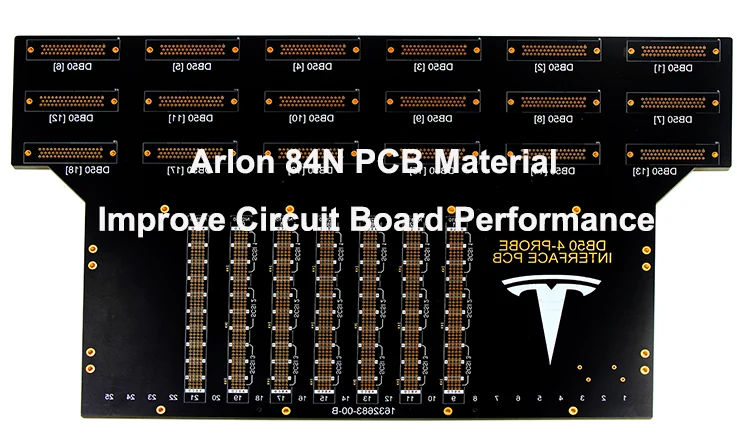

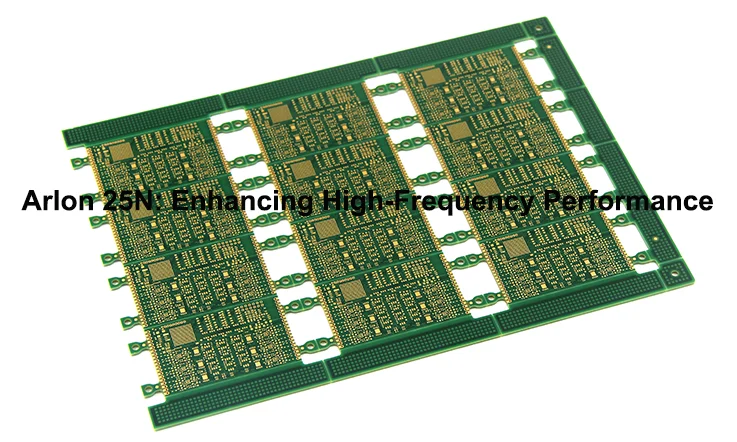

Arlon 25N PCB materials are engineered to meet the stringent demands of high-frequency and microwave applications, offering superior electrical performance, minimal signal loss, and exceptional reliability. Widely used in advanced communication systems, such as 5G, IoT, and military-grade electronics, these materials excel in applications that require high-speed, stable signal transmission over extended periods. With their low dielectric constant, low loss tangent, and impressive thermal stability, Arlon 25N materials optimize PCB design and manufacturing for high-frequency circuits.

Introduction to Arlon 25N PCB Materials: The Ultimate Solution for High-Frequency Circuits

When designing high-frequency circuits, choosing the right material can make all the difference in how well your design performs. Arlon 25N PCB materials stand out for their remarkable ability to maintain signal clarity and minimize loss at high frequencies. Used by engineers and manufacturers who require reliable, stable, and high-performance solutions, Arlon 25N is preferred for applications ranging from telecommunications to aerospace and defense.

What Makes Arlon 25N PCB Materials Ideal for High-Frequency Applications?

In high-frequency applications—whether for wireless communications, military systems, or satellite technologies—signal degradation is a major concern. Many materials struggle to keep up with the challenges posed by high-frequency signals, often resulting in signal loss and interference. Arlon 25N PCB materials are specifically engineered to overcome these hurdles.

With its thermoset resin system and ceramic-filled makeup, Arlon 25N features low dielectric constant (Er) and low loss tangent properties, which help maintain signal clarity and ensure that high-frequency signals travel with minimal interference. Therefore, whether it’s for radar, 5G infrastructure, or RF circuits, Arlon 25N minimizes the signal degradation that can occur with traditional PCB materials like FR-4.

Moreover, the material’s resistance to thermal expansion gives it an edge in applications that involve high heat or fluctuating temperatures. This makes Arlon 25N ideal for industries where performance and reliability must not be compromised, even under the most demanding conditions.

Key Properties of Arlon 25N PCB Materials: Low Loss and Signal Integrity

In high-frequency applications, maintaining signal clarity is a major consideration. Arlon 25N PCB materials are designed with this in mind, offering an ideal balance of low loss characteristics. This translates into less signal degradation during transmission, which helps the system stay efficient and precise. Thanks to its low loss, Arlon 25N helps keep signal quality intact over longer distances, reducing the chances of any performance hiccups. This makes it an excellent choice for designs where consistent, reliable performance is a must. So, whether you’re dealing with high-speed circuits or complex RF applications.

Arlon 25N excels with its low dielectric constant and low loss tangent. These features ensure the material consistently maintains signal fidelity, preventing unwanted noise or attenuation. For instance, when used in RF systems, Arlon 25N delivers reliable signal transmission across various frequency ranges, ensuring systems like 5G networks and microwave communications maintain optimal performance.

The ability of Arlon 25N to operate across a broad temperature range without degrading its electrical properties also adds to its appeal for use in high-demand applications, such as satellite communications, high-speed data transfer, and advanced radar systems.

How Arlon 25N PCB Materials Outperform Traditional PCB Materials?

When you stack Arlon 25N against conventional PCB materials like FR-4, the differences are clear. While FR-4 is widely used due to its lower cost, it’s not the best material for handling high-frequency signals. Its higher dielectric constant leads to increased signal loss, especially at high frequencies, making it less suitable for advanced RF and microwave applications.

Arlon 25N, however, offers superior electrical performance due to its low dielectric constant and low loss tangent. These qualities make it a good material for microwave circuits, military electronics, and telecommunications infrastructure that demand high-speed data transmission and minimal interference. The material’s ability to perform consistently under thermal stress also gives it a significant advantage in applications that experience temperature fluctuations.

Let’s break it down in the following comparison table:

| Property | Arlon 25N | FR-4 |

| Dielectric Constant (Er) | Low (3.38) | Higher (~4.2) |

| Loss Tangent (Df) | Low | Higher |

| Thermal Expansion | Low (stable) | Higher (unstable) |

| Signal Integrity | Consistent | Prone to degradation |

| Dimensional Stability | High | Lower |

Key Features of Arlon 25N PCB Materials: Why It’s the Top Choice for Advanced PCB Designs?

When you’re designing advanced electronic circuits, the material you choose can significantly impact performance and durability. Arlon 25N PCB Materials have earned a solid reputation for their combination of low dielectric constant, low loss, and exceptional thermal properties. These materials are suitable for high-frequency applications, RF systems, and high-power devices, offering a reliable solution to us who demand precision in their designs.

In the sections below, we will dive into the key features of Arlon 25N PCB Materials, from dielectric properties and dimensional stability to thermal efficiency, all of which are essential for maximizing the effectiveness of advanced electronic designs.

Low Dielectric Constant and Low Loss: Enhancing Signal Clarity in High-Frequency Circuits

The low dielectric constant and low loss properties of Arlon 25N are significant when designing circuits for high-frequency applications. A dielectric constant determines the material’s ability to store and transmit electrical energy, and a low loss value helps minimize signal degradation, ensuring the efficiency of signal transmission at high frequencies.

Arlon 25N boasts a dielectric constant (Er) of approximately 3.38 at 10 GHz, enabling signals to travel with minimal disruption. Combined with a low loss tangent (Tan δ) of 0.0025, this material proves to be a solid choice for RF circuits, microwave applications, and high-speed communication systems. The low loss properties help ensure that signal integrity remains intact, even in demanding environments where precision and clarity are a must.

The low dielectric constant and low loss of Arlon 25N enhance the design of high-speed, efficient circuits. This characteristic is especially useful in industries like telecommunications, where preserving the clarity of high-frequency signals ensures optimal system performance.

| Material | Dielectric Constant (Er) | Loss Tangent (Tan δ) | Application Suitability |

| Arlon 25N | 3.38 | 0.0025 | High-frequency circuits, RF, Microwave |

| FR4 | 4.5-5.5 | 0.02-0.025 | General-purpose PCBs, Low-frequency |

| Ceramic PCBs | 6.0-7.0 | 0.003-0.004 | High-frequency, high-precision |

Dimensional Stability of Arlon 25N: Ensuring Consistent Performance in Challenging Environments

The dimensional stability of Arlon 25N ensures that it maintains its structural integrity under varying temperature conditions. This is a core property for ensuring that signal paths and component alignments stay consistent, even when the material undergoes thermal cycling or exposure to environmental stressors.

With a coefficient of thermal expansion (CTE) of 16.5 ppm/°C, Arlon 25N remains stable when temperatures fluctuate, making it less likely to expand or contract significantly. This stability reduces the risk of signal distortion or failure caused by thermal stress. In environments like aerospace, military, and automotive industries, where extreme temperatures are common, this property ensures the long-term durability of the material.

For instance, in automotive electronics, where heat and vibration are constant, Arlon 25N provides the stability needed to prevent performance issues related to material expansion.

| Material | Coefficient of Thermal Expansion (CTE) | Max Operating Temperature | Application Suitability |

| Arlon 25N | 16.5 ppm/°C | 150°C | High-frequency circuits, RF, Military, Aerospace |

| FR4 | 17-20 ppm/°C | 120°C | General-purpose PCBs |

| Flex PCB | 30-40 ppm/°C | 105°C | Wearables, Compact Electronics |

Thermal Properties of Arlon 25N PCB Materials: Optimal Heat Dissipation for High-Power Designs

When designing high-power circuits, one of the most factors is how well the PCB material can dissipate heat. Arlon 25N PCB Materials offer superior thermal conductivity, helping to manage the heat produced in power-intensive applications.

With a thermal conductivity of 0.75 W/m·K, Arlon 25N outperforms FR4 (0.3 W/m·K), making it a preferred choice for high-power electronics, such as power converters and LED lighting systems. The material’s ability to dissipate heat efficiently ensures that components do not overheat, thereby maintaining system stability and extending product lifespans.

In high-power LED circuits, where heat accumulation can reduce the lifespan of components, Arlon 25N helps distribute the thermal load evenly across the PCB. This prevents hotspots from forming, which could negatively affect performance. Its thermal efficiency is particularly useful in systems running at higher currents and voltages, maintaining consistent device performance.

| Material | Thermal Conductivity (W/m·K) | Max Operating Temperature | Application Suitability |

| Arlon 25N | 0.75 | 150°C | High-power circuits, LED, Automotive |

| FR4 | 0.3 | 120°C | Low-power, General-purpose circuits |

| Metal Core PCB | 1.0-2.0 | 180°C | High-power LED, Thermal management |

How Arlon 25N PCB Materials Optimize Manufacturing and Design for High-Frequency PCBs?

In the demanding world of high-frequency PCB manufacturing, where precision and reliability are non-negotiable, Arlon 25N PCB Materials step in to simplify the process while meeting rigorous performance standards. These materials offer remarkable properties that improve signal integrity, thermal management, and impedance control — all main elements in high-frequency circuit design. Whether the end application is 5G, IoT, or microwave technology, Arlon 25N delivers solutions that balance both design performance and production efficiency. Let’s explore how these materials streamline the entire PCB fabrication journey and contribute to the next generation of high-performance electronics.

Streamlining PCB Fabrication with Arlon 25N: Materials and Techniques

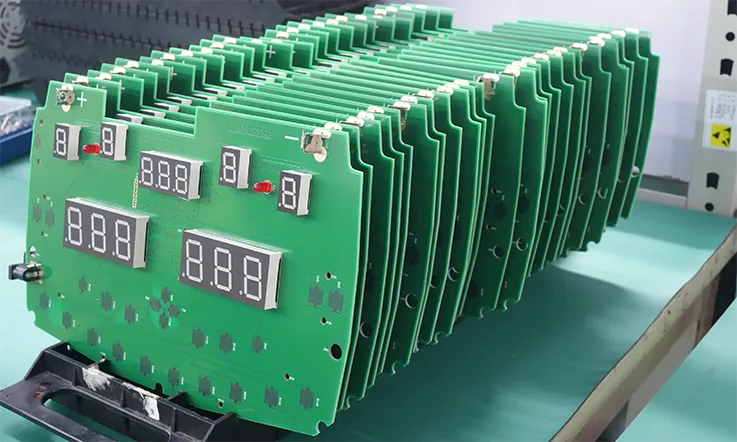

When it comes to high-frequency PCB fabrication, Arlon 25N materials provide manufacturers with a relaibel PCB base materials to improve both the speed and accuracy of the production process. One of the primary challenges in PCB fabrication is managing the numerous factors that can affect precision — from etching to drilling, lamination to coating. Arlon 25N is engineered to resist common fabrication challenges while maintaining its performance properties.

The low dielectric constant and low loss tangent of Arlon 25N allow for smoother signal propagation, reducing issues like signal degradation or interference. This directly contributes to more reliable high-frequency performance and ensures that signal clarity is maintained throughout the board. Furthermore, these materials exhibit excellent dimensional stability, meaning they stay true to design specs even in the face of the typical temperature fluctuations and mechanical stress encountered during production.

With Arlon 25N, PCB manufacturers can streamline their fabrication processes by reducing the chances of defects or inconsistencies, resulting in less rework and faster production times. As a result, designers can go from prototype to finished product more efficiently, without compromising on quality.

Example Data Table for PCB Fabrication:

| Parameter | Arlon 25N | Standard PCB Material |

| Dielectric Constant (Dk) | 3.38 | 4.30 |

| Loss Tangent (Df) | 0.0025 | 0.005 |

| Thermal Conductivity | 0.60 W/m·K | 0.50 W/m·K |

| Dimensional Stability | ±0.05% | ±0.10% |

| Fabrication Process Compatibility | Standard PCB Processes | Requires specialized handling |

How to Achieve Perfect Impedance Control with Arlon 25N PCB Materials?

Impedance control plays a huge role in the performance of high-frequency PCBs, especially in designs that demand signal clarity. Arlon 25N PCB materials are engineered to help our PCB engineers achieve accurate impedance matching, a must-have feature for high-speed, high-frequency applications such as 5G and IoT.

Thanks to its low dielectric constant and excellent uniformity over varying frequencies, Arlon 25N provides superior impedance control compared to traditional materials. The material maintains stable electrical properties even under high-frequency conditions, ensuring that signal transmission occurs without reflections or unwanted attenuation. In addition, the consistency of Arlon 25N’s electrical characteristics allows for precise impedance matching, reducing the need for time-consuming tweaks or adjustments during the manufacturing process.

By utilizing Arlon 25N, we can achieve the right impedance across the PCB, which is especially valuable for high-speed signals where even the smallest deviation can cause performance degradation. This material ensures that high-frequency signals travel efficiently and accurately from point A to point B, enhancing the overall functionality of the design.

Example Data Table for Impedance Control:

| Frequency Range (GHz) | Impedance Tolerance (Ohms) | Arlon 25N Impedance Stability (%) | Standard Material Impedance Stability (%) |

| 1–5 | ±5 | ±2 | ±4 |

| 5–10 | ±5 | ±3 | ±6 |

| 10–20 | ±5 | ±4 | ±8 |

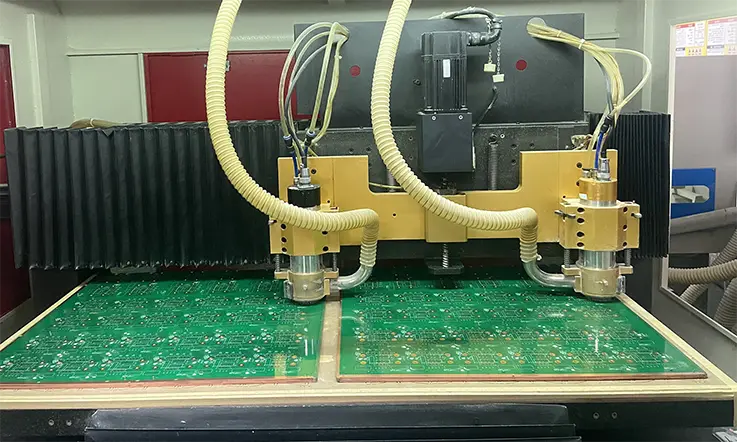

Arlon 25N’s Compatibility with Standard Manufacturing Processes: A Key Advantage

Arlon 25N PCB materials are engineered to easily integrate into standard PCB manufacturing processes, offering a streamlined and efficient production experience. Unlike other advanced materials that might require specialized handling or costly adjustments to current workflows, Arlon 25N works well with conventional PCB fabrication methods. This compatibility eliminates the need for a steep learning curve or investment in new equipment, making it a practical choice for manufacturers.

Whether it’s etching, drilling, or lamination, Arlon 25N can be processed using standard tools and methods while still maintaining superior performance. This compatibility translates into reduced production costs and faster time-to-market, as we can leverage existing equipment and facilities without the need for extensive modifications. It also reduces the chance of manufacturing errors, as there’s no need for specialized adjustments or processes when working with this material.

Arlon 25N delivers both simplicity and efficiency, allowing us to achieve high throughput without compromising the quality of the final PCB. This streamlined approach makes Arlon 25N an attractive option for both large-scale production runs and more specialized applications.

Example Data Table for Manufacturing Compatibility:

| Process Step | Arlon 25N Compatibility | Standard PCB Material Compatibility |

| Etching | High | High |

| Drilling | Standard | Standard |

| Lamination | High | Standard |

| Specialized Equipment Needed | No | Sometimes Required |

Comparing Arlon 25N PCB Materials to Other High-Frequency PCB Materials

When selecting PCB materials for high-frequency applications, we must evaluate a variety of properties including dielectric constant, loss tangent, thermal performance, and manufacturing ease. Arlon 25N has emerged as a strong contender in this space, but how does it stack up against other high-frequency materials like Rogers RO4000, Taconic TLY Series, and Isola IS680? By comparing these materials side by side, it’s possible to see where Arlon 25N excels and where other options might be more suitable for specific applications.

Arlon 25N vs. Rogers RO4000 Series: A Comparative Analysis of Dielectric and Thermal Properties

Both Arlon 25N and Rogers RO4000 Series are designed to serve the high-frequency PCB market, but they each have distinct advantages. Arlon 25N’s dielectric constant and loss characteristics are specifically engineered for applications requiring stable signal integrity and minimal signal degradation. However, Rogers RO4000 materials also cater to similar needs but offer some variations in dielectric performance and thermal management.

Here’s a breakdown of the key differences:

| Property | Arlon 25N | Rogers RO4000 Series |

| Dielectric Constant (Dk) | 3.38 | 3.48 |

| Loss Tangent (Df) | 0.0025 | 0.00366 |

| Thermal Conductivity | 0.45 W/m·K | 0.69 W/m·K |

| Maximum Operating Temp | 180°C | 180°C |

| Price per Square Meter | Competitive | Premium |

As the table highlights, Arlon 25N has a slightly lower dielectric constant compared to Rogers RO4000. This makes Arlon 25N a better fit for high-frequency designs where minimizing signal delay and maintaining precise impedance control are key factors. On the other hand, Rogers RO4000 offers thermal properties that are comparable, making it a suitable option when thermal management is a priority in certain designs.

How Taconic TLY Series and Arlon 25N PCB Materials Compare for Microwave and RF Applications?

In microwave and RF applications, the dielectric properties of the material are often the determining factor for selecting the right PCB substrate. Arlon 25N and Taconic TLY Series are both popular choices, but they offer different benefits depending on the application.

While Arlon 25N is known for its low loss and stable dielectric properties, Taconic TLY materials excel in applications where lower dielectric loss and higher RF stability are necessary. Here’s how they compare:

| Property | Arlon 25N | Taconic TLY Series |

| Dielectric Constant (Dk) | 3.38 | 2.55 |

| Loss Tangent (Df) | 0.0025 | 0.0028 |

| Thermal Conductivity | 0.45 W/m·K | 0.25 W/m·K |

| Max Frequency | 40 GHz | 60 GHz |

| Price per Square Meter | Competitive | Premium |

As the table highlights, Taconic TLY has a slightly lower dielectric constant compared to Arlon 25N. This makes Taconic TLY a better fit for high-frequency designs where minimizing signal delay and maintaining precise impedance control are core factors. On the other hand, Arlon 25N offers thermal properties that are comparable, making it a suitable option when thermal management is a priority in certain designs.

Isola IS680 vs. Arlon 25N: Comparing Cost and Performance for High-Frequency Designs

When considering cost versus performance, Isola IS680 and Arlon 25N offer distinct advantages. While both materials are widely used in high-frequency applications, the choice often comes down to cost constraints and specific performance requirements such as impedance control, signal integrity, and thermal properties.

The following comparison highlights these materials’ attributes:

| Property | Arlon 25N | Isola IS680 |

| Dielectric Constant (Dk) | 3.38 | 3.45 |

| Loss Tangent (Df) | 0.0025 | 0.0025 |

| Thermal Conductivity | 0.45 W/m·K | 0.38 W/m·K |

| Price per Square Meter | Competitive | Premium |

| Max Frequency | 40 GHz | 35 GHz |

Isola IS680 offers a slightly higher dielectric constant compared to Arlon 25N, which may influence its use in designs where tight impedance control is required. However, the lower thermal conductivity of Isola IS680 makes Arlon 25N a better option in designs where heat dissipation is a concern.

Overcoming Challenges with Arlon 25N PCB Materials in High-Performance PCB Design

In high-performance PCB design, the combination of complex requirements and tight tolerances often presents unique challenges. Arlon 25N PCB materials, known for their stable dielectric properties and low loss, are an excellent solution for high-frequency applications. However, there are still several considerations we must address to fully optimize its potential. Let’s dive into how these challenges manifest and how you can tackle them head-on.

Material Costs and Performance Considerations: Is Arlon 25N Worth the Investment?

When choosing materials for high-frequency PCBs, it’s common for us to face the dilemma of balancing cost with performance. Arlon 25N is generally seen as a premium material, so it’s natural to question whether its performance justifies the cost. Arlon 25N offers exceptional signal integrity, low loss, and dimensional stability—attributes that make it suitable for demanding designs like 5G, RF, and microwave applications. But does this justify the cost compared to other alternatives?

Let’s take a closer look at cost and performance trade-offs:

| Property | Arlon 25N | Competitor A (e.g., FR4) |

| Dielectric Constant (Dk) | 3.38 | 4.2 |

| Loss Tangent (Df) | 0.0025 | 0.02 |

| Thermal Conductivity | 0.45 W/m·K | 0.20 W/m·K |

| Max Frequency | 40 GHz | 10 GHz |

| Price per Square Meter | Premium | Lower |

Arlon 25N offers significant advantages in terms of signal integrity and thermal management compared to more affordable alternatives like FR4. However, if your application doesn’t require ultra-low loss or high-frequency capabilities, you might consider other options that provide lower upfront costs with compromises in performance.

The bottom line? For designs that prioritize high-frequency performance and minimal signal loss, Arlon 25N stands out as a solid option—especially when those specific traits are necessary for the success of the project.

Material Supply Chain Challenges: How to Ensure Reliable Procurement of Arlon 25N PCB Materials

The procurement of specialized materials like Arlon 25N can sometimes face disruptions in the supply chain, particularly when global markets experience volatility. High-performance materials such as Arlon 25N are often subject to fluctuating availability and pricing, which can disrupt project timelines and increase costs unexpectedly.

To address these challenges, it’s must to need set up reliable sourcing channels early in the process. Below are some strategies to help ensure a steady supply of Arlon 25N:

| Strategy | Description |

| Multiple Suppliers | Working with multiple suppliers reduces the risk of stockouts or delays. |

| Long-Term Contracts | Securing long-term agreements can help lock in pricing and ensure availability. |

| On-Site Inventory | Keep a buffer stock on-site for critical components to avoid delays. |

Proactive planning and building relationships with trusted suppliers can smooth out potential bumps in the road. Ensuring consistent procurement of Arlon 25N ensures that your project’s timelines stay on track, and your designs maintain their integrity from start to finish.

Design Limitations of Arlon 25N PCB Materials and How to Overcome Them

While Arlon 25N offers numerous advantages for high-frequency applications, it does come with its own set of design limitations. These limitations primarily revolve around its high cost relative to other materials, as well as potential challenges when working with ultra-fine pitch designs or very high-frequency applications.

Let’s break down these limitations:

| Limitation | Description |

| Higher Material Costs | Arlon 25N’s price point can be a barrier for cost-sensitive projects. |

| Drill Hole Precision | While the material handles etching and lamination well, drilling very fine holes can be tricky. |

| Frequency Threshold | For extremely high-frequency applications (above 40 GHz), other materials may offer better performance. |

To overcome these limitations, careful design choices must be made. For example, when working with finer drill holes, ensure that the PCB manufacturer has the appropriate capabilities to handle the material’s drilling requirements. Additionally, if your application exceeds the maximum frequency threshold for Arlon 25N, it may be worth considering alternative materials like Rogers’ high-frequency laminates.

By understanding these design constraints early, you can adjust your design process or select compatible materials where needed.

Arlon 25N in Military and Space Communication Systems

In the high-stakes fields of military and space communication systems, the need for dependable performance is a non-negotiable requirement. Systems in these sectors demand components that can withstand extreme conditions, while maintaining signal integrity over long distances and across varying frequencies. Arlon 25N, with its superior dielectric properties and thermal stability, has proven itself as a top choice for these demanding applications. The material’s consistency and performance ensure that communication links remain reliable, even in the harshest environments.

How Arlon 25N Supports Long-Range Communication Systems in Space?

Space communication systems rely on precise signal transmission over vast distances, often facing interference, signal degradation, and extreme environmental challenges. Arlon 25N’s low dielectric constant and minimal loss tangent make it ideal for these long-range systems, helping to maintain high-fidelity signals even across thousands of miles. Its performance is consistent across a wide range of frequencies, ensuring reliable data transmission and clear communication, whether it’s from Earth to spacecraft or between satellites.

Here’s a breakdown of how Arlon 25N supports these high-stakes communication systems:

| Property | Arlon 25N | Typical Space Communication Material |

| Dielectric Constant (Dk) | 3.0 | 3.3-3.5 |

| Loss Tangent (Df) | 0.003 | 0.004-0.005 |

| Operating Frequency Range | Up to 40 GHz | Up to 20 GHz |

| Thermal Conductivity | 0.38 W/m·K | 0.30 W/m·K |

| Material Durability | High resistance to thermal cycling | Moderate resistance to thermal cycling |

With these properties, Arlon 25N delivers reliable signal fidelity, even in the most challenging space applications where high performance over long distances is a must.

High-Reliability PCB Designs for Military and Aerospace Systems with Arlon 25N

When designing PCBs for military and aerospace systems, component reliability is non-negotiable. These systems are exposed to harsh environments, including extreme vibration, temperature variations, and high-power conditions. Arlon 25N’s durable physical properties make it a solid choice for these demanding applications, ensuring that the PCBs perform consistently even under challenging conditions.

Arlon 25N’s exceptional thermal stability and mechanical properties allow it to withstand high-stress environments without compromising performance. Additionally, its low loss tangent ensures minimal signal distortion, even in high-speed, high-frequency applications common in military radar and aerospace communication systems.

Here’s a snapshot of why Arlon 25N is favored for military and aerospace designs:

| Feature | Arlon 25N | Military Grade Material |

| Thermal Stability | High (Up to 200°C) | Moderate (150°C-180°C) |

| Mechanical Strength | Stronger than standard FR4 | Comparable to other high-reliability materials |

| Signal Integrity | Excellent across high frequencies (5G, 40GHz) | Moderate performance at high frequencies |

| Vibration Resistance | High resistance to mechanical stress | Often lower performance in extreme conditions |

Arlon 25N’s ability to perform reliably under these challenging conditions makes it the preferred choice for PCB designs in military and aerospace systems that cannot afford failure.

Arlon 25N for Secure and Stable Communication in Harsh Environments

Military and space communication systems face an array of challenges, not only from the extreme environments but also from the need for secure, uninterrupted data transmission. In these critical applications, Arlon 25N’s characteristics—low loss, dimensional stability, and high reliability—ensure that communications remain stable and secure even in the most demanding environments, such as space or battlefields.

Arlon 25N’s robust chemical resistance and tolerance to environmental stressors make it good for maintaining stable and secure communications in conditions where other materials may fail. Therefore, if dealing with intense heat, radiation, or electromagnetic interference (EMI), Arlon 25N ensures that the communication system performs reliably.

Here’s a closer look at how it stands up in these challenging environments:

| Environmental Challenge | Arlon 25N | Alternative Materials |

| Temperature Extremes | Excellent performance from -55°C to 200°C | Limited performance over 150°C |

| Electromagnetic Interference (EMI) | High resistance to EMI | More susceptible to EMI |

| Radiation Resistance | Good resistance to radiation | Limited resistance |

| Chemical Resistance | Strong resistance to harsh chemicals | Often weaker resistance |

Arlon 25N’s high performance in these extreme environments makes it indispensable for applications where secure and stable communication must be maintained, regardless of external conditions.

Arlon 25N PCB Materials in High-Frequency and Microwave Applications

High-frequency and microwave applications demand PCB materials that offer exceptional electrical performance, reliable signal transmission, and long-term stability. Arlon 25N PCB materials are engineered to meet these demands, offering a combination of low loss, minimal signal degradation, and consistent performance across a broad range of frequencies.

For industries such as telecommunications, aerospace, and defense, Arlon 25N enables the design and production of PCBs that support advanced applications like 5G, microwave communications, and IoT. Let’s take a closer look at how these materials deliver superior results in high-frequency and microwave designs.

Achieving Superior Signal Integrity with Arlon 25N PCB Materials in Microwave Designs

When it comes to microwave designs, signal integrity is one of factors in ensuring that a PCB performs reliably in high-speed, high-frequency environments. Arlon 25N PCB materials help to minimize signal distortion and maintain clear, stable signal transmission by providing excellent dielectric properties. The low dielectric constant and low loss tangent of Arlon 25N ensure that microwave signals propagate with minimal attenuation and reflection, even at high frequencies.

The consistency and stability of Arlon 25N contribute to reliable signal transmission in microwave circuits. With a dielectric constant around 3.38, the material helps minimize variations from batch to batch, leading to more predictable and stable designs.

Here’s how Arlon 25N excels in microwave designs:

| Property | Arlon 25N | Typical Microwave Materials |

| Dielectric Constant (Dk) | 3.38 | 3.2-3.5 |

| Loss Tangent (Df) | 0.0025 | 0.003-0.004 |

| Operating Frequency | Up to 40 GHz | Up to 30 GHz |

| Thermal Stability | High (up to 200°C) | Moderate (150°C) |

Arlon 25N’s outstanding performance in maintaining signal integrity under these conditions ensures that we can trust it for demanding microwave applications.

Arlon 25N’s Low Loss: Ensuring Reliable High-Frequency Signal Transmission

High-frequency designs require materials that can handle rapid signal transmission without introducing significant loss. Arlon 25N is specifically engineered to meet this challenge. With a low loss tangent, it helps ensure that signal strength remains consistent across long distances and high-speed circuits, reducing the need for complex compensatory adjustments.

The material’s low dielectric loss minimizes signal degradation and power loss, which is particularly crucial for high-speed communication systems, such as 5G networks and high-frequency radar systems. As signal frequencies increase, even small losses can result in significant performance issues. Arlon 25N’s minimal loss ensures high-quality transmission without compromising the efficiency of the circuit.

Here’s a breakdown of the loss performance of Arlon 25N compared to standard materials used in high-frequency applications:

| Property | Arlon 25N | Standard High-Frequency Material |

| Loss Tangent (Df) | 0.0025 | 0.005-0.008 |

| Signal Integrity | High (low loss) | Moderate to low |

| Thermal Conductivity | 0.45 W/m·K | 0.30-0.35 W/m·K |

As you can see, Arlon 25N outperforms standard materials, ensuring that signals remain intact, even in complex, high-speed applications.

Arlon 25N PCB Materials in 5G and IoT Applications: Supporting Next-Gen Communication Technologies

5G and IoT applications represent the future of global connectivity, demanding ultra-reliable, high-speed communication systems. Arlon 25N PCB materials are a strong contender for enabling these technologies, offering precise impedance control, low loss, and high-frequency stability required for next-generation communication networks.

5G, with its ultra-low latency and high-speed data transmission, demands materials that can handle extremely high-frequency signals with minimal interference and distortion. Arlon 25N’s properties, including its low loss tangent and stable dielectric constant, make it highly effective in managing the complex signal requirements of 5G networks. This material is used in the design of high-frequency PCBs for base stations, antennas, and other communication equipment that are integral to 5G infrastructure.

Similarly, in IoT applications, where devices are interconnected through wireless networks, the need for high-speed data transmission over short and long ranges is critical. Arlon 25N ensures that signal integrity remains intact across these diverse use cases, whether it’s for smart cities, connected healthcare, or automotive systems.

A quick comparison of the advantages of Arlon 25N for 5G and IoT designs:

| Feature | Arlon 25N | Standard 5G Material |

| Impedance Control | Excellent | Moderate |

| Signal Integrity at High-Frequency | High | Moderate |

| Loss Tangent | 0.0025 | 0.005-0.006 |

| Operating Frequency Range | Up to 40 GHz | Up to 30 GHz |

With Arlon 25N, we can design PCBs that meet the demanding specifications of 5G and IoT applications, ensuring that each component in the communication chain works seamlessly together.

FAQ & Arlon 25N PCB Materials

1.Does Arlon 25N support the miniaturization of high-frequency circuits?

Yes, Arlon 25N’s low loss and consistent dielectric properties enable the miniaturization of high-frequency circuits without sacrificing performance.

2.How does Arlon 25N compare to other materials in terms of cost-effectiveness for large-scale production?

While Arlon 25N may have a higher initial cost, its superior performance and reduced need for rework in high-frequency designs can make it cost-effective in the long term.

3.Can Arlon 25N be used for both digital and analog high-frequency designs?

Yes, Arlon 25N is suitable for both digital and analog high-frequency designs, providing optimal performance across a wide frequency spectrum.

4.What are the processing temperature limits for Arlon 25N?

Arlon 25N can withstand processing temperatures up to 200°C, making it suitable for high-temperature environments typically found in industrial and aerospace applications.

5.How does Arlon 25N’s dimensional stability affect PCB manufacturing?

Arlon 25N offers excellent dimensional stability, which helps maintain precise alignment and consistency during the manufacturing process, especially for high-density, high-frequency designs.

6.How does Arlon 25N handle impedance control in PCBs?

Arlon 25N provides excellent impedance control, ensuring signal integrity without the need for excessive tuning during manufacturing.

7.Can Arlon 25N be used in flexible PCB designs?

No, Arlon 25N is not designed for flexible PCBs; it is primarily used in rigid high-frequency and microwave designs.

Our services

Arlon PCB Laminate & Materials Series