For any electronic manufacturing company, the utilization of turnkey printed circuit board assembly services is crucial to their function. Therefore, it is essential to identify an appropriate business partner who can fulfill your manufacturing requirements. JarnisTech offers turnkey PCB assembly services that enable you, the customer, to focus on the design and development of your exclusive product lines, while we handle the specifics of assembling them. This allows you to concentrate on other essential aspects of your business. We not only oversee the complete material procurement process, but we also handle the entire printed circuit board assembly process.

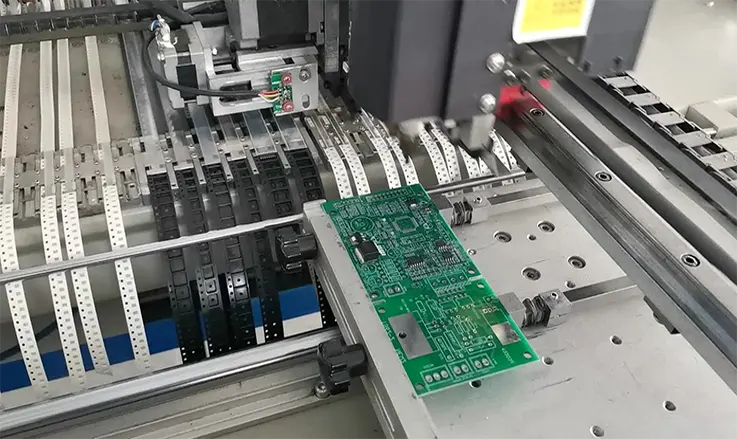

With four manual placement lines and four high-speed assembly lines, our business is suitably equipped to cater to diverse assembly requirements. Whether your project involves high-volume production of standard PCB assembly or advanced engineering for unique PCBA prototypes, JarnisTech can provide your company with the effectiveness and innovation that your products deserve.

Definition of PCB Assembly

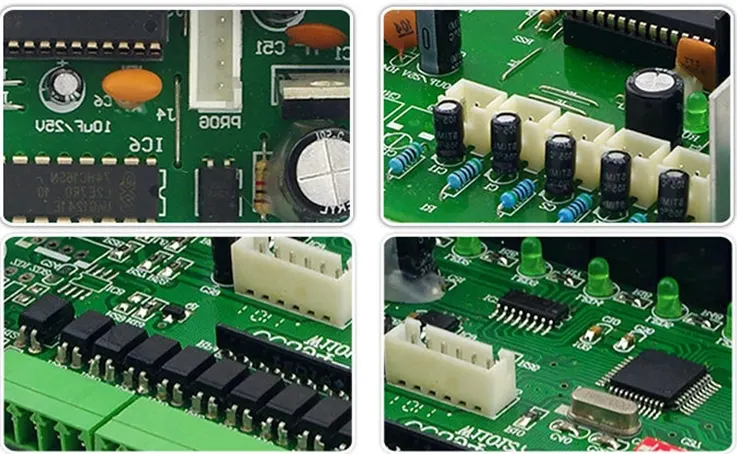

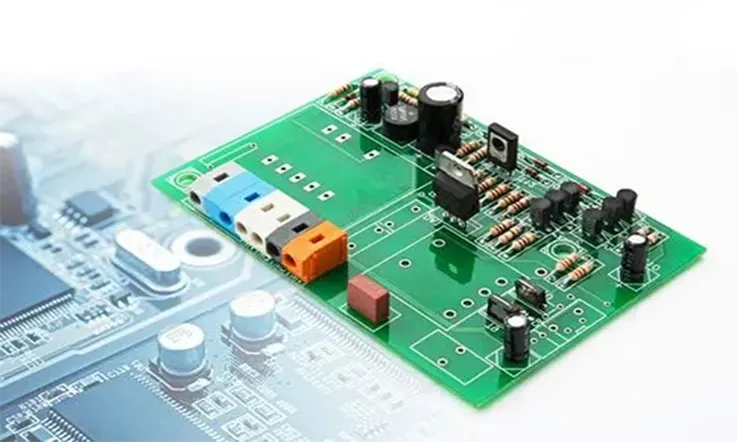

Printed Circuit Board (PCB) Assembly is the process of mounting and soldering electronic components onto a PCB. It involves several stages, including component placement, soldering, and inspection, and is a critical step in the development of any electronic device, from simple circuit boards to complex systems. PCB Assembly can be done manually or with the help of automated machinery, depending on the scale and complexity of the project. The assembly process can be divided into two main categories – Full Turnkey and Partial Turnkey – each with its own benefits and limitations. Ultimately, choosing the right PCB Assembly method and service provider is crucial for ensuring high-quality, reliable electronics.

What Is Turnkey PCB Assembly ?

For PCB design engineers, the term “turnkey” when referring to printed circuit board (PCB) assembly denotes a product or service that is readily available for immediate use by the buyer. In the context of PCB assembly, this term indicates that the provider will handle all aspects of the project, including the procurement of parts and components, as well as the production of PCBs. Turnkey PCB assembly is a process that leverages internet-based cloud software and PCB manufacturers to develop printed circuit boards for small businesses. This method is known for its speed, efficiency, and cost-effectiveness.

In essence, opting for a full turnkey solution enables PCB design engineers to focus on designing PCBs, while allowing the provider to manage all other aspects of the project. The utilization of turnkey solutions can streamline the assembly and testing of circuit boards for products, thereby saving time and money. Furthermore, businesses can acquire printed circuit boards in the shortest possible time with turnkey solutions. A comprehensive turnkey PCB assembly service includes all the necessary services, including PCBA, required to build finished goods. These may include, but are not limited to, the following:

● PCB prototypes.

● High volume PCB assembly.

● Box build.

● Management of Inventory.

● Shipment to clients

Aspects That Make Turnkey PCB Assembly Services Beneficial

● Quick Turnaround Times: In a turnkey PCB assembly service, all the steps involved in the process are carried out under the same roof, which results in a greatly reduced turnaround time. When multiple suppliers are utilized, particularly if they are located in different countries, a substantial amount of time is often consumed in the process of communication and shipment. The consolidation of all the necessary services in a turnkey PCB assembly solution leads to a faster production timeline, ultimately allowing for quicker delivery of the completed product to the customer.

● Competitive Prices: Opting for a turnkey PCB assembly service eliminates the need to send raw PCB boards and electronic components to an assembly facility, reducing the financial burden associated with shipping. Turnkey PCBA service providers generally have a trustworthy supply chain in place, allowing them to acquire components at a substantially lower rate than the market average. The incorporation of procurement services into their turnkey assembly offering, enables them to leverage economies of scale and optimize production, thereby passing the cost savings onto the customer.

● Better Process Management: A dependable PCB assembly partner possesses the capability to closely monitor every facet of the process, commencing from the procurement of components to the production and finally, the testing phase. Their expertise enables them to stay fully informed about the status of each stage, allowing them to identify any potential issues early on and take appropriate corrective measures. By doing so, they can execute the project in a more efficient and seamless manner.

How Many Types for Turnkey PCB Assembly ?

Turnkey PCB assembly services can be categorized as partial or full depending on the extent to which the third-party provider is involved in the assembly process.

Basics of Full Turnkey PCB Assembly

Full Turnkey PCB Assembly is a comprehensive service that involves the assembly of a complete PCB, from component procurement to final testing and inspection. This means that the PCB supplier manages the entire process, from selecting and purchasing electronic components and PCB fabrication to assembly, testing, and delivery. The supplier is responsible for ensuring that all components and materials are of the highest quality, and that the final PCBs meet all specifications and requirements.

The full turnkey method eliminates the need for the customer to manage multiple vendors or contractors, as the PCB supplier handles everything from start to finish. This approach is ideal for customers who do not have the time, resources, or expertise to manage the PCB Assembly process themselves. Additionally, full turnkey PCB Assembly offers faster turnaround times, improved quality control, and lower overall costs compared to other methods.

Some of the benefits of full turnkey PCB Assembly include:

● Reduced lead times and fast delivery.

● Consistent quality control throughout the entire process.

● Lower overall costs due to bulk purchasing power.

● Increased production efficiency.

● Single point of contact for all aspects of PCB Assembly.

However, some of the drawbacks of full turnkey PCB Assembly can include limitations on component choices and potential loss of control over the assembly process.

Benefits of Full Turnkey PCB Assembly

Full Turnkey PCB Assembly offers several benefits over other PCB Assembly methods. Some of these benefits include:

● Faster Turnaround Time: With full turnkey PCB Assembly, the entire process is handled by a single supplier, which helps to streamline the process and reduce lead times, resulting in faster delivery times.

● Single Point of Contact: By working with a single supplier for the entire PCB Assembly process, customers have one point of contact for all aspects, from component selection to final testing and delivery.

● Improved Quality Control: The supplier is responsible for ensuring that all components are of high quality and that the final product meets all specifications and requirements. This results in consistent quality control throughout the entire process.

● Lower Overall Costs: With full turnkey PCB Assembly, suppliers can take advantage of bulk purchasing power for components and materials, resulting in lower unit costs for the customer.

● Increased Production Efficiency: Full turnkey PCB Assembly allows for greater production efficiency as the entire process is managed by a single supplier, resulting in reduced downtime and improved overall efficiency.

Limitations/Drawbacks of Full Turnkey PCB Assembly

While full turnkey PCB Assembly has many benefits, there are also some drawbacks to consider:

● Limited Component Selection: Because the supplier is responsible for procuring components, customers may have limited options for components compared to other methods where they purchase their own components.

● Reduced Control Over the Process: With full turnkey PCB Assembly, customers may have less control over the process as it is managed by the supplier. This can result in reduced flexibility, and potentially fewer options for customization or changes.

● Higher Upfront Costs: Full turnkey PCB Assembly requires customers to pay for the entire PCB Assembly process upfront, which can be a significant investment for some customers.

● Dependency on the Supplier: Customers who rely on full turnkey PCB Assembly may develop a dependency on their supplier, potentially making it more difficult to switch to different suppliers in the future.

Basics of Partial Turnkey PCB Assembly

Partial Turnkey PCB Assembly is a PCB Assembly method where the customer supplies some or most of the electronic components, and the supplier provides the remainder of the components and handles the PCB Assembly process. In partial turnkey PCB Assembly, customers typically supply high-value components such as microcontrollers or custom integrated circuits while leaving the rest of the components to the supplier.

The supplier is responsible for managing the assembly process, including PCB fabrication, component procurement, assembly, testing, and inspection. Partial turnkey PCB Assembly is a more flexible option than full turnkey as it allows customers to supply some of their components without having to manage the entire process.

Partial turnkey PCB Assembly is ideal for customers who have unique or specialized components that they want to use in their PCB but do not have the resources or expertise to handle the entire assembly process. This approach offers a good balance between flexibility and cost-effectiveness, as customers can save money by providing their expensive components and leaving the rest of the assembly process to the supplier.

Benefits of Partial Turnkey PCB Assembly

● Flexibility: Customers can choose which components they want to supply and which ones to leave to the supplier, giving them more control over the process.

● Cost-Effective: Customers can save money by providing their high-value components while still benefiting from the supplier’s bulk purchasing power for the remaining components.

● Reduced Lead Time: By working with a PCB Assembly supplier, customers can benefit from faster lead times and delivery than if they handled the process in-house.

● Quality Control: The supplier is responsible for ensuring that the final product meets all specifications and requirements, resulting in consistent quality control throughout the process.

Limitations/Drawbacks of Partial Turnkey PCB Assembly

While partial turnkey PCB Assembly has many benefits, it also has some limitations and potential drawbacks to consider. These include:

● Limited Component Selection: Customers still may have limited options for components compared to other methods where they purchase their own components. Also, there may be compatibility issues between the customer supplied components and the remaining components assembled by the supplier.

● Reduced Control Over the Process: Customers may not have complete control over the entire assembly process, potentially leading to reduced flexibility or customization options.

Higher Upfront Costs: Partial turnkey PCB Assembly requires customers to pay for both the supplier provided components and their own components, which can be a significant investment for some customers.

● Increased Complexity: By combining customer supplied components with supplier supplied components, the PCB Assembly process can become more complex, increasing the risk of miscommunications or errors.

● Dependence on the Supplier: Customers who rely on partial turnkey PCB Assembly may still develop a dependency on their supplier, potentially making it more difficult to switch to different suppliers in the future.

Comparison between Full and Partial Turnkey PCB Assembly

Full and partial turnkey PCB assembly differ in terms of the level of involvement of the service provider in the manufacturing process. Here’s a brief comparison between full and partial turnkey PCB assembly:

● Cost: Full turnkey PCB Assembly can be more expensive than partial turnkey, as the supplier provides all components. Customers should determine the cost-effectiveness of each method based on their component needs and their budget.

● Lead Time: Full turnkey PCB Assembly can have faster turnaround times since the supplier handles all aspects of the assembly process. But partial turnkey assembly may still offer quick delivery times compared to in-house assembly.

● Component Selection: Partial turnkey PCB Assembly allows customers to have more control over the components used in their PCB since they provide some or most of them.

● Control over the Process: Full turnkey PCB Assembly may provide less control for customers who want complete oversight over every aspect of the assembly process. Partial turnkey assembly could provide more control to the customer.

● Supplier Expertise: Customers who rely on partial turnkey PCB Assembly can benefit from working with a supplier who has experience in the assembly process and can provide additional expertise. Full turnkey can provide a larger range of supplier expertise as they handle all of the assembly.

Ultimately, the decision between full or partial turnkey PCB Assembly will depend on the project’s specific requirements and the customer’s priorities. Customers should consider the above factors when determining which assembly method will best meet their needs for cost-effectiveness, time efficiency, control, flexibility, and supplier expertise.

Factors to Consider When Choosing a PCB Assembly Service Provider

Selecting a PCB Assembly service provider involves assessing various factors. Some important factors to consider include:

● Quality and Reliability: The provider’s reputation for quality, reliability, and product consistency is a critical consideration. The service provider should have strict quality control measures, use quality components, and follow standard industry practices.

● Experience and Expertise: The service provider’s range of experience, years of operation, technical knowledge, and expertise can significantly impact the project’s success.

● Capability and Capacity: The service provider’s equipment and production facilities should be modern and sophisticated to handle PCB Assembly projects successfully. The service provider should also have the capacity to manage various project sizes, production runs, and customer requirements.

● Cost and Pricing: The PCB Assembly service provider’s pricing structure should be competitive and offer value for money. The provider should also be transparent about the cost elements, including additional charges in the future.

● Lead Time: The service provider should have the ability to deliver a product within the desired lead time. The provider should have considerable capability to execute a project efficiently, manage the supply chain, and implement best practices.

● Customer Service and Support: The service provider should offer customer support and be responsive, accommodating, and communicative in addressing concerns.

● Certifications and Standards: The service provider should comply with industry certifications and standards such as ISO9001, IPC-A-610, and RoHS.

● Flexibility and Customization: The PCB Assembly service provider should offer various assembly customization options such as quick turn-around time, special testing, and customized packaging.

JarnisTech takes pride in catering to a diverse range of industries, such as Industrial, Communications, Medical, Wearable Devices, IoT, Navigation System, Bio-robotics, Monitoring System, Aviation, LED Lighting, and many others. Our unwavering commitment to meeting the unique specifications, quality standards, cost considerations, and delivery timelines of our individual customers sets us apart.

Our PCB manufacturing and assembly manufacturing facilities are situated in Shenzhen, and we adhere to stringent international standards, including ISO 9001, RoHS, IPC-A-600, and IPC-A-610, to ensure that every single printed circuit board assembly meets both the environmental and regulatory requirements and the highest quality standards. Furthermore, the final stages of production – the manufacture of PCBs and PCBAs in our SMT facility – reflect our dedication to customer satisfaction.

As a result, By considering these factors when choosing a PCB Assembly service provider, customers can ensure that they work with a provider who has a reputation for quality, expertise, and reliable delivery and can meet specific project requirements within budget.

Why Choose JarnisTech ?

When outsourcing your end-to-end PCB assembly to a reputable service provider like JarnisTech, you can focus on your core competencies while benefiting from reduced costs and faster time to market. Our comprehensive services include material sourcing, design, manufacturing, and supply chain management, allowing us to fulfill all your requirements and help you reach your customers quickly.

Our turnkey electronic manufacturing services cover the entire production process, starting from material acquisition to final assembly. By taking care of all aspects of production, including design, procurement, assembly, and supply chain management, we can provide a hassle-free and efficient service to our clients.

Our services are tailored to meet the specific requirements of each client, allowing them to save time and money in the production of their products. By leveraging our expertise and experience in electronic manufacturing, we can help our clients optimize their designs, reduce their production costs, and bring their products to market faster.

Here is a rundown of what our turnkey electronic manufacturing services entail, as well as an explanation of how you can make use of them to cut down on the amount of time and money spent constructing your product:

● Complete Bill of Materials: As a reliable production partner, we understand the significance of creating and keeping track of the Bill of Materials (BOM) for every product development process. We acknowledge the time and resources involved in this vital function, and therefore, we take on the responsibility of creating and monitoring the BOM. Our team is committed to ensuring that your project schedule stays on track while performing a range of activities such as rapid and cost-effective sourcing of components and managing resources in sync with the production process to avoid delays.

We offer exceptional part procurement services that enable you to obtain high-quality Printed Circuit Board (PCB) components at the best possible prices that suit your budget. We assure you of superior output quality by maintaining consistent and open communication channels throughout the production process. We value your valuable time and offer quick quotations in as little as four hours, and you can expect quick delivery within 24 hours of your order placement. By choosing us as your PCB manufacturer, you can start your projects faster and with greater efficiency.

● Expert Services of PCB Layout: As a manufacturer, nothing can be more detrimental than the cost of rework and production delays. To mitigate such risk, we offer manufacturing feasibility evaluations that can assess the viability of your designs and help you stay on schedule to bring your product to market without any delay. Our team works forward-thinking to ensure that your designs are converted into an end product that is fit for sale by leveraging the latest cutting-edge technologies such as PADS, Altium, and Cadence.

By our manufacturing feasibility evaluations, you can be assured that your design will be reviewed and evaluated against our extensive industry experience and knowledge. This service also enables you to identify any potential roadblocks early in the design process and determine the most efficient and cost-effective manufacturing solutions. With our focus on delivering high-quality results, we ensure that your product development process stays on track and avoids unnecessary delays, which ultimately leads to improved market competitiveness.

● Solutions of Customized PCB Assembly: Our organization is an industry-leading provider of circuit board assembly services and has significant experience delivering customized solutions that cater to the most challenging requirements and timeframes.

Our expertise in PCB assembly is hard to match, and we are always ready to accommodate your specific manufacturing needs as per your schedule and budget. We have a team of highly skilled professionals whose creativity and innovation allow us to deliver custom solutions that meet your unique demands.

We understand the importance of timely delivery in today’s rapidly evolving business world, and thus we have streamlined our processes to ensure that we deliver on time regardless of the complexity of the project or the deadline. Our commitment to quality is second to none, and we leverage modern technologies and techniques to ensure the reliability and durability of our PCB assemblies.

● Stringent of Testing Procedures: As a professional Printed Circuit Board (PCB) manufacturer, we fully comply with industry and regulatory standards and have implemented rigorous quality control procedures to meet the ISO-9000 and ITAR certification requirements.

Our quality control procedures are designed to ensure that each circuit board is manufactured and tested to function accurately and reliably. We conduct extensive testing and inspection at every stage of the production process to identify any potential defects, faults, or errors that could compromise the performance of the PCB.

We firmly believe in adhering to internationally recognized industry standards, and our quality control policies help us ensure that your circuit boards are manufactured and tested to the highest standards. Our commitment to quality is reflected in our strict adherence to all applicable regulatory and environmental standards.

● Quality Control of PCB Assembly: As a professional Printed Circuit Board manufacturer, we are committed to maintaining the highest standards of quality and reliability in every aspect of our operations. We follow the IPC-A-610 requirements meticulously during the assembly of all bare PCB boards to ensure that our products meet industry and customer standards.

Our team consists of highly experienced and skilled technicians and inspectors who have the expertise to handle every aspect of the PCB manufacturing process. We handle all aspects of the manufacturing process in-house, which enables us to ensure compliance with IPC Class II or III standards based on the customer’s needs.

We ensure that every bare PCB is subjected to comprehensive electrical testing, using either a flying probe or a fixture, to ensure accuracy and reliability. We follow a 100% visual examination process after the electronic PCB assembly is completed. For further assurance, we offer an optional 100% functional test performed in accordance with documented test procedures.

Our commitment to quality goes beyond the manufacturing process. We ensure that every finished PCB is cleaned 100% to remove any dust or debris that might affect its performance. We also enforce strict controls on electronic static discharge (ESD) to prevent any chance of damage to the PCB.

Therefore, partnering with JarnisTech for turnkey electronic manufacturing services means that our clients can concentrate on their core strengths, while benefitting from cost savings and faster time to market. Our comprehensive services cover the entire product life cycle, ensuring that our clients’ requirements are met efficiently and effectively

Turnkey PCB Assembly: Files Requirement

● Gerber or ODB++ Files: Copper, solder mask, silkscreen, solder paste, outline, thru-via hole, blind and buried via, micro-via, carbon ink printing, FPC stiffener, EMI film, and any other layers necessary should be included.

Excel version of the Bill of Materials (BOM) document. Your BOM ought to contain the following:

● Description (optional).

● Manufacturer (optional).

● Quantity per board (required).

● Reference designators (required).

● Manufacturer part number (required).

● Package (QFN32, SOIC, SOT23-5, 0402, etc.) (optional).

● Type (SMD, Thru-Hole, Fine-Pitch, BGA, etc.) (optional).

● IColumns indicating whether the parts were consigned by you, JarnisTech supplied, or not populated are highly desirable.

● Centroid File: The necessary file for PCB assembly is commonly referred to as the coordinates file, or the select and place file, and must be in CSV format. This file should include accurate component positions, rotations, and reference designators. Optionally, if a solder paste layer is included in the Gerber file package, Assembly Drawings may also be provided.

For complex PCBs, Assembly Notes can be incredibly useful during production, and can be saved in PDF format for convenience.

JarnisTech Capabilities of Turnkey PCB Assembly

| Capability | Standard |

| Certifications: | ISO 9001: 2008, AS 9100 Rev D, ISO 13485: 2016 |

| Lead Time: | 3-7 Days(Prototype Assembly),2-4weeks(High volume Assembly) |

| Parts procurement: | Full Turnkey, Partial Turnkey, and Knitted |

| Assembly Types: | Surface Mount (SMT), Thru-hole, Mixed Technology, Single and double-sided SMT/PTH.Rigid Board, MCPCB and Rigid-Flex PCB assembly. Prototype PCB Assembly, low-volume PCB assembly, high-volume PCB assembly, BGA Assembly, FPC PCB Assembly, Lead-free (RoHS) PCB assembly. |

| Stencils: | Laser cut stainless steel and Nano-coating |

| Components: | Passive components smallest size 0201, Fine pitch components smallest size 8 Mils pitch. |

| Component packaging: | Reels, Cut Tape, Tube, and lose parts. |

| Inspection: | X-ray analysis, AOI, and Microscope to 20X |

| Solder Type: | Leaded and Lead-free/ RoHS compliant |

| Assembly Surface mount connectors: | Yes |

| Wave Soldering: | Yes |

| PCB Finish: | SMOB/HASL, Electrolytic gold, Electroless gold, Electroless silver, Immersion gold, Immersion gold, Immersion tin, and OSP. |

| Panelized PCB: | Tab routed, Breakaway tabs, V-scored and Routed + V scored |

| Rework: | BGA removal and replacement station, SMT IR rework station, and Thru-hole reworks station. |

| Design file format: | Gerber RS-274, 274D, Eagle and Auto CAD’s DXF, DWG BOM, and Pick and place a file |

PCB Assembly Request For Quote

We are pleased to inform our valued customers that our team is readily available to address any inquiries or concerns related to order placement. At JarnisTech, we offer competitive pricing and direct savings pass-throughs to our customers who choose to purchase our full or partial turnkey PCB assembly services. To request a price estimate, we encourage customers to visit our RFQ page and provide the necessary information. Furthermore, our dedicated customer support staff can be reached at 0086-755-23034656 for additional assistance. For a comprehensive list of the required documents that must accompany the quote request, please contact us now.

Conclusion

When deciding between full and partial turnkey PCB Assembly, customers should consider their component needs, budget, control, and flexibility.

To choose a reliable PCB Assembly service provider, customers should conduct research and consider factors such as the provider’s reputation, experience, expertise, capacity, cost, lead time, customer service and support, and adherence to industry standards and best practices.

In short, taking the time to thoroughly evaluate PCB Assembly service providers and consider the necessary factors will help ensure that the chosen provider can meet your project requirements

In China, JarnisTech is a highly reputable and experienced PCB manufacturer that has been providing quality services to clients for many years. we offer a wide range of PCB manufacturing services, including turnkey and prototype assembly, PCB layout and design, and PCB fabrication. And if you want to know more and more, please contact us today.

Related Posts:

- Mixed PCB Assembly Technology Services For Your Next New Project

- Why Electronic Potting is So Important in PCB Assembly?

- A Full Guide to Electro mechanical Assemblies

- Cable and Wire Harness Assembly

- Electronics Components PCB Assembly

- China:The Best PCB Consignment Assembly Services At JarnisTech

- PCB Box Build Assembly

- Nine Method of Save Cost PCB Assembly Production

- What Is Printed Circuit Boards Assembly?