Regardless of your intended use for a Bluetooth device, the ability to quickly establish a pairing connection is essential. For instance, if you wish to enjoy your favorite music during your vacation, it’s wise to bring along a Bluetooth speaker capable of playing your playlists for extended periods. Similarly, if you want to transfer some impressive selfies to your friend’s cellphone, you can accomplish this by activating the Bluetooth connection and sending the images via the link.

Bluetooth technology has become ubiquitous, enabling various functionalities facilitated by Bluetooth circuit boards. This article offers an in-depth exploration of Bluetooth circuit boards, including their types and applications.

The initial chapter provides a brief overview of Bluetooth technology before delving into the intricate details of Bluetooth circuit boards themselves.

Bluetooth Technology

Bluetooth technology is a wireless communication protocol that enables short-range data transmission between devices. It uses radio waves within the 2.4 GHz frequency band to establish connections between devices like smartphones, computers, speakers, headphones, and IoT devices.

Key features of Bluetooth Technology Include

Pairing: Bluetooth devices establish a secure connection by pairing with each other. Pairing involves exchanging authentication and encryption keys to ensure a secure and private connection.

Profiles: Bluetooth profiles define specific functionalities and capabilities for different types of devices. Common profiles include Hands-Free Profile (HFP), Advanced Audio Distribution Profile (A2DP), and Human Interface Device (HID) profile.

Range: Bluetooth has a typical range of up to 10 meters, known as Class 2 devices. Bluetooth Class 1 devices can have an extended range of up to 100 meters.

Data Transfer: Bluetooth supports various data transfer modes, including asynchronous data transfer (ACL) for sending larger amounts of data and synchronous connection-oriented (SCO) for real-time audio.

Low Energy: Bluetooth Low Energy (BLE) is a power-efficient version of Bluetooth that enables devices to operate on battery power for extended periods. It is widely used in wearable devices, healthcare applications, and IoT devices.

Compatibility: Bluetooth technology is backward compatible, allowing newer Bluetooth devices to connect and communicate with older ones. However, the features and capabilities may vary depending on the supported Bluetooth version.

Security: Bluetooth technology incorporates security measures like encryption and authentication to protect data transmission and prevent unauthorized access.

Bluetooth technology has become ubiquitous, providing convenient wireless connectivity for a wide range of devices, including smartphones, audio peripherals, smart home devices, wearable technology, and more. It continues to evolve with each new version, offering improved performance, higher data rates, and enhanced features for seamless device connectivity.

What is Bluetooth Circuit Board ?

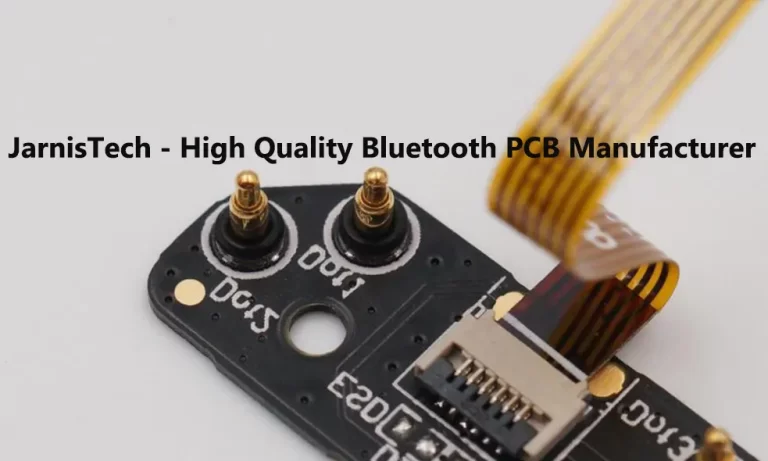

A Bluetooth circuit board, also known as a Bluetooth module or Bluetooth chip, is an electronic component that integrates the Bluetooth technology into a compact circuit board. It is designed to facilitate wireless communication between devices using Bluetooth technology.

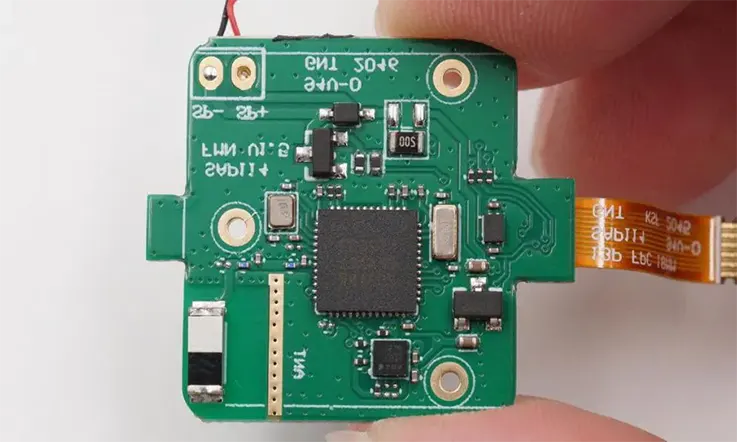

The Bluetooth circuit board typically consists of several key components, including a Bluetooth transceiver, antenna, microcontroller, and necessary support circuitry. The transceiver is responsible for transmitting and receiving Bluetooth signals, while the antenna facilitates wireless connectivity. The microcontroller handles the data processing and manages the communication protocols.

Bluetooth circuit boards come in various form factors, such as surface mount modules, system-on-chip (SoC) modules, or stand-alone modules. They can be embedded in various devices, such as smartphones, tablets, laptops, wireless headphones, speakers, smartwatches, and other IoT (Internet of Things) devices.

The Bluetooth circuit board enables these devices to establish short-range wireless connections with other compatible Bluetooth-enabled devices. It allows for data transmission, audio streaming, device pairing, and control functionalities, making it a versatile technology for wireless communication in numerous applications.

Types of Applications of Bluetooth Circuit Board

Bluetooth circuit boards find application in various domains and industries. Some common applications of Bluetooth circuit boards include:

Consumer Electronics: Bluetooth-enabled devices, such as smartphones, laptops, headphones, speakers, and smartwatches, rely on Bluetooth circuit boards to enable wireless connectivity, data transfer, and audio streaming between devices.

Home Automation: Bluetooth circuit boards are used in home automation systems to connect and control smart devices, such as lights, thermostats, door locks, and security systems. They allow for convenient wireless control and monitoring within a home network.

Automotive: Bluetooth circuit boards are integrated into car infotainment systems, enabling hands-free calling, audio streaming, and wireless connectivity with smartphones. They also facilitate features like Bluetooth-enabled keyless entry and vehicle diagnostics.

Healthcare: Bluetooth circuit boards are utilized in healthcare devices for data monitoring and tracking. For example, wearable fitness trackers, blood glucose monitors, and heart rate monitors incorporate Bluetooth technology to transmit health-related data to smartphones or other compatible devices.

Industrial Automation: Bluetooth circuit boards play a role in industrial applications, such as wireless sensors, equipment monitoring, and control systems. They provide wireless connectivity and data exchange between devices in industrial automation environments.

IoT (Internet of Things): Bluetooth circuit boards are important components in IoT devices that rely on wireless communication. They enable connectivity and data exchange between interconnected IoT devices, creating a cohesive IoT ecosystem.

Gaming: Bluetooth circuit boards are used in gaming consoles, controllers, and accessories to establish wireless connections and enable multiplayer gaming experiences across different devices.

These are just a few examples, and Bluetooth circuit boards have a wide range of applications beyond these industries. Their versatility and compatibility make them a widely adopted technology for wireless communication and connectivity.

Key Considerations of Designing a Bluetooth PCB

Designing a Bluetooth PCB (Printed Circuit Board) involves the following key considerations:

Bluetooth Module Selection: Choose a suitable Bluetooth module that meets the requirements of your application. Consider factors such as range, power consumption, data rate, supported Bluetooth profiles, and integration options.

RF Layout Design: Pay close attention to the RF circuit layout, considering factors like trace length, impedance matching, and signal integrity. Place the Bluetooth module and associated components carefully to minimize signal loss and interference.

Antenna Design and Placement: Determine the type of antenna that suits your application, such as chip antennas, trace antennas, or external antennas. Ensure proper clearance around the antenna, avoid nearby metallic objects, and optimize the antenna placement for optimal signal strength and range.

Power Supply and Decoupling: Provide stable and clean power to the Bluetooth module, ensuring appropriate voltage levels and noise reduction. Use suitable decoupling capacitors near the power supply pins of the module to filter out noise and maintain a stable power source.

Signal Integrity: Implement good PCB design practices to maintain signal integrity. Minimize noise coupling, use proper ground planes and power planes, and apply impedance matching techniques where necessary.

EMI/EMC Considerations: Pay attention to electromagnetic interference (EMI) and electromagnetic compatibility (EMC) requirements. Implement EMI shielding techniques, use proper grounding, and follow PCB layout guidelines to mitigate EMI/EMC issues.

Mechanical Constraints: Consider mechanical constraints, such as the size, shape, and mounting requirements of your Bluetooth PCB. Ensure that the PCB fits within the desired enclosure and aligns with mechanical components such as connectors, buttons, and indicators.

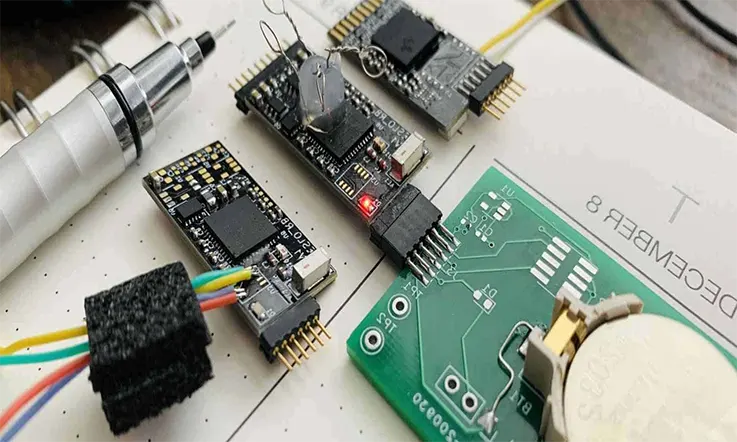

Testing and Prototyping: Plan for testing and prototyping stages to validate the Bluetooth PCB design. Verify functionality, RF performance, power consumption, and compliance with relevant standards and regulations.

Documentation and Manufacturing Files: Prepare comprehensive documentation, including schematics, layout files, bill of materials (BOM), and assembly drawings, to facilitate the manufacturing process.

It is crucial to follow Bluetooth design guidelines provided by the module manufacturer and consult relevant design resources and standards, such as the Bluetooth SIG (Special Interest Group) specifications, to ensure a reliable and robust Bluetooth PCB design. Additionally, collaborating with experienced RF engineers or PCB designers can provide valuable insights and expertise for successful Bluetooth PCB design.

Manufacturing Bluetooth PCBs Step

Manufacturing Bluetooth PCBs (Printed Circuit Boards) typically involves the following steps:

PCB Fabrication

Start by generating the manufacturing files, including Gerber files that contain the PCB layout information. Provide these files to a PCB manufacturer or fabrication house. The manufacturer will use the files to produce the PCBs according to your design specifications. The fabrication process involves processes like layer alignment, copper deposition, etching, drilling, and solder mask application.

Component Sourcing

Source the required electronic components for your Bluetooth PCB. This includes the Bluetooth module, passive components (resistors, capacitors, etc.), connectors, and any other specific components needed for your design. Choose reputable component suppliers or distributors to ensure component authenticity and quality.

PCB Assembly

The process of assembling components onto the PCB is known as PCB assembly or manufacturing. This can be done in-house if you have the necessary equipment and expertise, or you can outsource it to a contract manufacturer (CM) or electronic manufacturing services (EMS) provider. The assembly process typically involves the following steps:

a. Solder Paste Stencil: A stencil is used to apply solder paste onto the PCB, defining the locations where components will be placed.

b. Pick and Place: Automated pick-and-place machines accurately place surface-mount components onto the solder paste on the PCB. This includes the Bluetooth module, resistors, capacitors, ICs, and other components.

c. Soldering: After component placement, the PCB goes through a reflow soldering process where heat is applied to melt the solder paste, creating a permanent electrical connection between the components and the PCB.

d. Inspection and Testing: Visual inspection, automated optical inspection (AOI), and/or X-ray inspection are performed to ensure the quality of the solder connections. Functional testing may also be conducted to verify the functionality of the Bluetooth circuitry.

Quality Assurance and Testing

Quality control measures are taken to ensure the manufactured Bluetooth PCBs meet the required standards and specifications. This may include electrical testing, functional testing, and performance testing of the Bluetooth functionality.

Packaging and Shipping

Once the manufacturing and testing processes are complete, the Bluetooth PCBs are packaged securely to protect them during transportation. They are then shipped to the desired destination.

It’s important to work closely with the PCB manufacturer and assembly provider to ensure clear communication, provide detailed documentation, and address any specific requirements or considerations for the Bluetooth PCB manufacturing process.

Components of a Bluetooth Circuit Board

A Bluetooth circuit board consists of various components that work together to enable wireless communication using Bluetooth technology. The key components typically found on a Bluetooth circuit board include:

Bluetooth Transceiver: The Bluetooth transceiver is responsible for transmitting and receiving Bluetooth signals. It converts data into radio waves for transmission and demodulates received radio waves into usable data.

Antenna: The antenna is essential for wireless connectivity. It is used to send and receive Bluetooth signals between devices. The type and design of the antenna can vary depending on the specific application and range requirements.

Microcontroller (MCU): The microcontroller acts as the brain of the Bluetooth circuit board. It handles the data processing, manages communication protocols, and controls the overall operation of the Bluetooth module. The MCU also interfaces with other components on the circuit board.

Support Circuitry: The Bluetooth circuit board includes additional circuitry to support its operation. This may include voltage regulators, filters, oscillators, and capacitors. These components ensure stable power supply, frequency stability, and noise reduction for optimal performance.

Memory: Bluetooth circuit boards often have integrated memory to store firmware, configuration data, and other necessary information for operation. The memory can be in the form of flash memory or EEPROM (Electrically Erasable Programmable Read-Only Memory).

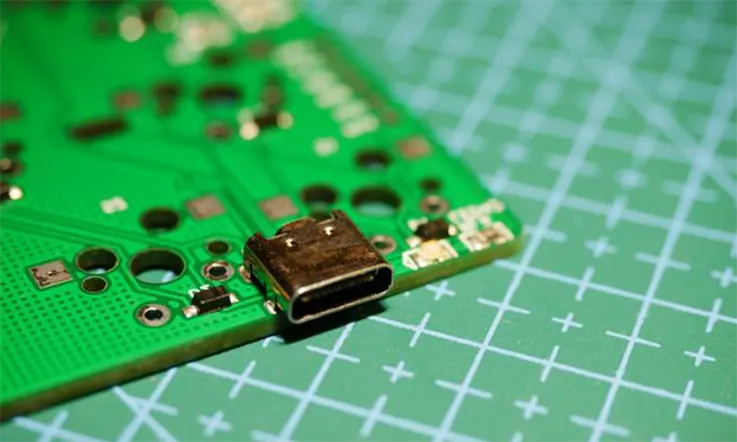

Interfaces: Bluetooth circuit boards typically have interfaces for connecting to external devices or systems. This can include UART (Universal Asynchronous Receiver-Transmitter) for serial communication, SPI (Serial Peripheral Interface) or I2C (Inter-Integrated Circuit) for interfacing with other devices, and GPIO (General-Purpose Input/Output) pins for general-purpose connections.

Power Supply: Bluetooth circuit boards require a power supply to operate. They may include voltage regulation circuitry to ensure stable power to the components. The power supply can come from batteries, USB ports, or other power sources depending on the specific application.

These components work together to enable wireless communication and functionality provided by Bluetooth technology. The specific configuration and components can vary depending on the design and purpose of the Bluetooth circuit board.

How To Find High quality Bluetooth Circuit Boards Manufacturer?

To find a high-quality Bluetooth circuit board manufacturer, you can follow these steps:

Research and compile a list: Start by conducting online research to identify potential manufacturers. Look for companies with a strong reputation, positive customer reviews, and a track record of producing high-quality products.

Assess their experience and expertise: Check the manufacturer’s website or contact them directly to gather information about their experience in producing Bluetooth circuit boards. Look for their specialization in electronic manufacturing and inquire about their expertise in Bluetooth technology.

Quality certifications: Determine if the manufacturer holds relevant quality certifications such as ISO 9001 or IPC standards. These certifications indicate their commitment to maintaining high-quality standards in their manufacturing processes.

Request samples: Ask the manufacturer if they can provide samples of Bluetooth circuit boards they have previously produced. Evaluate the quality and reliability of these samples to assess whether they meet your requirements.

Inquire about production capabilities: Discuss the manufacturer’s production capabilities in terms of volume, lead times, and capacity to ensure they can meet your specific requirements.

Cost and pricing structure: Obtain quotes from multiple manufacturers and compare their pricing structures. Be cautious of unusually low prices, as they may indicate compromises in quality or reliability.

Communication and responsiveness: Evaluate the manufacturer’s level of communication and responsiveness. A reliable manufacturer should be proactive in addressing your inquiries and providing updates throughout the production process.

Additional services: Consider whether the manufacturer offers additional services such as design assistance, prototyping, customization options, and technical support. These services can be valuable for ensuring the success of your Bluetooth circuit board project.

References and reviews: Request references from the manufacturer and reach out to their previous clients for feedback on their experience working with the manufacturer. Online reviews and testimonials can also provide valuable insights.

Visit the facility (optional): If feasible, consider visiting the manufacturer’s facility to observe their operations firsthand and assess their manufacturing processes and quality control measures.

By following these steps, you can identify a high-quality Bluetooth circuit board manufacturer that meets your specific requirements and standards.

Your Professional Bluetooth PCB Manufacturer – JarnisTech

Why More Than 3000 Clients Over the World Love to Work with Us:

Customized Design

JarnisTech specializes in the production of multi-layer circuit boards, offering a comprehensive range of services to cater to diverse client requirements. Our extensive service scope encompasses PCB design, circuit simulation, and PCB design technology training. We also provide assistance in schematic component library design, PCB packaging library design, as well as consultation on PCB processing and inspection techniques. Furthermore, we are well-versed in SMT (Surface Mount Technology) and reflow soldering technology, providing expert guidance and support in these areas. By leveraging our expertise and resources, we aim to deliver superior solutions tailored to the specific needs of our valued clients.

Quality Control

At JarnisTech, we hold an unwavering commitment to delivering products of the highest quality to our esteemed customers. To ensure this, we have meticulously implemented the ISO9001 quality system and diligently adhere to stringent quality protocols. Our overarching objective is to eliminate the production of defective products altogether. Hence, we rigorously enforce a zero-tolerance policy that entails not producing, accepting, or manufacturing any items that fall short of our rigorous quality standards. We firmly believe that quality is a result of the dedicated efforts of our skilled workforce and not merely reliant on testing procedures. By prioritizing excellence at every stage of our operations, we strive to exceed customer expectations and maintain our reputation as a provider of top-tier quality products.

Fast Delivery Time

JarnisTech is a trusted provider of comprehensive printed circuit board and assembly solutions, catering to a wide range of client needs. Our extensive product line encompasses express prototype services as well as quick turn mass production capabilities. Notably, we understand the importance of urgent prototype board orders and prioritize swift execution. In this regard, we offer expedited production within 24 to 48 hours, ensuring prompt delivery facilitated by reputable shipping carriers such as UPS, DHL, and FedEx. Rest assured, our streamlined processes and efficient service will seamlessly integrate with your production schedule, minimizing any disruptions.

One- Stop Solution for You

JarnisTech provides a comprehensive suite of services encompassing PCB layout and design, electronic components sourcing, PCB manufacturing, and assembly. By offering a one-stop solution, we eliminate the need for engaging multiple suppliers for various project requirements. Moreover, our experienced engineers are equipped to offer valuable insights and guidance throughout the design phase of your product, ensuring efficient resource allocation and time-saving advantages. As a result, we strive to optimize cost-effectiveness while delivering exceptional quality and convenience to our clients.

One Professional and Exprienced Team

At JarnisTech, our team comprises seasoned professionals who are recognized as industry experts in their respective fields. With a wealth of experience exceeding 20 years, our engineering and technical personnel have honed their skills while working in prominent manufacturing facilities involved in PCB fabrication, assembly, and components sourcing. This extensive expertise enables us to deliver prompt and proficient PCB solutions, ensuring the utmost satisfaction of our valued customers.

Advanced Equipments

At JarnisTech, we pride ourselves on utilizing cutting-edge equipment sourced from renowned manufacturers around the globe, including the United States, Germany, Japan, and other leading countries. Our commitment to delivering exceptional quality stems from our continual investment in acquiring state-of-the-art machinery. By staying at the forefront of technological advancements, we strive to meet and exceed the requirements of our valued clients.

Conclusion

When assembling Bluetooth circuit boards, it is crucial to uphold professional standards to ensure optimal functionality, range, and other key features. In this regard, we offer a reliable and experienced solution. With years of industry expertise, we specialize in collecting Bluetooth PCBs, guaranteeing high quality while adhering to your precise specifications.

By collaborating with us, you can benefit from the services of a trusted partner dedicated to providing exceptional Bluetooth circuit boards. Whether you require customized orders or bulk quantities, our team is well-equipped to meet your needs. Furthermore, we prioritize cost-effectiveness to support the growth of your business.

To avail yourself of our services and secure Bluetooth PCBs that meet your requirements, please don’t hesitate to get in touch with us. We look forward to the opportunity to serve you.

Related Posts:

1. Exceptional Manufacturer of Antenna PCBs

3. FAQ Guide About Wireless PCB

4. Why Carrier PCB in Telecommunication Is So Useful?

5. What Is GPS PCB and How to Use GPS Integration into PCB?

6.The Evolution of 5G PCB Technology: Transforming the Telecommunication Industry