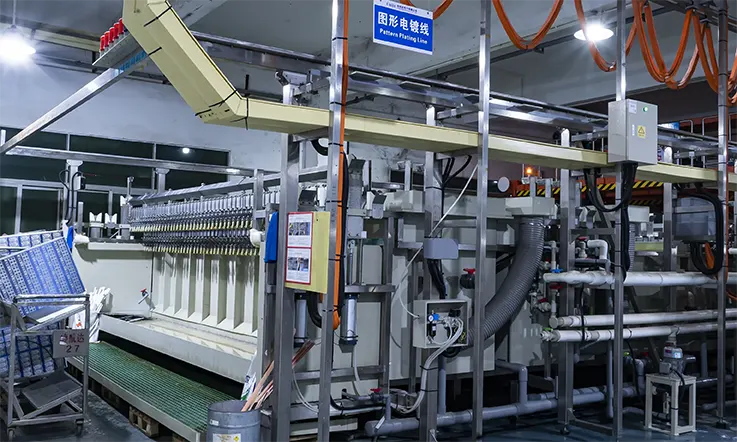

● The PCB manufacturer fabricates the PCB panels, including processes like copper deposition, etching, drilling, and laminating layers together.

Copper Plating and Heavy Copper:

If required, the PCB may undergo a process of copper plating or heavy copper application to achieve thicker copper layers for improved power handling.

Solder Mask and Silkscreen:

● Apply a solder mask to protect copper traces and prevent unintended solder bridging during assembly.

● Add silkscreen markings, component labels, and indicators for easy identification and assembly guidance.

Component Placement:

● Automated or manual pick-and-place machines accurately position surface mount components on the PCB.

● Through-hole components are inserted into pre-drilled holes manually or using automated insertion machines.

Soldering and Reflow:

● Solder paste is applied to the PCB pads for SMT components.

● In the reflow process, the PCB is subjected to controlled heating that melts the solder paste, creating electrical and mechanical connections between the components and the PCB.

Inspection and Testing:

● Visual inspection is performed to check for solder joint quality, component alignment, and any potential defects or errors.

● Electrical testing verifies the functionality and performance of the PCB, including power delivery, signal integrity, and thermal characteristics.

Thermal Management:

As part of the manufacturing process, additional thermal management components like heat sinks, thermal pads, or fans may be added to ensure proper heat dissipation.

Assembly and Packaging:

● If necessary, the PCB may undergo additional assembly processes such as enclosure installation, connectors, or final integration with other system components.

● Once the assembly is complete, the high power PCBs are packaged and prepared for shipment or integration into the final product.

It’s important to note that the manufacturing process may vary depending on the specific requirements, design complexity, and manufacturing capabilities. Actual manufacturing processes can be more detailed and involve specific steps tailored to the high power PCB’s unique design and production needs.

How Many Types of High Power PCB ?

There are several types of high power PCBs commonly used in different applications. Here are a few examples:

Double-sided High Power PCB: This type of PCB has conductive layers on both the top and bottom sides, allowing for increased routing flexibility and higher power handling capability.

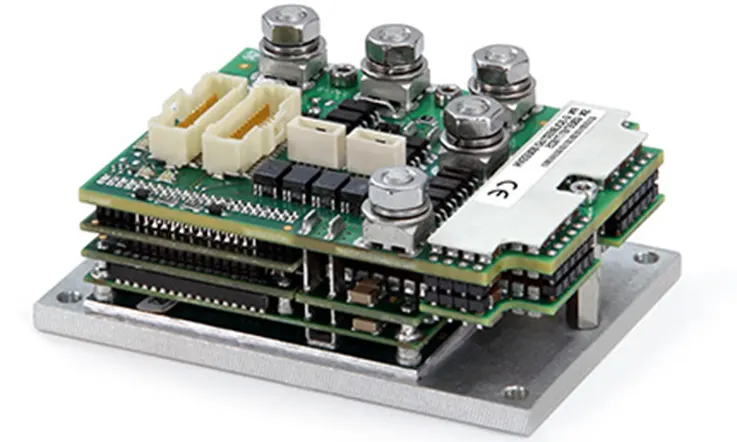

Multilayer High Power PCB: These PCBs have multiple layers of conductive material separated by insulating layers. They offer enhanced power distribution and heat dissipation compared to single or double-sided PCBs.

Metal Core PCB (MCPCB): MCPCBs feature a metal core, typically aluminum or copper, which provides excellent thermal conductivity. They are widely used in high-power LED lighting applications and other designs that require efficient heat dissipation.

Hybrid/Mixed Material PCB: In some high-power applications, a combination of different materials is used to optimize electrical and thermal performance. For example, combining FR-4 (standard PCB material) and metal core layers in specific areas can provide a balance between power handling capacity and cost.

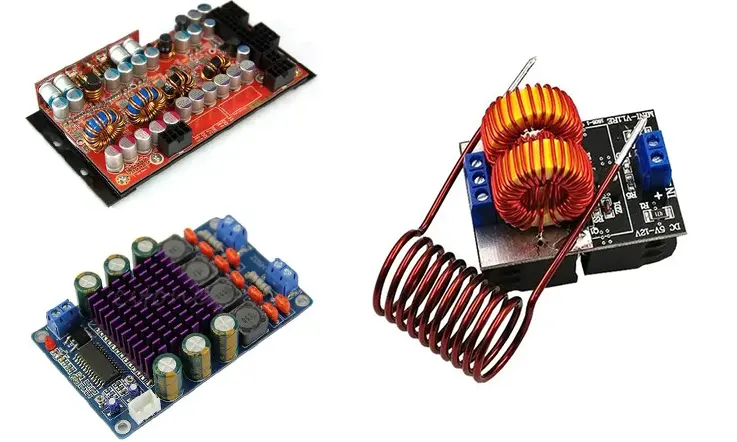

Thick Copper PCB: These PCBs have thicker copper traces and wider conductor widths to handle higher currents with minimal heating. They are commonly used in power electronics, motor drives, and automotive applications.

These are just a few examples, and the specific type of high power PCB required will depend on the power requirements, thermal considerations, and specific application needs.

High Power PCB Features

High power PCBs typically incorporate several features to ensure reliable operation and efficient heat dissipation. Here are some common features found in high power PCBs:

Thick Copper Traces: High power PCBs often have thicker copper traces to handle higher currents without excessive resistance and heating. The copper thickness can vary depending on the power requirements of the application.

Large Copper Pads: To facilitate better current flow and heat dissipation, high power PCBs feature larger copper pads for components such as power devices or connectors. These pads provide a larger surface area for effective heat transfer.

Heat Sinks: Heat sinks are often integrated into high power PCB designs. They are usually mounted on components that generate a significant amount of heat, such as power transistors. Heat sinks help dissipate the heat efficiently and maintain the temperature within acceptable limits.

Thermal Vias: Thermal vias are plated holes that extend from one layer of the PCB to another. They enhance heat dissipation by providing a path for heat to transfer between different layers of the PCB and reach the external heat sink or ambient environment.

Copper Fill Areas: Copper fill areas are large copper planes placed strategically on the PCB. They serve as heat spreaders, minimizing temperature gradients on the board and aiding in overall heat dissipation.

Specialized Insulation Materials: High power PCBs may employ specialized insulation materials with higher thermal conductivity properties, such as metal core PCBs (MCPCBs) or high-temperature laminates. These materials can effectively transfer heat away from high-power components.

Design Considerations for Current Paths: The layout of high power PCBs takes into account minimizing the length and impedance of current paths. Careful routing and placement of traces help reduce voltage drops, heating, and electromagnetic interference.

These features combine to offer improved power handling, efficient heat dissipation, and reliable operation in high power PCB applications. The specific features employed will depend on the power requirements, thermal considerations, and design constraints of the given application.

Where to Use High Power PCB ?

High power PCBs find applications in a wide range of industries and devices that require robust power handling and efficient heat dissipation. Here are some common areas where high power PCBs are used:

Power Electronics: High power PCBs are extensively used in power electronic devices such as inverters, motor drives, power supplies, converters, and amplifiers. These applications require PCBs that can handle high current levels, minimize voltage drops, and efficiently dissipate heat.

Electric Vehicles (EVs): EVs rely on high power PCBs for various components, including motor controllers, battery management systems, charging systems, and power distribution modules. The high power demands in EVs necessitate PCBs capable of handling high currents and thermal management to ensure reliable performance.

Renewable Energy Systems: Power generation systems like solar inverters and wind turbine converters utilize high power PCBs to handle the significant amount of current generated. These PCBs support efficient power conversion, distribution, and management in renewable energy installations.

Industrial Machinery: High power PCBs are integral to industrial machinery and equipment, including robotics, machine tools, industrial automation systems, and heavy machinery. These applications often involve high power consumption and require PCBs that can withstand heavy loads and maintain stable performance.

LED Lighting: High power PCBs are widely used in high-brightness LED lighting systems, especially for commercial and industrial applications. These PCBs help distribute power to the LEDs efficiently while managing heat generated by the high-power LEDs.

Telecom and Datacom: Telecom and data communication equipment, such as routers, switches, base stations, and servers, require high power PCBs to handle data processing and transmission. These PCBs help deliver stable power supply, manage high currents, and dissipate heat effectively.

Medical Devices: High power PCBs are used in medical devices like diagnostic equipment, imaging systems, surgical tools, and therapy devices. These applications often involve high power requirements and require reliable PCBs capable of managing power and dissipating heat safely.

Component Selection for High Power Applications

When selecting components for high-power applications on a PCB, it’s crucial to consider their ability to handle high currents, power dissipation, voltage ratings, and other relevant specifications. Here are some key factors to consider during component selection:

Power devices: Choose power devices such as transistors, MOSFETs, IGBTs, or power modules that have appropriate current and voltage ratings for your application. Look for low on-resistance (Rds(on)) values in MOSFETs or low saturation voltage (VCE(sat)) in transistors to minimize power losses and increase efficiency.

Capacitors and inductors: Select capacitors and inductors with suitable current and voltage ratings that can handle the power demands. Consider low equivalent series resistance (ESR) for capacitors and low DC resistance (DCR) for inductors to ensure efficient power delivery and high-frequency performance.

Heat sinks and cooling systems: Evaluate the thermal management requirements of high-power components and choose appropriate heat sinks or cooling systems to dissipate heat effectively. Consider factors such as thermal resistance, airflow, and mounting options to ensure efficient heat dissipation.

PCB layout and footprints: Ensure that the components’ package sizes and footprints are suitable for the PCB layout. Consider the thermal requirements, electrical clearance, and spacing when selecting component packages.

Voltage isolation: If voltage isolation is required for safety or functionality, select appropriate isolation components such as optocouplers or transformers that meet the required voltage isolation rating and can handle the power demands.

Reliability and quality: High-power applications demand components with high reliability and quality. Choose components from reputable manufacturers with a proven track record of providing reliable and durable components. Look for certifications and ratings such as AEC-Q100 for automotive-grade components.

Protection devices: Incorporate appropriate overcurrent protection devices, such as fuses, circuit breakers, or polymeric positive temperature coefficient (PPTC) devices, to protect against excessive current flow or short circuits. Choose devices with appropriate current ratings and response times for effective protection.

Application-specific requirements: Consider any specific requirements of your application, such as high-frequency operations or high-voltage handling. Select components that meet those requirements, such as high-speed diodes, gate driver ICs, or high-voltage capacitors, accordingly.

Electrical characteristics: Evaluate the electrical characteristics such as voltage ratings, current ratings, power dissipation, switching speed, and frequency response of components to ensure compatibility with the high-power application’s requirements.

Cost and availability: Consider the cost and availability of the selected components. Ensure that the preferred components are readily available within your budget constraints and can be sourced in the desired quantities.

By carefully considering these factors and thoroughly reviewing the datasheets and specifications of the components, you can choose the most suitable and reliable components for your high-power application, ensuring optimal performance and overall system integrity.

Assembly Method of High Power PCB

The assembly method for high power PCBs can vary depending on the specific requirements and complexity of the design. Here are some common assembly methods used for high power PCBs:

Surface Mount Technology (SMT):

● Surface mount components are mounted directly onto the PCB using solder paste and reflow soldering techniques.

● SMT allows for compact and high-density placement of components, suitable for high power applications.

Through-Hole Technology (THT):

● Through-hole components have leads that go through pre-drilled holes on the PCB and are soldered on the opposite side.

● THT is often used for larger or higher current-carrying components in high power PCBs.

Mixed Technology:

● High power PCBs may use a combination of SMT and THT components to optimize the design for performance and power requirements.

● SMT components provide size and weight advantages, while THT components offer higher current carrying capacity.

Manual Assembly:

● In some cases, especially for low-volume or highly specialized high power PCBs, manual assembly may be employed.

● Skilled technicians carefully place and solder components by hand, ensuring precise connections and thermal management.

Automated Assembly:

● For high-volume production, automated assembly processes such as pick-and-place machines and reflow soldering ovens are commonly used.

● Automated assembly ensures consistent and efficient placement of components with high accuracy.

It’s important to note that the assembly method may depend on several factors, including the specific design requirements, manufacturing capabilities, volume production needs, and thermal considerations of the high power PCB. Manufacturers often tailor the assembly process to meet the unique needs of the design and ensure the reliability and performance of the final product.

Advantages and Disadvantages of High Power PCB Design

Advantages of High Power PCB Design:

Efficient Power Delivery: High power PCB designs are specifically optimized for efficient power distribution, minimizing voltage drops and ensuring stable and reliable power delivery to high-power components.

Compact and Integrated Designs: High power PCBs allow for compact and integrated designs by efficiently routing power traces, minimizing space requirements, and reducing the overall footprint of the power distribution system.

Improved Thermal Management: High power PCB designs incorporate effective thermal management techniques, such as heat sinks, thermal vias, and copper pours, to dissipate heat generated by high-power components. This helps maintain optimal operating temperatures and improves overall system reliability.

Enhanced Power Handling Capability: High power PCB designs are engineered to handle high current levels and power dissipation, enabling the system to handle demanding applications with robust power capabilities.

Reduced Signal Interference: Careful layout design and grounding techniques in high power PCBs minimize signal interference and electromagnetic interference (EMI), leading to improved signal integrity and reduced noise in the system.

Disadvantages of High Power PCB Design:

Complexity: High power PCB designs tend to be more complex compared to low power designs due to the need for proper thermal management, larger trace widths, and often more advanced component selection.

Cost: High power PCBs typically require higher-quality components, specialized materials, and additional measures for thermal dissipation, all of which can contribute to higher manufacturing and assembly costs.

Design Constraints: Designing high power PCBs often involves meeting specific clearance and spacing requirements, which can limit design flexibility and require careful consideration of component placement and routing.

Heat Dissipation Challenges: Managing heat generated by high-power components can be a significant challenge. It may require the use of heat sinks, fans, or other cooling methods to maintain optimal operating temperatures, adding complexity and potential costs.

Safety Considerations: High power PCBs carry higher risks associated with high currents and voltages. Safety precautions, such as implementing appropriate insulation, protective devices, and adhering to safety standards, are crucial but can add complexity and cost to the design.

Compliance and Safety Considerations

Compliance and safety considerations are crucial aspects of high power PCB design to ensure the reliability and protection of the system. Here are some key topics that might be covered under the section on Compliance and Safety Considerations in an article:

Regulatory Standards and Certifications

● Overview of applicable standards and regulations (e.g., UL, IEC, RoHS).

● Compliance requirements for high power PCBs.

Safety Measures and Practices

● Fire safety precautions and prevention

● Electrical safety guidelines (e.g., isolation, grounding)

● Protection against potential hazards (e.g., thermal, electrical)

Electrostatic Discharge (ESD) Protection

● ESD risks and mitigation strategies.

● Proper grounding techniques and ESD protection components.

Overcurrent and Overvoltage Protection

● Circuit protection methods (e.g., fuses, circuit breakers, surge protectors).

● Design considerations for mitigating overcurrent and overvoltage risks.

Thermal Management and Heat Dissipation

● Guidelines for managing excessive heat and preventing thermal damage.

● Proper selection and installation of heat sinks, thermal pads, and fans.

Environmental Considerations

● Guidelines for designing environmentally friendly high power PCBs.

● Reduction of energy consumption and waste generation.

Reliability Testing and Analysis

● Importance of reliability testing for safety-critical systems.

● Methods for evaluating the performance and reliability of high power PCBs.

Documentation and Labeling

● Requirements for labeling, marking, and documentation of safety-related information.

● Traceability and compliance documentation for high power PCBs.

Maintenance and Serviceability

● Considerations for easy maintenance and troubleshooting.

● Safe handling procedures during repairs or component replacements.

It’s important to note that the specific content and order may vary depending on the article and its focus on compliance and safety considerations in high power PCB design.

How to Find a Right High Power PCB Fabricator ?

To find the right high power PCB fabricator, consider the following steps:

Evaluate capabilities and expertise: Review the fabricators’ technical expertise, equipment capabilities, and manufacturing processes. Ensure they have experience with high power PCB designs, including thermal management and high current handling.

Quality and certifications: Verify if the fabricator complies with quality standards such as ISO 9001 and IPC-A-600 for PCB manufacturing. Look for any additional certifications relevant to your industry or specific requirements.

Samples and references: Request samples of high power PCBs they have fabricated to assess their quality and workmanship. Seek client references and testimonials to gauge their track record and customer satisfaction.

Communication and support: Evaluate their communication responsiveness, technical support capabilities, and willingness to collaborate throughout the manufacturing process. Clear and prompt communication is crucial for a successful partnership.

Flexibility and customization: Determine if the fabricator can accommodate your specific customization requirements, including special materials, finishes, or unusual form factors.

Prototyping and testing: Inquire about their prototyping services as well as testing capabilities, such as electrical testing, thermal analysis, and reliability testing, to ensure quality control.

By following these steps, you can find a high power PCB fabricator that meets your specific requirements and provides quality manufacturing services.

Choose JarnisTech For Your PCB Project

High Power printed circuit boards (PCBs) are crucial components utilized in various devices and industries. When it comes to your project’s High Power board requirements, JarnsTech is here to provide reliable assistance. As a reputable supplier of bare PCBs, we hold an ISO 9001 certification since 2003, ensuring our commitment to quality. The experience and expertise of our team enable us to effectively identify the most suitable circuit board for your specific application and deliver exceptional customer service.

By opting for JarnsTech as your established PCB supplier, you gain the advantages of cost-effective prices and comprehensive knowledge in handling High Power configurations. We encourage you to reach out to us today through our online platform or by phone at 0086-0755-23034656 to explore how we can cater to your requirements.

Related Posts:

1.Everything to Know about Inverter PCB Why So Important

2.High Voltage PCBs: Design, Manufacturing, Assembly and Industry Standards