The 4+N+4 HDI PCB, denoting High-Density Interconnect Printed Circuit Board, stands as a notable progression in the sphere of PCB design and production. This sophisticated circuit board offer enhanced capabilities for complex electronic applications, providing improved signal integrity, reduced power consumption and increased miniaturization.

In this article, we will delve into the features, benefits, Challenges ,Limitations, applications, design, stack up and manufacturing of the 4+N+4 HDI PCB, exploring its role in advancing various industries and driving innovation in electronic devices.

Overview of 4+N+4 HDI PCB

A 4+N+4 HDI PCB pertains to a high-density interconnect printed circuit board harboring a defined layer arrangement. HDI technology is used to create PCB with high-density and fine-pitch components, empowering the creation of more intricate and compact electronic devices.

The “4+N+4” notation in 4+N+4 HDI PCB refers to the layer stack-up of the board. Let’s break it down:

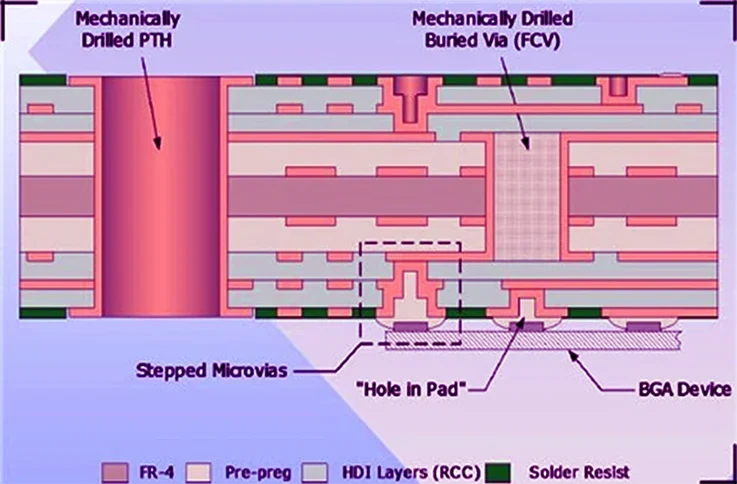

The first numeral “4” signifies four standard layers within the PCB, typically crafted from a core material like FR-4, housing the fundamental circuitry along with power/ground planes. The symbol “N” stands for any number of extra layers or “microvia” layers, denoted by small, laser-drilled apertures utilized to establish electrical connections amid the layers. The density of microvia layers fluctuates per the unique design requisites and is generally abundant in HDI boards to accommodate high-density components. The concluding “4” again is reflective of the last four traditional layers, akin to the initial four, providing supplementary routing space and power/ground planes.

In total, the 4+N+4 configuration consists of four conventional layers, a variable number of microvia layers (N), and another four conventional layers. This stack-up allows for increased routing density, finer traces, and smaller via sizes, enabling complex and compact electronic designs.

4+N+4 HDI PCB Stack-up

Generally, the composition for a 4+N+4 HDI PCB chiefly comprises four exterior signal layers, N quantity of microvia (build-up) layers, and an additional four interior signal layers.

Top Signal Layer: This is the topmost layer of the PCB, where high-speed signal traces and components are placed. This layer may further incorporate top-side solder mask and silkscreen, depending on the specific application.

Inner Signal Layers (1-4): Representing the four inner layers of the PCB, sandwiched between the outer signal layers. Typically, they comprise signal traces, power planes, and ground planes, contingent upon the specific design needs and specifications.

Microvia (Build-up) Layers (1-N): Indicating the middle layers within the stack-up structure, the count of microvia layers, referred to as N, can alter based on the intricacy of the design and the density requisites. To establish connections between the interior signal layers and facilitate high-density interconnections, the employment of microvias is utilized.

Core Layer: Representing the central layer of the PCB, this provides the structural strength and stability necessary for operational integrity. It may be comprised of a solid core substrate or an amalgamation of different laminated core materials.

Prepreg Layers: Prepreg layers are essentially fiberglass layers enriched with resin, these layers used to bond the core layer and the inner signal layers together. These layers not only offer insulation but also play a pivotal role in sustaining the PCB’s structural soundness.

Inner Signal Layers (5-8): Closely mirroring the characteristics of the inner signal layers (1-4), these layers consist of signal traces, power planes, and grounding planes. They are positioned below the microvia layers and above the bottom signal layer.

Bottom Signal Layer: Representing the absolute bottom layer of the PCB, this area can place additional signal traces and components. Additionally, the application of bottom-side solder mask and silkscreen may also be included in this layer.

Importance and Applications of 4+N+4 HDI PCB

The 4+N+4 HDI PCB holds a substantial edge over the conventional PCB, thereby rendering it indispensable in diverse sectors demanding high-density and compact electronic designs.

Miniaturization:

The cardinal significance of 4+N+4 HDI PCB rests in their capacity to encourage the miniaturisation of electronic equipment. Courtesy of their high-density interconnet technology, these PCB permit smaller and more condensed designs, which is especially valuable in portable consumer electronics such as smartphones, tablets, wearable technology and IoT devices. The diminished size and weight of these devices augment their portability and ease of use.

High-density component integration:

The HDI technology used in 4+N+4 PCB allows for the placement of high-density and fine-pitch components. This makes the integration of more functionality feasible within a confined board space. The augmented routing density and scaled-down via dimensions the introduction of cutting-edge features, such as sophisticated sensors, high speed connectors, processors and memory modules. As a result, HDI PCB become instrumental for applications demanding multifaceted electronic systems, inclusive of telecommunications, automotive electronics, medical apparatuses, and aerospace systems.

Improved signal integrity:

The high-density interconnects and reduced trace extents in 4+N+4 HDI PCB bestow superior signal integrity. This means that high-frequency signals can be transmitted with minimal loss or distortion, promising dependable operationality of the electronic gadget. This characteristic is especially crucial in applications such as high speed data communication, wireless contrivances and high-frequency RF utilizations.

Enhanced reliability:

The incorporation of microvias in 4+N+4 HDI PCB extends numerous reliability advantages. Microvias enable more direct signal routing, reducing the length of signal paths and minimizing the risk of signal degradation. In tandem, the lesser via dimensions lessen the likelihood of solder joint mishaps and ameliorate thermal administration. These elements collectively bolster the comprehensive dependability and lifespan of the electronic apparatuses.

Cost optimization:

Though the HDI PCB may come with a heftier price tag due to their intricate fabrication processes, they compensate by conferring cost reductions elsewhere. The miniaturization and the heightened functionality which the HDI PCB facilitates, curtails the necessity for more components, connectors and cables, resulting in cost savings in assembly, material and overall system costs.

Design Considerations for 4+N+4 HDI PCB

Designing a 4+N+4 HDI PCB requires careful consideration of various factors to ensure optimal performance and reliability. Here are some key design considerations to keep in mind:

Signal Integrity and Impedance Control:

Maintain signal integrity by properly controlling impedance throughout the PCB design.

Implement controlled impedance traces and ensure consistent trace widths, spacing, and dielectric materials to achieve desired impedance figures.

Adopt impedance matching methods for high speed signal routes to curtail signal reflections and uphold signal integrity.

Thermal Management:

Effective heat dissipation is paramount for the dependability and efficacy of electronic constituents.

Incorporate thermal vias and thermal pads to facilitate heat transfer from hot components to the PCB’s copper planes or heat sinks.

Ensure proper component placement and thermal relief to minimize heat buildup and temperature differentials.

Component Placement and Routing:

Optimize component placement to curtail signal interferences, diminish electromagnetic disturbances (EMI), and guarantee proficient signal traversing.

Group components based on their functional requirements and signal characteristics to minimize signal interference.

Utilize advanced design tools and techniques, such as blind and buried vias, to optimize the layout and routing of the PCB.

Power and Ground Plane Distribution:

Distribute power and ground planes strategically to provide low-impedance paths for power distribution and effective noise shielding.

Use multiple power and ground planes to minimize voltage drops, reduce noise, and provide stable power supply to sensitive components.

Ensure proper decoupling capacitor placement near high-speed components to suppress power supply noise and maintain signal integrity.

EMI/EMC Considerations:

Implement proper grounding techniques, such as star grounding, to minimize ground loops and reduce EMI.

Use shielding techniques, such as ground planes and signal isolation, to prevent electromagnetic interference between different circuit sections.

Follow EMC (Electromagnetic Compatibility) guidelines and standards to ensure compliance with electromagnetic emission and immunity requirements.

Design for Manufacturability (DFM):

Consider manufacturing constraints and capabilities during the design phase to ensure ease of fabrication and assembly.

Use design rules and guidelines provided by the PCB manufacturer to avoid issues related to minimum trace widths, spacing, and manufacturing tolerances.

Collaborate closely with the PCB manufacturer to optimize the design for manufacturability and achieve desired performance within manufacturing constraints.

Reliability and Testing:

Consider reliability aspects, such as thermal stress, vibration, and mechanical stability, during the design phase.

Perform thorough design verification and testing, including signal integrity analysis, thermal analysis, and functional testing, to ensure the reliability and performance of the PCB.

By taking these design considerations into account, you can optimize the performance, reliability, and manufacturability of 4+N+4 HDI PCB for your specific application requirements.

Manufacturing Process of 4+N+4 HDI PCB

The fabrication progression of 4+N+4 HDI PCB entails varied phases to give rise to the sought-after layer structure and interconnections. Here is typical manufacturing process for 4+N+4 HDI PCB:

1.Layer Stack-up and Material Selection:

Determine the layer stackup configuration based on the design requirements, including the number of signal layers, power and ground planes, and additional signal layers.

Select high-quality materials with excellent electrical properties, such as high Tg (glass transition temperature) laminates, to ensure optimal performance.

2.Inner Layer Processing:

Start with a copper-clad laminate sheet, which acts as the base material for the inner layers.

Clean the laminate surface and apply a photosensitive dry film or liquid photoresist to create a protective layer.

Use a photomask to expose the desired circuit patterns on the photoresist and develop it to remove the unexposed areas.

Etch the exposed copper to create the circuit traces and remove the remaining photoresist.

3.Microvia Fabrication:

Microvias are small drilled holes used to establish connections between different layers in HDI PCBs.

Utilize laser drilling or mechanical drilling techniques to create microvias in the appropriate locations.

Copper is then plated inside the microvias to create reliable interconnections.

4.Build-Up Process:

The build-up process involves laminating multiple thin layers of dielectric material and copper foils to create the desired layer structure.

Each layer is carefully aligned and bonded together using heat and pressure.

Excess material is removed through chemical or mechanical processes, leaving behind the desired circuit patterns.

5.Outer Layer Processing:

Similar to the inner layer processing, the outer layer processing involves applying a photosensitive dry film or liquid photoresist on the outer copper layers.

The desired circuit patterns are exposed and developed, and the exposed copper is etched to create the outer layer circuitry.

6.Surface Finish and Solder Mask Application:

Apply a surface finish to protect the exposed copper and provide a solderable surface. Common surface finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservative).

Apply a solder mask over the entire PCB surface, leaving openings for component pads and vias.

The solder mask protects the copper traces and prevents solder bridges during assembly.

7.Silkscreen Printing and Legend Marking:

Silkscreen printing is used to apply component designators, logos, and other markings on the PCB surface.

Legend marking is performed to provide additional information, such as component values, reference designators, and assembly instructions.

8.Electrical Testing and Inspection:

Conduct electrical testing, such as continuity testing and impedance measurement, to ensure the integrity of the circuitry.

Perform visual inspection and automated optical inspection (AOI) to detect any manufacturing defects or soldering issues.

9.PCB Panelization and Separation:

Multiple PCB are often fabricated on a single larger panel to optimize manufacturing efficiency.

After testing and inspection, the panel is separated into individual PCB using methods like routing, scoring, or laser cutting.

10.Final Inspection

Conduct a final inspection to verify the quality and performance of the finished PCB.

Challenges and Limitations of 4+N+4 HDI PCB

While 4+N+4 HDI PCB Provide benefits they also present certain challenges and limitations that designers and manufacturers must carefully consider.

Complexity of Design:

Designing a 4+N+4 HDI PCB may be intricate given the high density of components and interconnections. The signal integrity, power distribution, thermal management and routing constraints demand prudent deliberation.

Manufacturing Complexity:

The production procedure for 4+N+4 HDI PCB is intricate in its nature, especially when contrasted against traditional PCB. It demarcates additional phases consisting of microvia drilling, sequential lamination, and multiple build-up iterations, it maybe increase the time and cost of production

Cost:

The intricacy and additional production steps necessary for crafting 4+N+4 HDI PCB can lead to elevated manufacturing expenses compared to standard PCB. The utilization of specialized materials coupled with cutting-edge manufacturing methods can intensify the overall expenditure.

Manufacturing Yield:

The high density and sophistication of 4+N+4 HDI PCB can augment the probability of production flaws. Achieving significant production yield and maintaining unvarying quality may prove to be a challenges, especially with intricate design layouts and fine pitch components.

Signal Integrity and Crosstalk:

With the increasing density of components and interconnections, maintaining signal integrity and minimizing crosstalk become critical. Proper impedance control, controlled routing, and careful placement of components are essential to mitigate signal integrity issues.

Thermal Management:

The high component density in 4+N+4 HDI PCB can lead to thermal challenges. Effective heat dissipation becomes crucial to prevent overheating and ensure the reliability of components. Designers need to consider proper thermal management techniques, such as thermal vias and heat sinks.

Design for Manufacturability (DFM):

The complex nature of 4+N+4 HDI PCB requires close collaboration between designers and manufacturers. Ensuring that the design is manufacturable and meets the capabilities and constraints of the manufacturing process is essential to avoid costly rework or manufacturing issues.

Testing and Debugging:

The increased complexity and density of 4+N+4 HDI PCB can pose challenges during testing and debugging. Accessing and probing individual components or signals can be difficult, requiring specialized testing techniques and equipment.

Component Availability and Size Limitations:

The miniaturization and high density requirements of 4+N+4 HDI PCB may limit the availability of certain components, especially for fine pitch and high pin count devices. Designers need to carefully select components that meet the size and performance requirements.

Final Thought

The 4+N+4 HDI PCB represents a noteworthy accomplishment in PCB technology, revolutionising the panorama of the electronic industry. With its high-density interconnet, multi layer , and progressive fabrication techniques, this PCB provide unmatched performance, reliability, and miniaturisation. It has turned into an indispensable element in a wide array of applications, ranging from smartphones and tablets to medical apparatuses and automotive systems. As technology persistently accelerates, the 4+N+4 HDI PCB will unquestionably serve a critical function in facilitating the advent of cutting edge electronic devices, extending the limitations of potentialities in the innovation sphere.